Patents

Literature

45results about How to "Efficient and durable use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

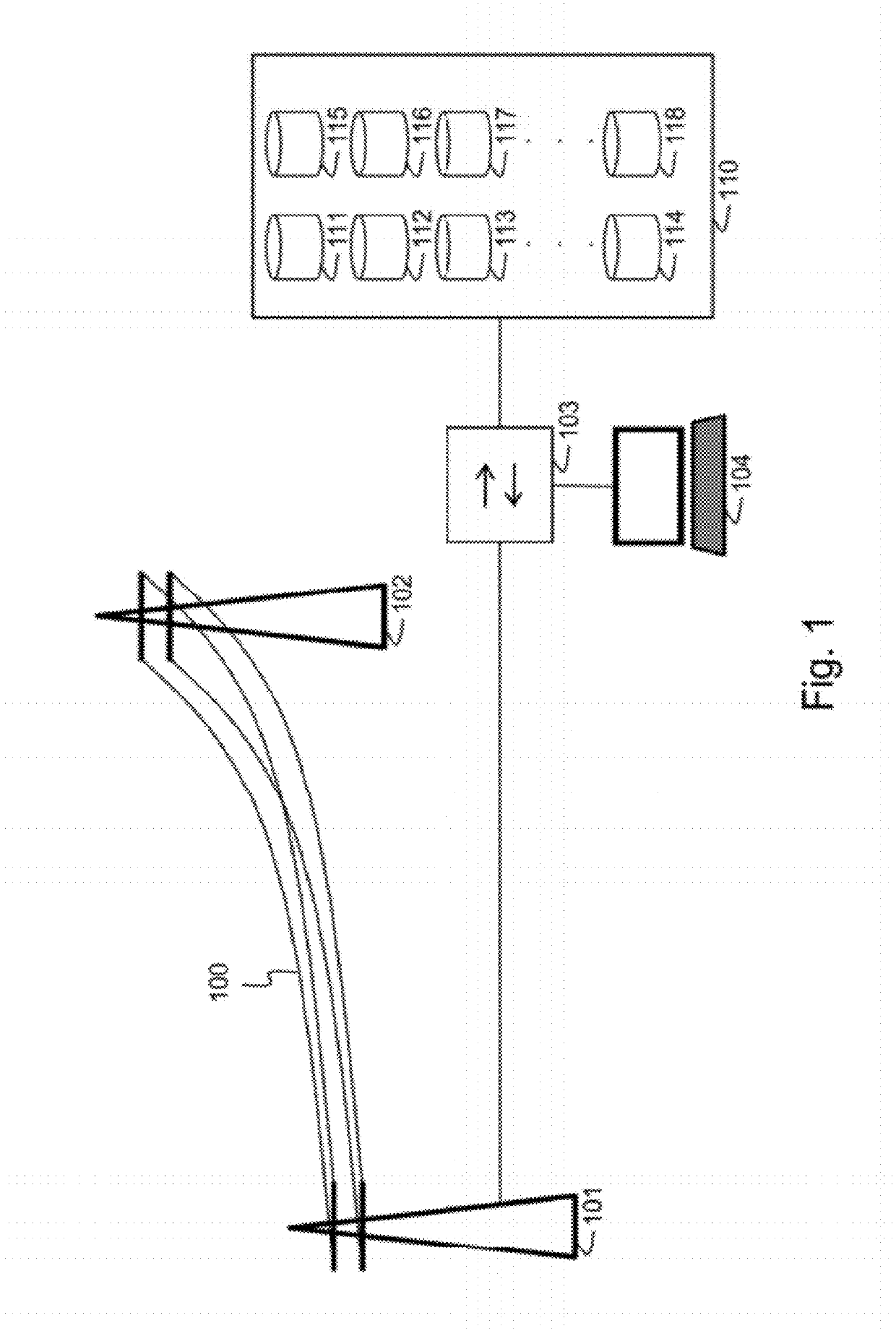

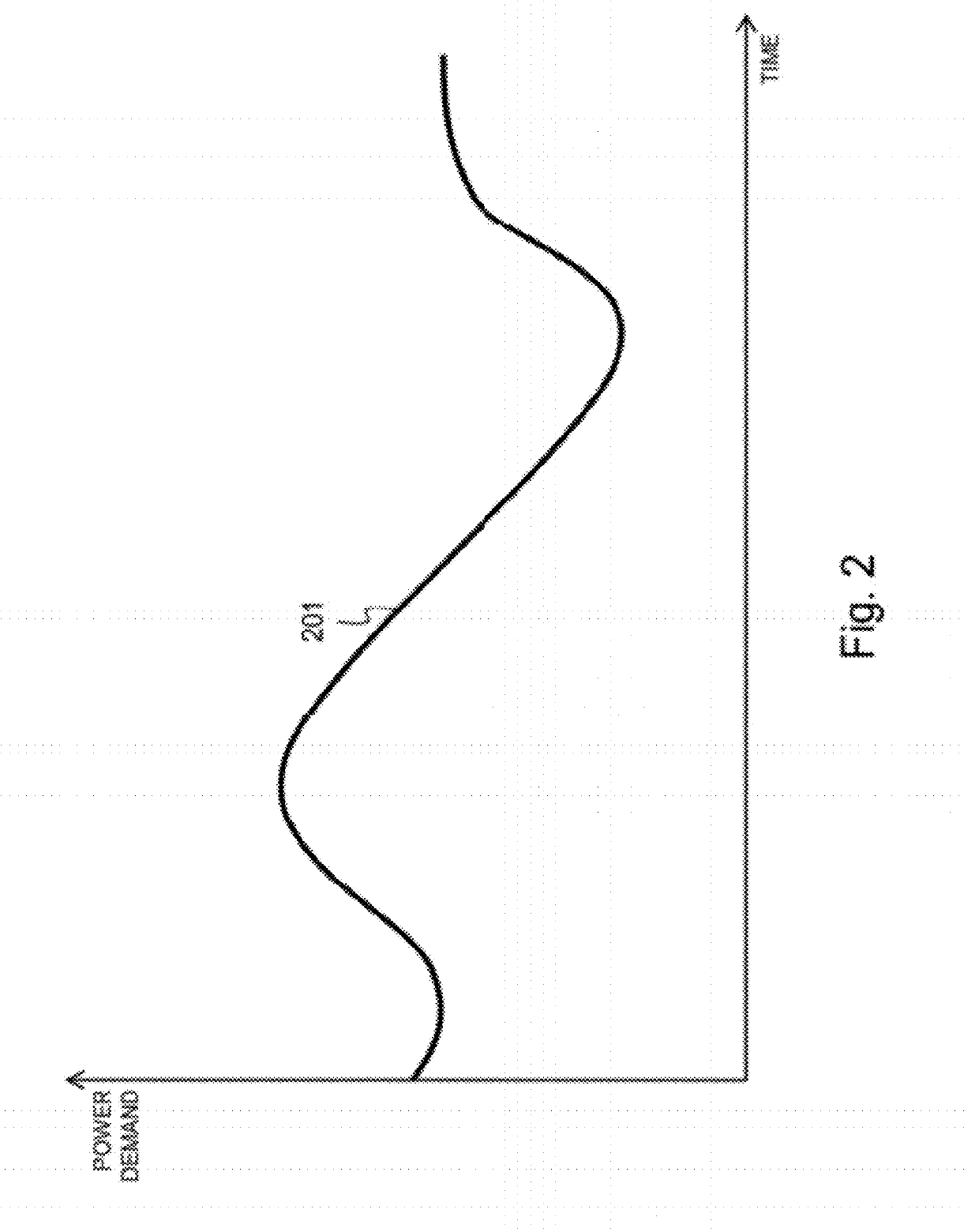

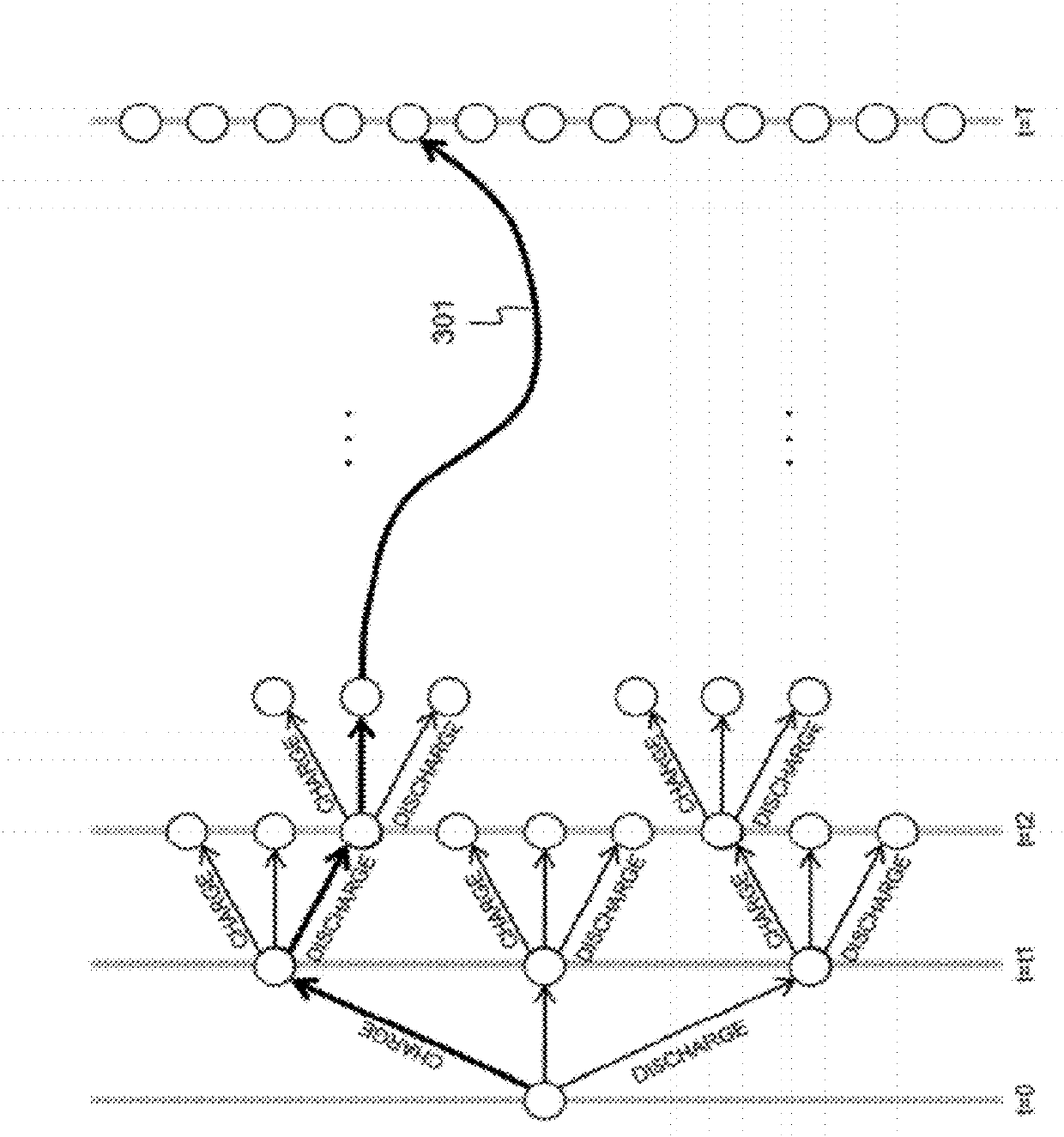

Method and system for charging a fleet of batteries

InactiveUS20120133337A1Energy balanceEfficient and durable usePayment architectureVehicular energy storageBattery chargeElectrical battery

In a method for charging a fleet of batteries (110) from a power grid (100), a fleet charge schedule (301) is determined and thereafter individual battery charge schedules are dynamically optimized. The fleet charge schedule (301) for the entire fleet (110) is determined optimizing an energy portfolio balance of an energy portfolio manager. Thereafter, battery charge schedules for individual batteries (111, 112, 113, 114, 115, 116, 117, 118) in the fleet (110) are dynamically optimized such that the battery charge schedules in aggregation realize the fleet charge schedule (301). The battery charge schedules are dynamically optimized in consideration of at least technical specifications of assets in the battery fleet and user constraints of the battery users.

Owner:RESTORE

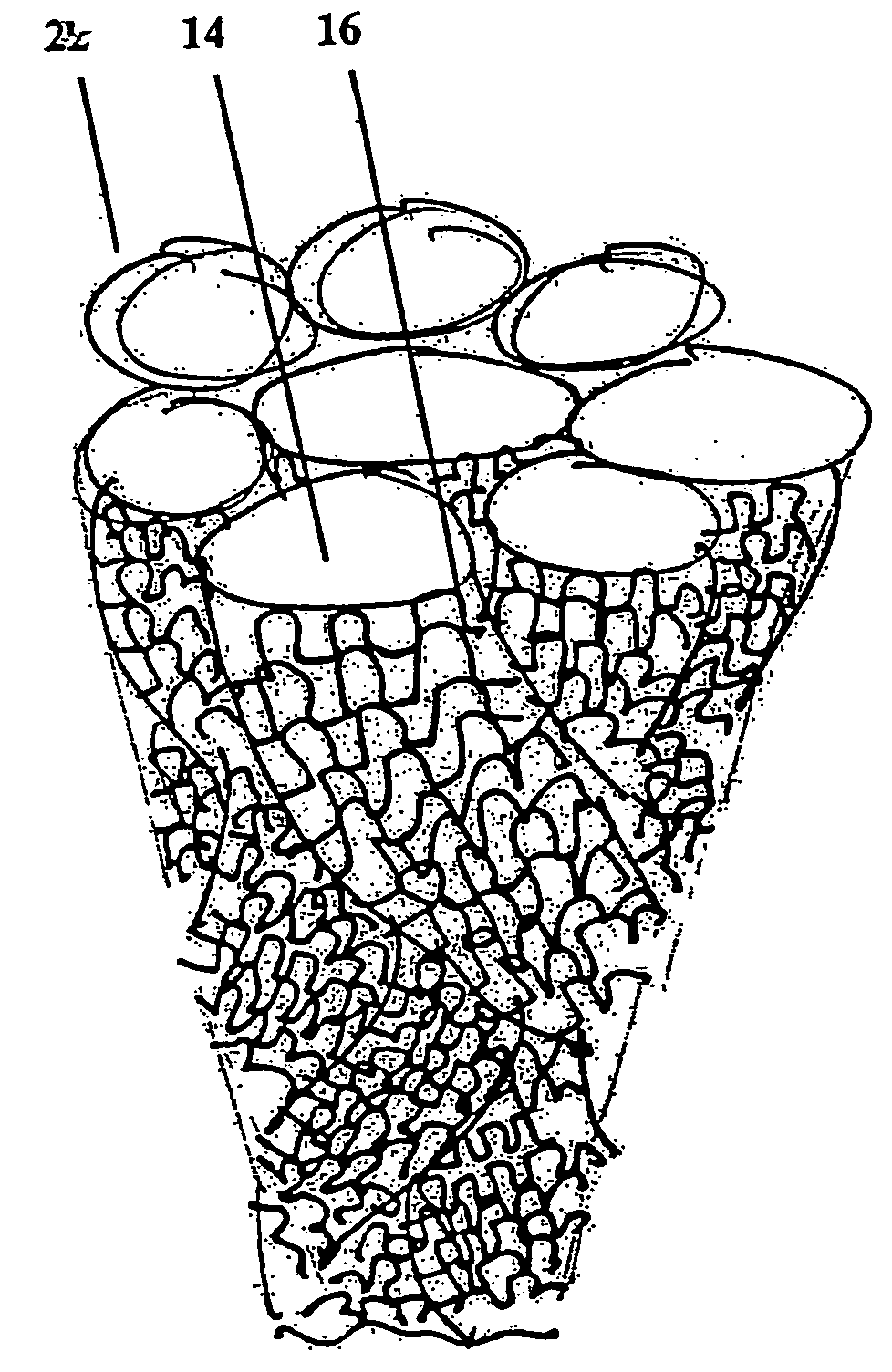

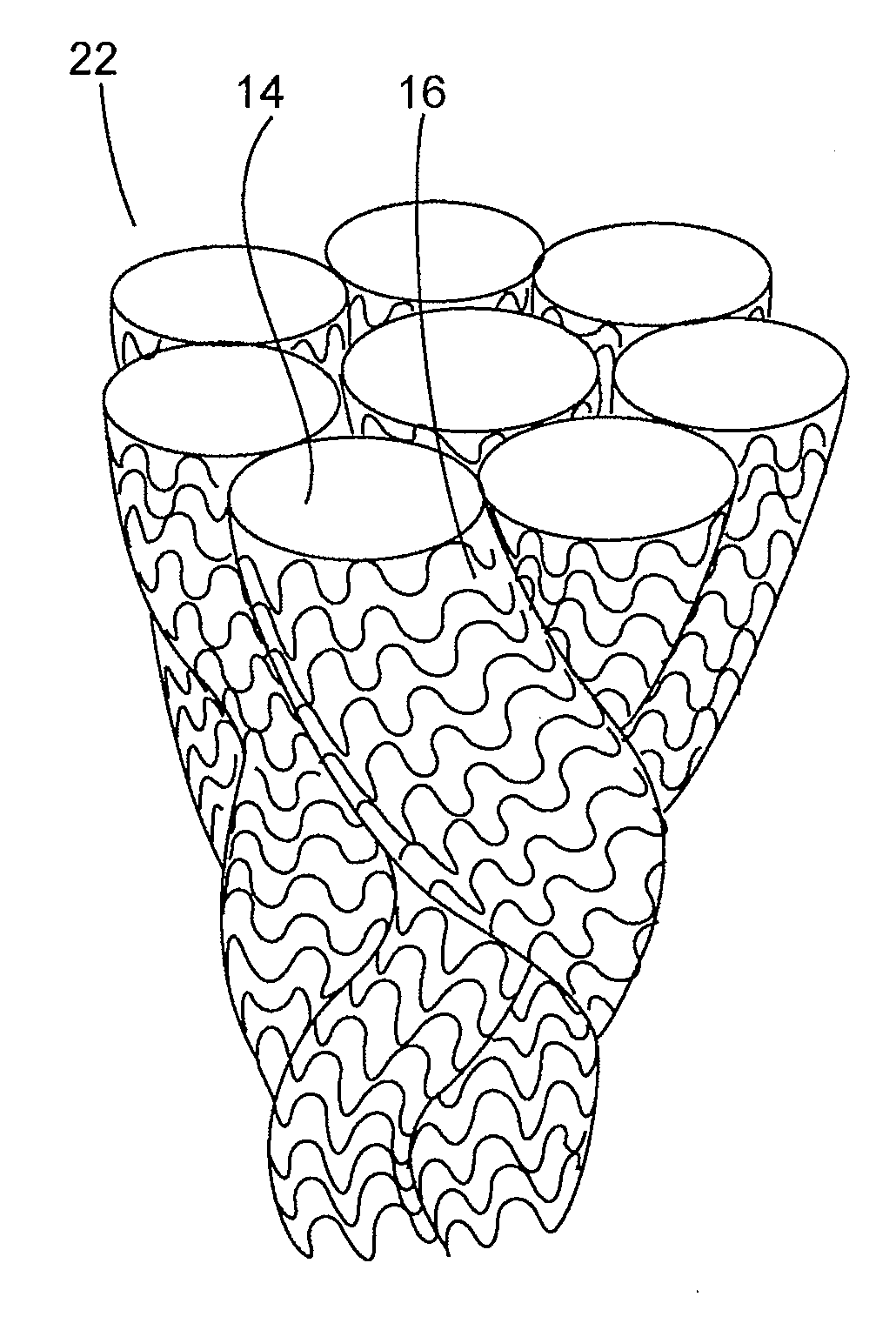

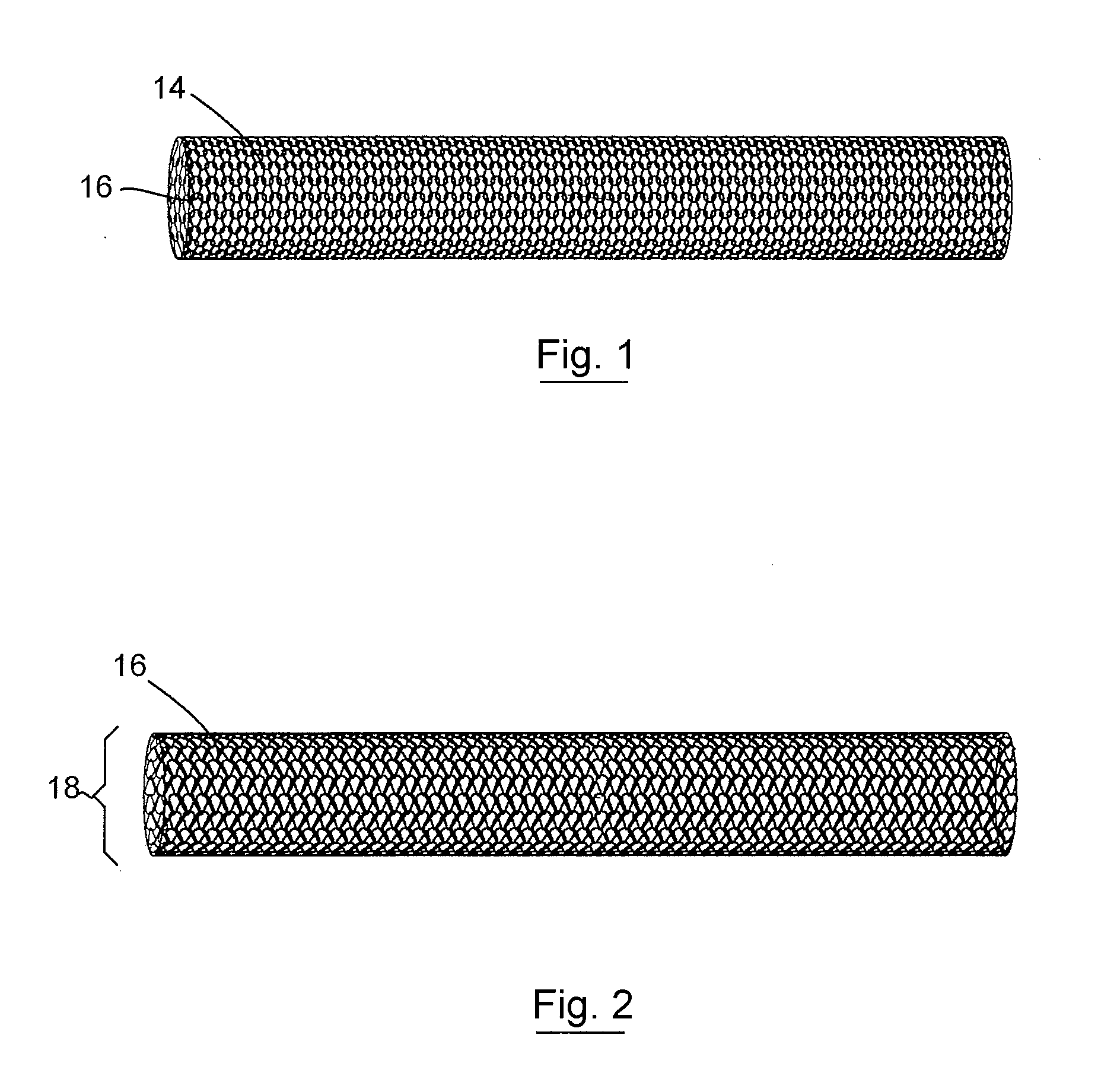

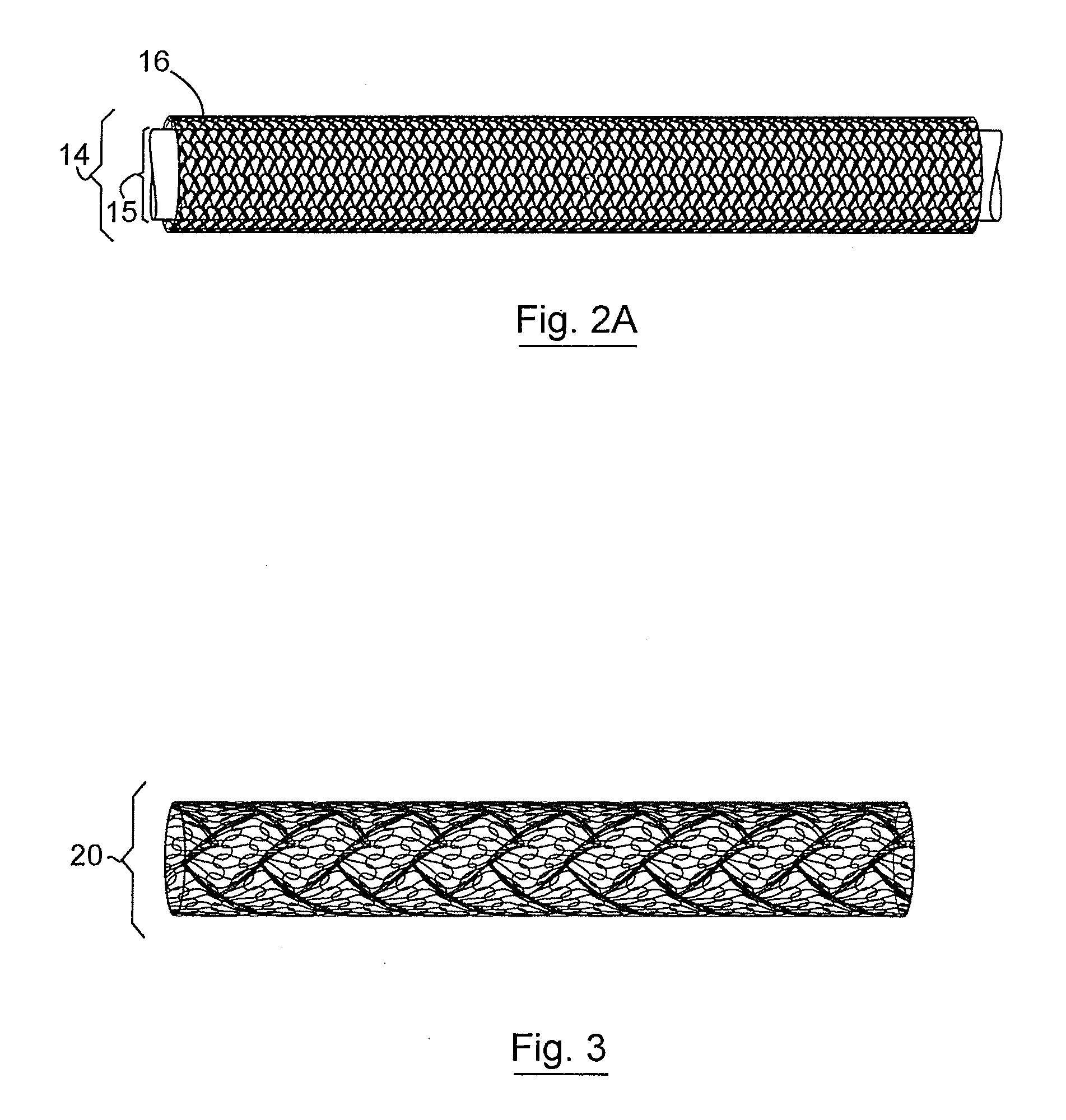

Three dimensional implant

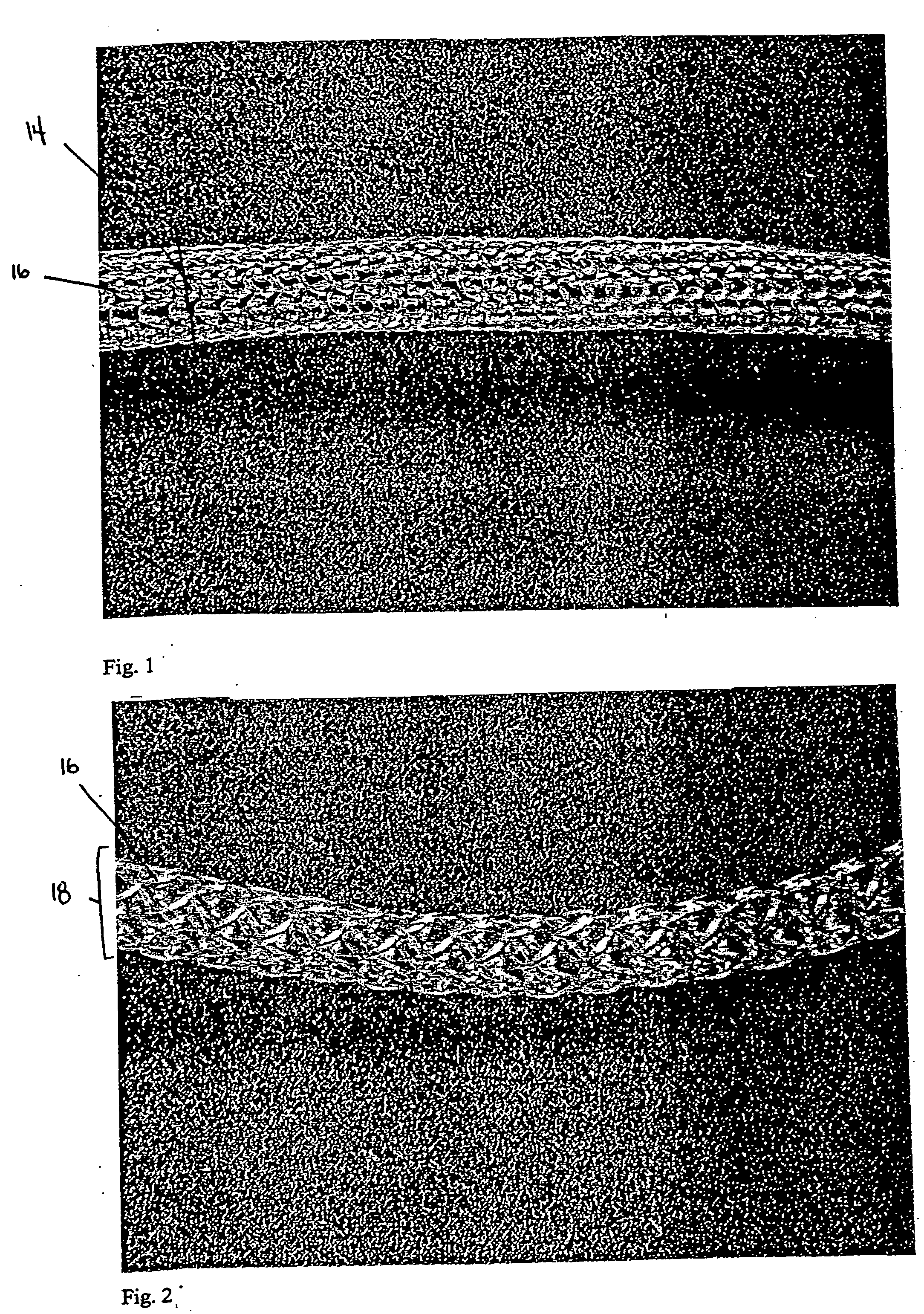

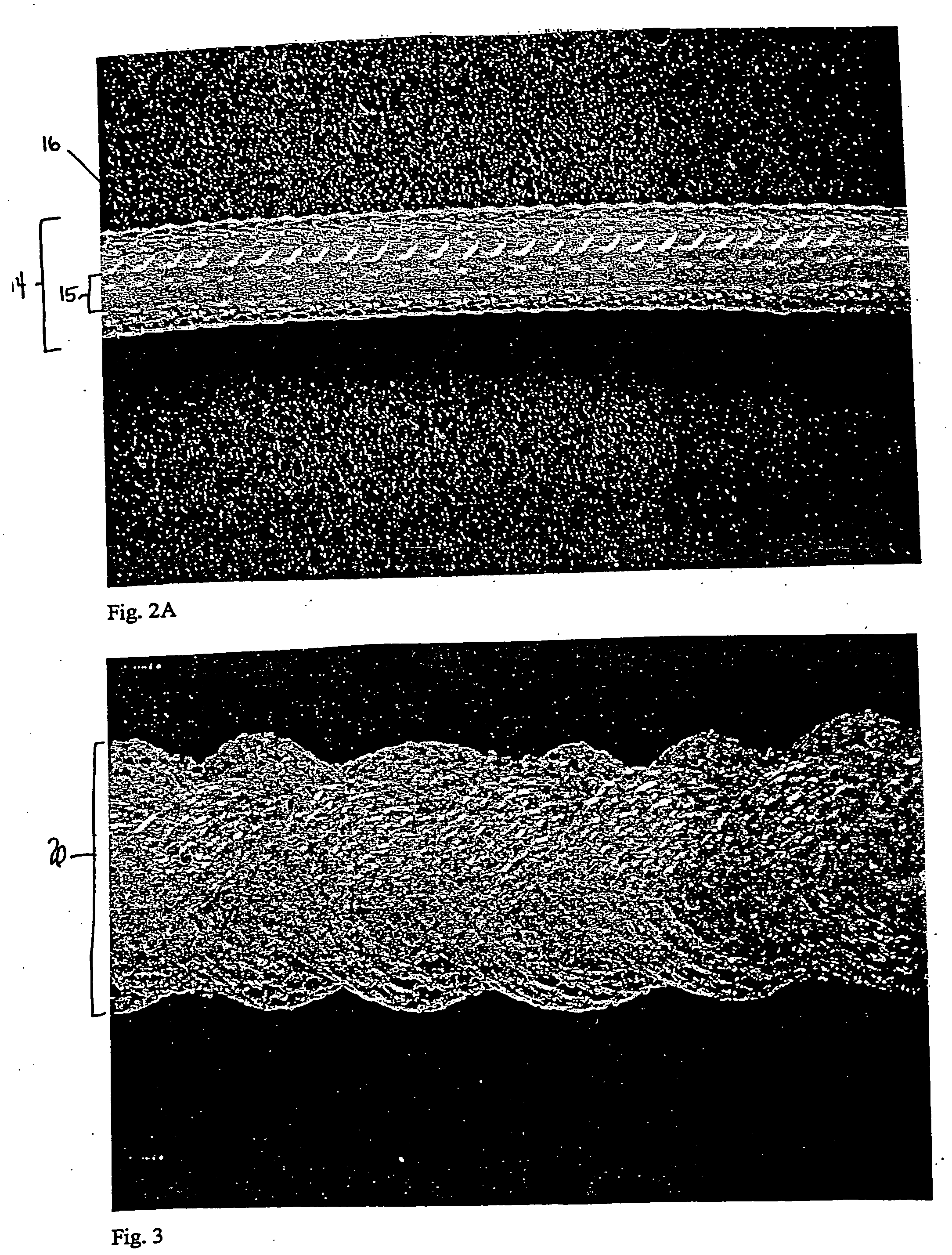

InactiveUS20060106419A1Low densityLow implant surface area ratioStentsBlood vesselsLow densityTissue ingrowth

Implants (20, 22) and methods of making the implants for treating bodily defects or remodeling tissue. The implants have a low density and open pores (49) which may permit tissue ingrowth.

Owner:PROXY BIOMEDICAL

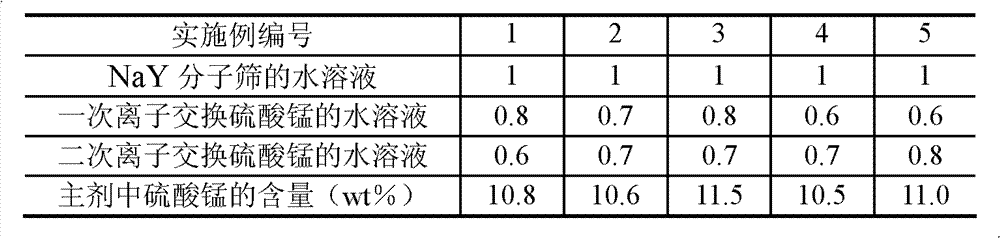

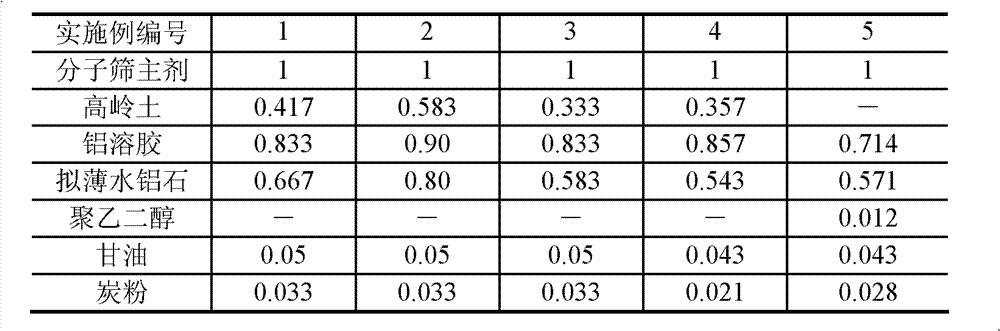

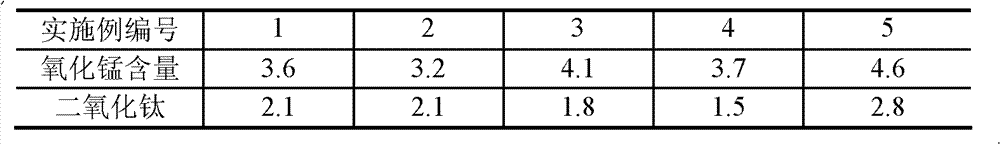

Supported catalytic ozonation catalyst and its preparation method

ActiveCN103240115AHigh activityStable structureMolecular sieve catalystsWater contaminantsMolecular sievePtru catalyst

The invention relates to a catalytic ozonation catalyst and its preparation method. The catalyst is mainly composed of a carrier NaY molecular sieve, active metal oxides manganese oxide and titanium dioxide, and catalyst molding auxiliary agents. The carrier NaY molecular sieve supported with manganese oxide is a main catalyst agent. The content of manganese oxide in the main agent is 10.5wt%-11.5wt%. The catalyst molding auxiliary agents contain kaolin, a binder, a lubricant and a pore forming agent, wherein the weight ratio of the main agent to kaolin is 1:0.3-0.6; the weight ratio of the main agent to the binder is 1:0.5-0.9; the weight ratio of the main agent to the lubricant is 1:0.5-0.85; the weight ratio of the main agent to the pore forming agent is 1:0.02-0.04; and the content of titanium dioxide in the catalyst is 1.5wt%-3.0wt%. By using the NaY molecular sieve as the carrier, by the adoption of ion exchange and dipping methods and with the combination of supporting heterogeneous metal, the comprehensive catalytic ozonation catalyst is prepared. The catalytic ozonation catalyst can be used to process organic wastewater and has advantages of high utilization rate, high dispersiveness, obvious processing effect and long service cycle.

Owner:PETROCHINA CO LTD

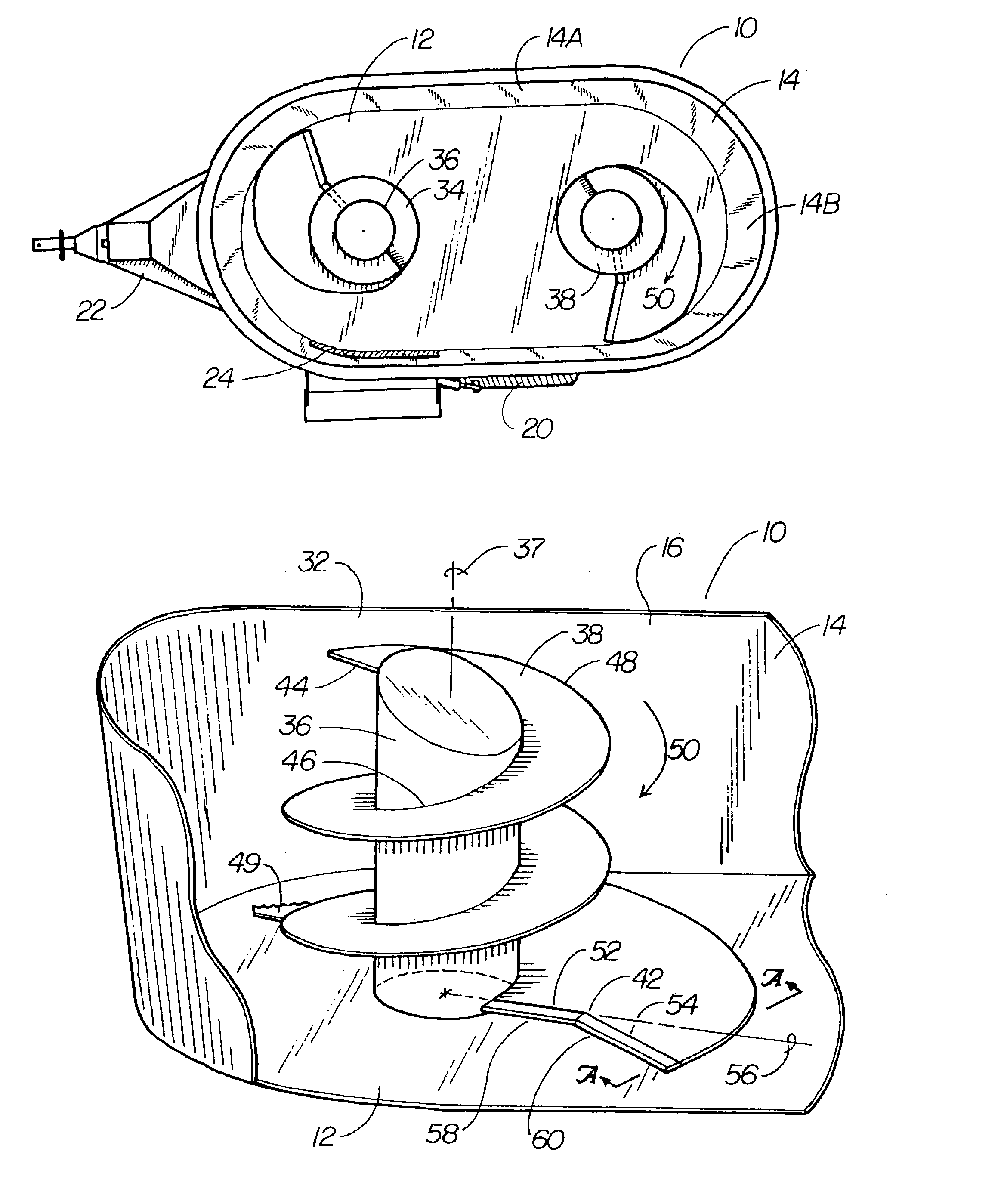

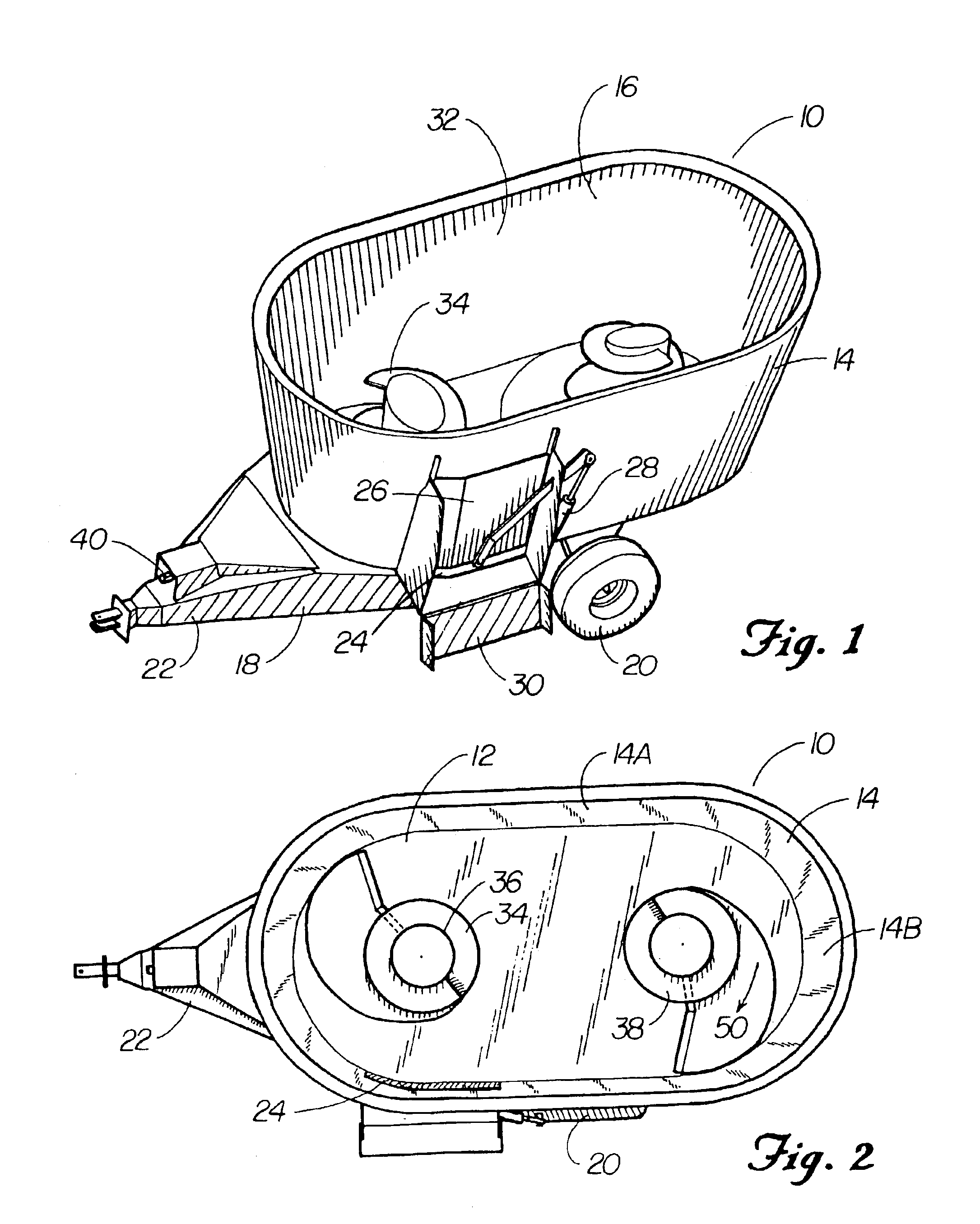

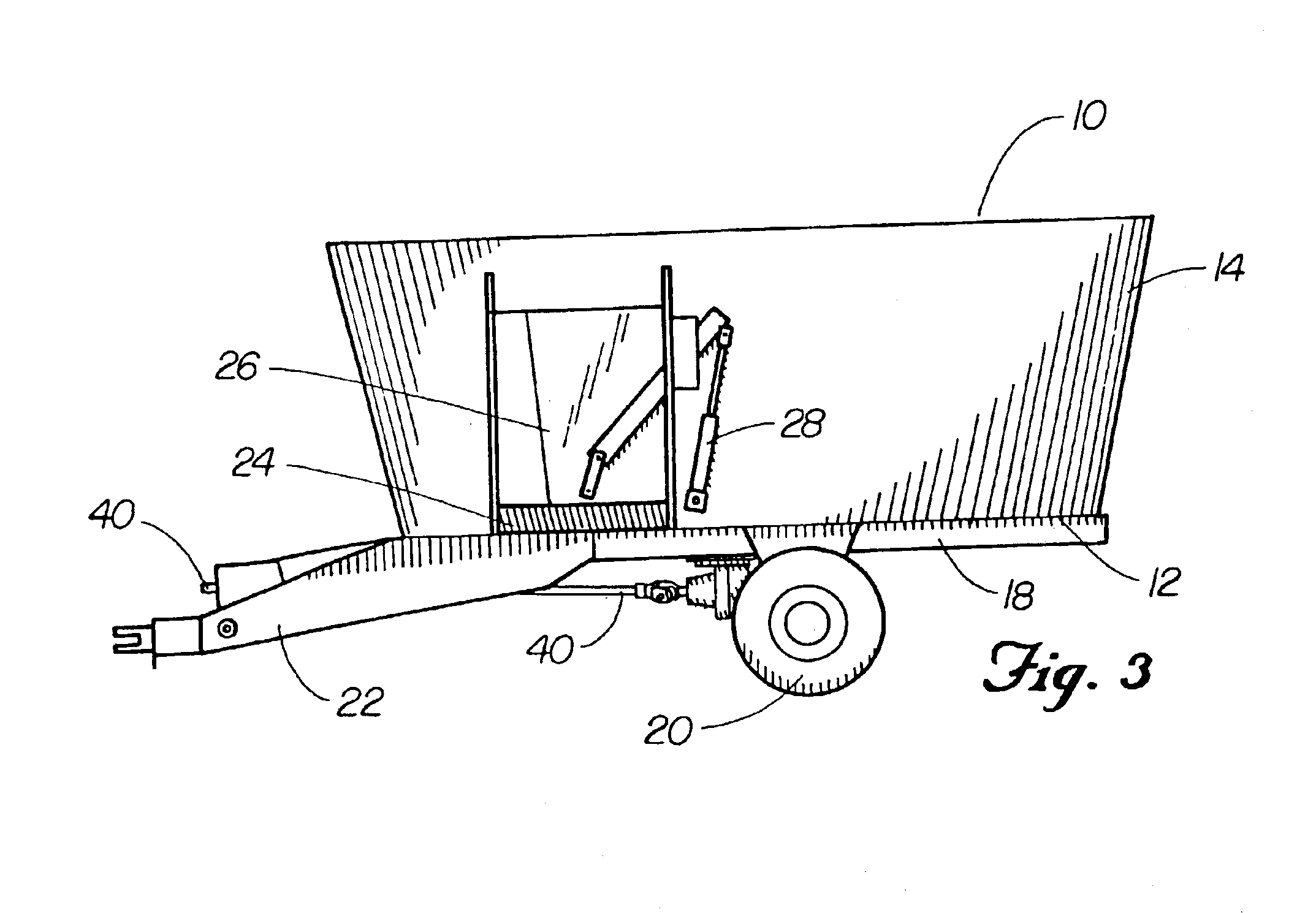

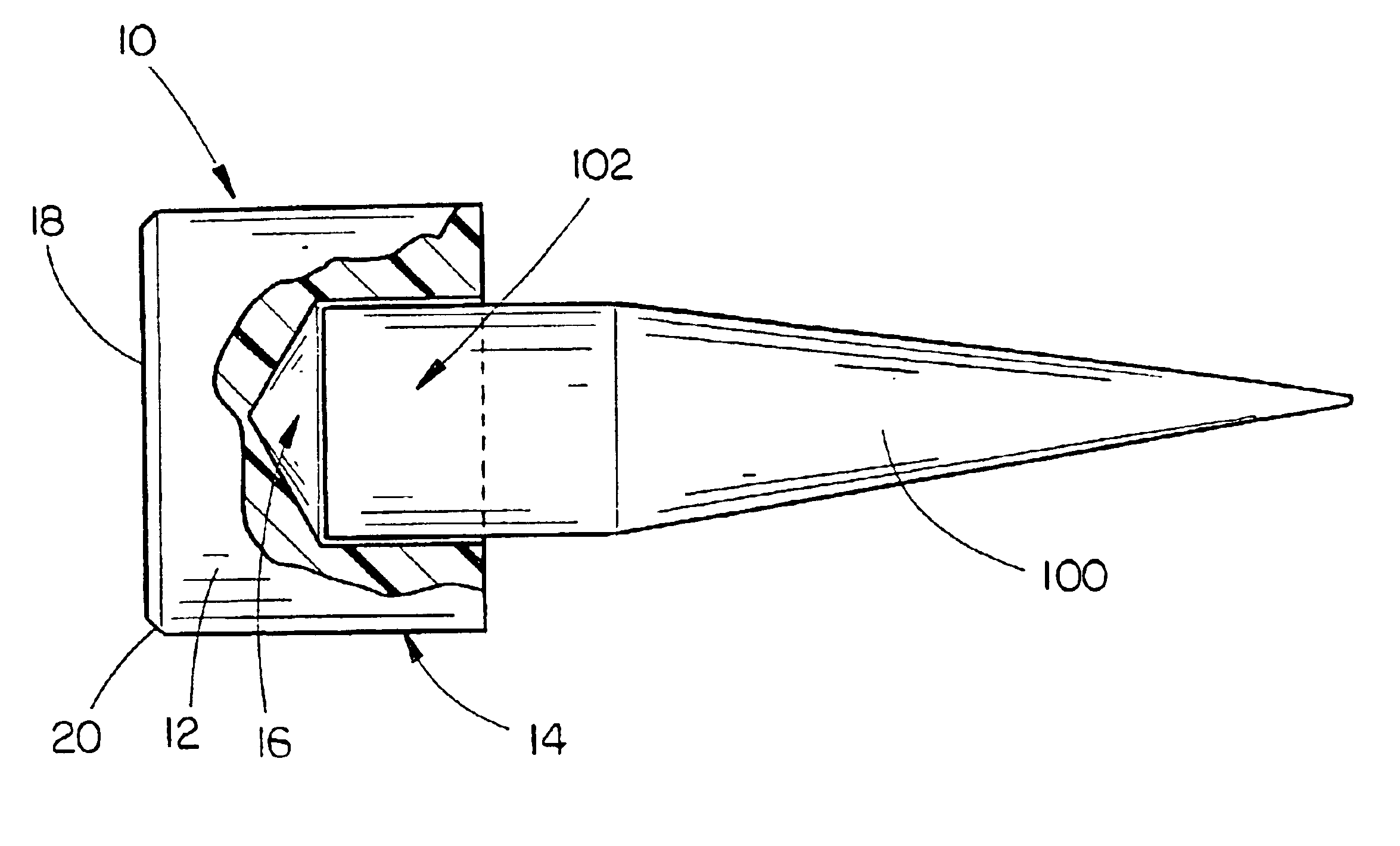

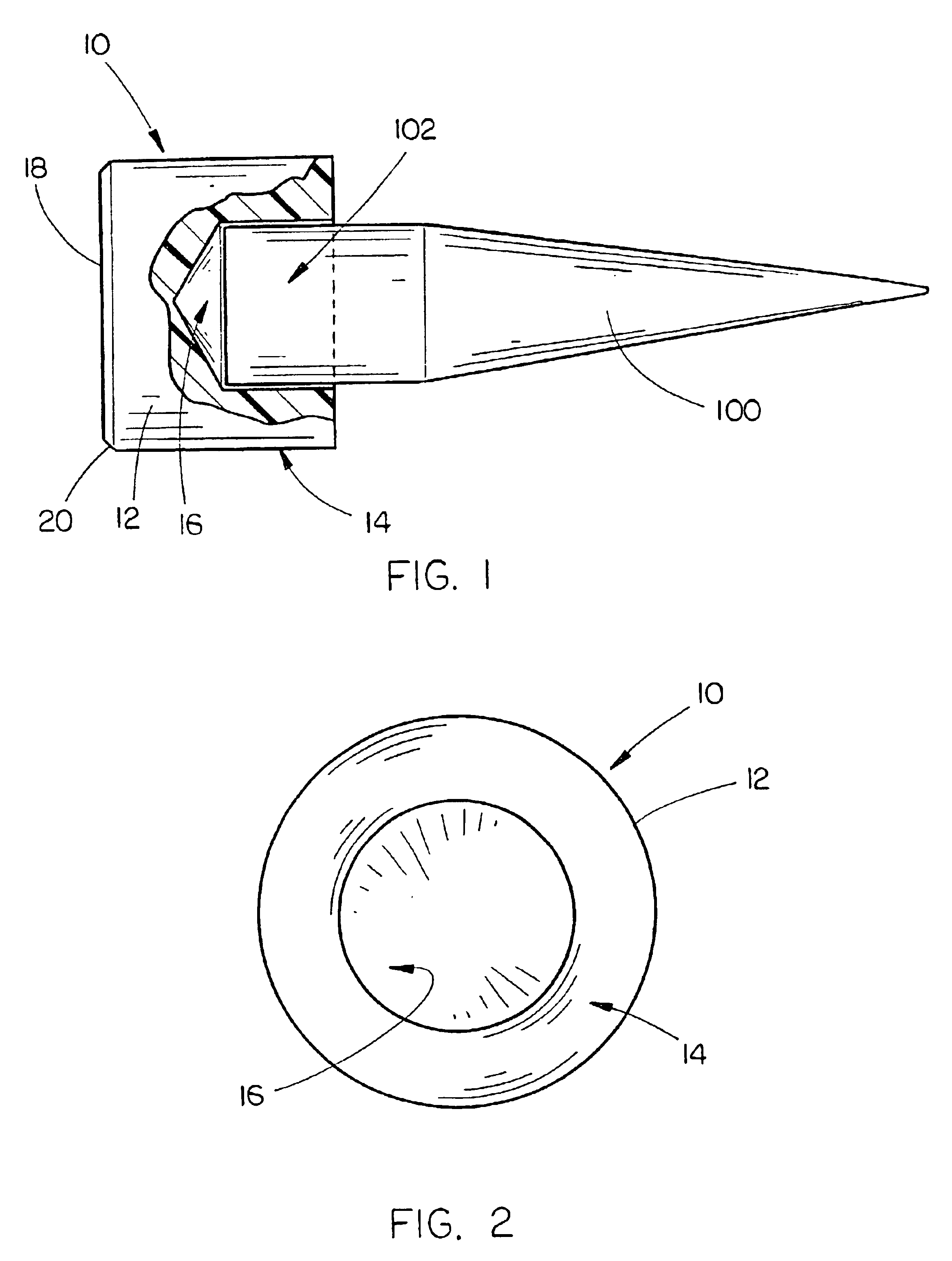

Auger with forward angled leading edge

InactiveUS6863433B2Reduce decreaseImprove productivityGrain huskingGrain polishingLeading edgeForward angle

An auger for vertical mixers includes a forward angled leading edge. The leading edge includes an inner portion, which may or may not be aligned with a radial line extending from the axis of rotation of the auger. The leading edge also includes an outer portion adjacent to the inner portion, which is angled forward of the radial line and extends forward of the inner portion.

Owner:KUHN KNIGHT

Three Dimensional Implant

InactiveUS20100280532A1Facilitate surgical procedureLow densityStentsNon-woven fabricsMedicineLow density

Implants (20, 22) and methods of making the implants for treating bodily defects or remodeling tissue. The implants have a low density and open pores (49) which may permit tissue ingrowth.

Owner:PROXY BIOMEDICAL

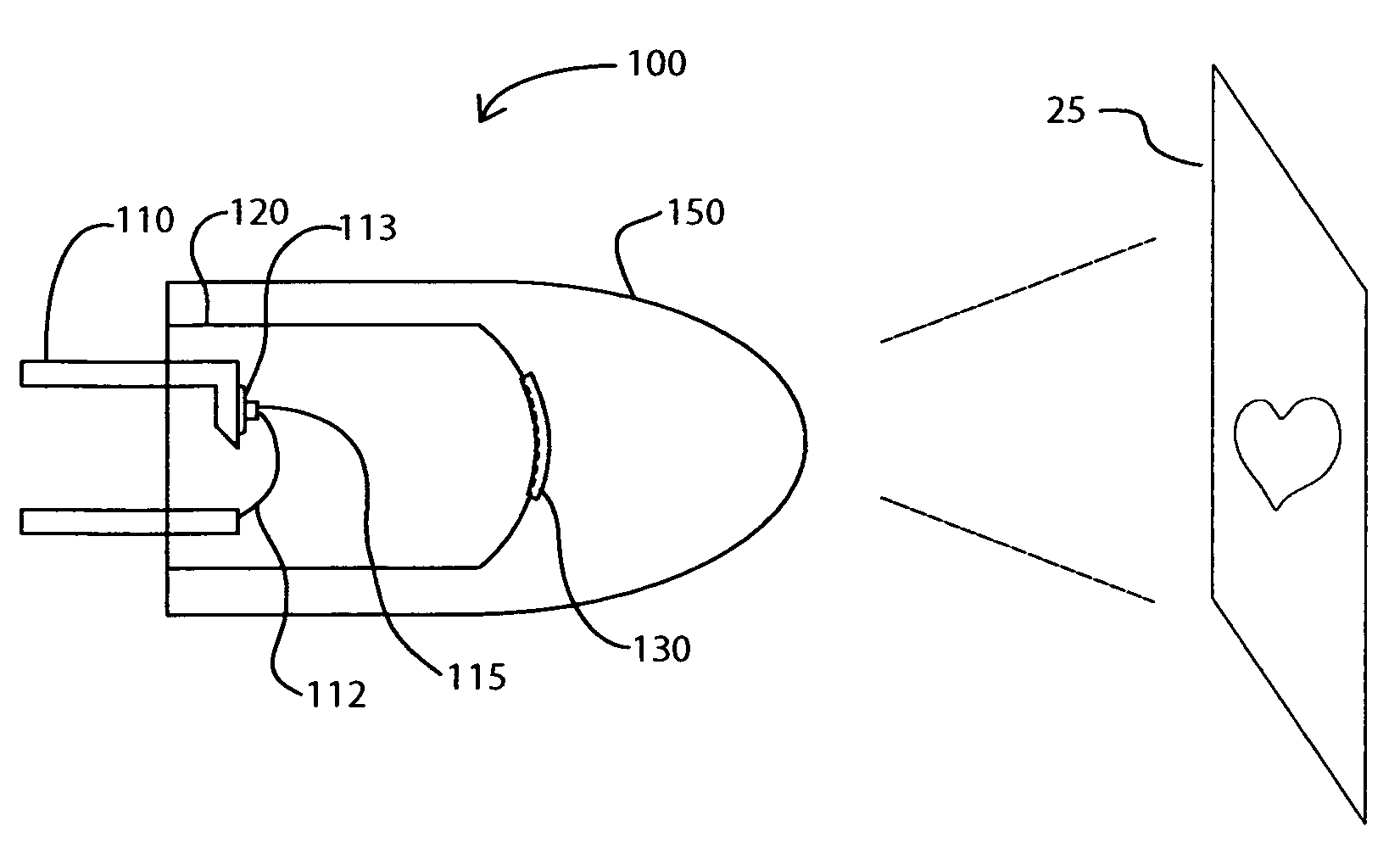

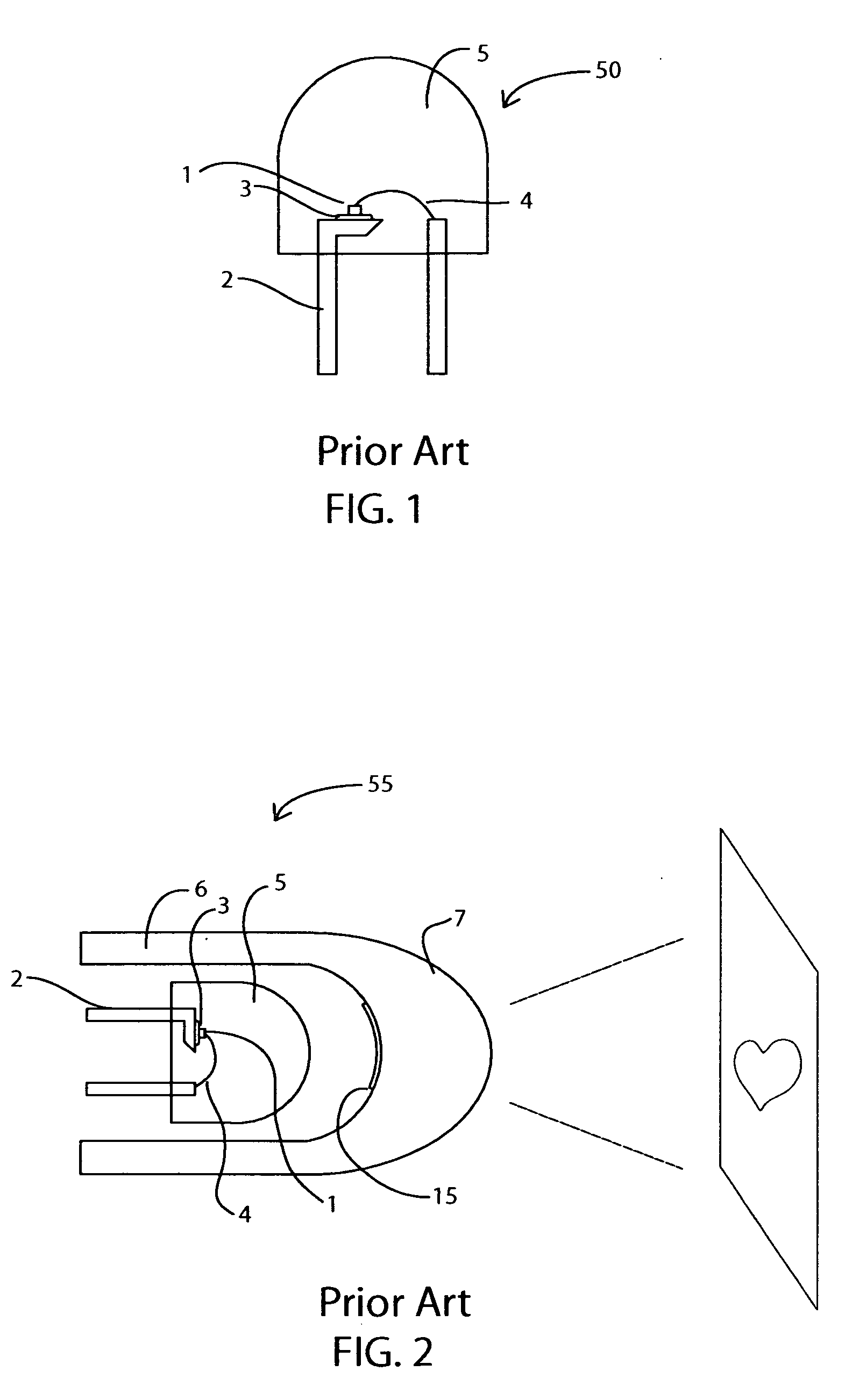

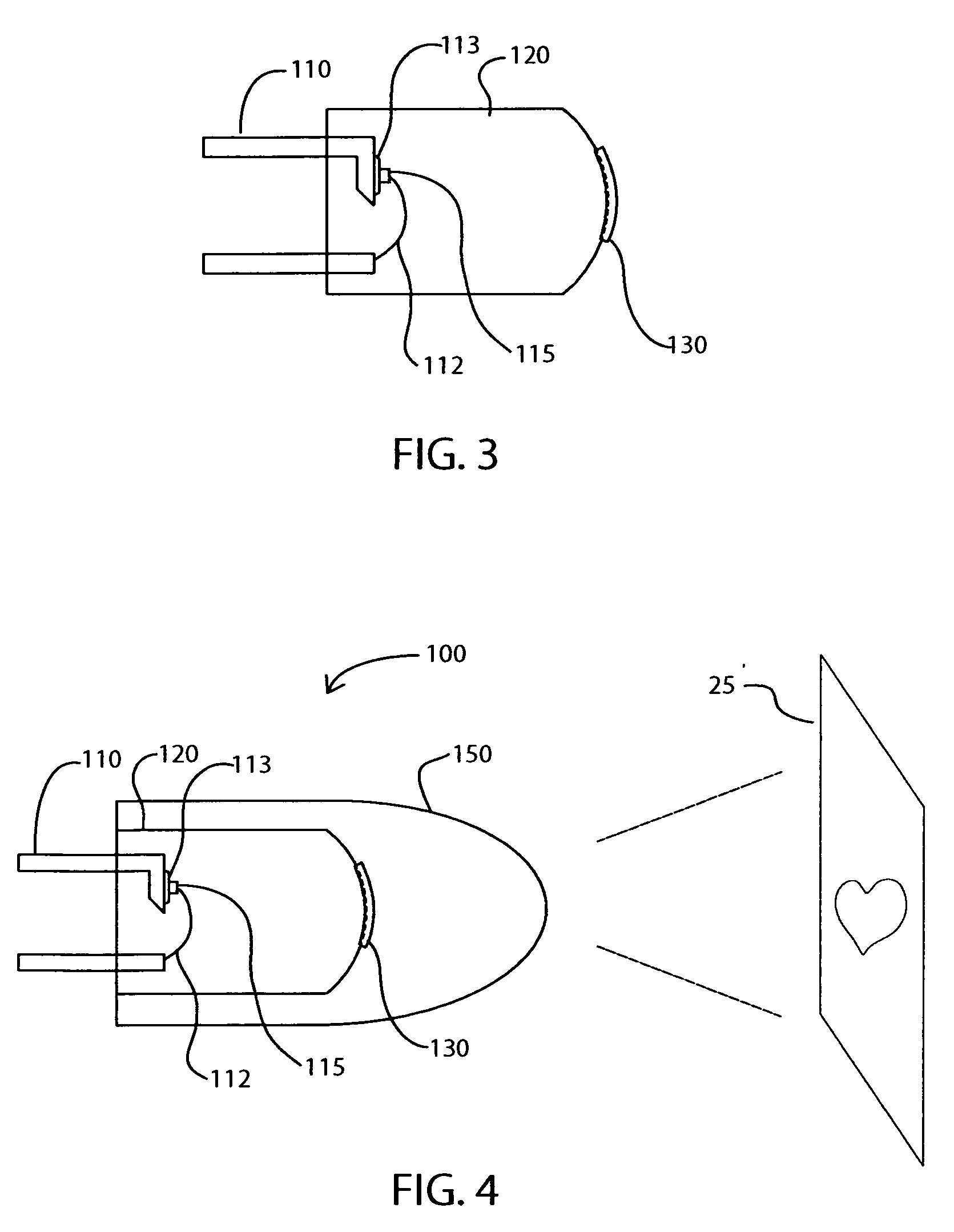

LED image projection apparatus

InactiveUS20130258298A1Easy and inexpensive to manufactureFew partsProjectorsSolid-state devicesLight reflectionLight-emitting diode

A light emitting diode image projection apparatus, comprising a light emitting diode as a light source, a transparent optical grade LED body, having a pattern layer and having an exterior epoxy layer formed about said LED body. The distal end of the LED body is a substantially flat-curved surface (while not being totally flat), while the transparent encapsulating epoxy layer is a sharp-curved, convex surface. This configuration of effective lens structures provides a double encapsulation such that structurally, the effects of the light reflection and the image projection are the same as those of the LED with external plastic outside shells, but the instant invention greatly reduces cost over the former.

Owner:WAITRONY OPTOELECTRONICS

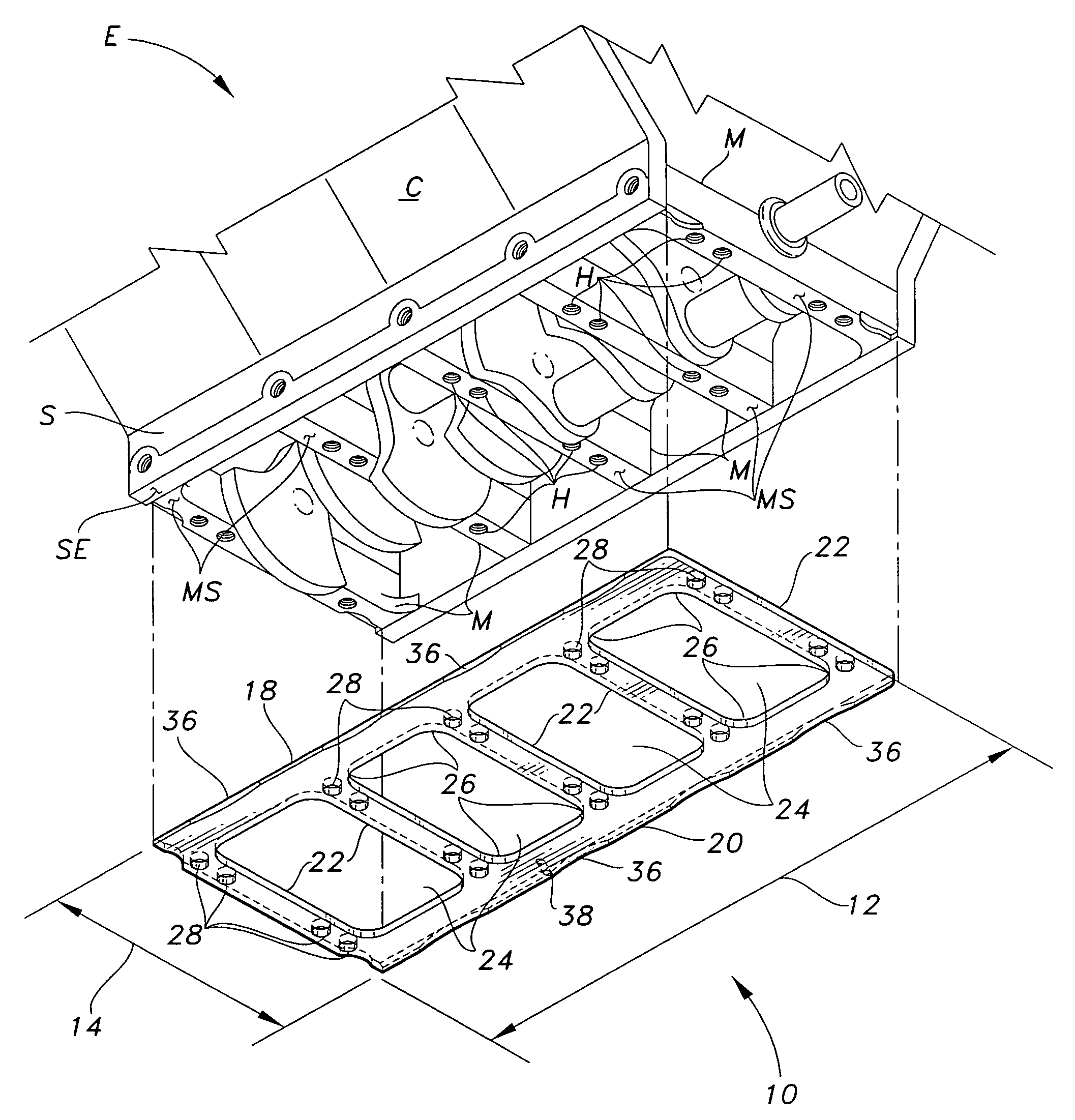

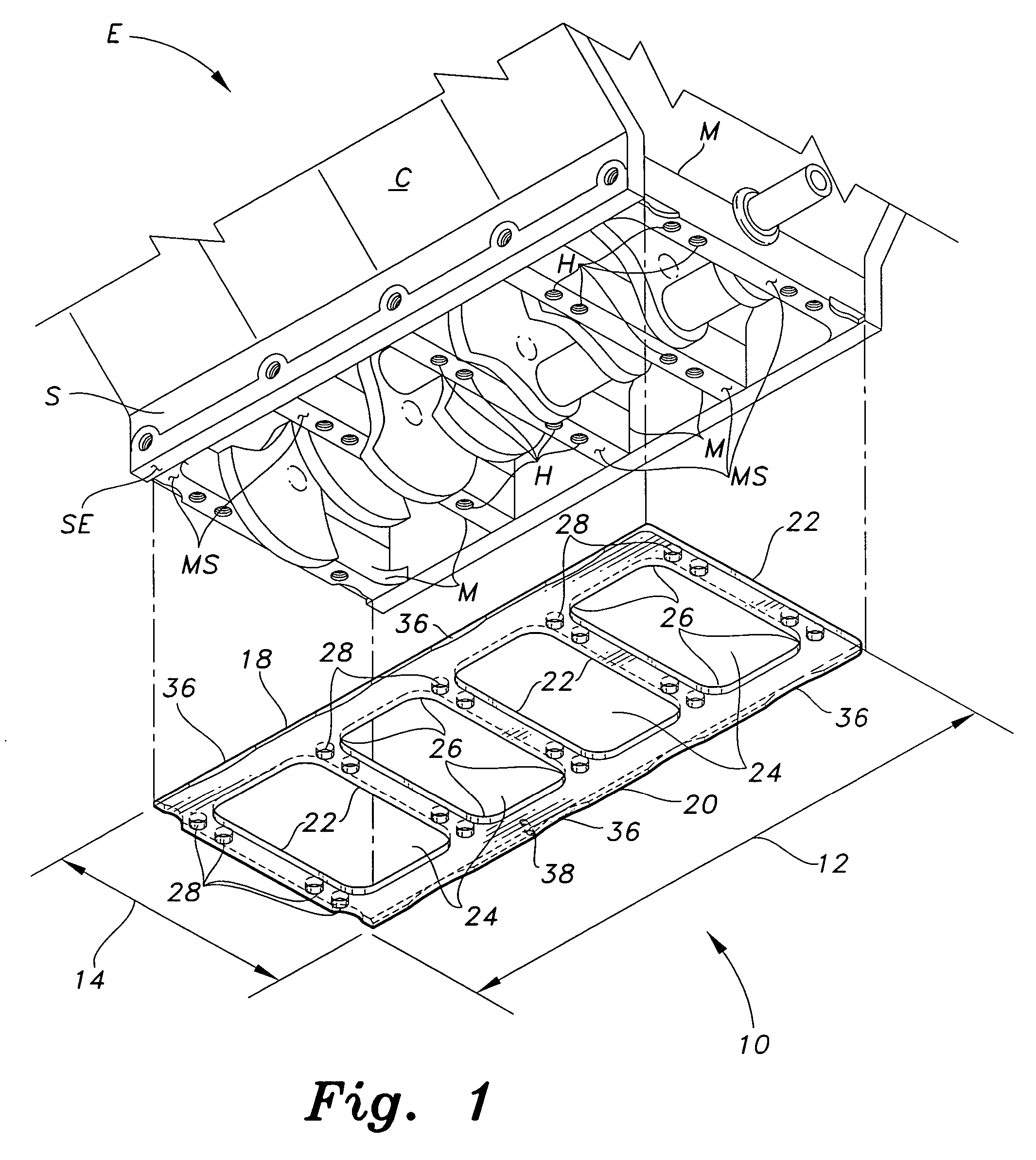

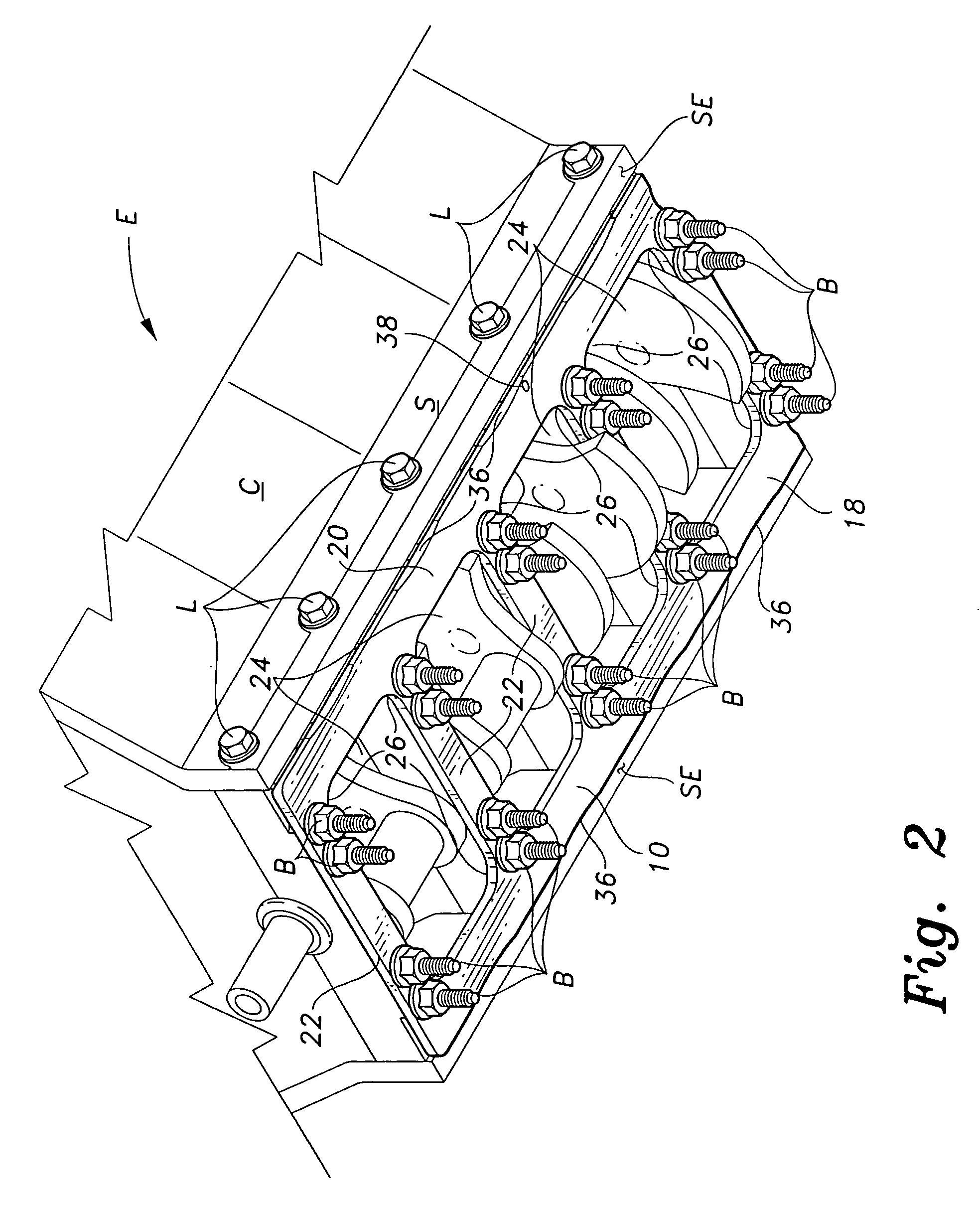

Reinforcement plate for a reciprocating engine

InactiveUS20050166887A1Reduce exerciseDecreasing bearing frictionCasingsOilsumpsStructural fatigueEngineering

The reinforcement plate for a reciprocating engine greatly reduces relative movement of the main bearings of a reciprocating engine, thereby reducing structural fatigue to increase engine durability and longevity. The reinforcement plate also maintains a more precise alignment between the main bearings to reduce friction during operation. The plate comprises a flat, planar steel sheet having opposite sides which fit within the lower skirt of the engine block. A series of lateral ribs or bars extend across the plate and bolt to all of the main bearing caps of the engine, using the stock cap bolts. Crankshaft counterweight and crank throw clearance openings, as well as other clearance areas, are provided in the plate. The reinforcement plate is adapted particularly well for installation in General Motors LS-1 aluminum block engines, but may be configured for installation in a number of different engines as desired.

Owner:MARKOU DEMETRIOS

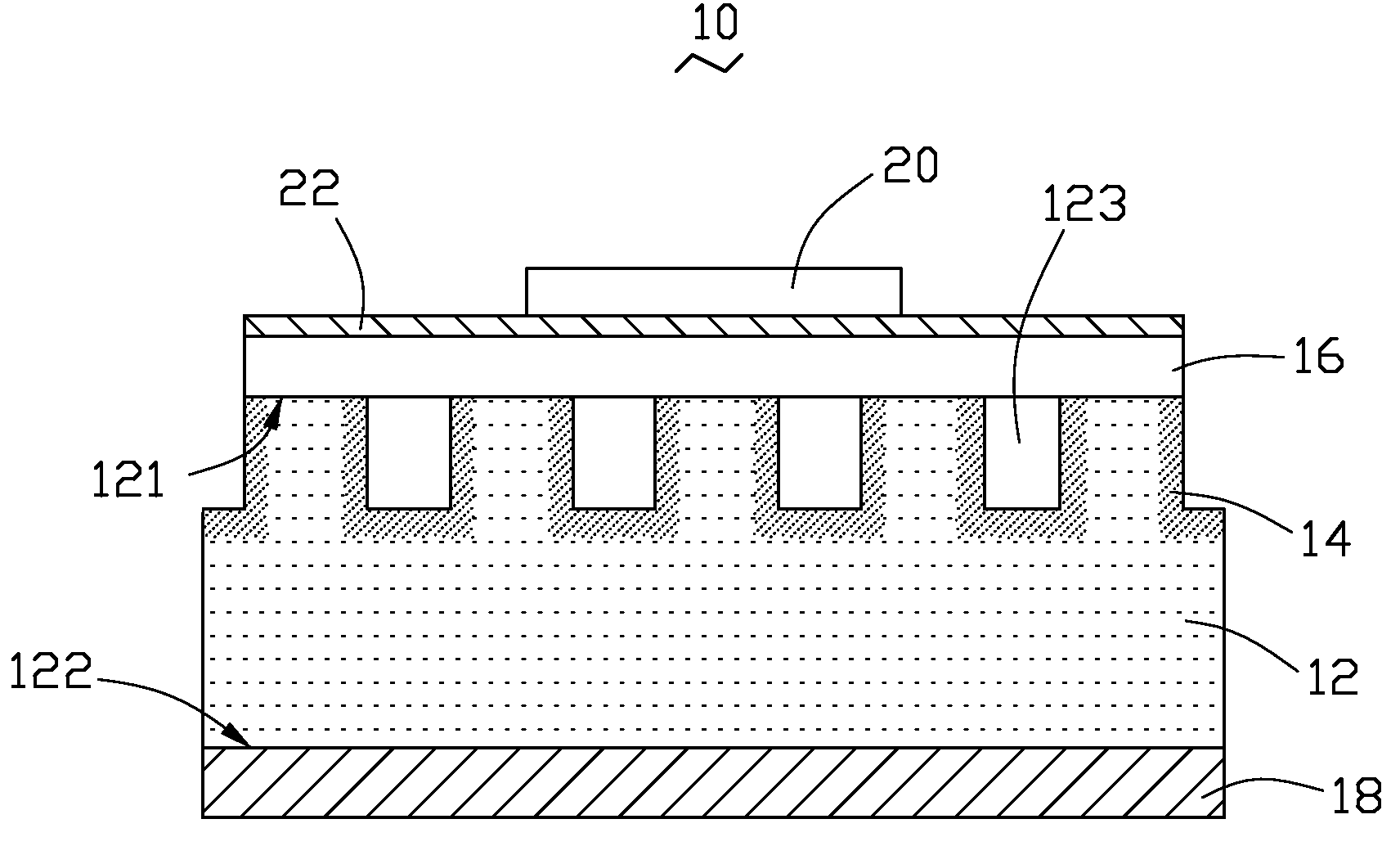

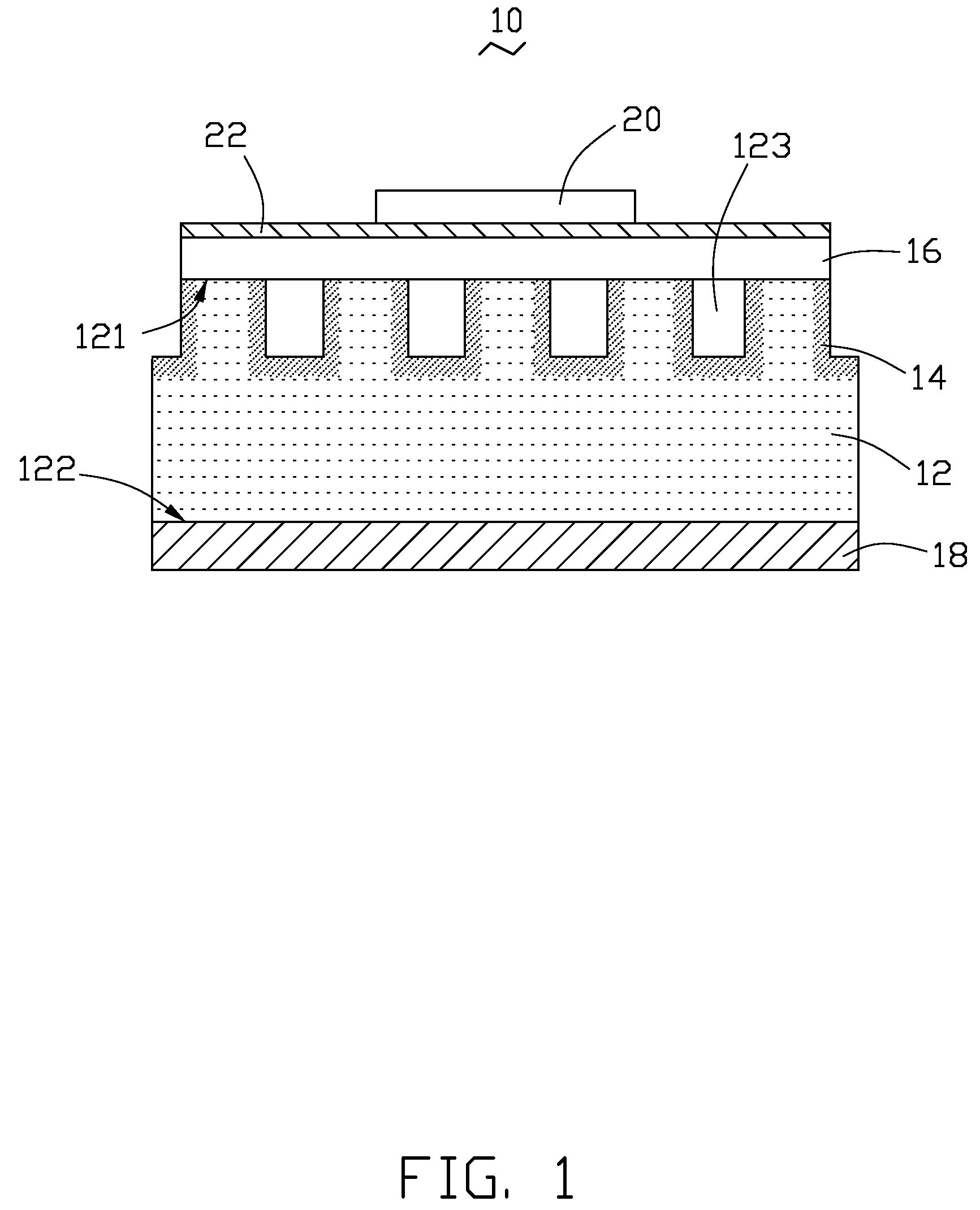

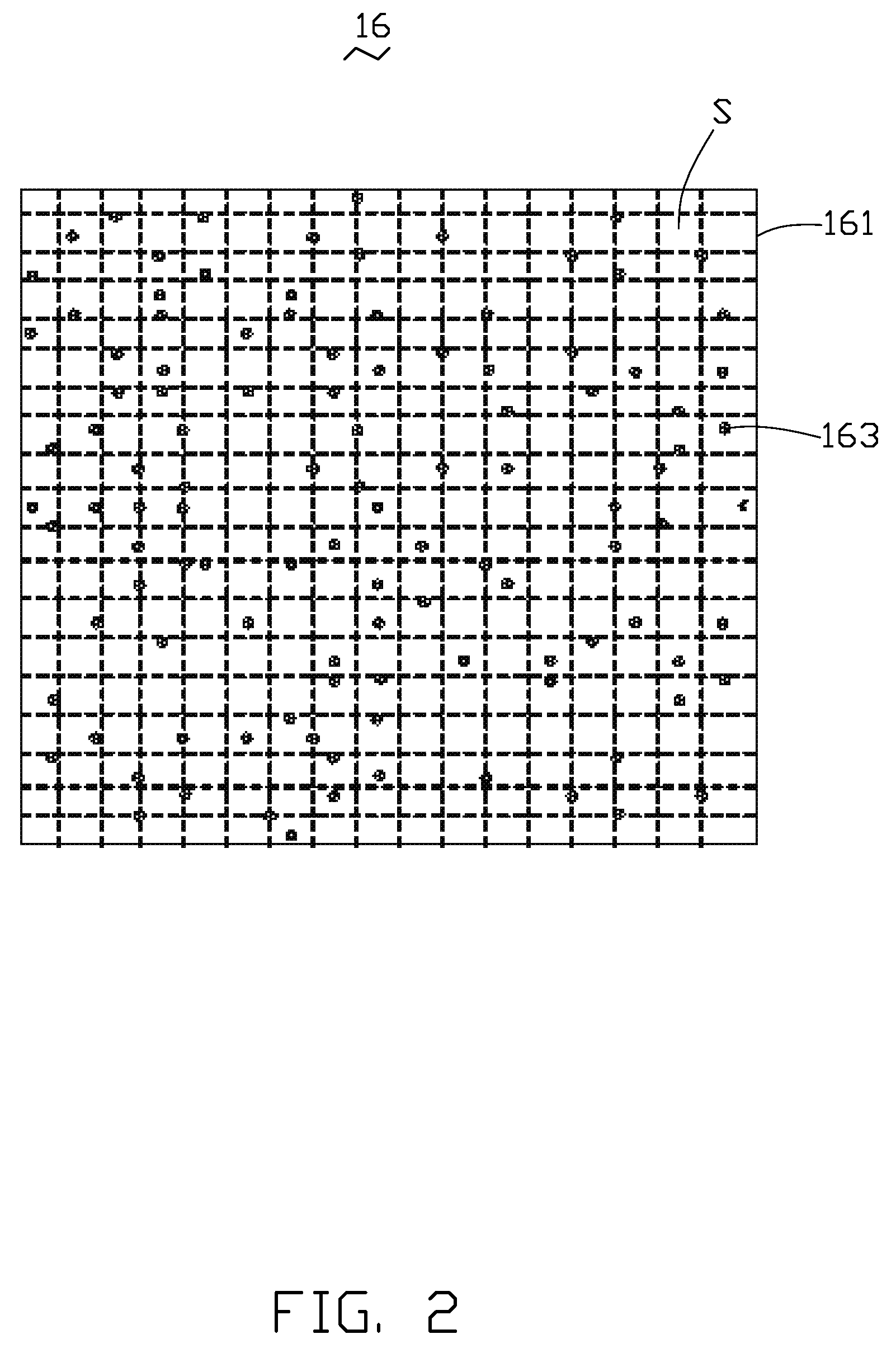

Photovoltaic device

InactiveUS20090260679A1Efficient and durable useNanoopticsPhotovoltaic energy generationCarbon nanotubeOptoelectronics

A photovoltaic device includes a substrate, a doped layer, a first electrode and a second electrode. The substrate has a plurality of cavities defined therein. The doped layer is in contact the substrate. The first electrode including a carbon nanotube composite material is adjacent to the substrate. The second electrode is attached to the substrate.

Owner:TSINGHUA UNIV +1

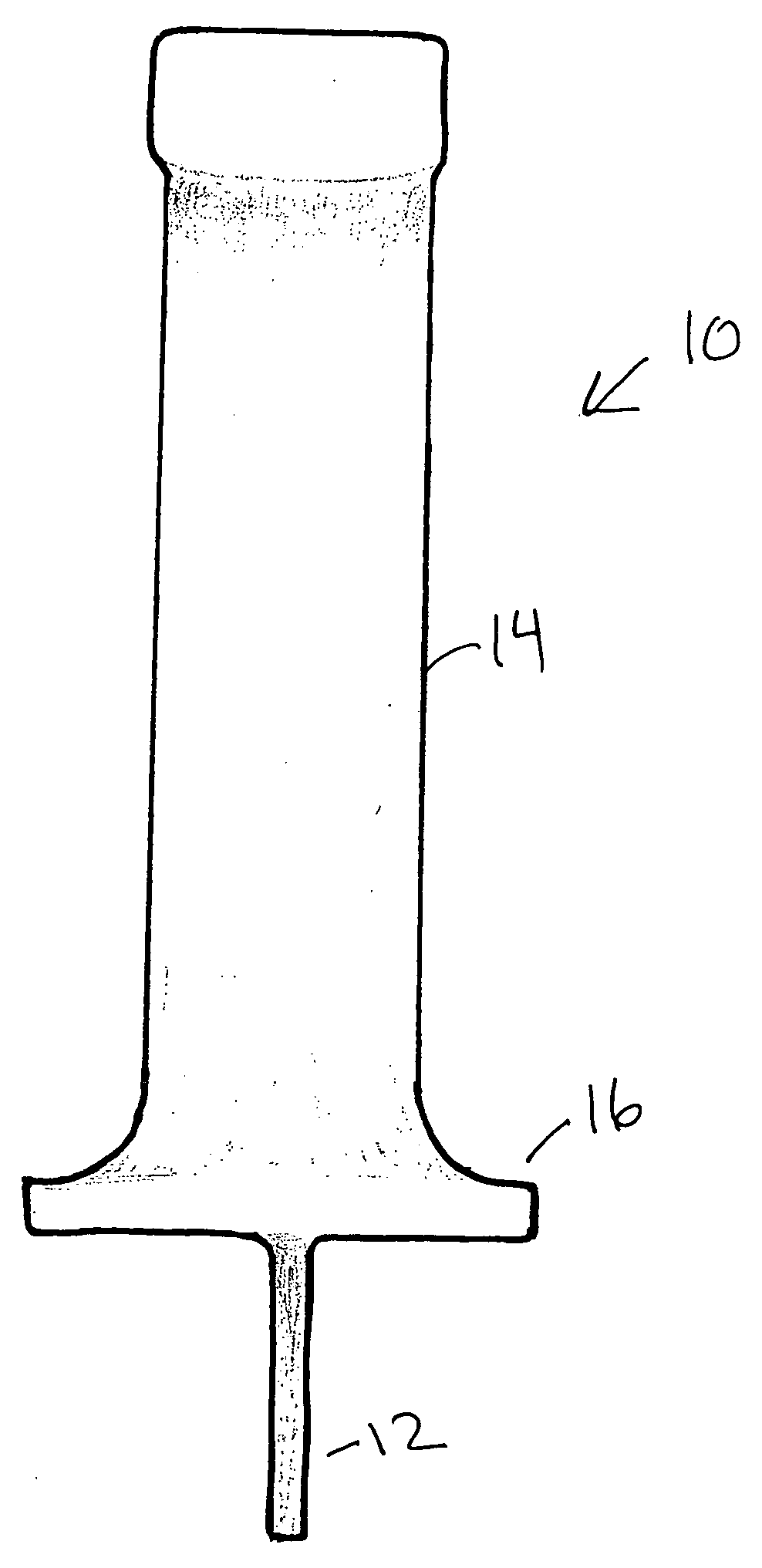

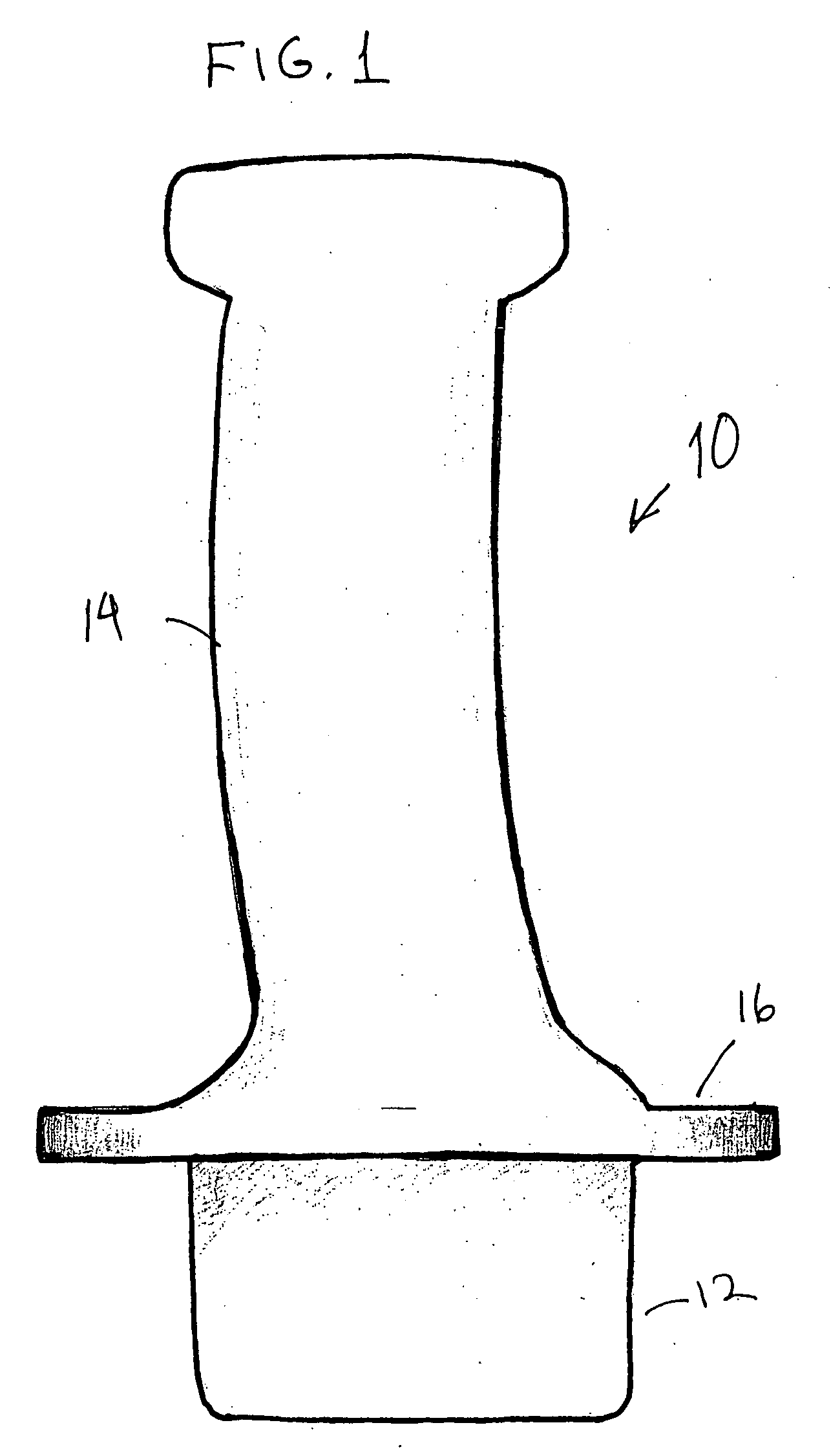

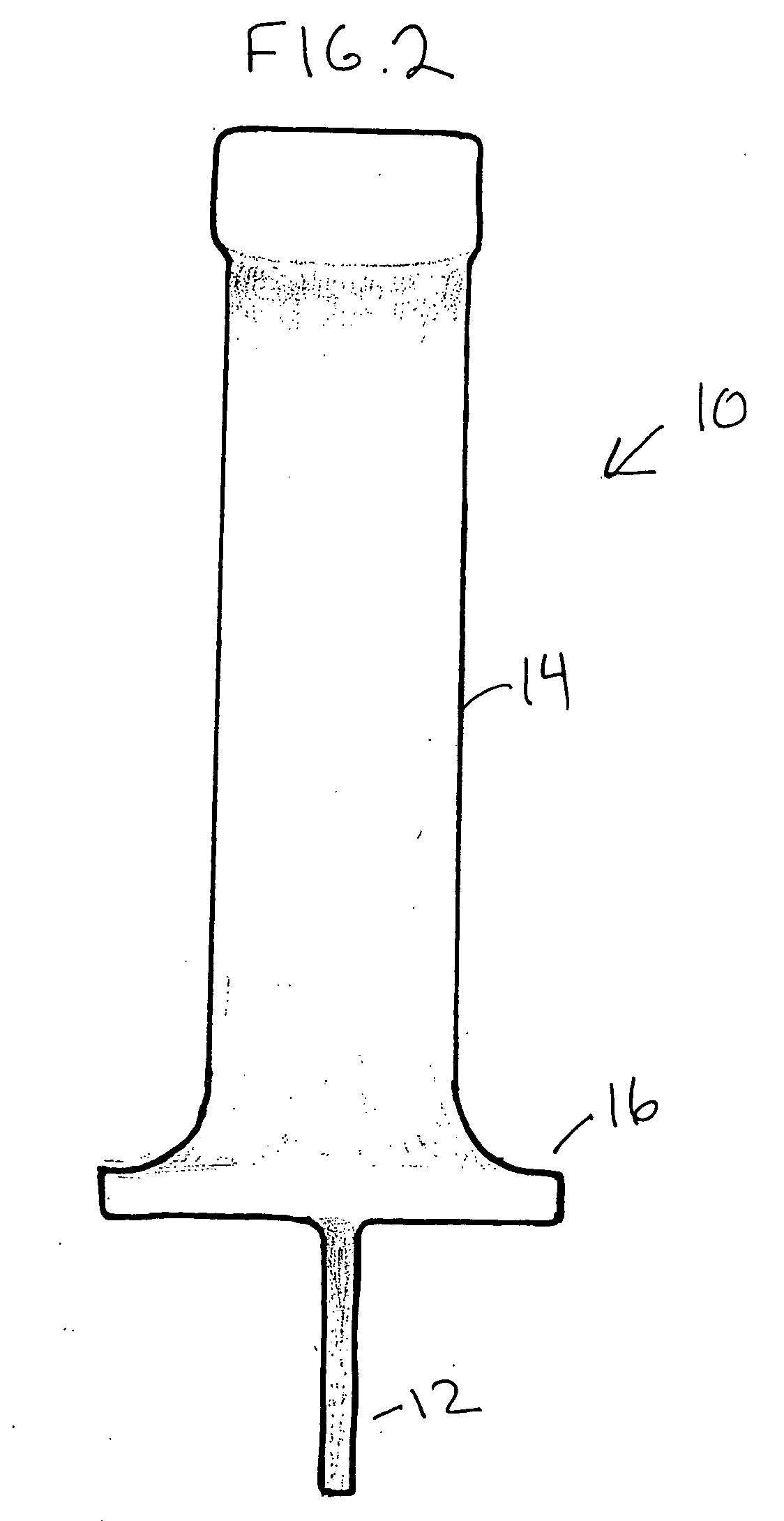

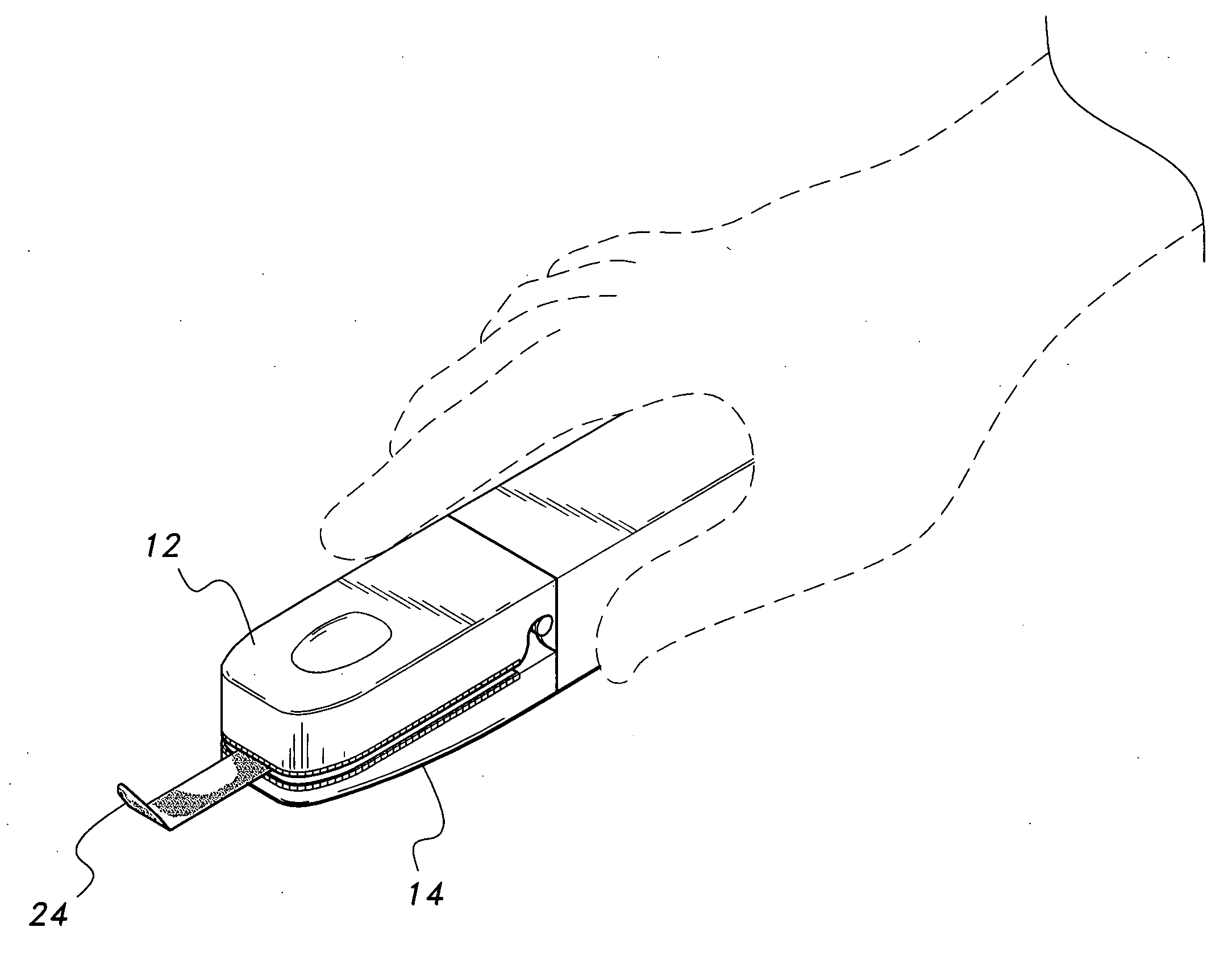

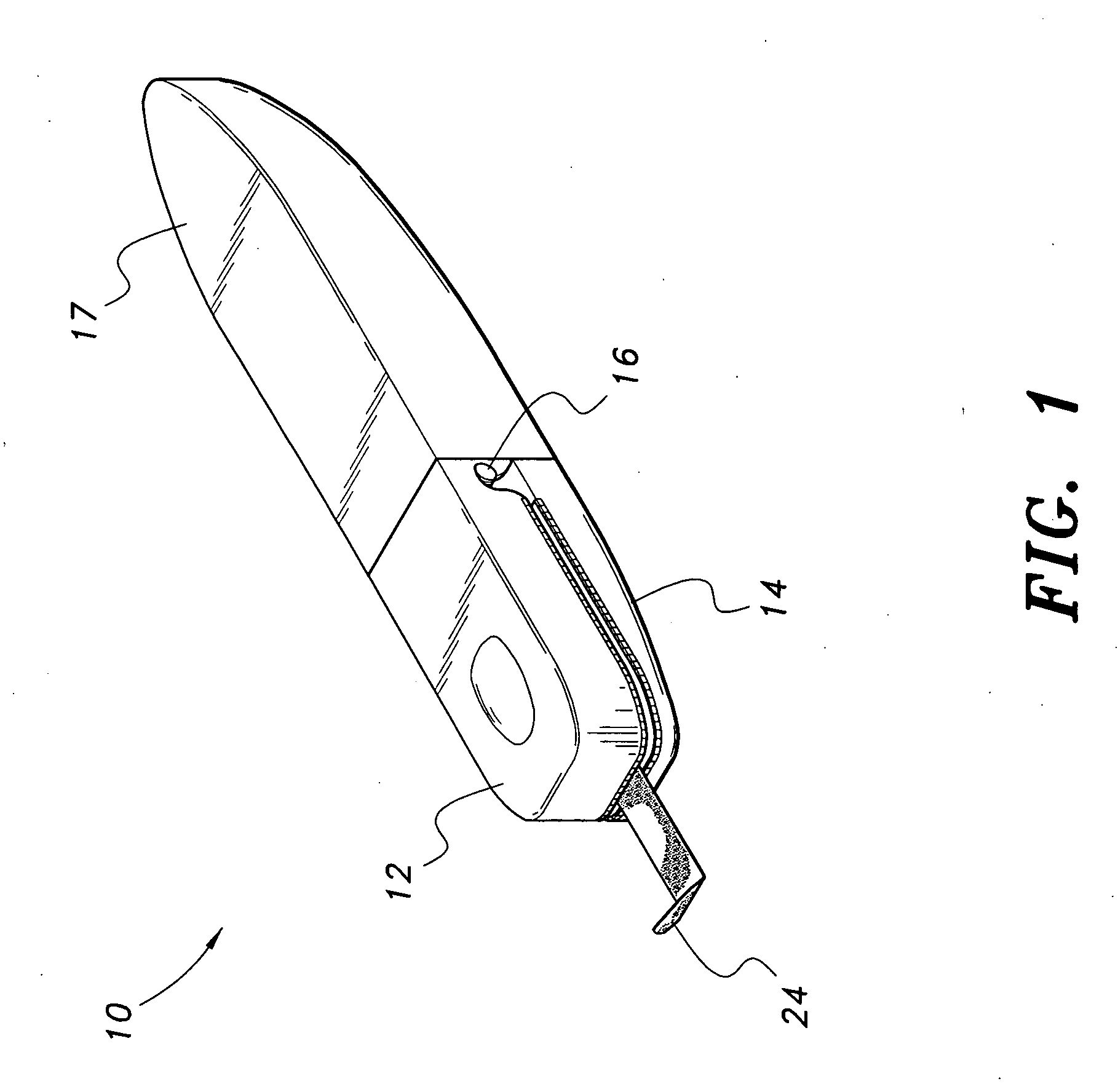

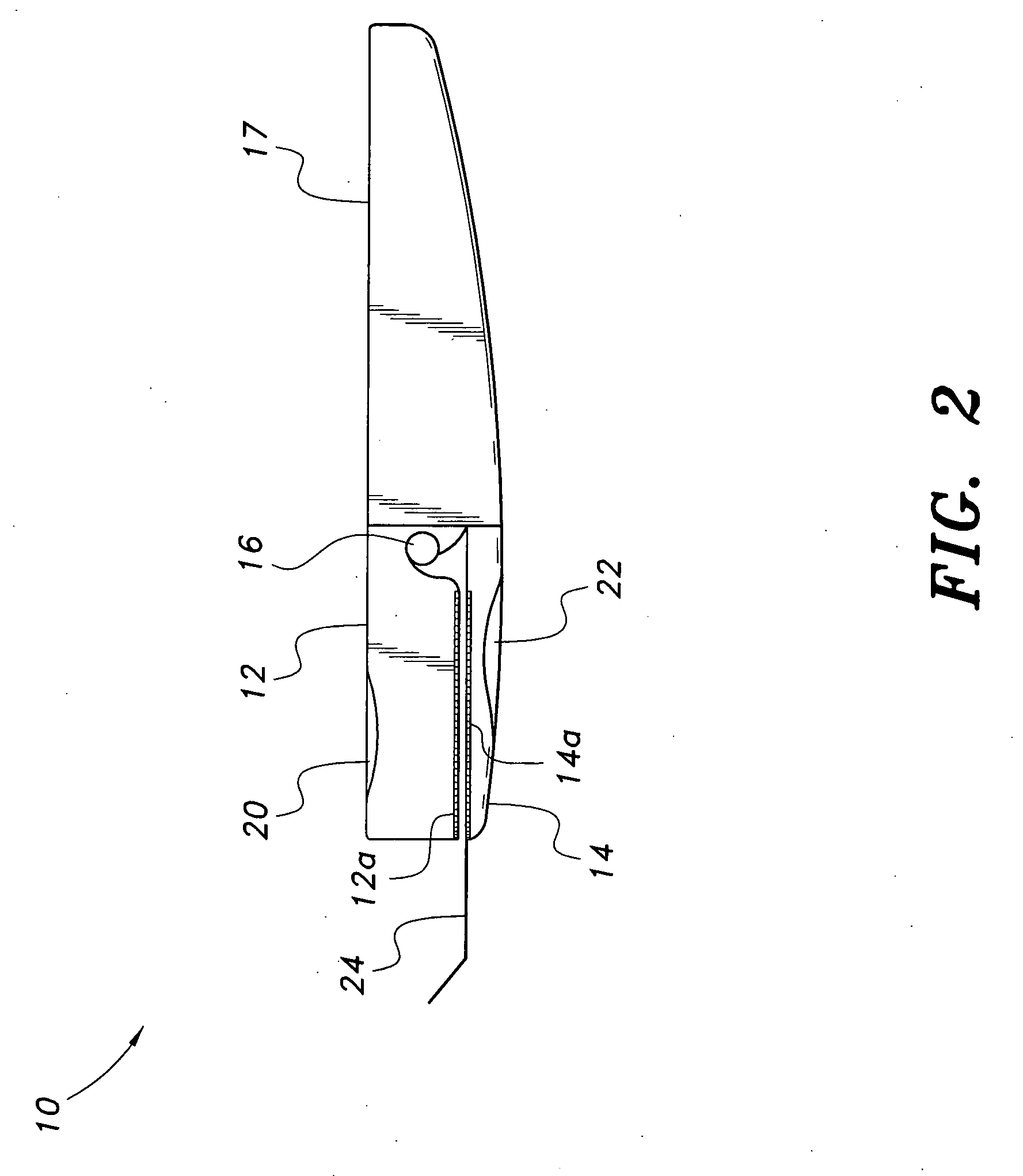

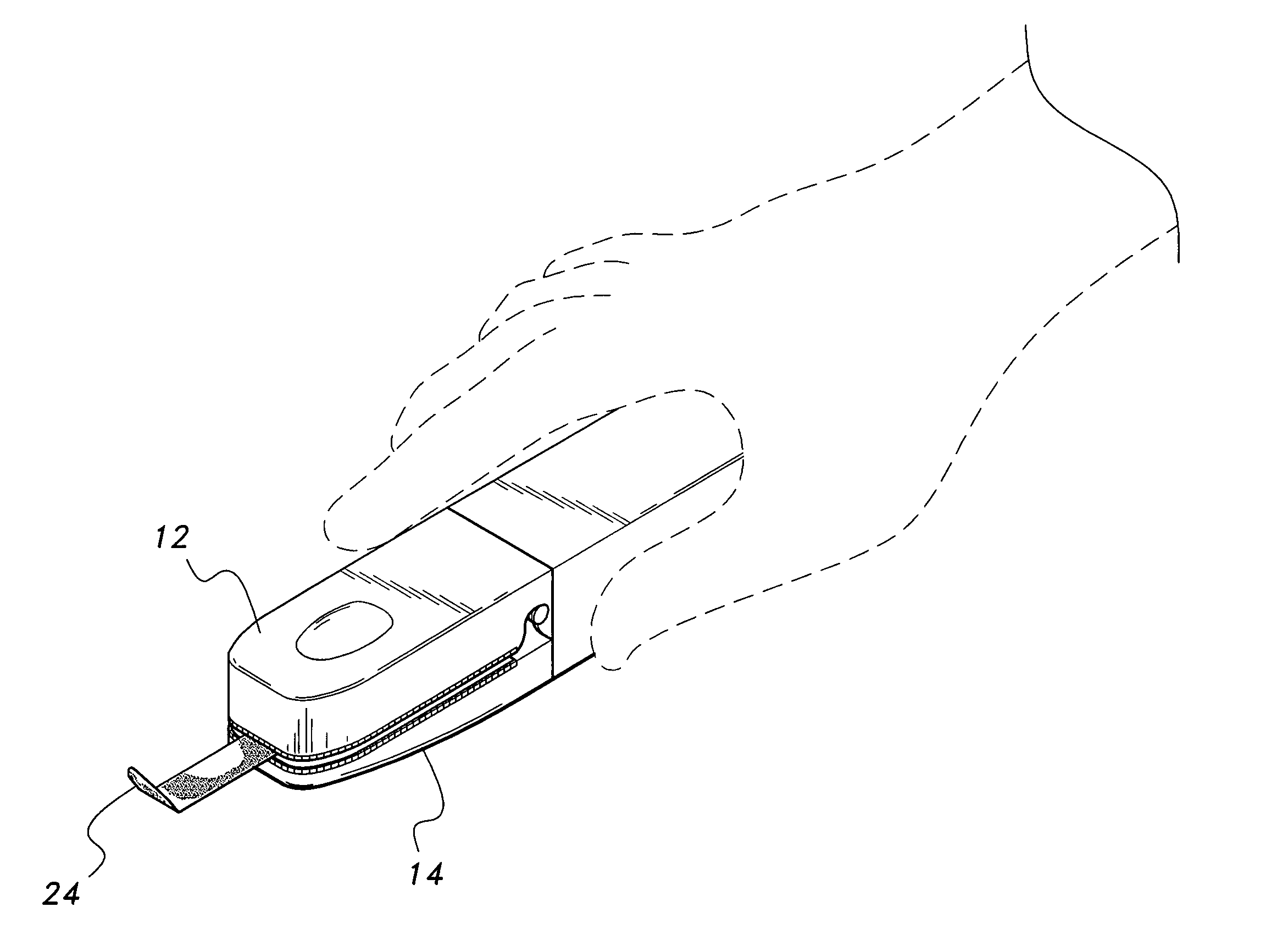

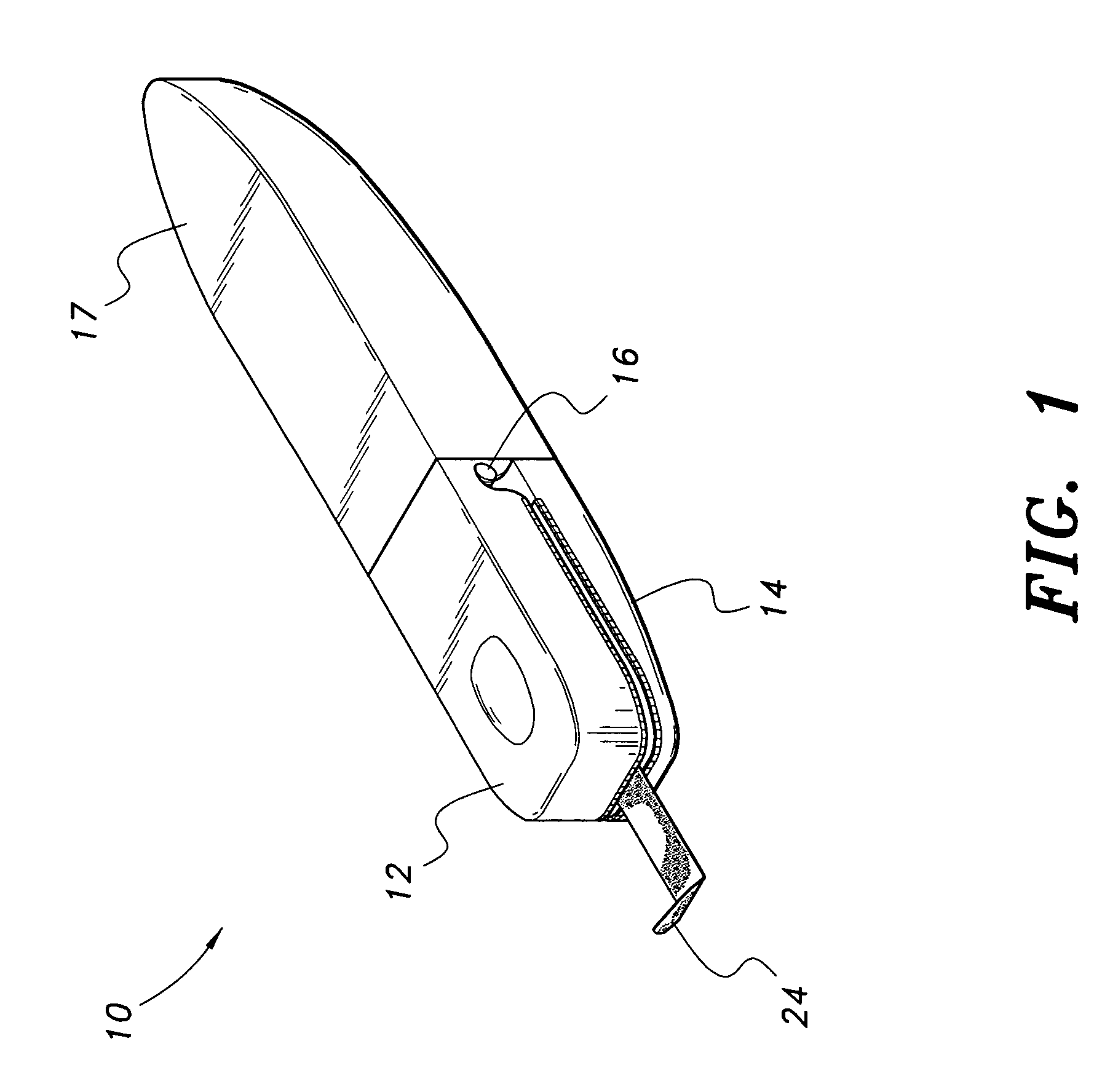

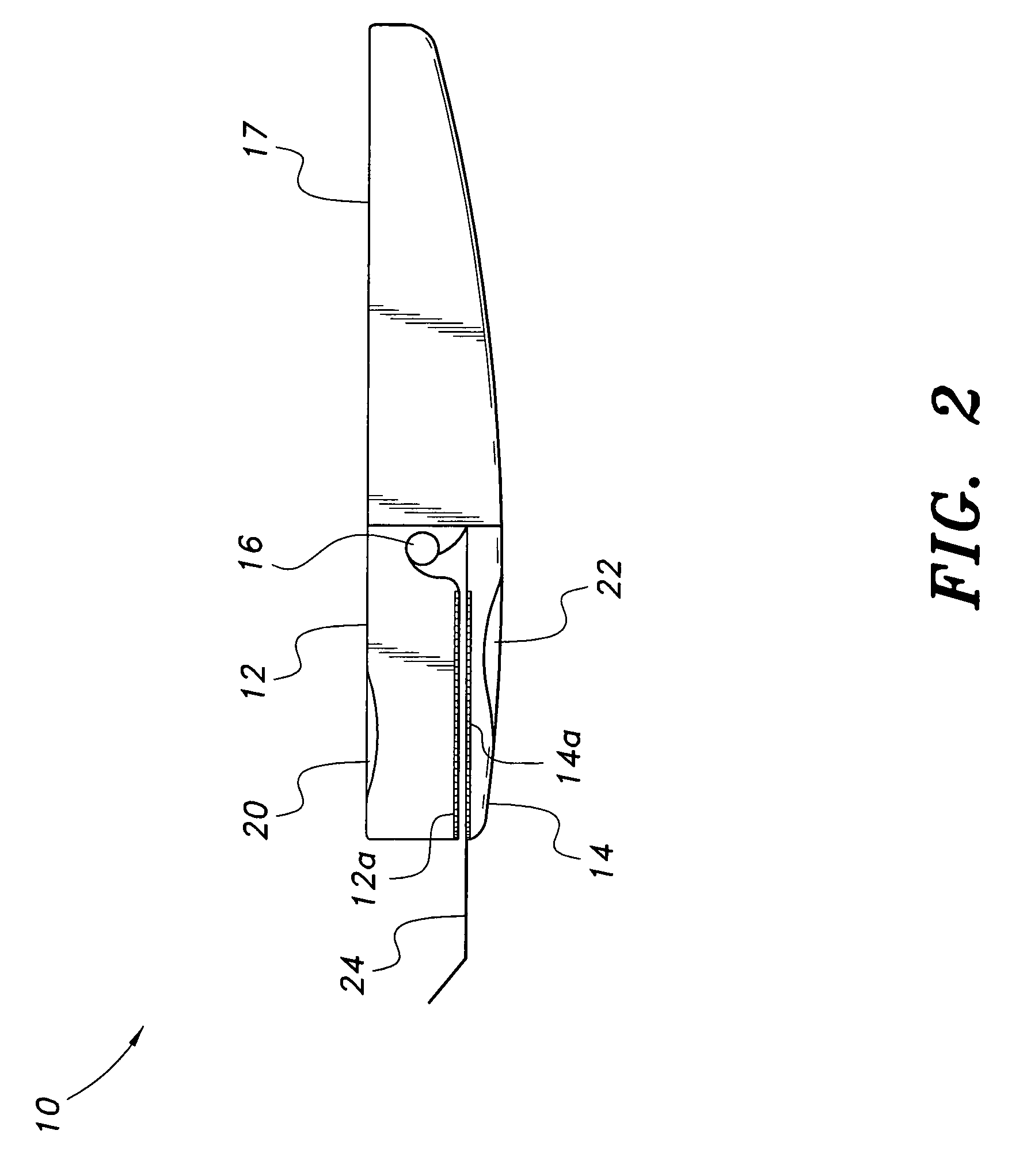

Spacing tool

InactiveUS20080010846A1Efficient and durable useEasy to useMeasurement devicesBuilding constructionsEngineeringHand tool

A hand tool (10) includes a generally planar body (12) having a thickness approximately equal to a predetermined desired spacing between two objects such as deck boards, a flange (16) having a contact surface generally perpendicular to the planar body, and a handle (14) extending from the flange in a direction away from the planar body. In use, the planar body is inserted between two boards while one or both boards are fastened to a substructure. The tool is removed by grasping the handle and either pulling it out or rocking it so that a portion of the flange acts like a fulcrum to pivot the planar body out of the space between the two boards.

Owner:BINGHAM JOHN FREDERICK

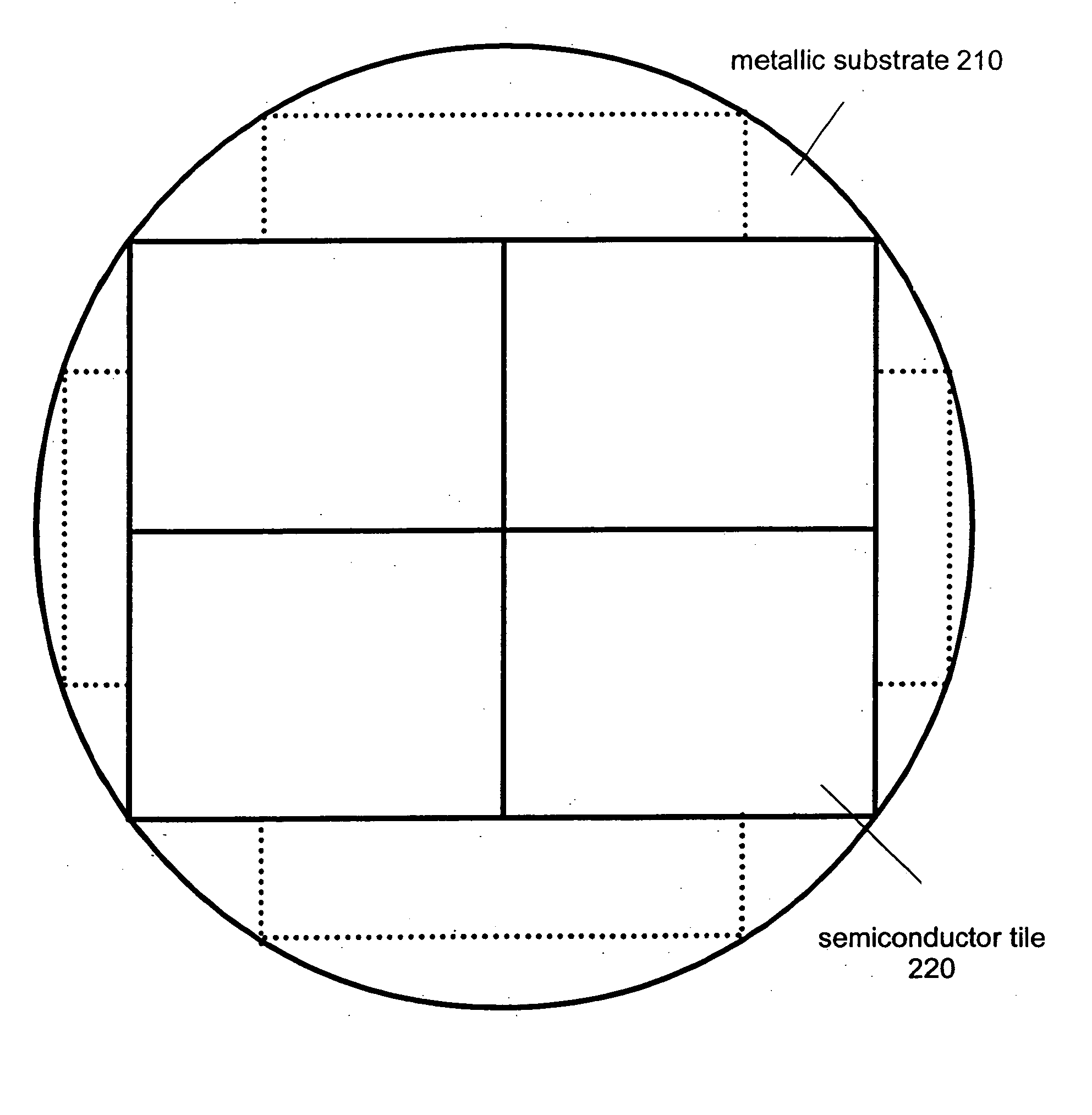

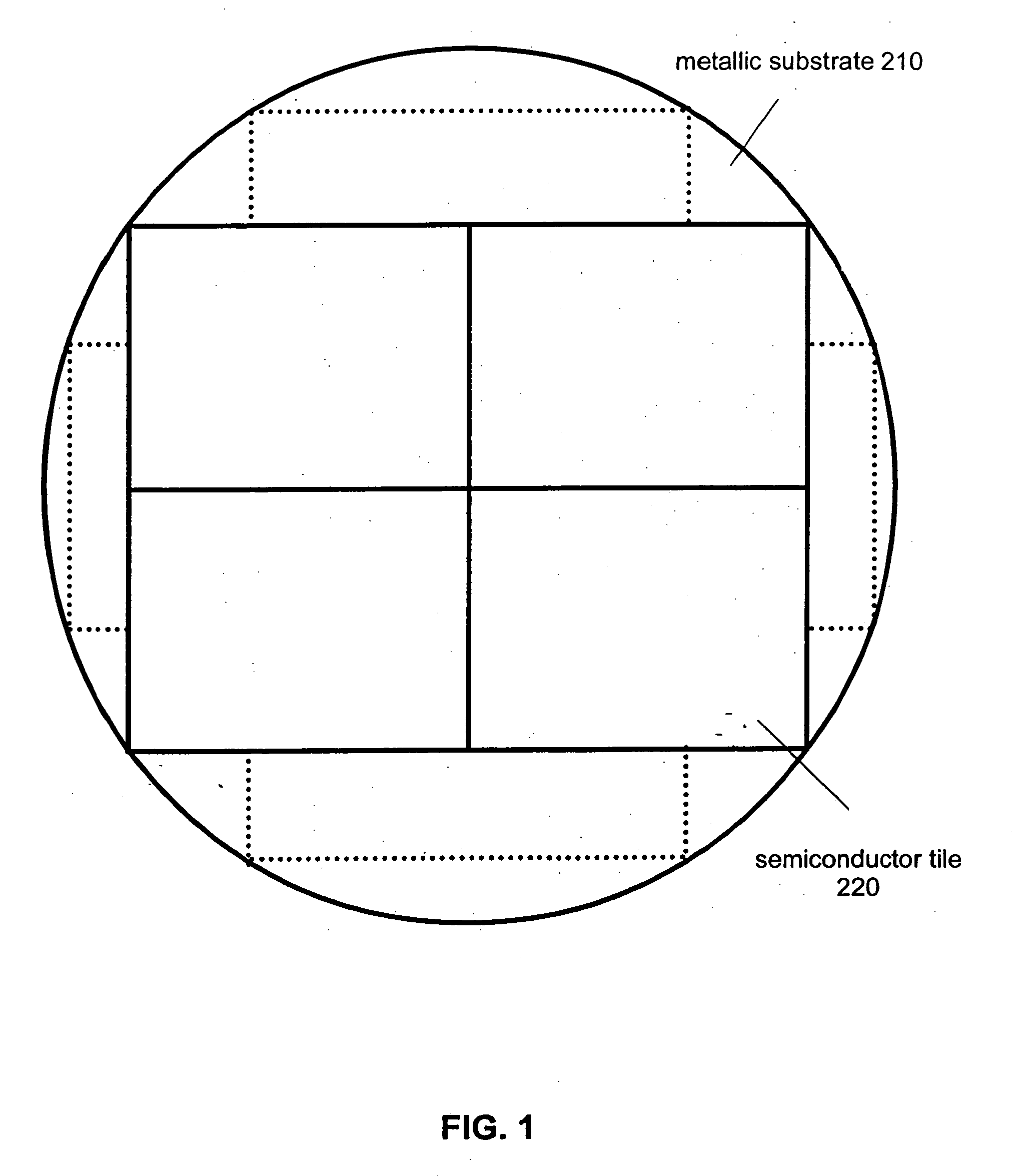

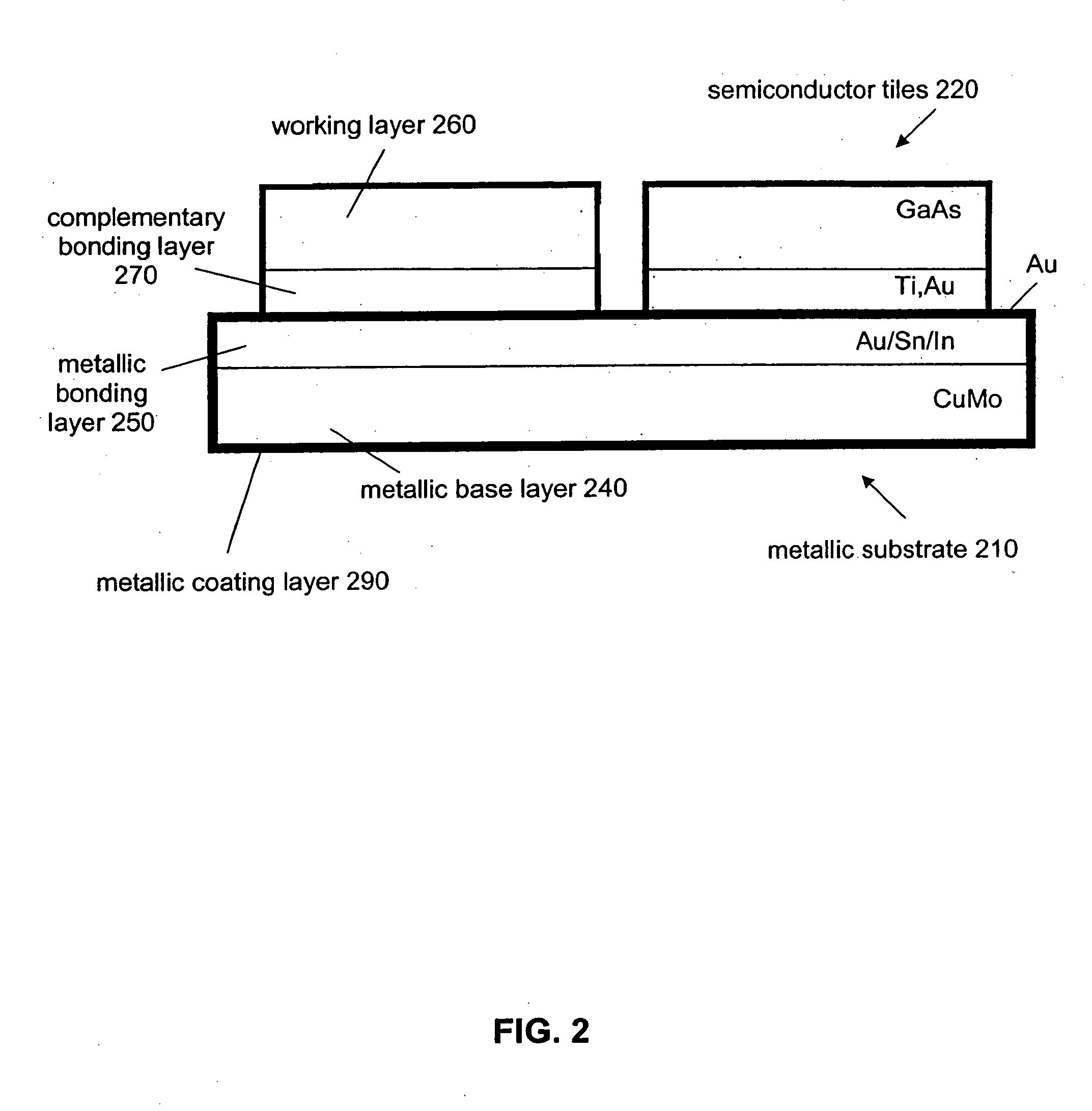

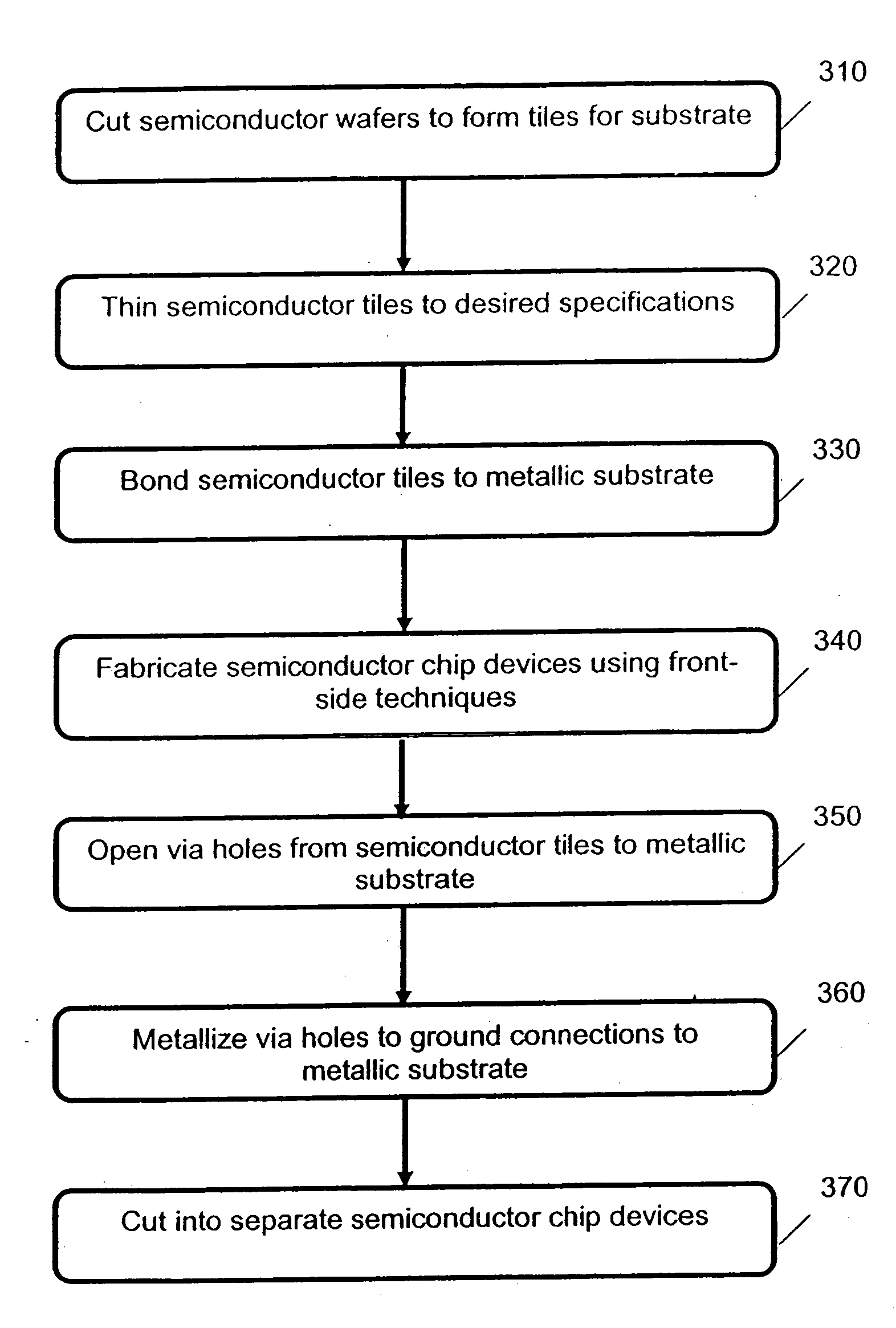

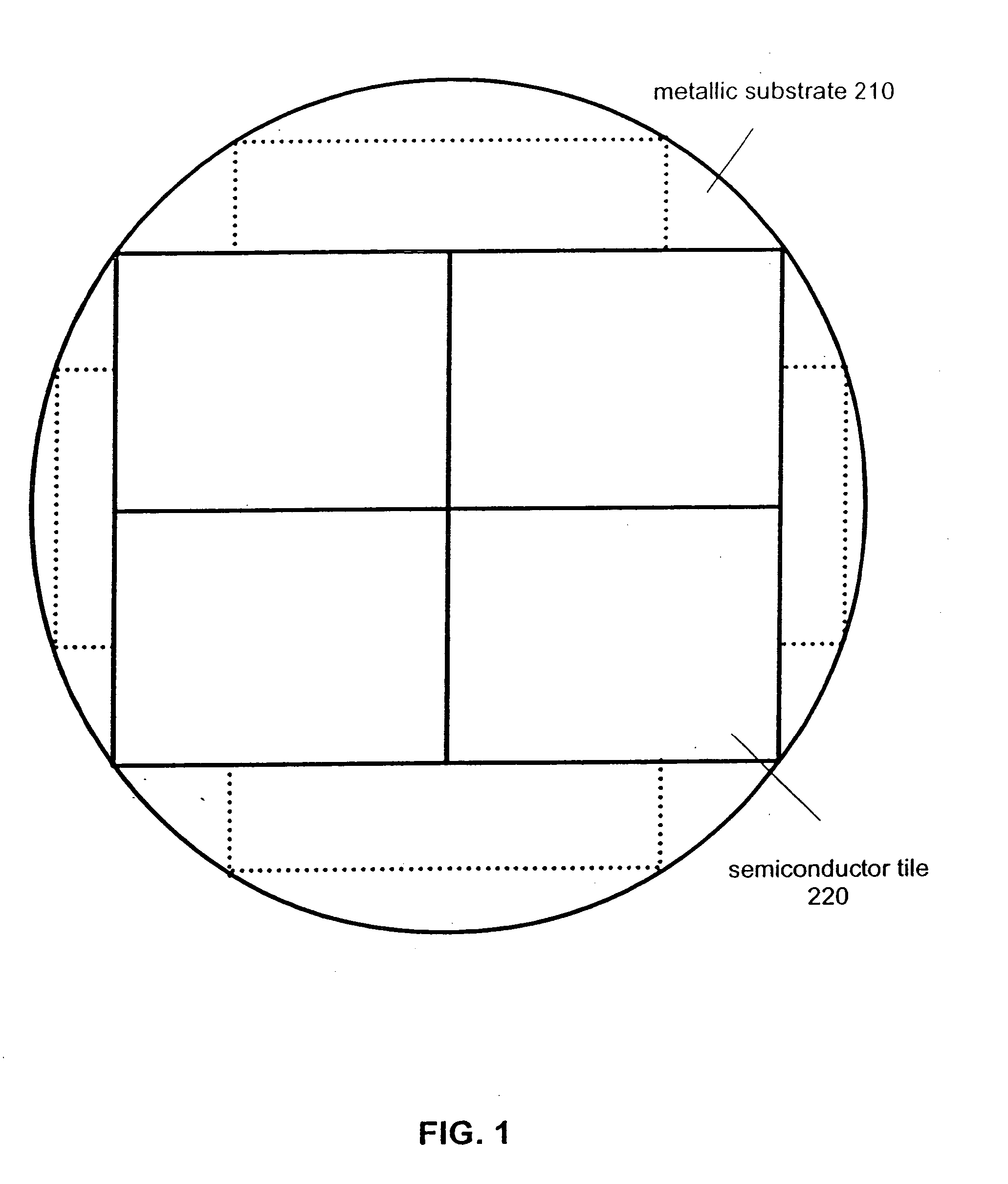

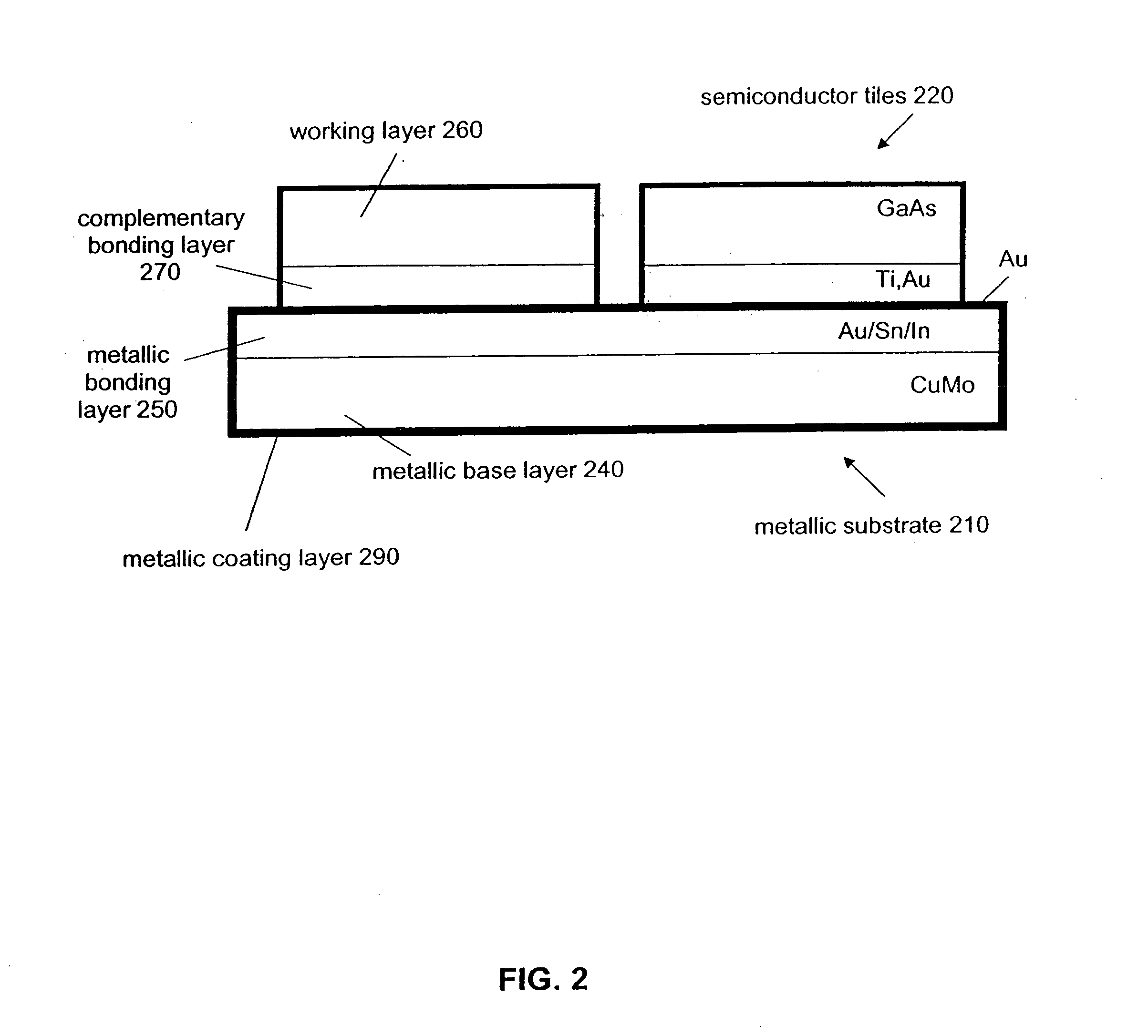

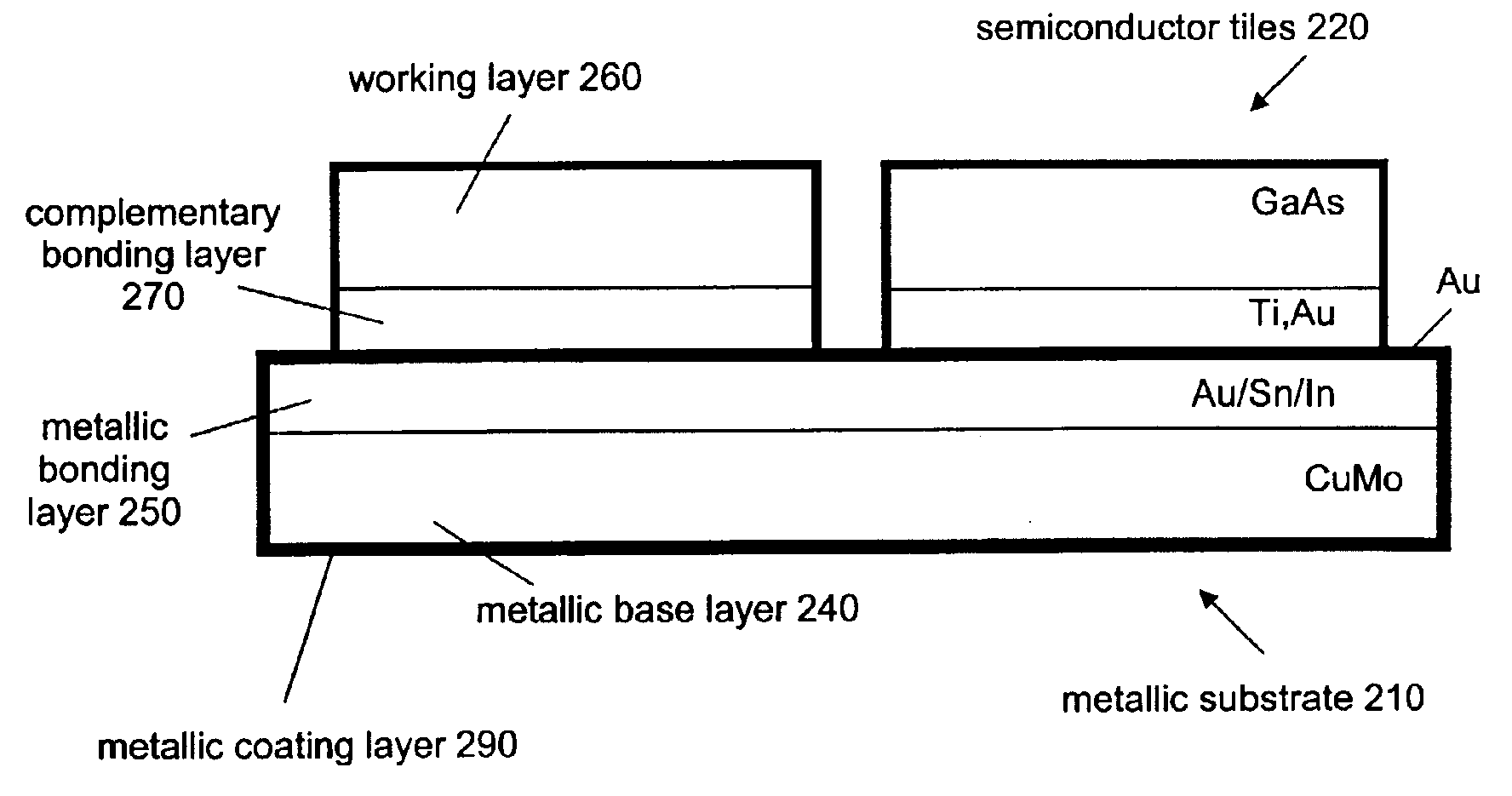

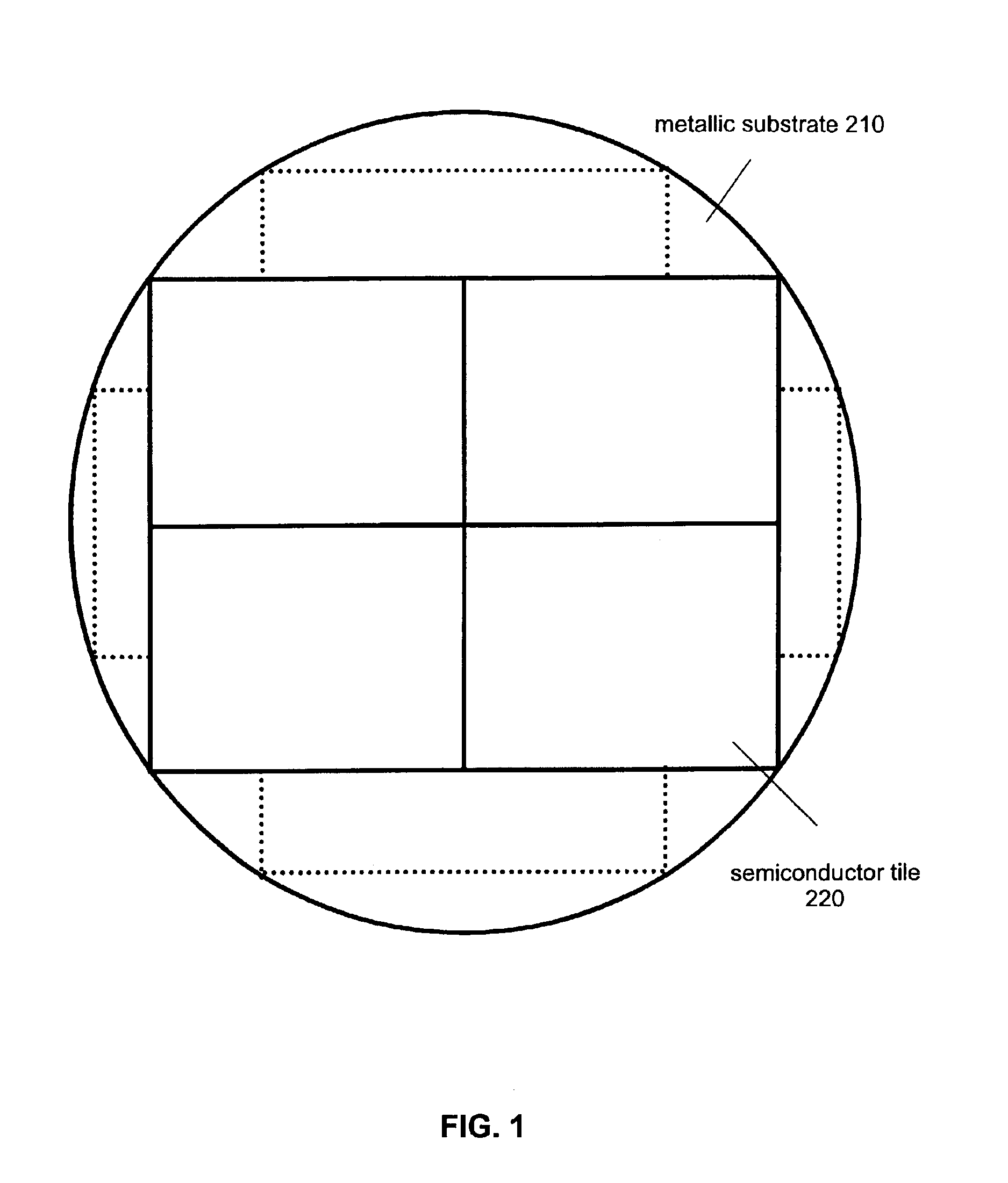

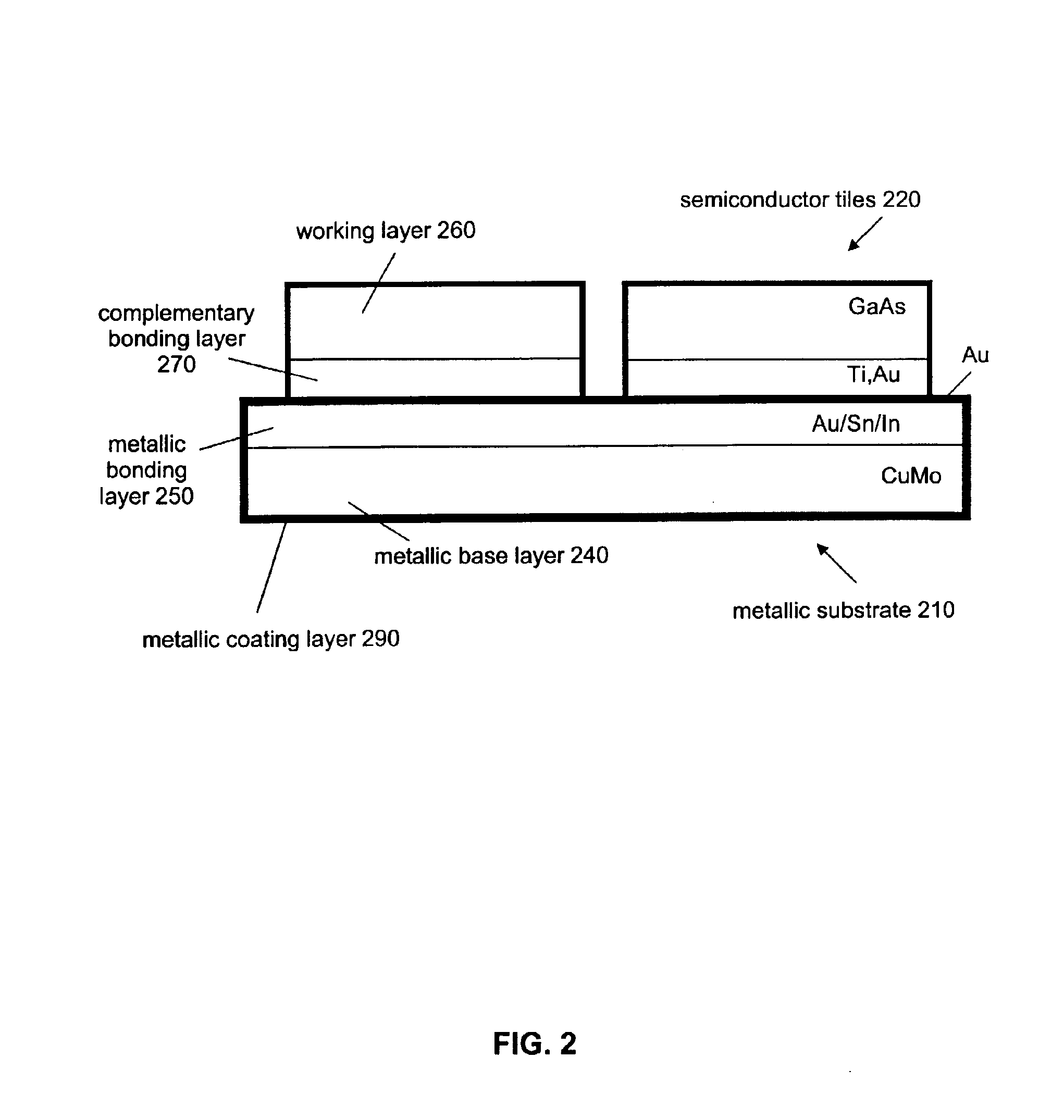

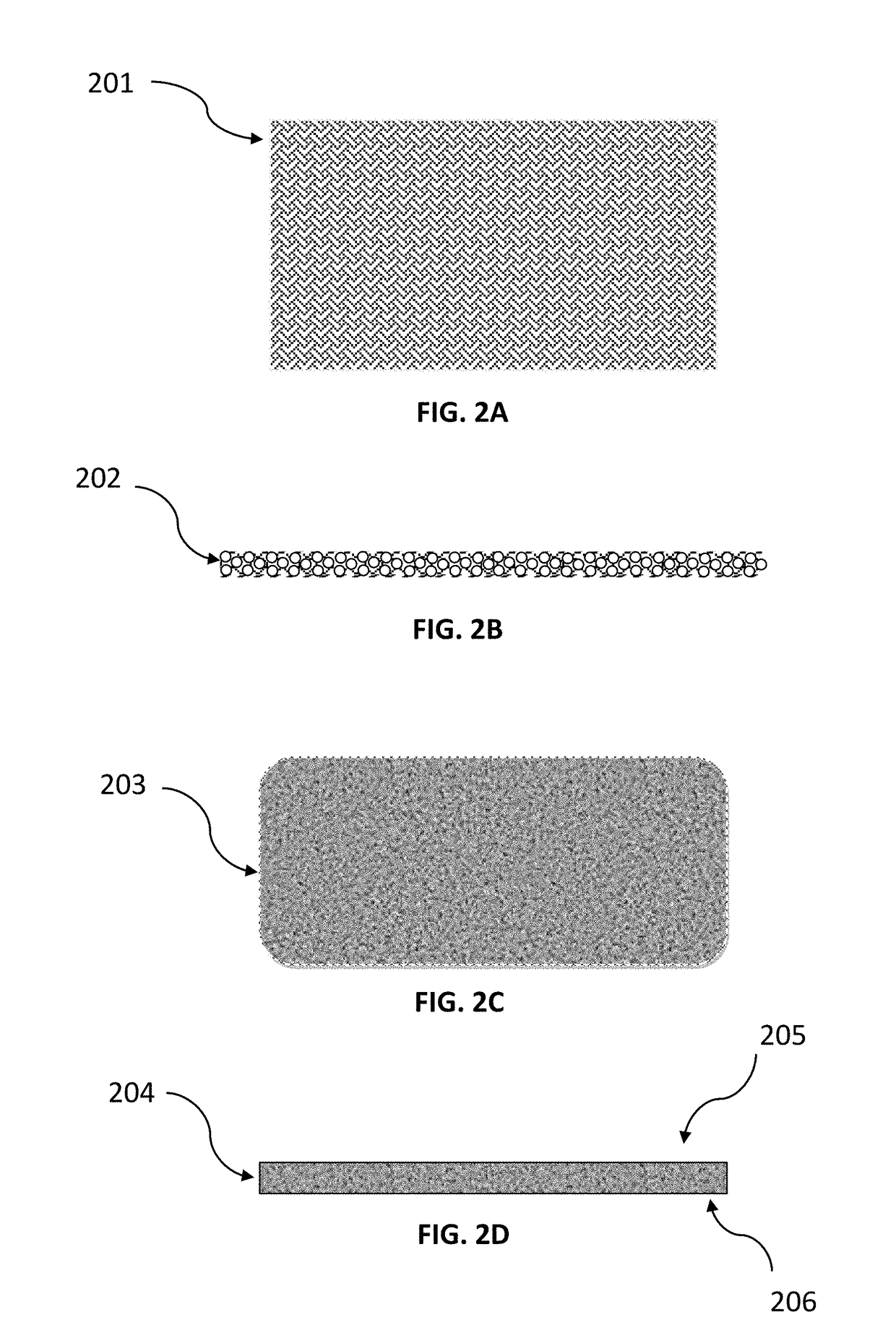

Method and resulting structure for manufacturing semiconductor substrates

InactiveUS20050160972A1Efficient and durable useSignificant to usePolycrystalline material growthSemiconductor/solid-state device detailsSemiconductor chipEngineering

A semiconductor wafer composite is used as a basis for fabricating semiconductor chips, especially compound semiconductor devices. The semiconductor wafer composite advantageously comprises a metallic substrate 210 and multiple semiconductor tiles 220 bonded to the surface of the metallic substrate 210. The semiconductor wafer composite is effectively used as a single large semiconductor wafer for volume fabrication, and can be used to fabricate semiconductor devices in a similar manner.

Owner:COMMONWEALTH SCI & IND RES ORG

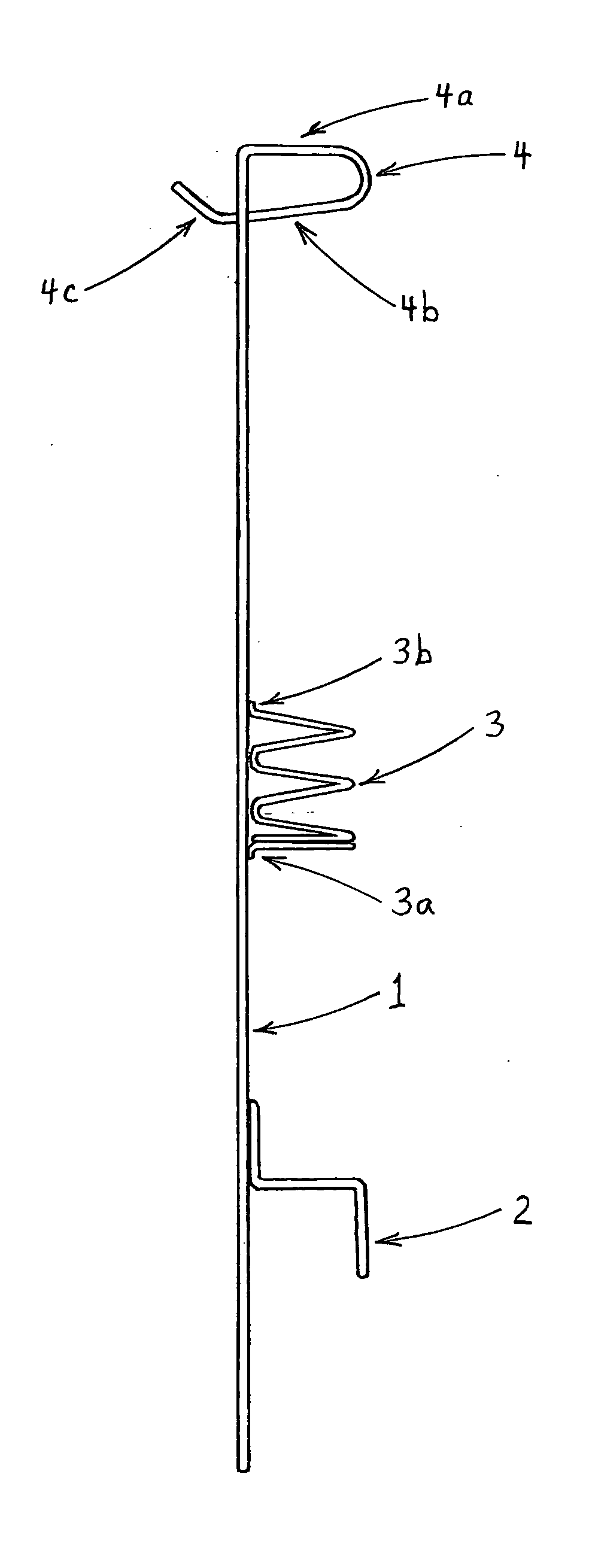

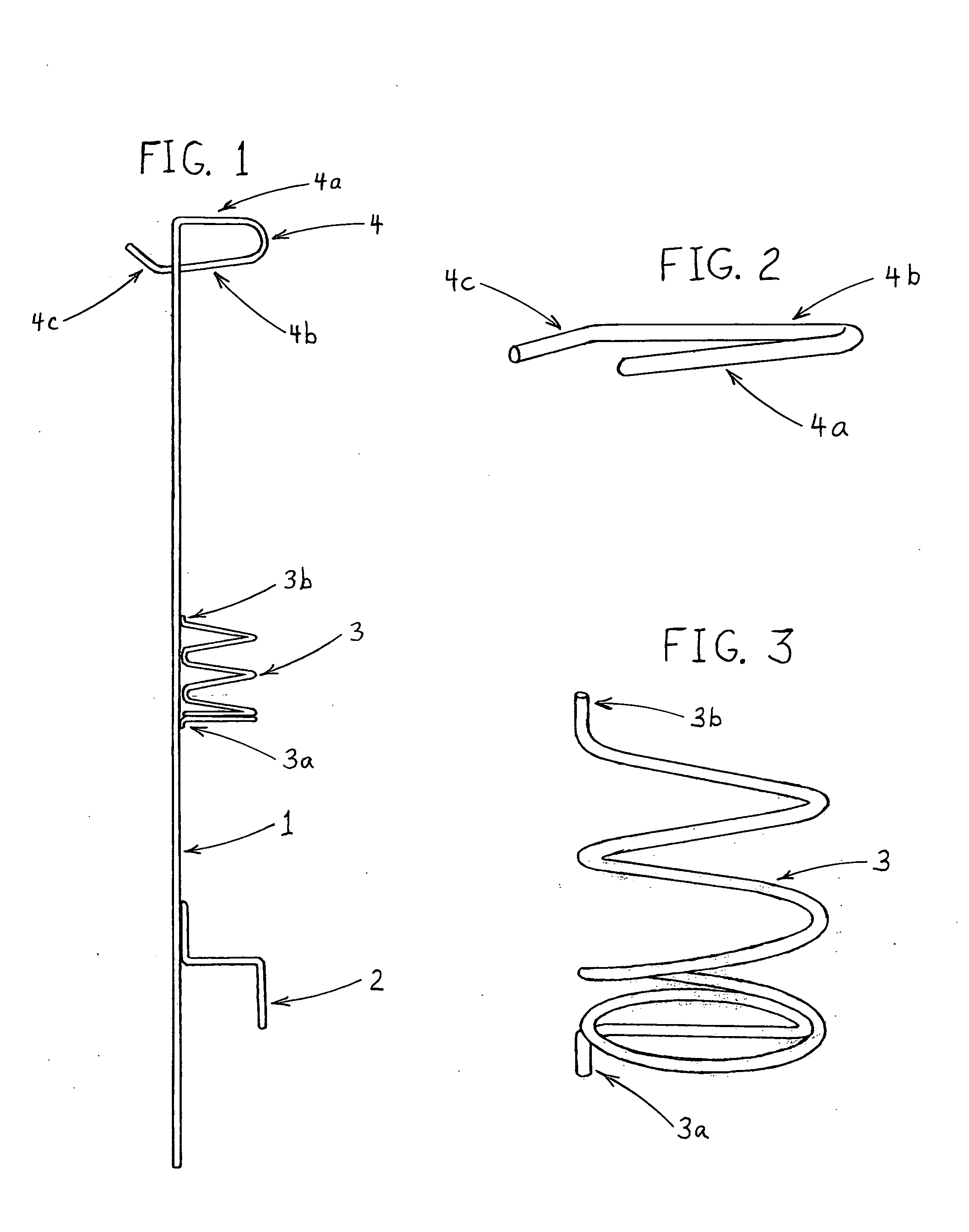

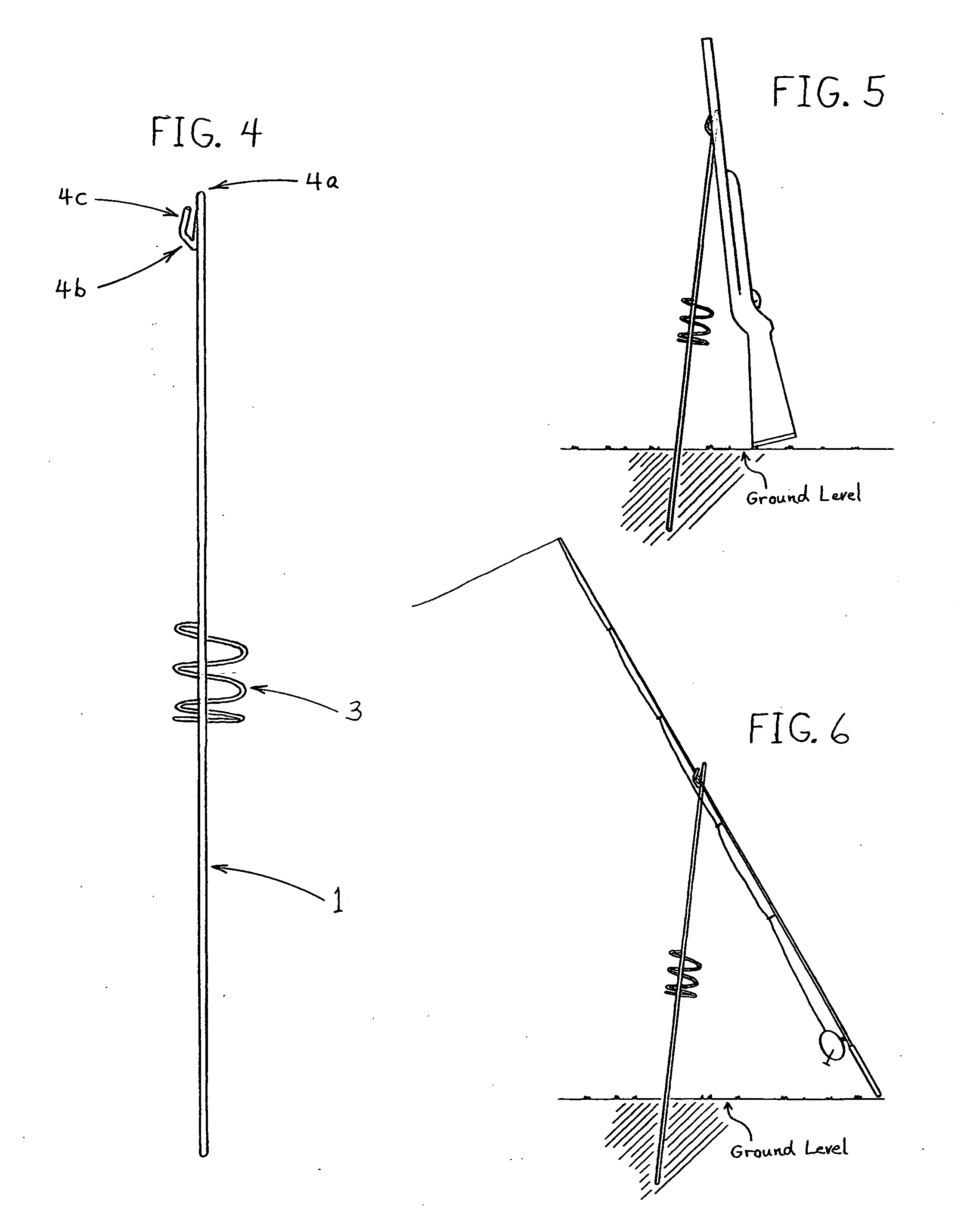

Fishing rod and hunting long gun holder walking stick with beverage holder

InactiveUS20060213109A1Efficient and durable useMore securityWalking sticksOther angling devicesEngineeringFishing

A combination walking stick and support apparatus for outdoor sport fishing, hunting, and camping is disclosed. The multiple function device includes a ground engaging, rigid support that; when engaged with the ground along with the stabilizing footing, safely holds a fishing rod or a hunting long gun in a generally upright position and at the ready for the outdoor enthusiast An integral beverage holder is fixed to the device and effectively works to secure beverages off of the ground in all applications. The formed handle support tip works effectively as a camp utility hook. The design balance and materials integration allows for a light weight, portable and efficient walking stick tool that works in multiple scenarios and significantly enhances the outdoors enthusiast experience.

Owner:ZUNKER JEFFERY ALLEN

Method and resulting structure for manufacturing semiconductor substrates

InactiveUS20050255672A1Efficient and durable useSignificant to usePolycrystalline material growthSemiconductor/solid-state device detailsWaferingDevice material

A semiconductor wafer composite is used as a basis for fabricating semiconductor chips, especially compound semiconductor devices. The semiconductor wafer composite advantageously comprises a metallic substrate 210 and multiple semiconductor tiles 220 bonded to the surface of the metallic substrate 210. The semiconductor wafer composite is effectively used as a single large semiconductor wafer for volume fabrication, and can be used to fabricate semiconductor devices in a similar manner.

Owner:COMMONWEALTH SCI & IND RES ORG

Method and resulting structure for manufacturing semiconductor substrates

InactiveUS6919261B2Wide rangeEfficient and durable usePolycrystalline material growthSemiconductor/solid-state device detailsSemiconductor chipEngineering

A semiconductor wafer composite is used as a basis for fabricating semiconductor chips, especially compound semiconductor devices. The semiconductor wafer composite advantageously comprises a metallic substrate 210 and multiple semiconductor tiles 220 bonded to the surface of the metallic substrate 210. The semiconductor wafer composite is effectively used as a single large semiconductor wafer for volume fabrication, and can be used to fabricate semiconductor devices in a similar manner.

Owner:EPITACTIX PTY LTD

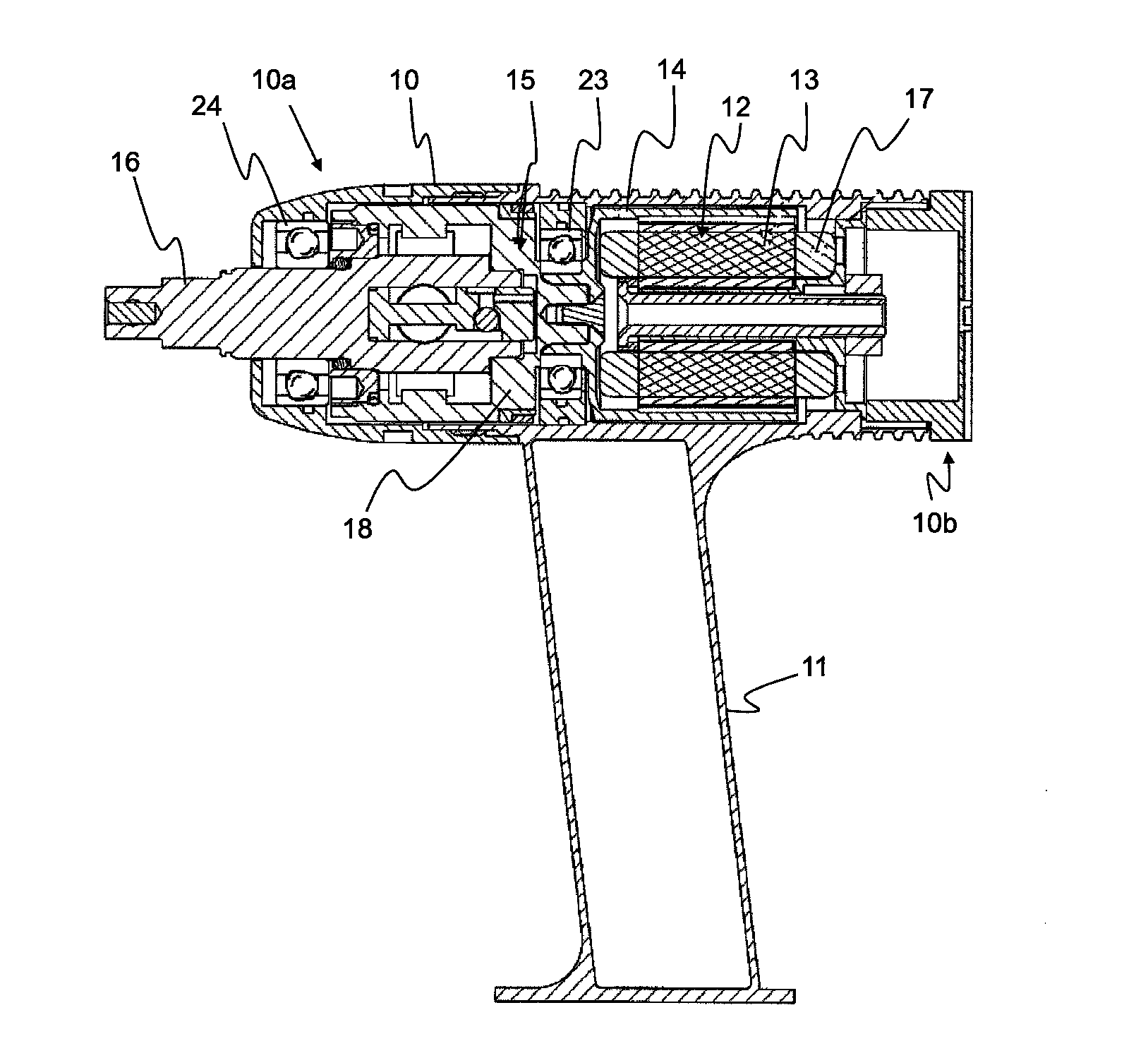

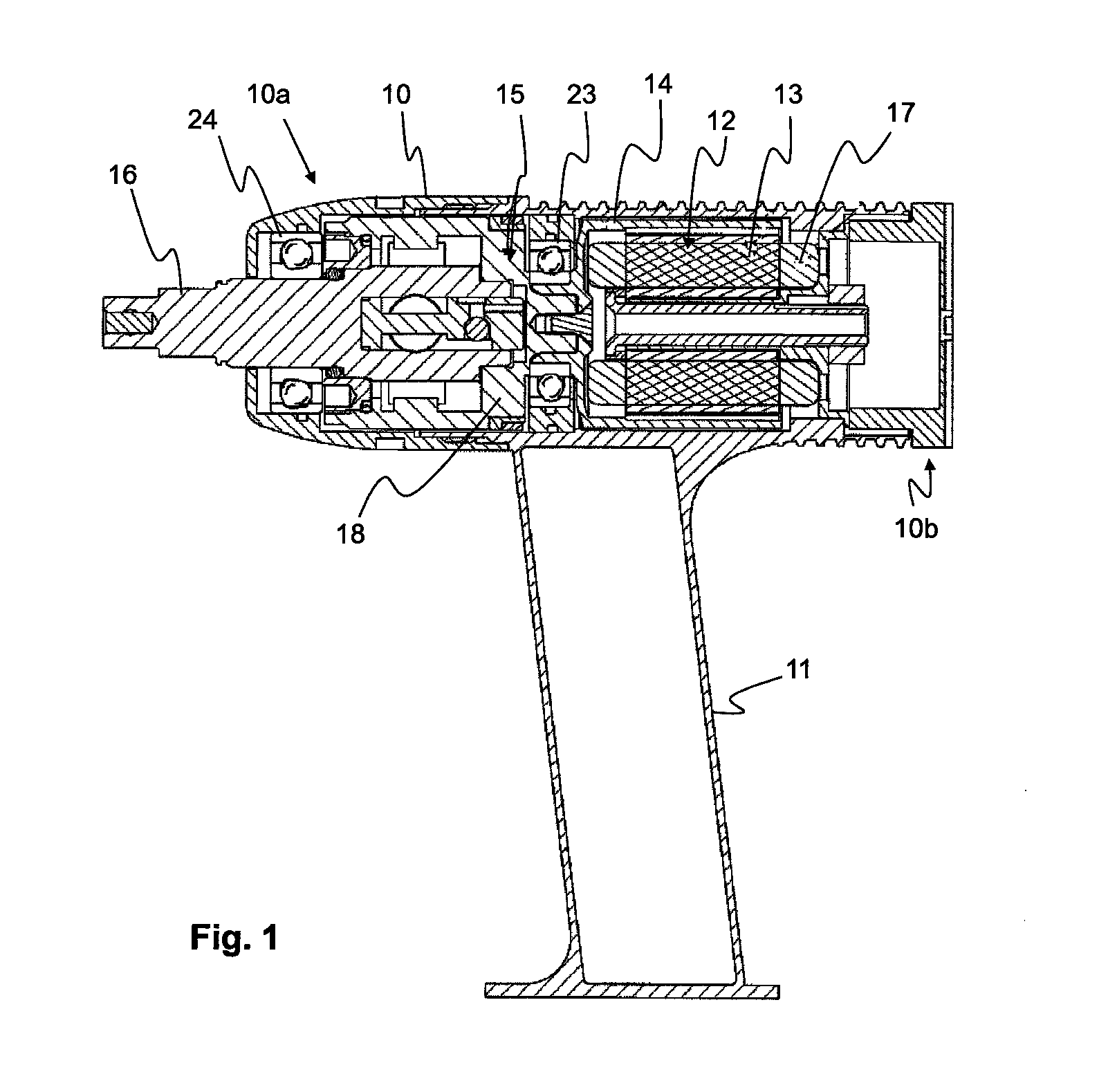

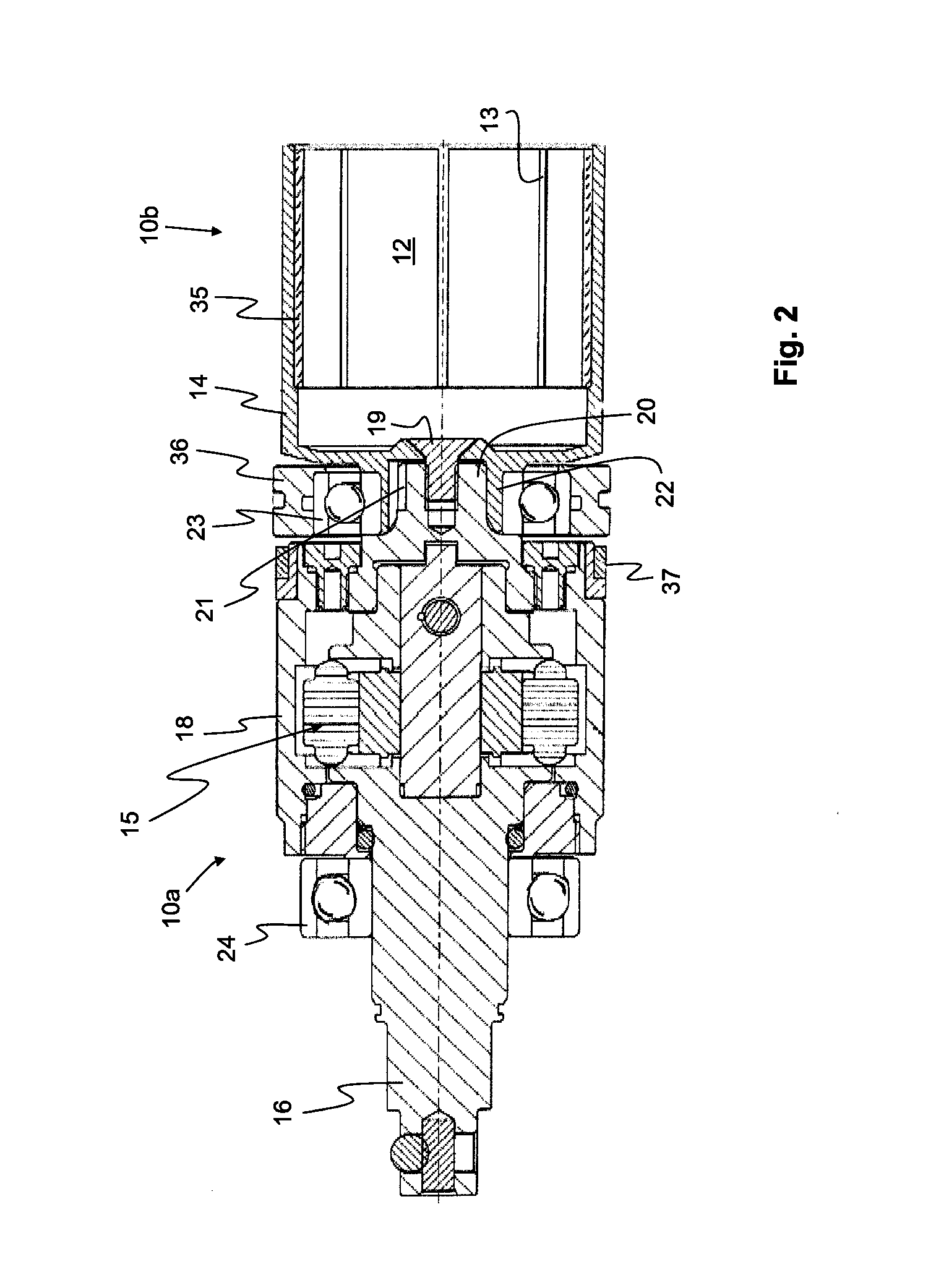

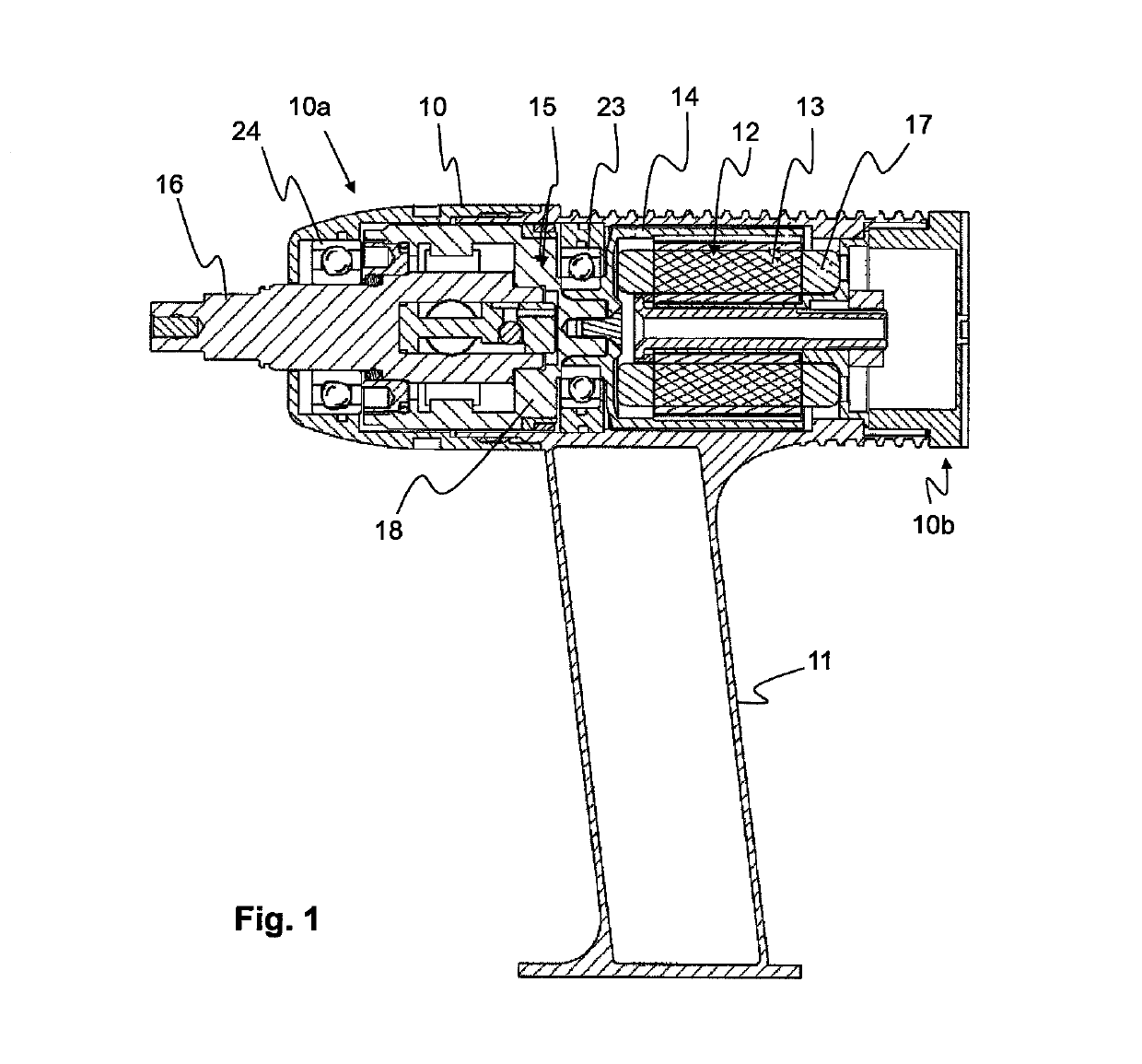

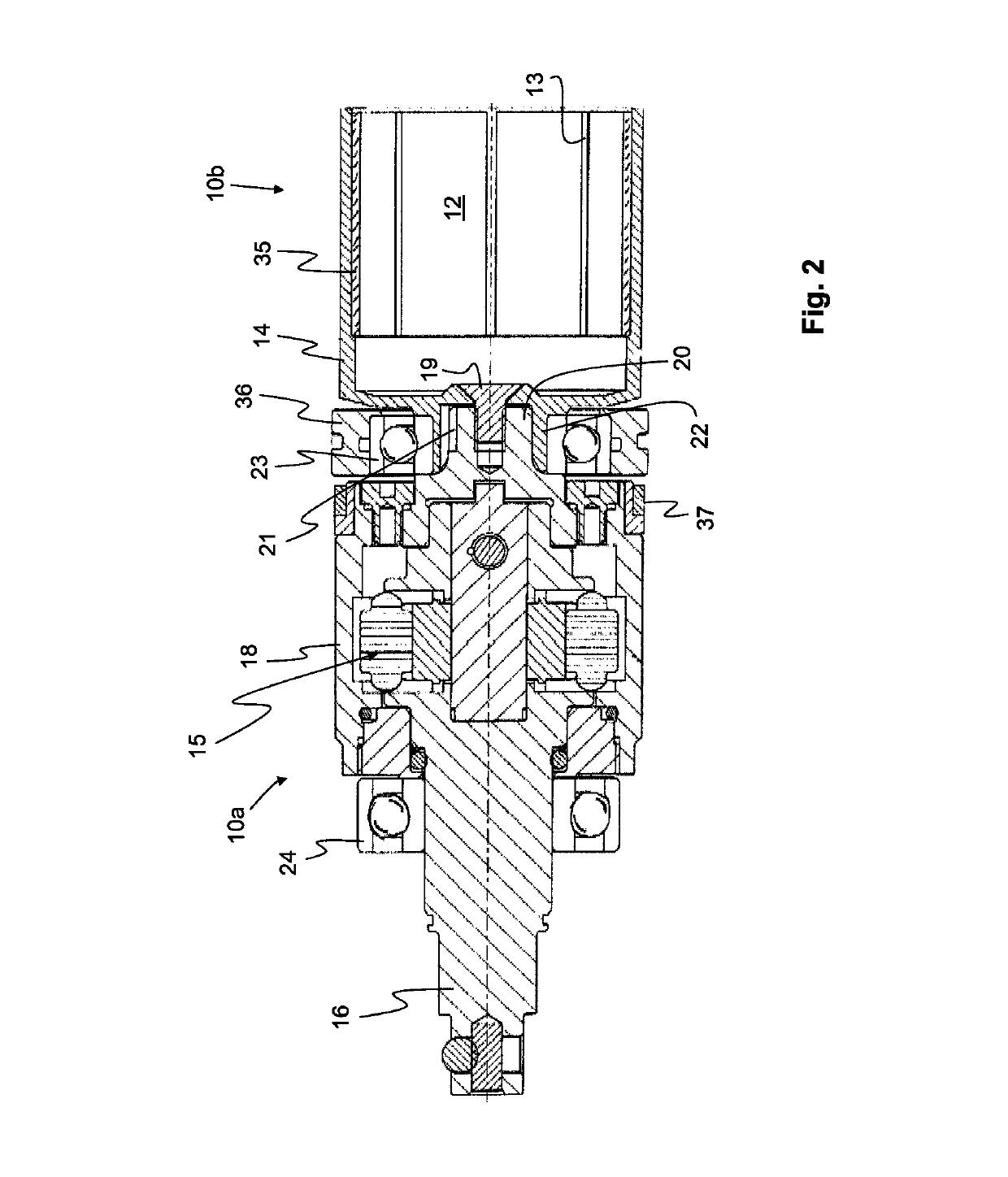

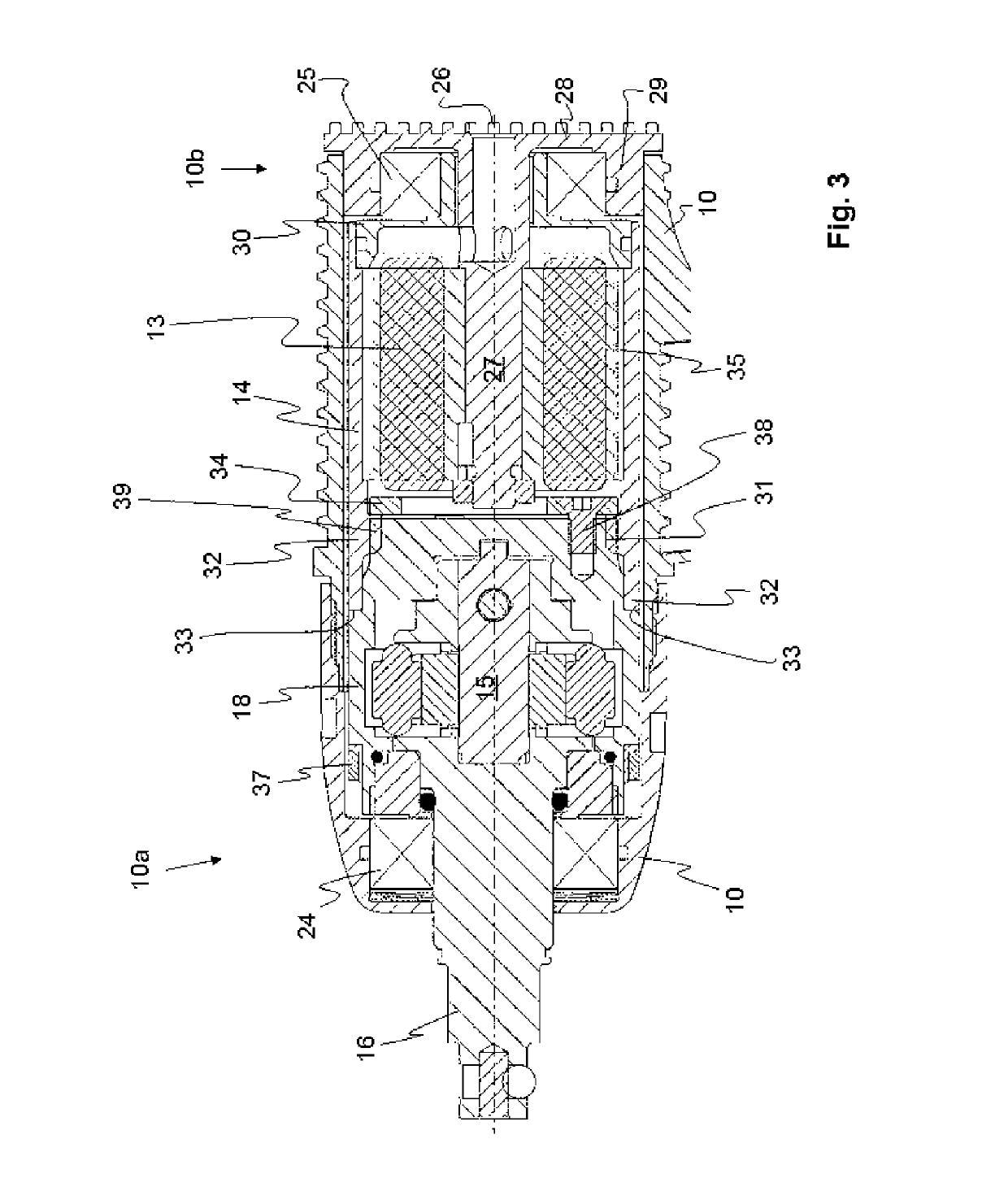

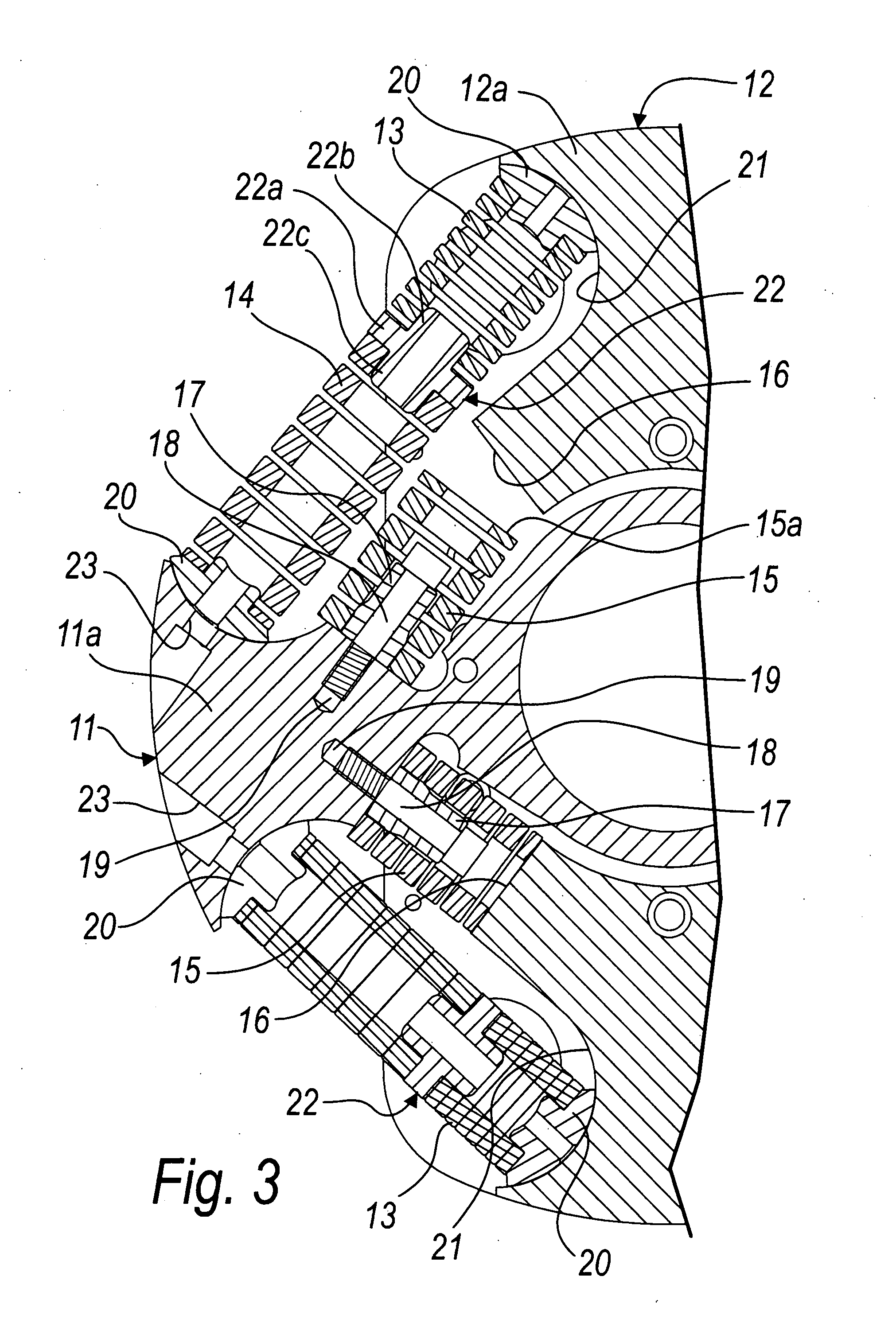

Electric power tool

ActiveUS20140124228A1Improve efficiencyReduce weightSpannersWrenchesElectric power systemEngineering

An electric torque delivering impulse tool includes a housing with a front end and a back end, an electric torque delivering motor with a rotor that is arranged to rotate with respect to a stator, an output shaft arranged at the front end of the housing, and a pulse unit intermittently coupling the motor to the output shaft, wherein the pulse unit includes an inertia drive member that is connected to the rotor. The rotor and the inertia drive member are rigidly assembled to each other without play so as to form one integrated rotatable structure which is mounted as one single unit inside the housing.

Owner:ATLAS COPCO INDAL TECHN AB

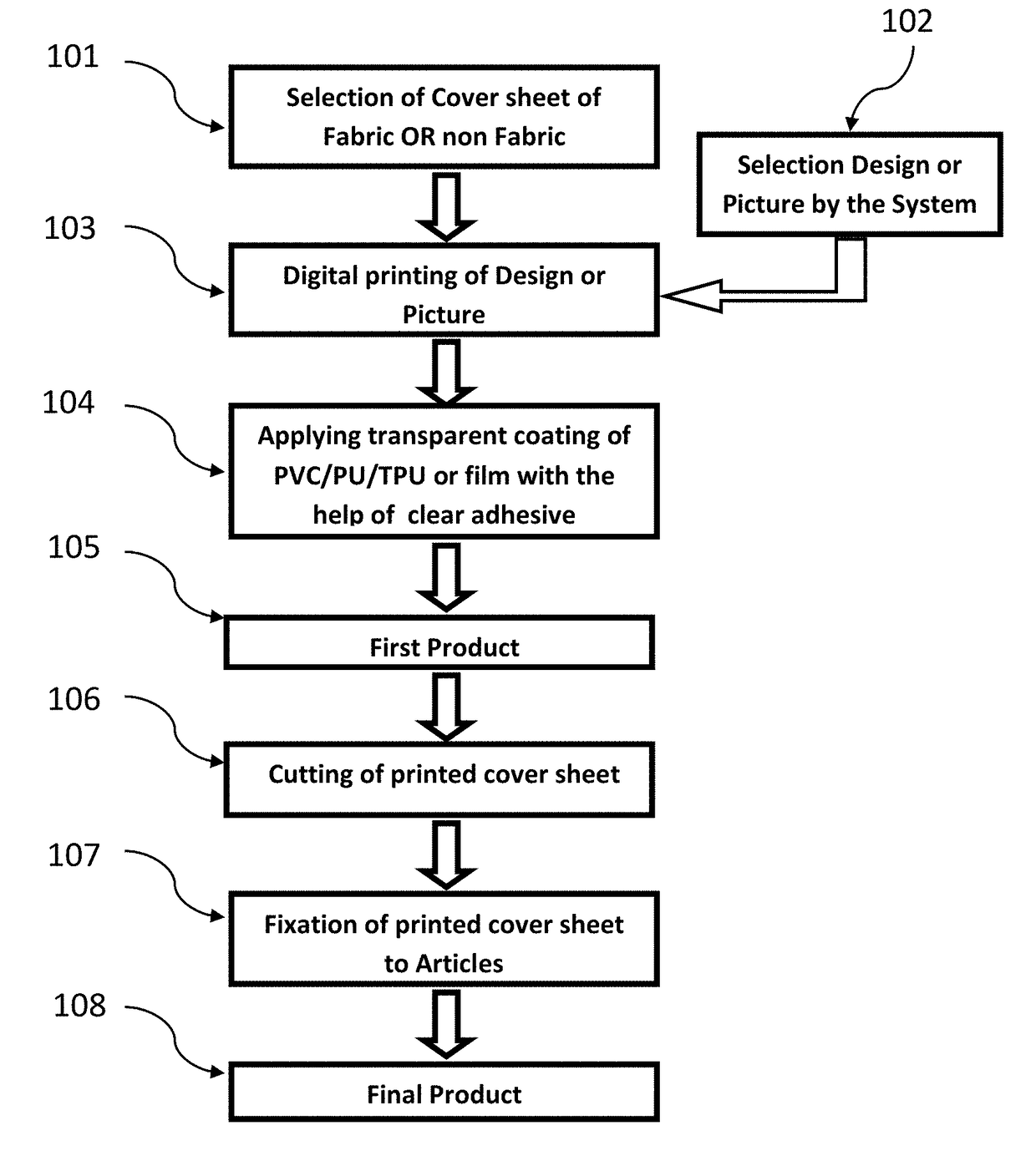

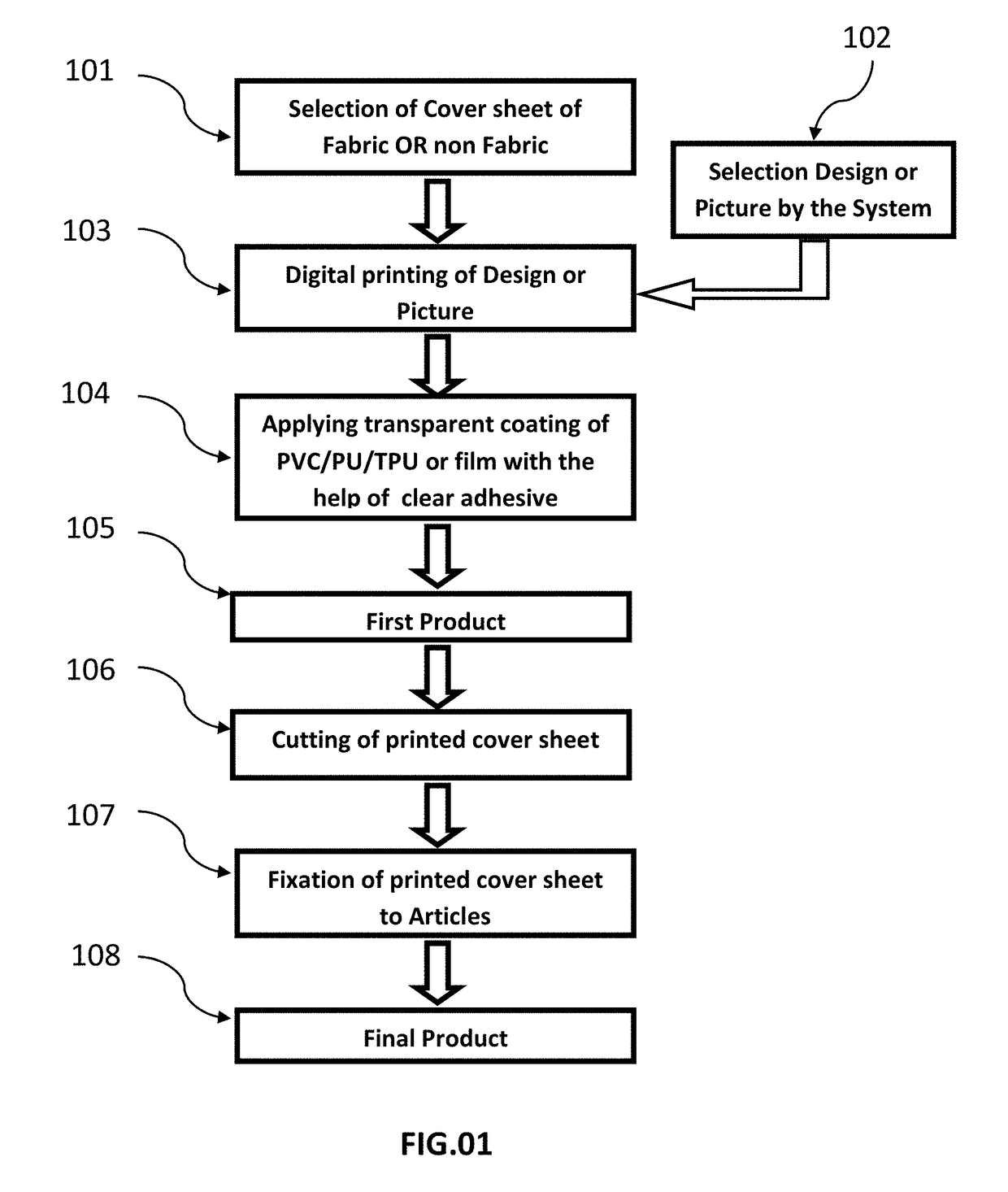

Under-glass digital printing method of multilayer synthetic leather

InactiveUS20170320336A1Cost effectiveRaise the possibilityDuplicating/marking methodsTypewritersWater basedSurface layer

This invention is about a digital printing method of cover sheet of a flexible material of required features of density, flexibility and thickness. This method includes steps of printing a cover sheet of woven or non-woven fabric, by using digital or computerized printing techniques, either direct printing or by transfer paper printing or sublimation printing technique. The printed side of the cover sheet is laminated or coated with a clear film of flexible transparent material like polyurethane, thermoplastic polyurethane, polyethylene or polyvinylchloride. This laminated or sealed printed and coated cover sheet may be fixed to different fabric, foam or of outer surface layer of an article at which printing is required. The said article may be sport's good, sport's wears, dresses, footwear, furniture covering sheets and vehicle items covers etc. The novel method of making cover sheet enables customized printing at required articles at user request with many design printing possibilities. While use of water based ink for digital printing provides an environment friendly, efficient, and durable method of printing the cover sheets of these products.

Owner:BUTT NOUMAN IDRIS +1

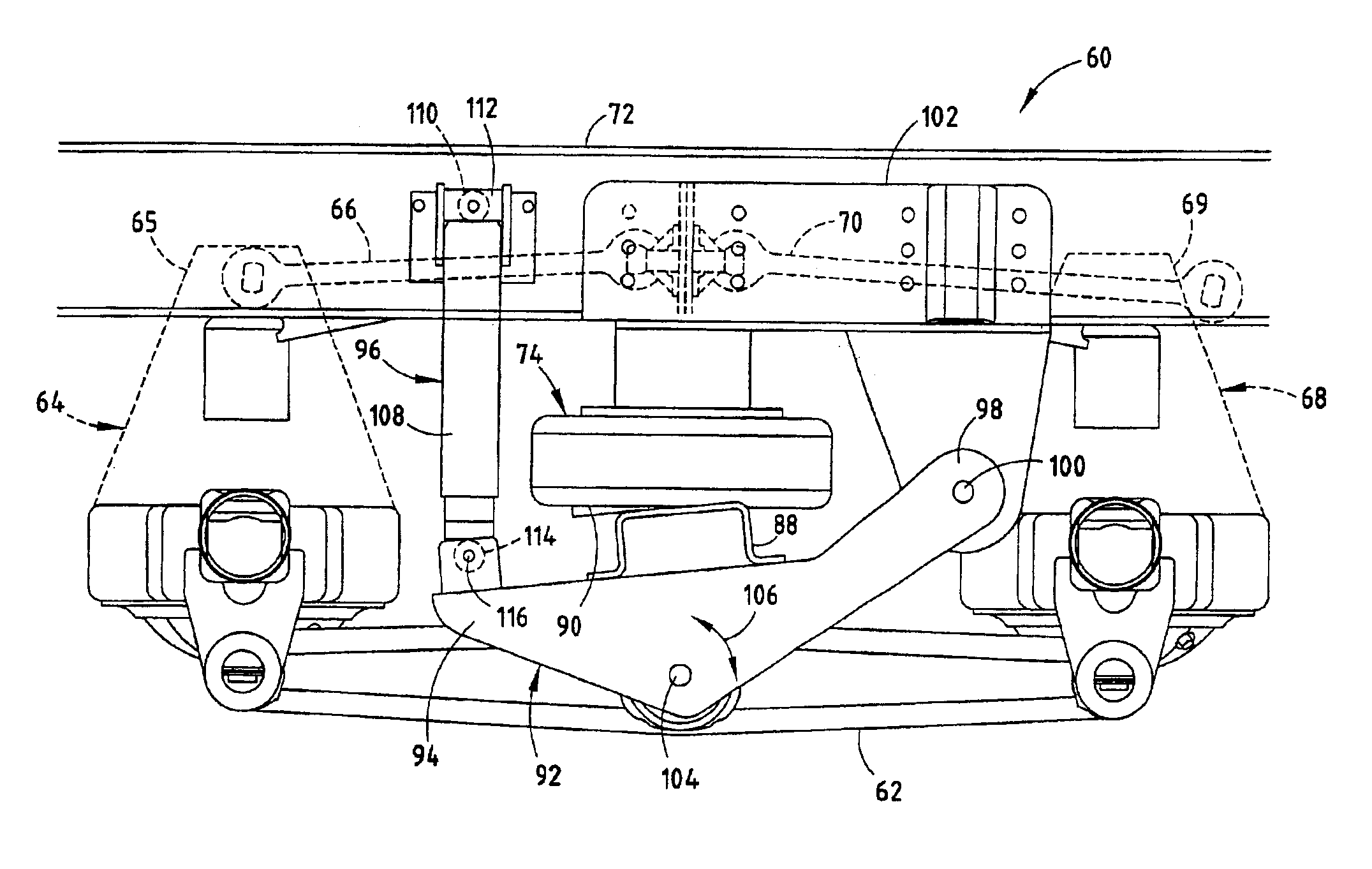

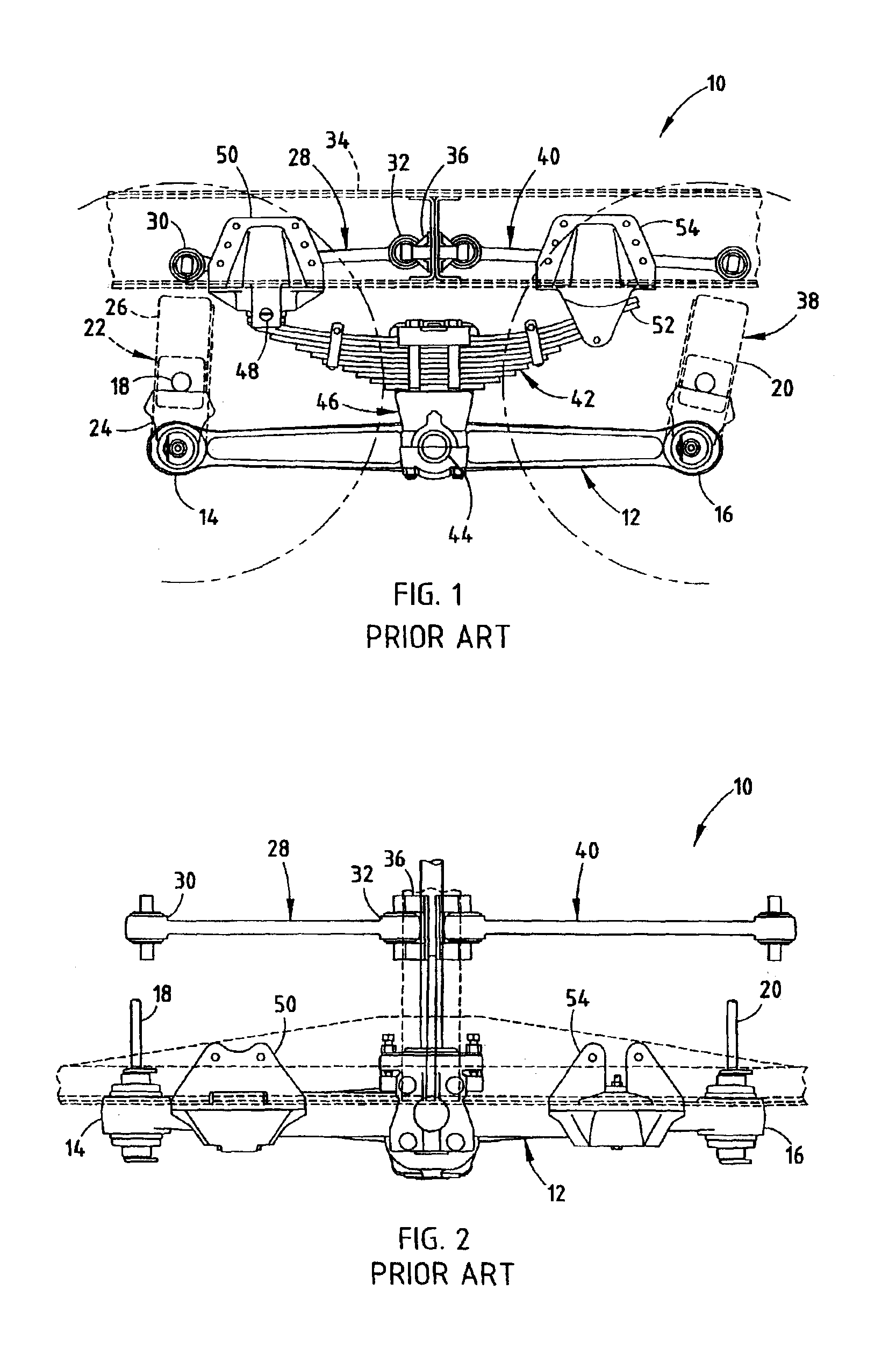

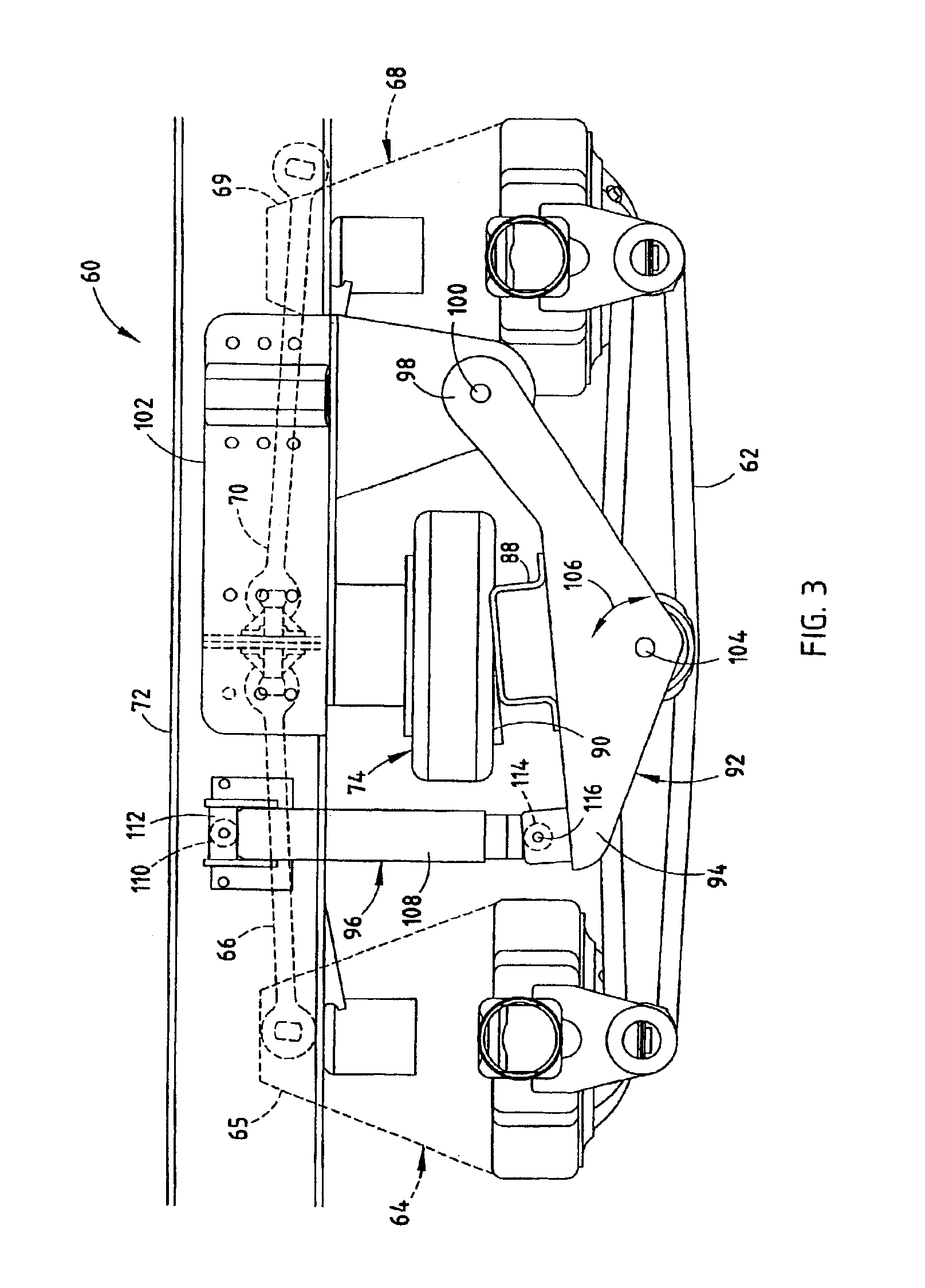

Vehicle suspension system

InactiveUS6916038B2Efficient and durable useMore economical to manufacture suspension systemInterconnection systemsResilient suspensionsVehicle frameLight beam

A vehicle suspension system includes a pair of equalizing beams, two pairs of axle housings each having a lower portion connected to opposite ends of the equalizing beams, two pairs of linkage arms operably connected to an upper portion of each of the axle housings and with a vehicle frame, and a pair of air cylinders operably connected to the equalizing beams at a point located between the ends of the beams and with the vehicle frame. The system further includes a torsional beam extending between the first and second air cylinders, wherein the torsional beam provides the operable connection between the first cylinder and the point of the first equalizing beam located between the ends of the first equalizing beam, and the operable connection between the second cylinder and the point of the second equalizing beam located between the ends of the second equalizing beam.

Owner:THE HOLLAND GROUP

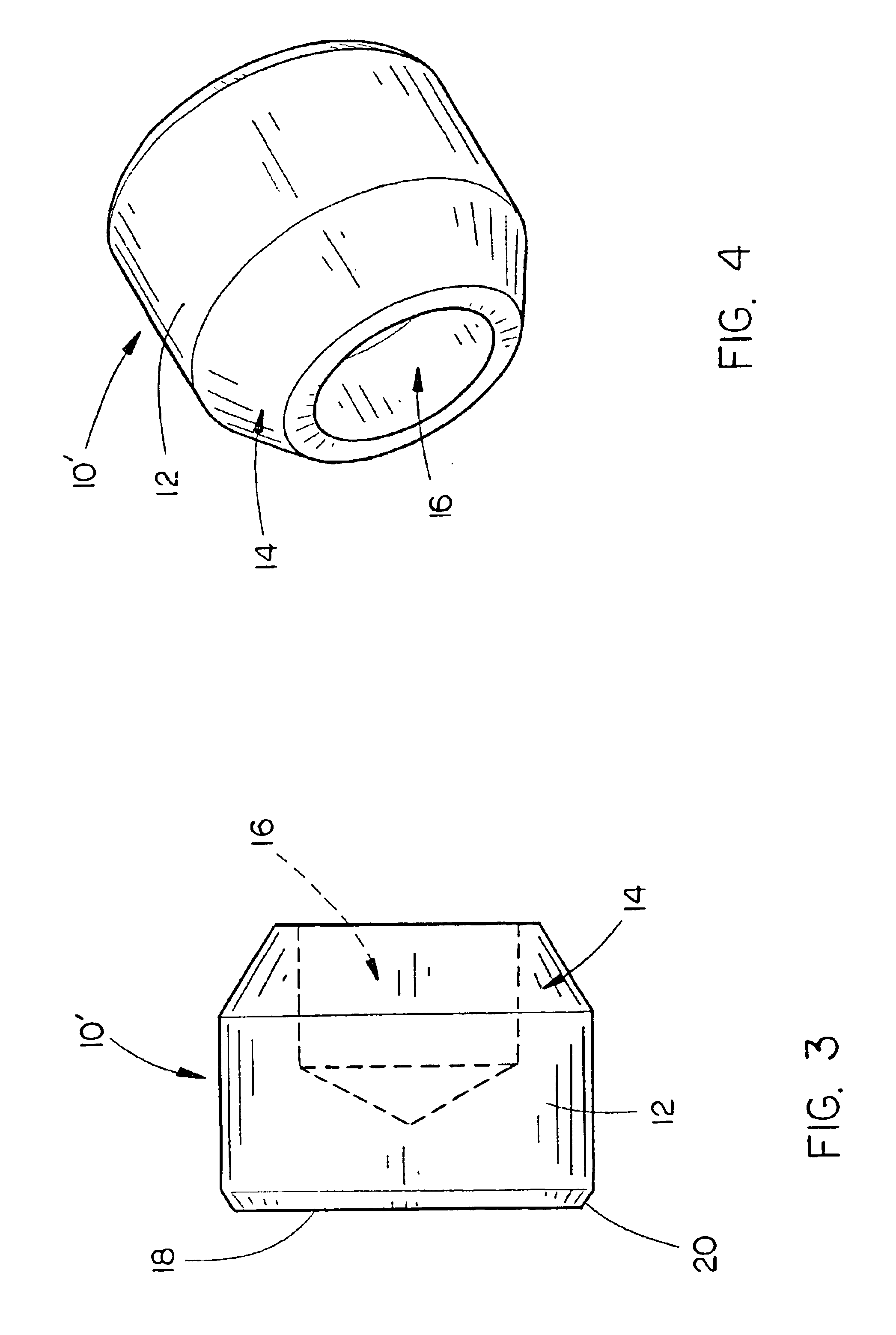

Drift pin cap and method of using same

InactiveUS6854945B2Avoid damageAvoid emissionsWood splittingMulti-purpose machinesBiomedical engineering

In combination, an elongated tool having a striking end and a tapered insertion end and a drift pin cap. The drift pin cap includes a cap body having an upper end, a lower end and at least one side wall extending between and connecting the upper end and the lower end. A drift pin receiving cavity is formed in the lower end of the cap body which extends upwards towards the upper end within the cap body, the pin receiving cavity having a diameter smaller than a diameter of the cap body. The pin receiving cavity is operative to fit over and be retained on the striking end of the tool such that when the tool is impacted by a driving device, the drift pin cap is interposed between the tool and the driving device to prevent damage to the tool yet still permit driving of the tool.

Owner:HUMPHREY JOHN +1

Electric power tool

An electric torque delivering impulse tool includes a housing with a front end and a back end, an electric torque delivering motor with a rotor that is arranged to rotate with respect to a stator, an output shaft arranged at the front end of the housing, and a pulse unit intermittently coupling the motor to the output shaft, wherein the pulse unit includes an inertia drive member that is connected to the rotor. The rotor and the inertia drive member are rigidly assembled to each other without play so as to form one integrated rotatable structure which is mounted as one single unit inside the housing.

Owner:ATLAS COPCO INDAL TECHN AB

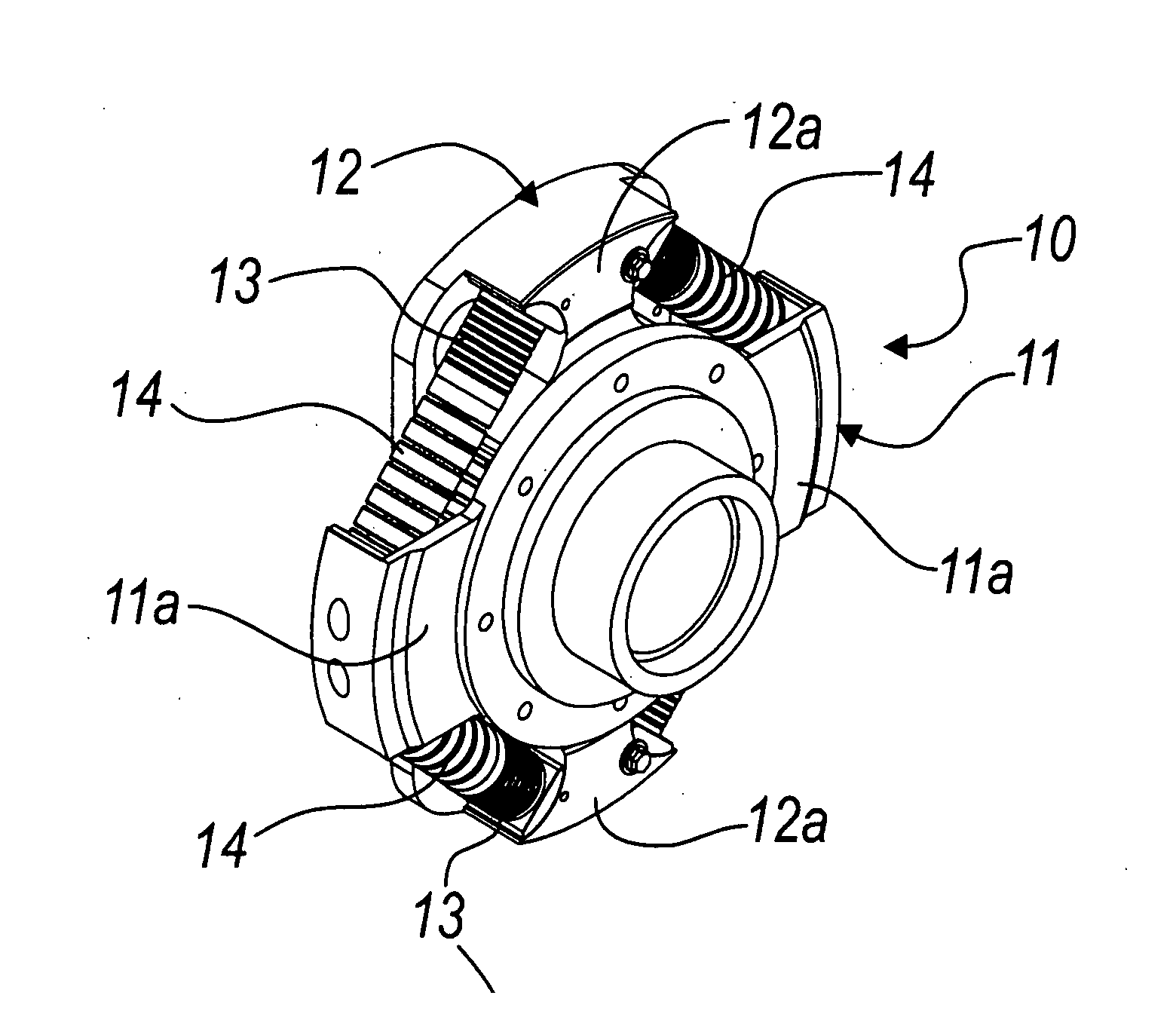

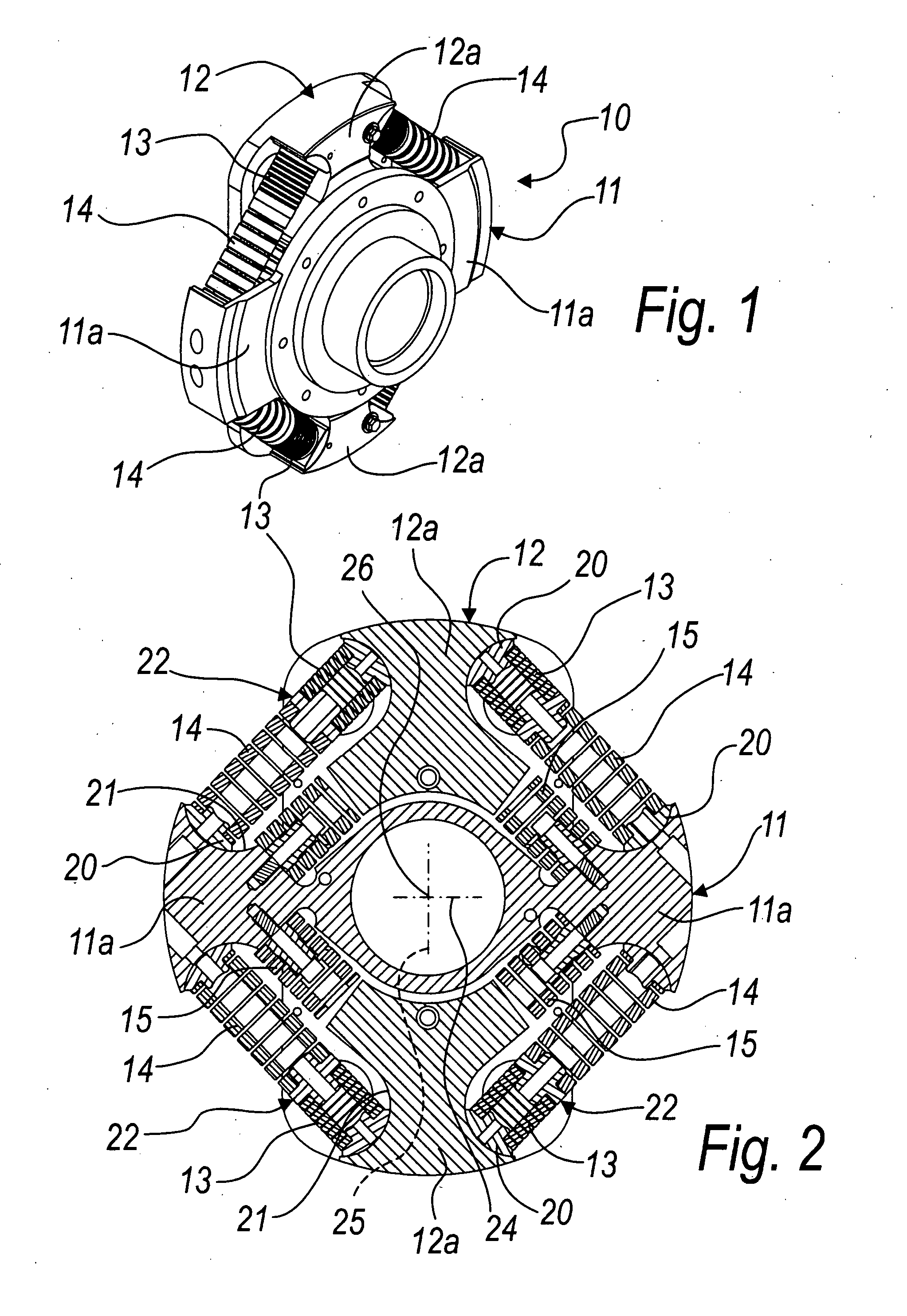

Device for combined rotation of a shaft about its own axis

InactiveUS20070200456A1Drawback can be obviatedEfficient and durable useYielding couplingPiezoelectric/electrostriction/magnetostriction machinesElastic compressionEngineering

A device for the combined rotation of a shaft about its own axis, having a first body elongated diametrically with respect to the axis of the shaft, the first body being rigidly coupled to an actuation for simple rotation about the axis, and a second diametrically elongated body arranged transversely to the first body coaxial thereto. The second body is associated with the first body and is rigidly coupled to elements for generating torsional vibrations about the axis and performs alternating angular movements with reduced extent oscillations. The second body is adapted to support the shaft to be turned. A pair of elastic compression elements are interposed between the adjacent consecutive portions of the first and second bodies to cushion small oscillations.

Owner:HOLMAC DI GASTALDI CHRISTIAN E C

Staple remover

Owner:ROBERTS JOHN D

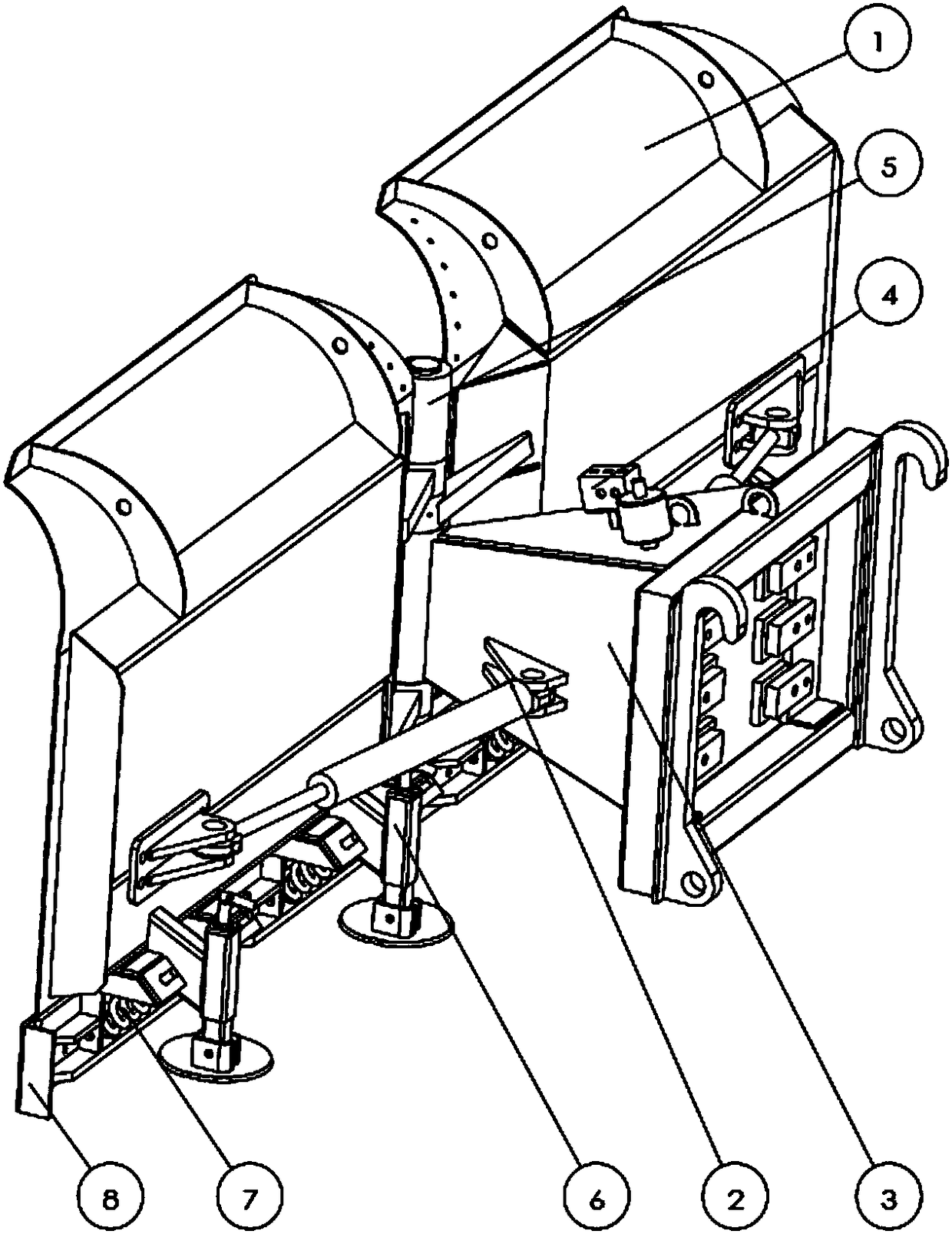

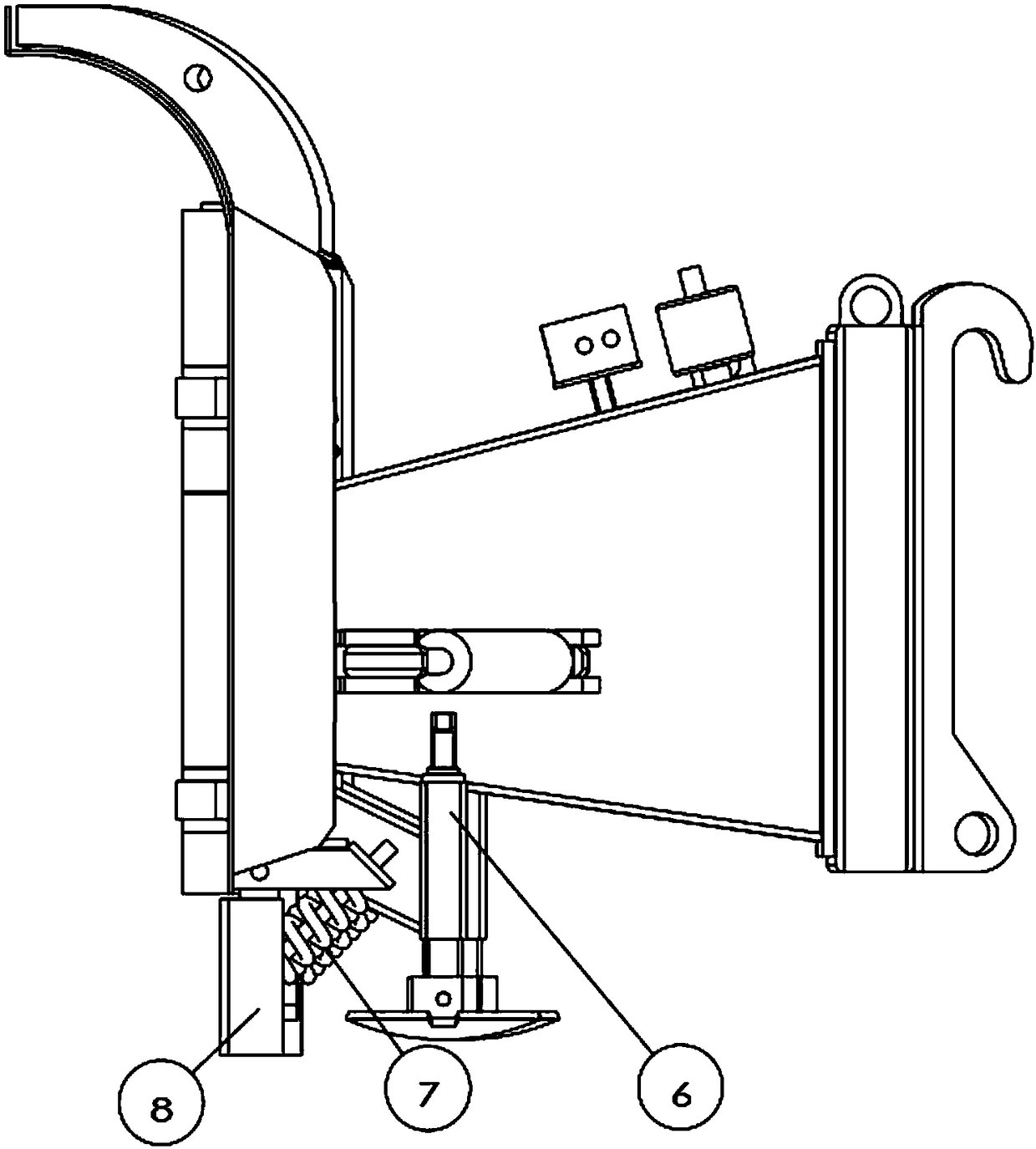

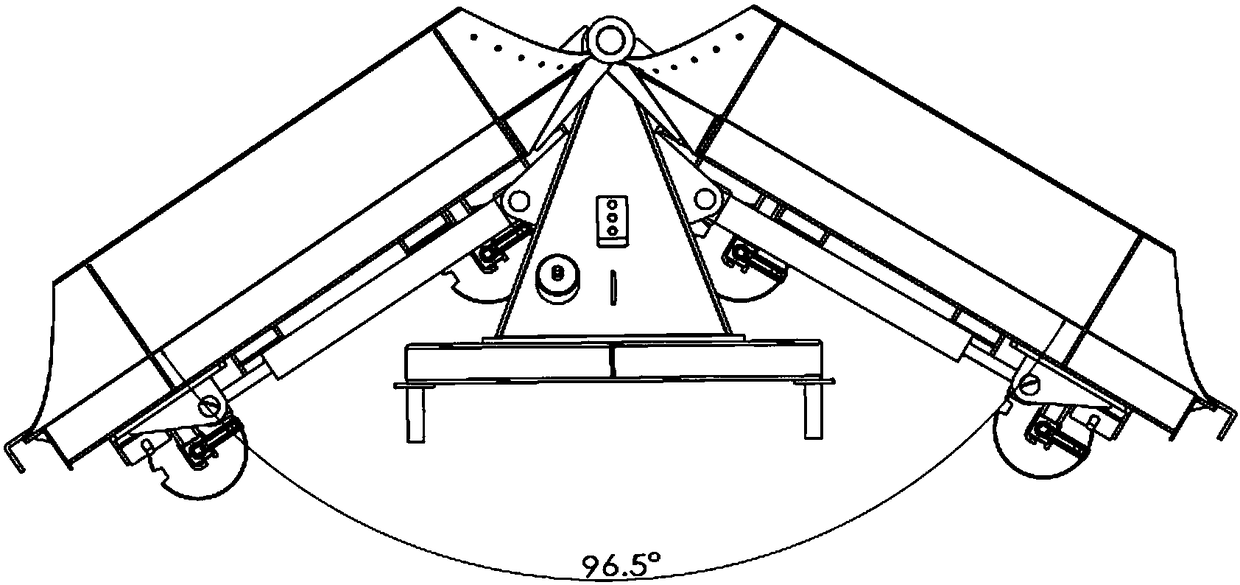

Multifunctional snow shoveling device

PendingCN108330885ASimple and fast operationControl depthSnow cleaningAgricultural engineeringTraffic accident

The invention provides a multifunctional snow shoveling device, and relates to a device used for removing accumulated snow on a road. Two oil cylinders are installed between a plough body and a connecting member, a valve group is installed on the connecting member to adjust and control an oil way, and the flexible rotation of the plough body around a rotary pin shaft is achieved; a plough blade isconnected with the plough body through the pin shaft, a spring is arranged between the plough body and the plough blade to achieve buffering and restoring effects; the distance between the plough blade and the ground can be adjusted by a supporting seat connected with the rear end of the plough body to achieve depth control of snow shoveling. The device has the advantages of being simple and flexible in mechanism, simple and convenient to operate, convenient to maintain, high in efficiency and durable, and has significant social economic benefit on improving the transportation efficiency of vehicles and avoiding the occurrence of severe traffic accidents.

Owner:INST OF INTELLIGENT MFG TECH JITRI

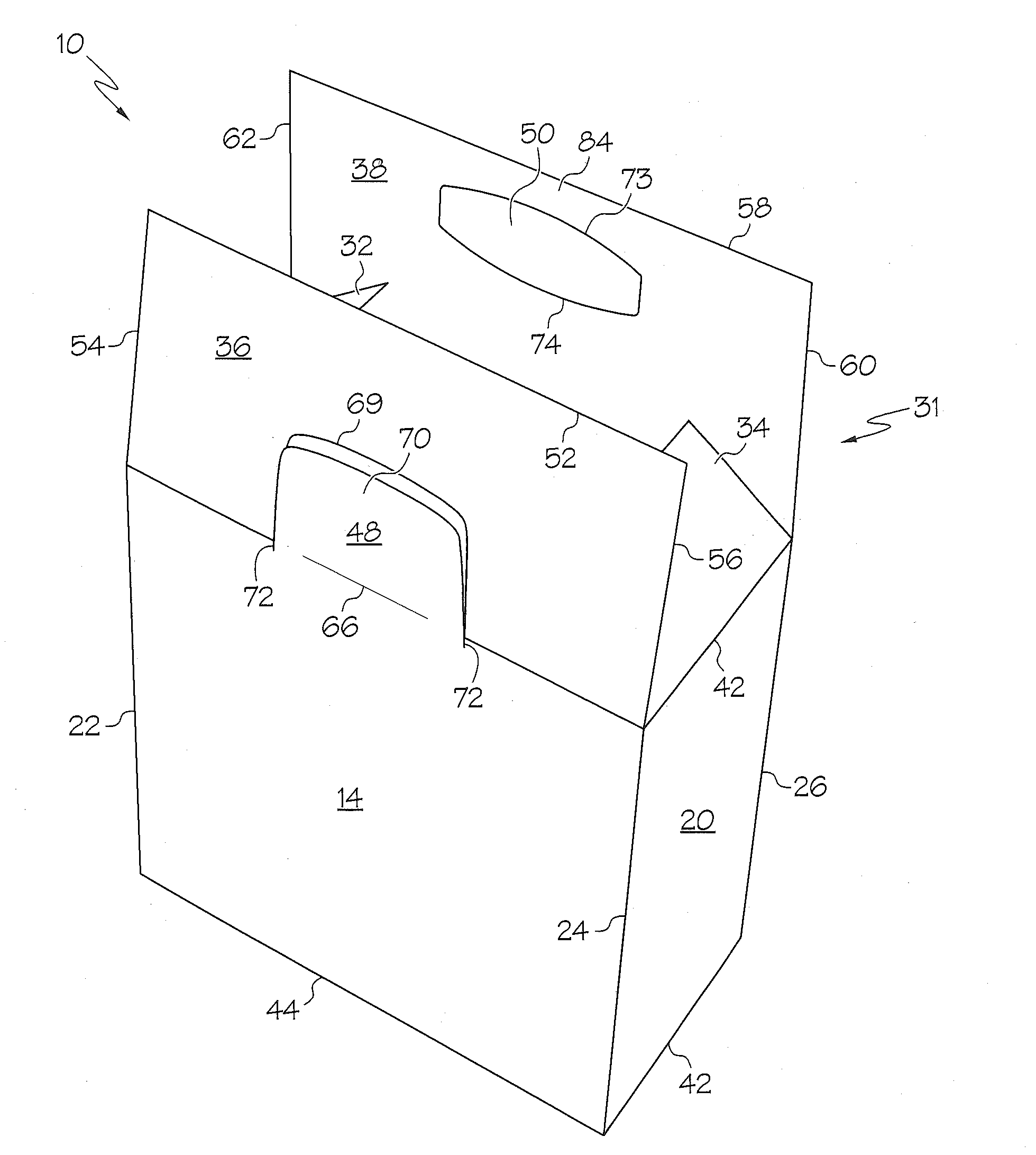

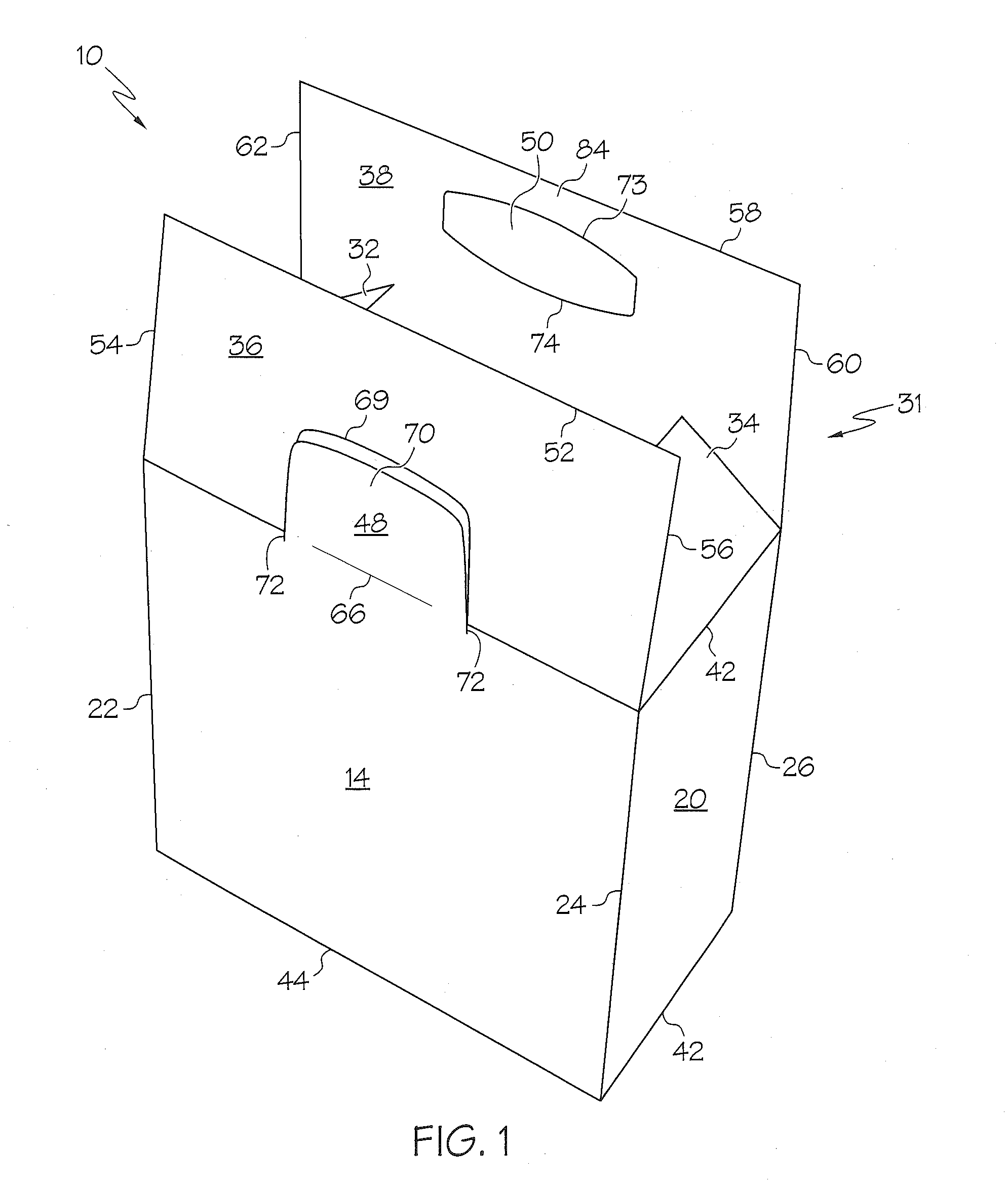

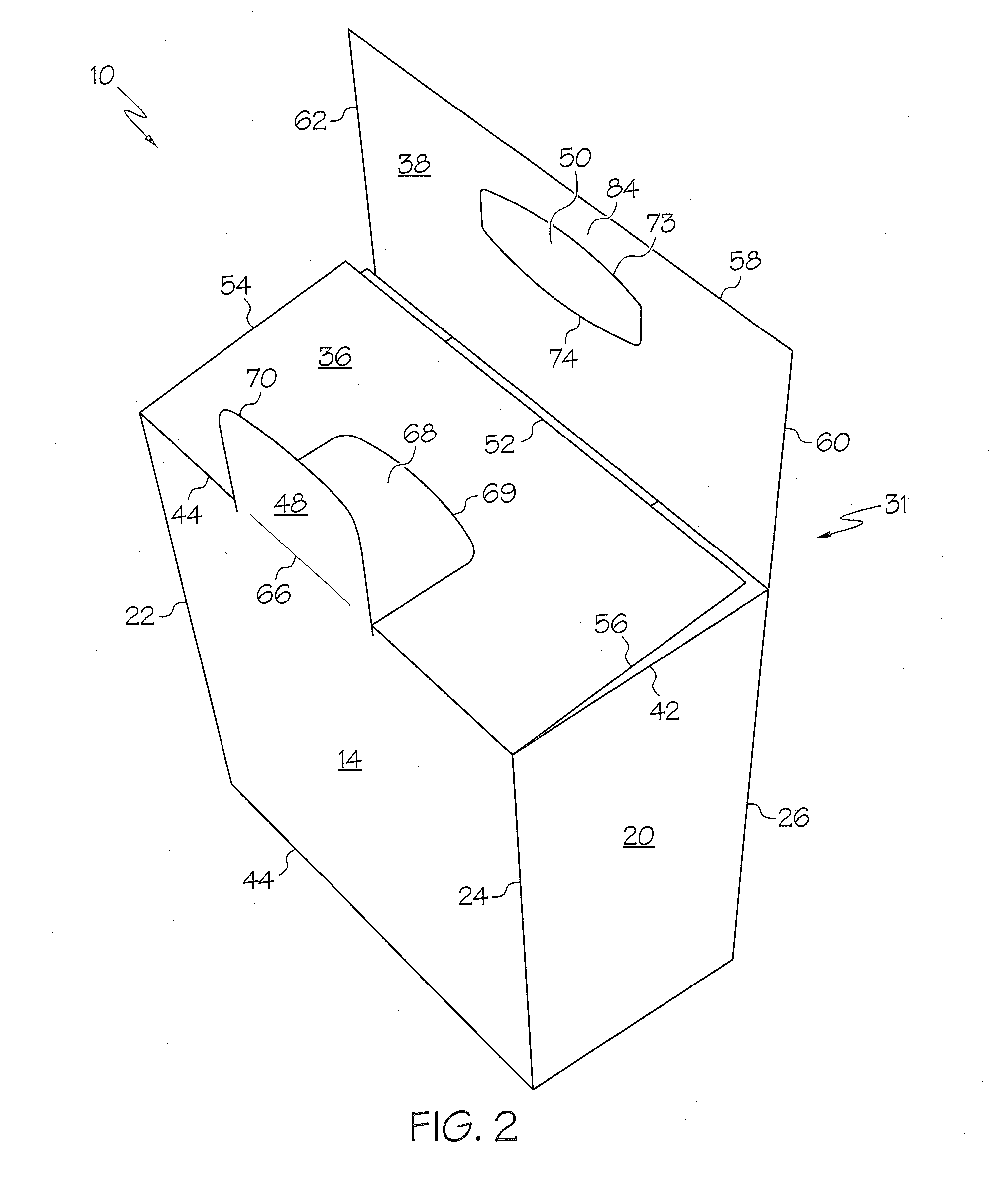

Tab lock closure for a container

InactiveUS20150291304A1Durable and efficientDurable and efficient and simple tabRigid containersEngineeringMechanical engineering

A container with a tab lock closure is provided. The container may be constructed from a folded blank of material. The container can consist of a front panel, rear panel, two opposing side panels, and first and second ends. The ends include two opposing minor end flaps and two opposing major end flaps. One major end flap includes a tab that is cut from the flap and is foldably connected to the front panel along a common fold line with the major end flap. The other major end flap includes a corresponding aperture. When the end is closed, the minor end flaps are folded inwardly, the major end flap with the tab is folded inwardly while the tab remains upright, and the other major end flap is then folded inwardly. The tab is then folded inwardly and inserted into the aperture thereby locking the container.

Owner:HUHTAMAKI INC

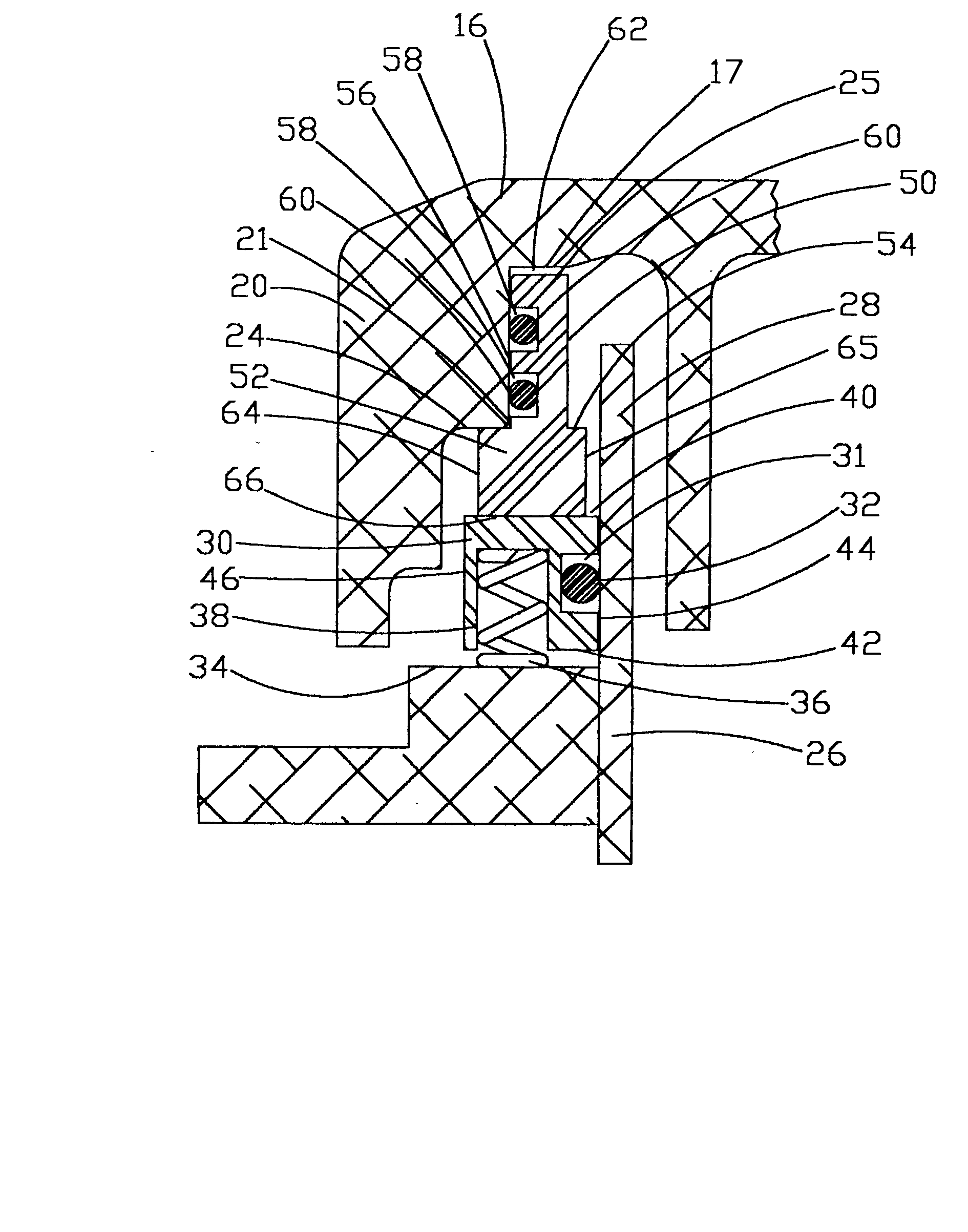

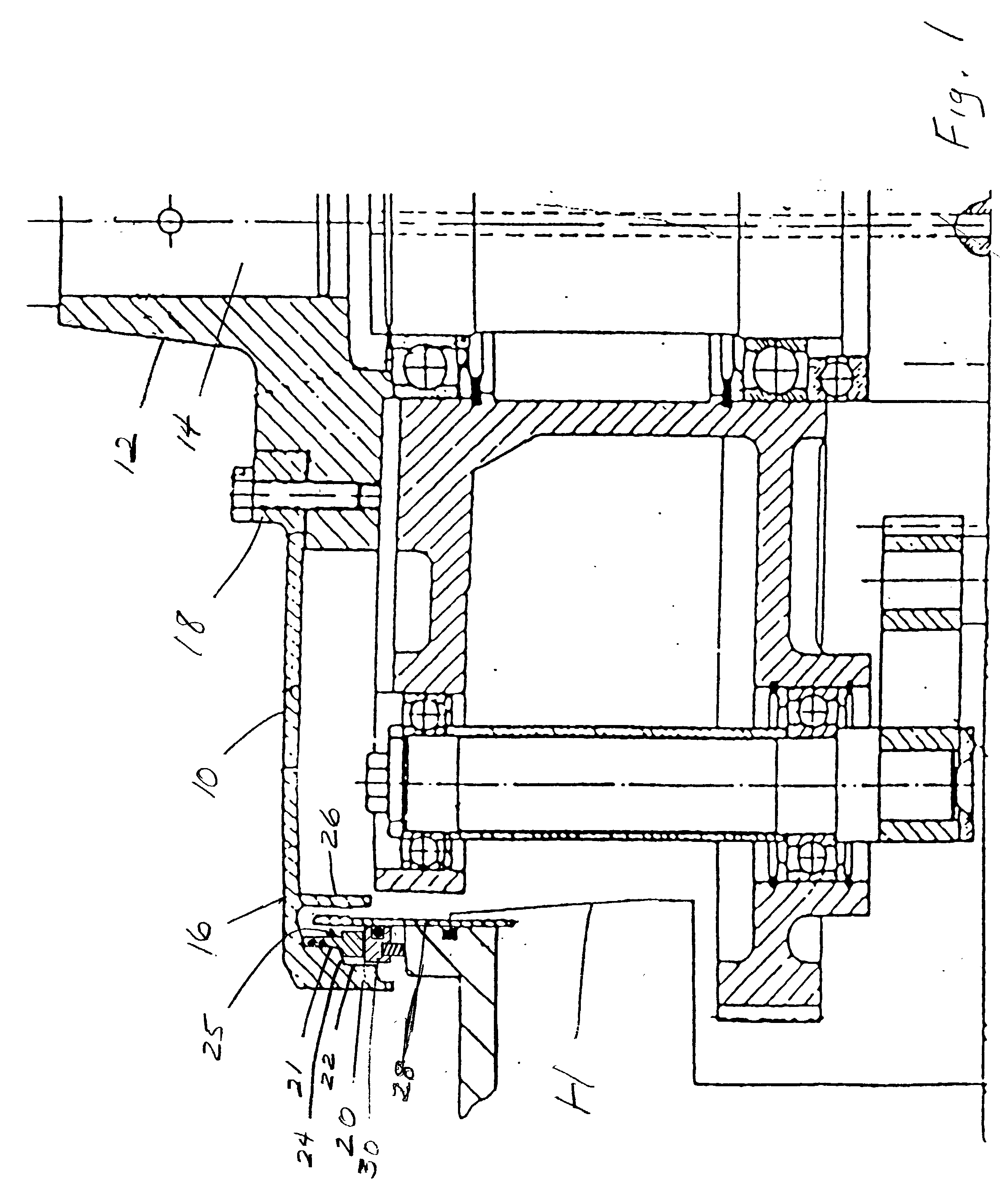

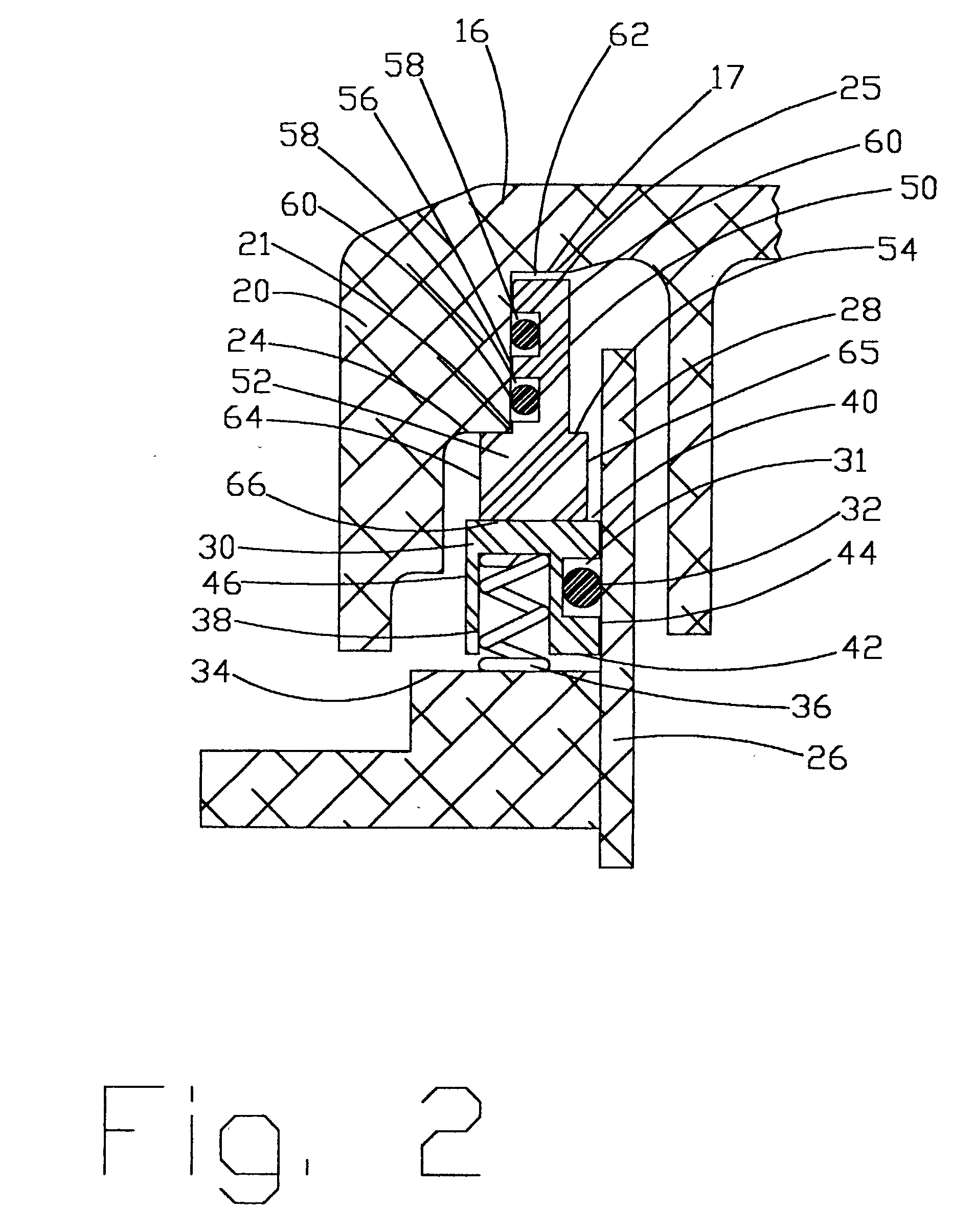

Mechanical face seal for materials handling apparatus

InactiveUS20030098132A1Minimize fluid leakageUniform sealing pressureEngine sealsMechanical working/deformationEngineeringBottle

In materials handling apparatus, such as, a bottle labeling machine of the type having annular rotating and fixed members in confronting relation to one another, a facial seal assembly is made up of first and second seal members between the rotating and fixed members which are of generally rectangular cross-sectional configuration and terminate in squared end portions defining relatively broad, flat annular bearing surfaces in flush sealed relation to one another as the turntable is rotated or driven with respect to the stationary mounting portion and prevents ingress and egress of liquid as well as solid materials to and from the interior of the apparatus.

Owner:MANSDORFER GARY A

Staple remover

Owner:ROBERTS JOHN D

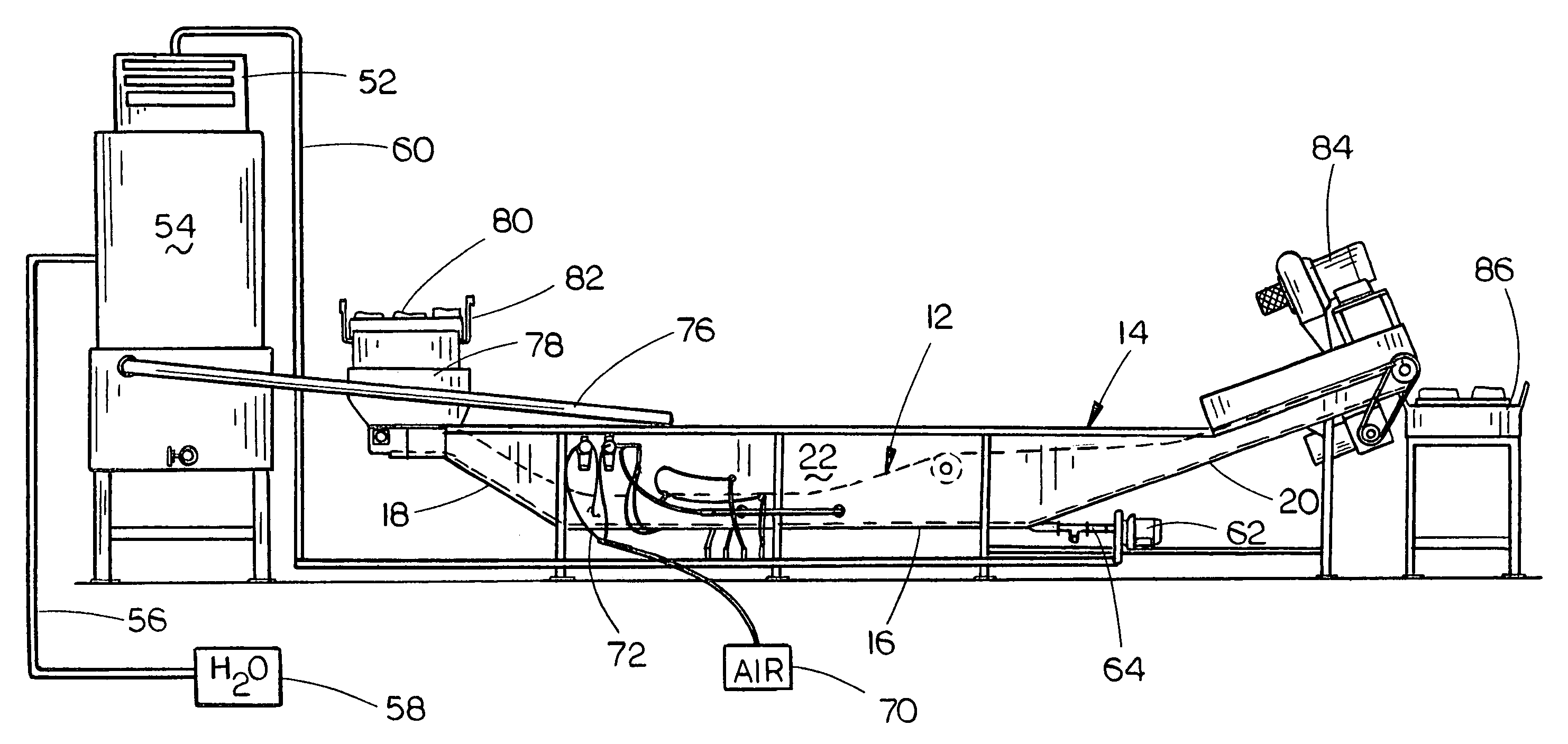

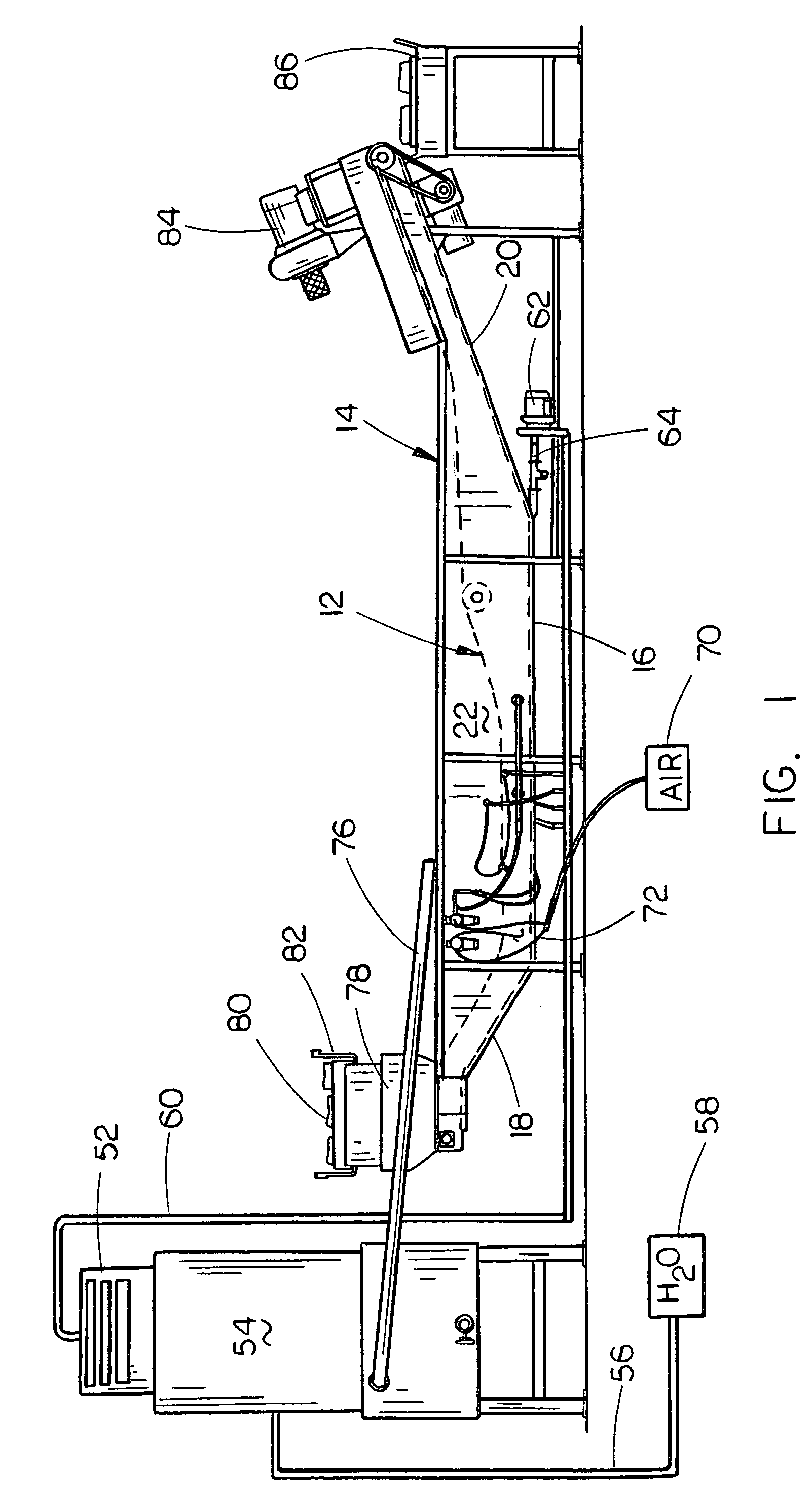

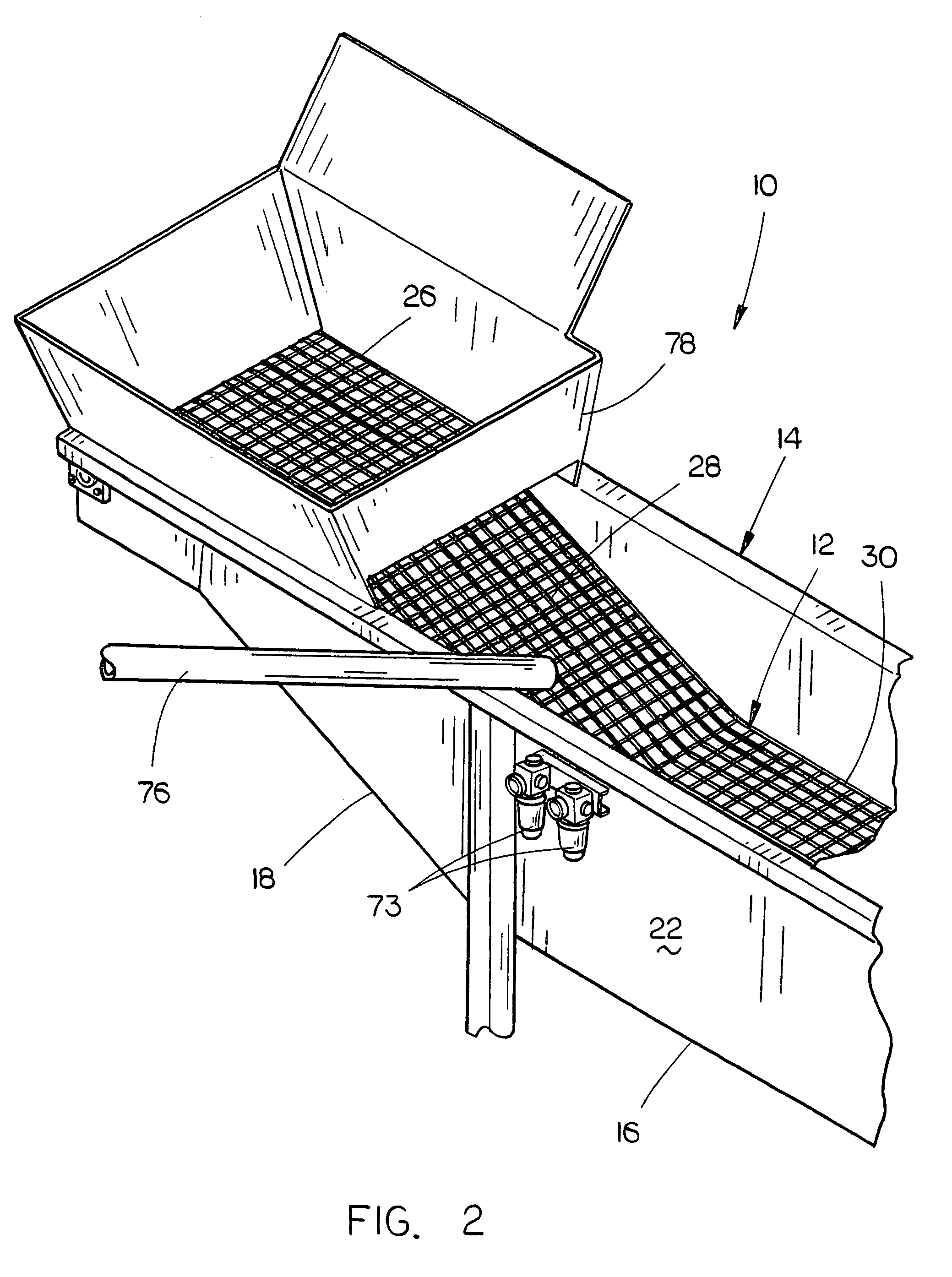

Meat processing system

ActiveUS7527550B1Eliminate needReduce manufacturing costFish washing/descalingPoultry plucking mechanismsEnvironmental engineeringWater chiller

An apparatus for processing meat comprising an endless conveyor having an infeed end and a discharge end with the conveyor passing through a housing or tank which is partially filled with agitated water. Pieces of meat are conveyed by the conveyor through the agitated water to remove foreign particles therefrom. The foreign particles are recirculated through a filter and a water chiller with the chilled and filtered water then being returned to the tank. Excess water is blown from the pieces of meat after the pieces of meat have been conveyed through the agitated water. The method of processing the meat is also described.

Owner:FREMONT BEEF

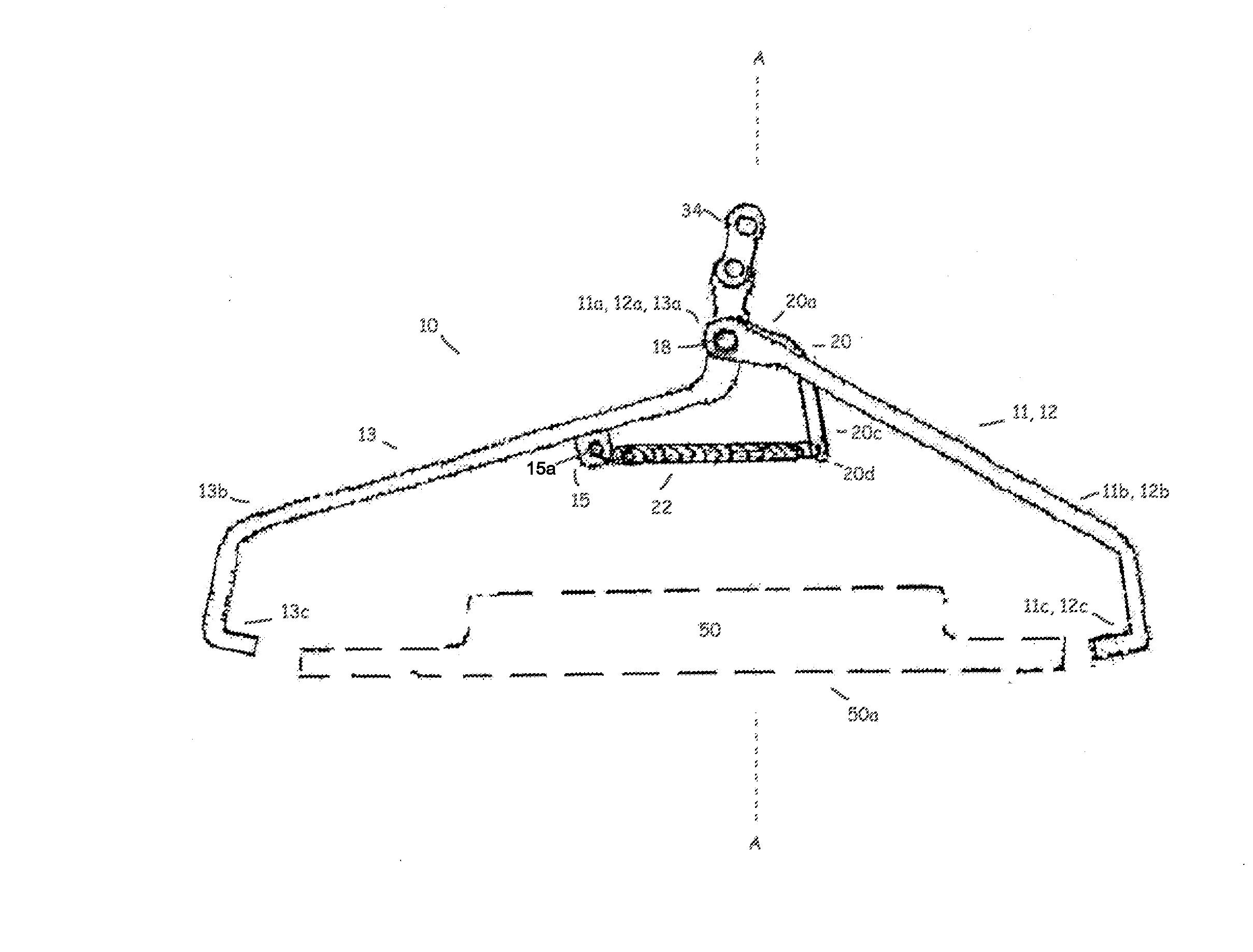

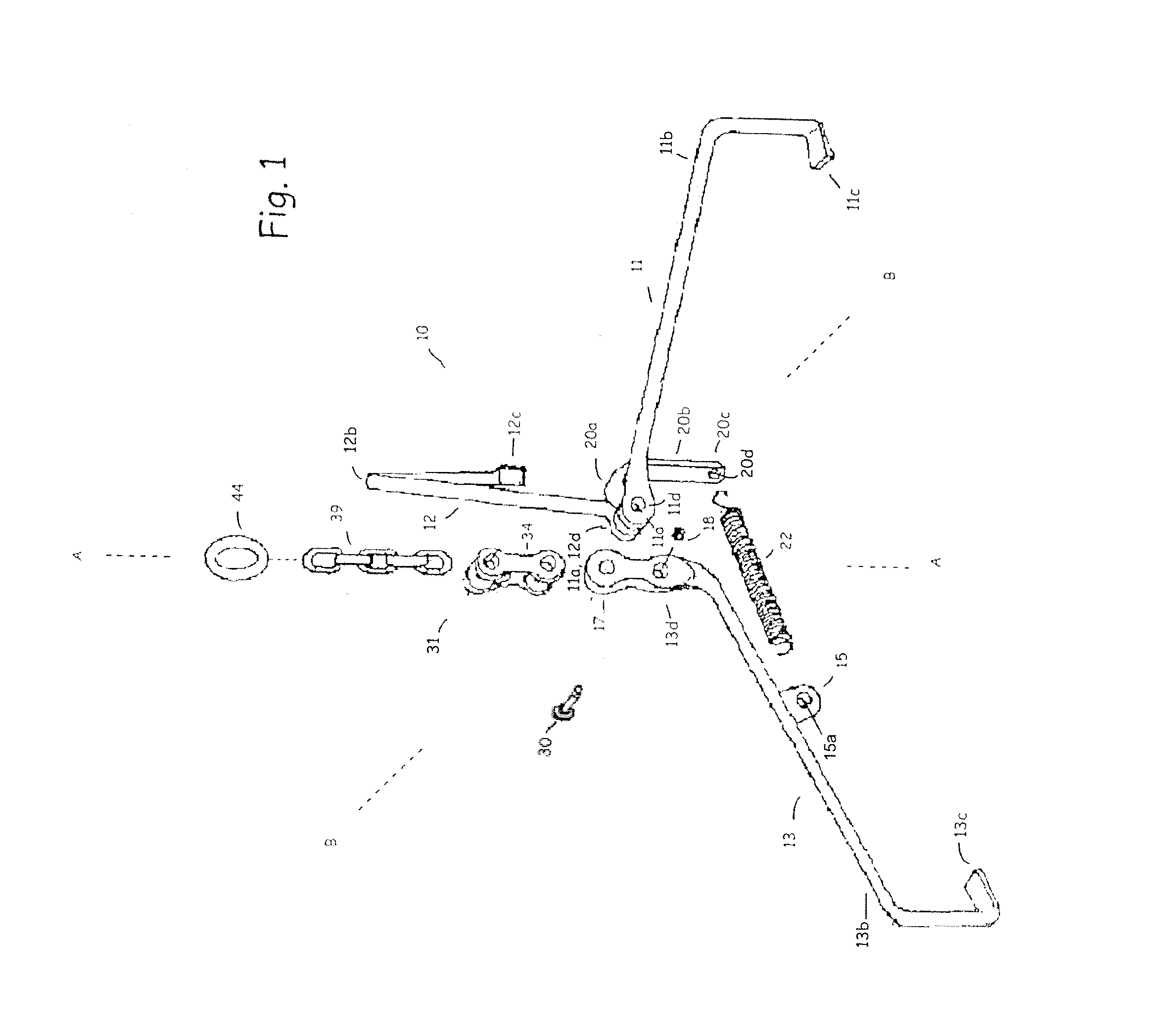

Device for grasping load structure

InactiveUS20070246958A1Efficient and durable useMinimizes numberLifting devicesLoad-engaging elementsEngineeringMechanical engineering

A device for grasping a load structure while it is being lifted, moved or lowered, comprising first, second and third legs, each extending radially outwardly from a vertical axis and adapted to pivotally engage a pivot member. The first, second and third legs are each adapted to pivot between an engaged position and a released position, and an urging member urges the legs toward the engaged position.

Owner:HERFORD SHANNON M

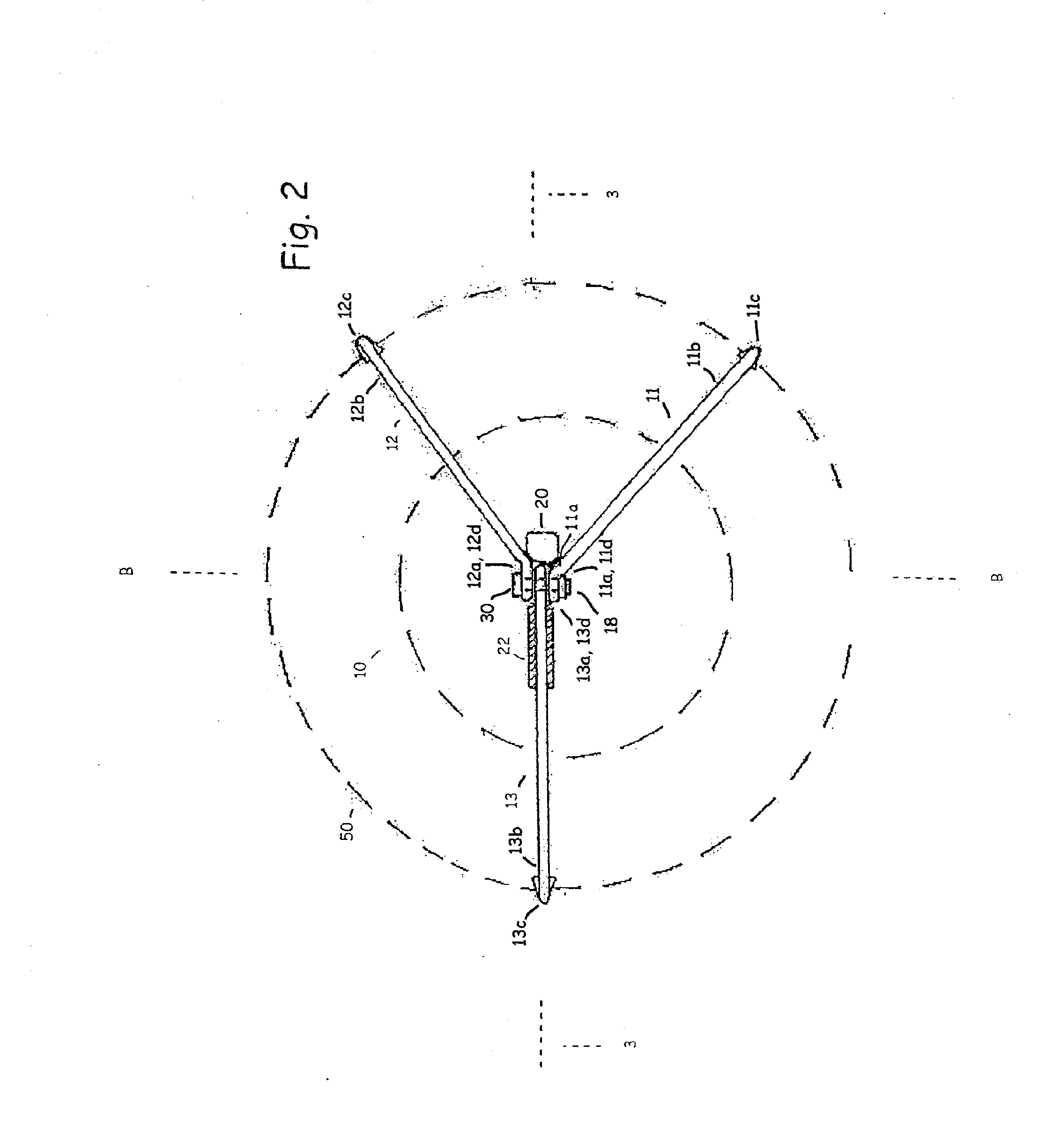

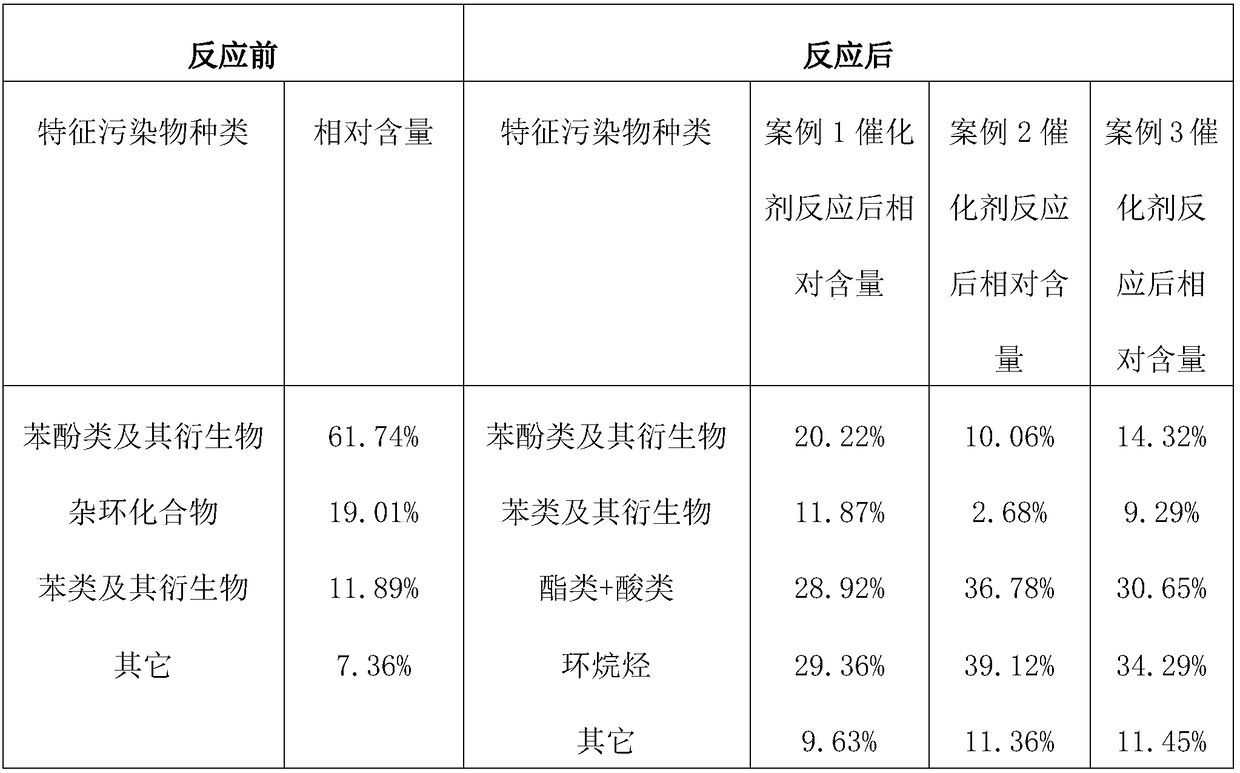

Preparation method of targeted catalyst for treating wastewater containing aromatic compounds

ActiveCN105879853AEfficient degradationLarge channelHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive componentChemical compound

Provided is a preparation method of a targeted catalyst for treating wastewater containing aromatic compounds. The method comprises the following steps that a solution containing 5%-15% of active component salt is dissolved in deionized water of 40 DEG C to 80 DEG C; an ammonium salt is added to enable the pH to be increased to be 6.5 to 7.5, the temperature is kept, and stirring is conducted for 40 min to 80 min at the speed of 60 r / min to 100 r / min; filtering is conducted, precipitates are washed 3-5 times with deionized water and dried for 3 h to 6 h in a muffle furnace of 100 DEG C to 110 DEG C, and granular powder is obtained; 10%-30% by mass of granular powder, 1%-5% by mass of lubricating agent, 4%-15% by mass of gelatinizing agent, 50%-80% by mass of alumina powder and 1%-3% by mass of pore-expanding agent are mixed and stirred to be uniform and then rolled to be 2 mm to 8 mm; an obtained product is dried for 3 h to 5 h in a drying oven of 100 DEG C to 200 DEG C; the dried product is roasted for 2 h to 6 h in the muffle furnace of 400 DEG C to 800 DEG C. The targeted catalyst is obtained through a mixed mode of precipitating and melting, larger channels can be formed in the catalyst, a larger specific surface area can be obtained, and therefore organic matter in the wastewater fully makes contact with active metal oxide in the catalyst, and the degradation effect on the organic matter is improved.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

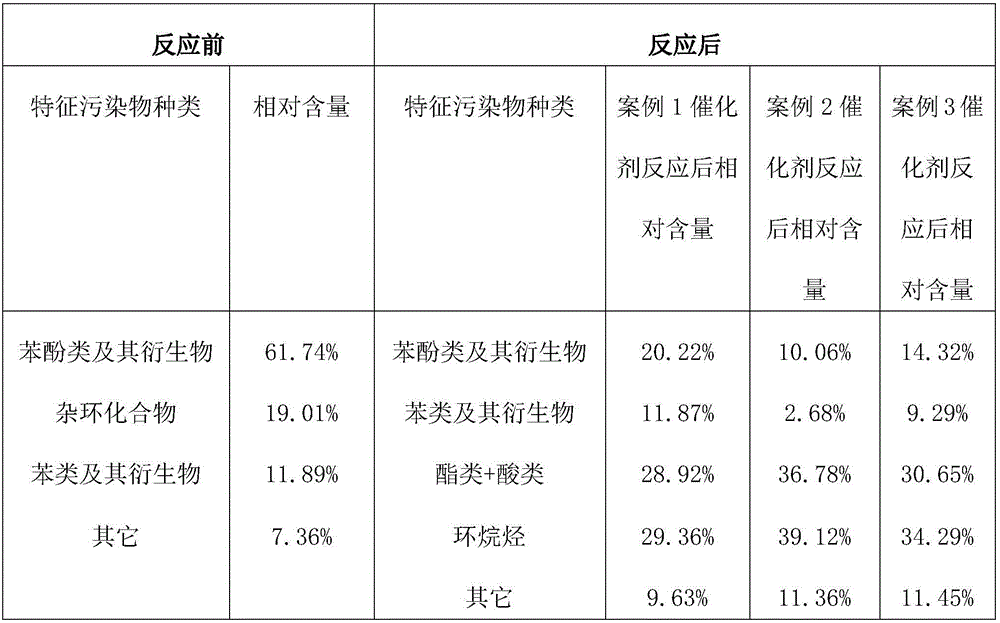

Municipal living waste destructive distillation system

PendingCN106753459ASolving the Dilemma of the SiegeSolve the problem of landfilling a large amount of landElectrical coke oven heatingSpecial form destructive distillationSludgeRemote control

The invention discloses a municipal living waste destructive distillation system which comprises a waste feeder, horizontal multi-tube living waste destructive distillation equipment, a heating system, a carbon discharge system, a living waste destructive distillation gas condensation purification system and a remote control system. The municipal living waste destructive distillation system is simple in structure and is prior to landfill, incineration and composting, living wastes can be efficiently treated, the living wastes can be turned into oil, gases and carbon, dioxin is not generated in the production process, and harmless, recycling and minimization treatment on living wastes, medical wastes, sludge and the like can be achieved indeed.

Owner:胡斌

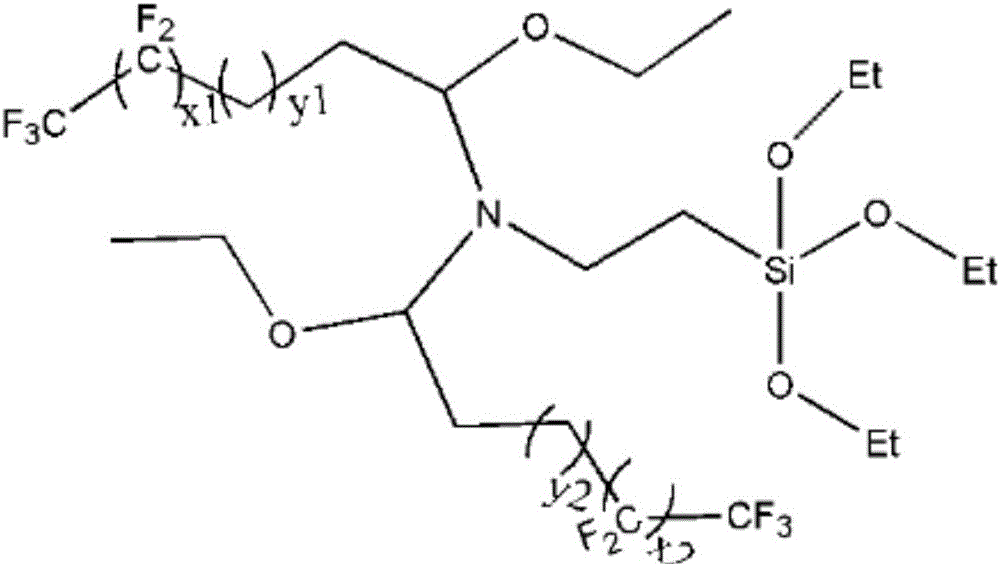

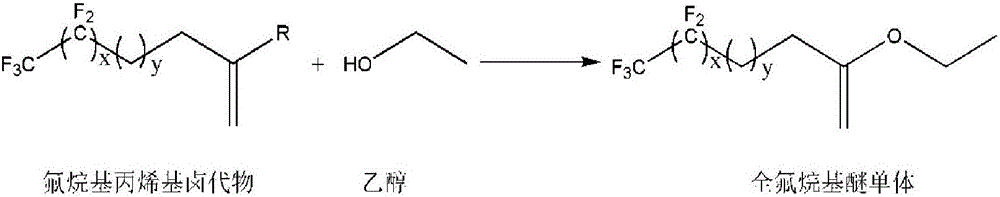

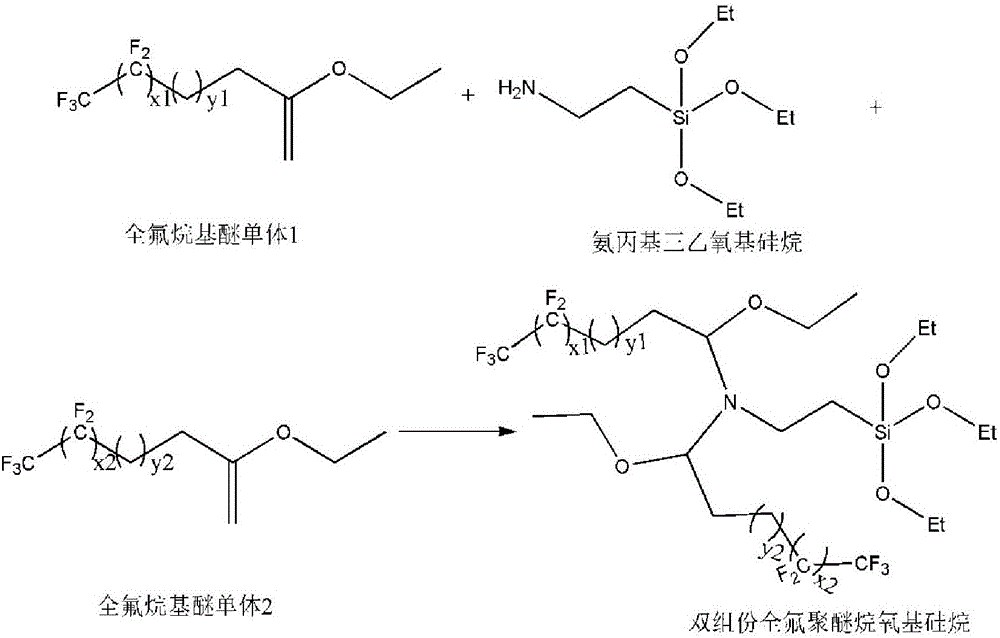

Two-component anti-corrosion agent with self-assembly function and preparation method thereof

InactiveCN105860635AMild reaction conditionsThe synthesis process is simpleGroup 4/14 element organic compoundsAnti-corrosive paintsSilanesDistillation

The invention discloses a two-component self-assembly functional anticorrosion agent and a preparation method thereof. Under the protection of nitrogen, react perfluoroalkylpropenyl halides and absolute ethanol under the action of a catalyst at room temperature for 12 hours, filter, reduce Unreacted ethanol was removed by pressure distillation to obtain perfluoroalkyl ether ethyl ester monomer; under nitrogen protection, two different perfluoroalkyl ether ethyl ester monomers were mixed with aminopropyltriethoxysilane, and added Alkaline solvent, stirred at room temperature for 24 hours, filtered, evaporated under reduced pressure to remove the solvent, and then separated on a silica gel column with an eluent to obtain a pure liquid of a two-component self-assembling functional anti-corrosion agent. The invention can form alkoxysilane containing polyfluorine long carbon chain, so that the chemical temperature performance, friction resistance and hydrophobicity and oleophobicity are better.

Owner:XIAMEN RUNNER IND CORP

A kind of target catalyst preparation method for treating wastewater containing aromatic compounds

ActiveCN105879853BEfficient degradationLarge channelHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsMuffle furnaceChemistry

Provided is a preparation method of a targeted catalyst for treating wastewater containing aromatic compounds. The method comprises the following steps that a solution containing 5%-15% of active component salt is dissolved in deionized water of 40 DEG C to 80 DEG C; an ammonium salt is added to enable the pH to be increased to be 6.5 to 7.5, the temperature is kept, and stirring is conducted for 40 min to 80 min at the speed of 60 r / min to 100 r / min; filtering is conducted, precipitates are washed 3-5 times with deionized water and dried for 3 h to 6 h in a muffle furnace of 100 DEG C to 110 DEG C, and granular powder is obtained; 10%-30% by mass of granular powder, 1%-5% by mass of lubricating agent, 4%-15% by mass of gelatinizing agent, 50%-80% by mass of alumina powder and 1%-3% by mass of pore-expanding agent are mixed and stirred to be uniform and then rolled to be 2 mm to 8 mm; an obtained product is dried for 3 h to 5 h in a drying oven of 100 DEG C to 200 DEG C; the dried product is roasted for 2 h to 6 h in the muffle furnace of 400 DEG C to 800 DEG C. The targeted catalyst is obtained through a mixed mode of precipitating and melting, larger channels can be formed in the catalyst, a larger specific surface area can be obtained, and therefore organic matter in the wastewater fully makes contact with active metal oxide in the catalyst, and the degradation effect on the organic matter is improved.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com