Supported catalytic ozonation catalyst and its preparation method

A technology of ozone catalytic oxidation and catalyst, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of carrier pore blockage, reduce active metal content, reduce catalytic effect, etc., and achieve high utilization rate , High dispersion, obvious treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

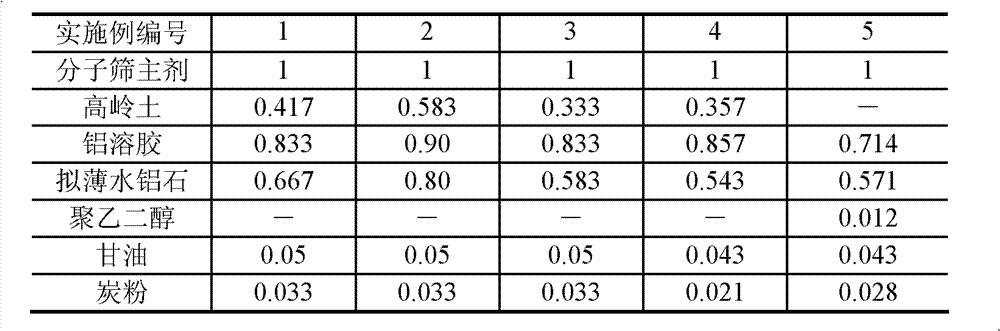

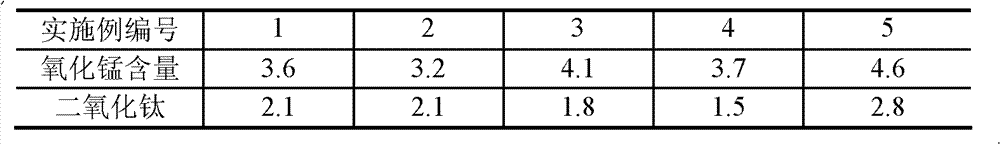

Examples

Embodiment 1~5

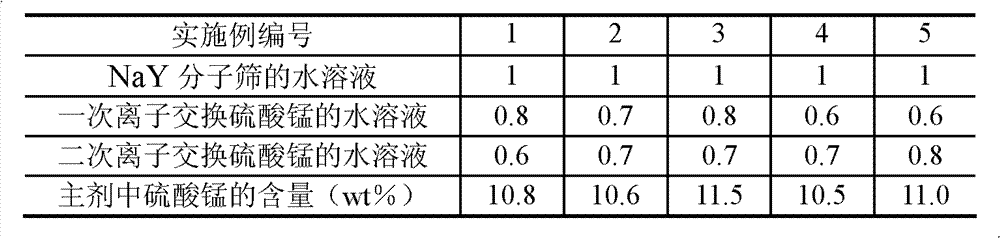

[0024] ① Take 150g of NaY molecular sieve to make 300g / L aqueous solution, slowly add dropwise manganese sulfate aqueous solution (2mol / L), molecular sieve: manganese sulfate=1:0.6-0.8 (volume ratio), and stir at 80°C for 20-30min. After the exchange, it is filtered, and then calcined at 400°C for 4 hours. The calcined molecular sieve is exchanged for a second time. At this time, molecular sieve: manganese sulfate = 1:0.6~0.8 (volume ratio), the product of the second exchange is filtered and then calcined at 600°C 4h, get the main agent of molecular sieve.

[0025] Table 1: The ratio of molecular sieve and manganese sulfate aqueous solution (volume ratio) corresponding to Examples 1 to 5

[0026]

[0027] ② Take 40ml of tetrabutyl titanate, 160ml of ethanol, and 10ml of diethanolamine to mix, stir well for 5min, add 0.5ml of concentrated nitric acid dropwise during the stirring process, then slowly add the mixed solution to 400ml of deionized water, stir for 30min, the solution wil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com