A kind of target catalyst preparation method for treating wastewater containing aromatic compounds

A technology of aromatic compounds and catalysts, which is used in the preparation of targeted catalysts and the treatment of wastewater characterized by aromatic compounds. It can solve the problems of limited hydroxyl radicals, low removal rate, and high COD removal effect. Achieve strong anti-pollution ability and improve degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

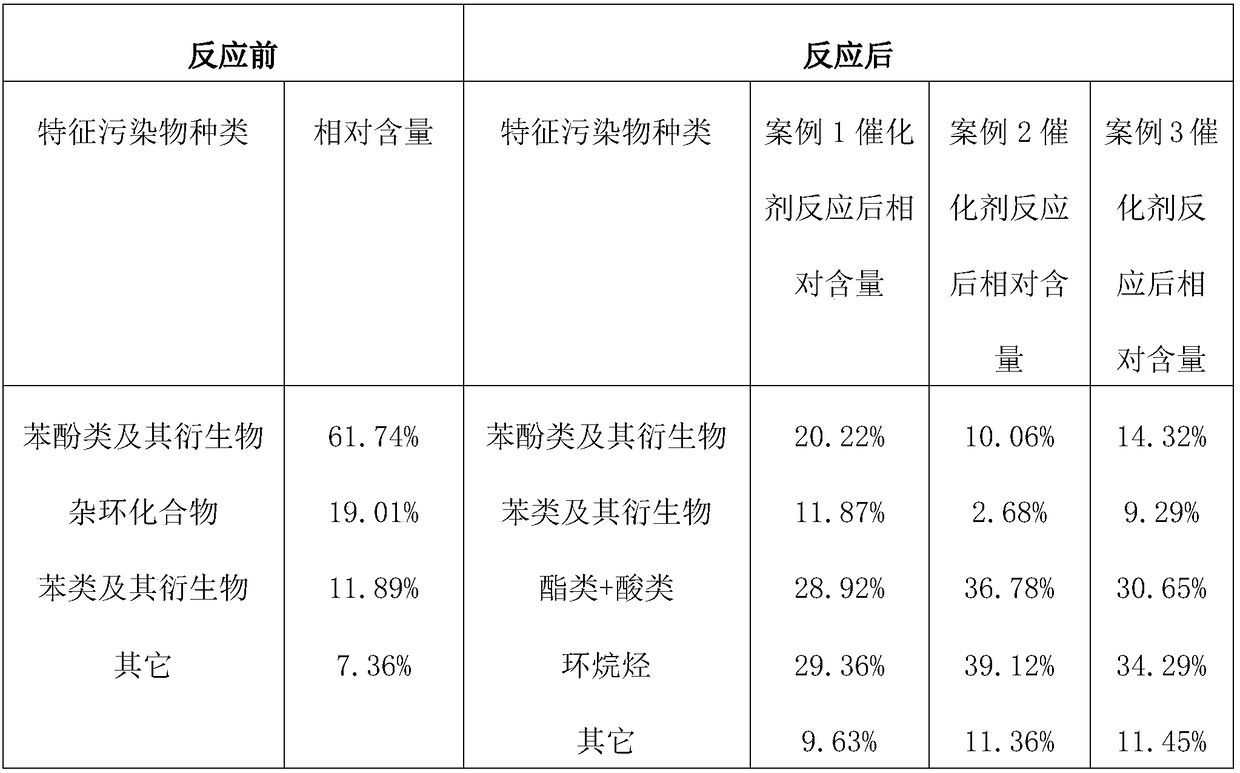

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0037] A method for preparing a targeted catalyst for treating wastewater containing aromatic compounds, comprising the following steps:

[0038] Step (1), dissolve the active component salt in deionized water at 40-80°C to prepare a solution with a mass concentration of 5-15%; then add ammonium salt to raise the pH to between 6.5-7.5, and the solution Precipitation begins to form in the medium, keep the temperature of the solution at 40-80°C, keep the temperature and stir at a speed of 60-100 rpm for 40-80 minutes; wherein, the active component salt is mixed rare earth nitrate, Mn( NO 3 ) 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com