Method and device for preparing graphene oxide

A fossil and graphene technology, which is applied in the field of preparing graphene oxide, can solve the problems of low utilization rate of potassium permanganate, cumbersome operation, safety accidents, etc., and achieve the benefits of industrial production, uniform material mixing, and safe production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

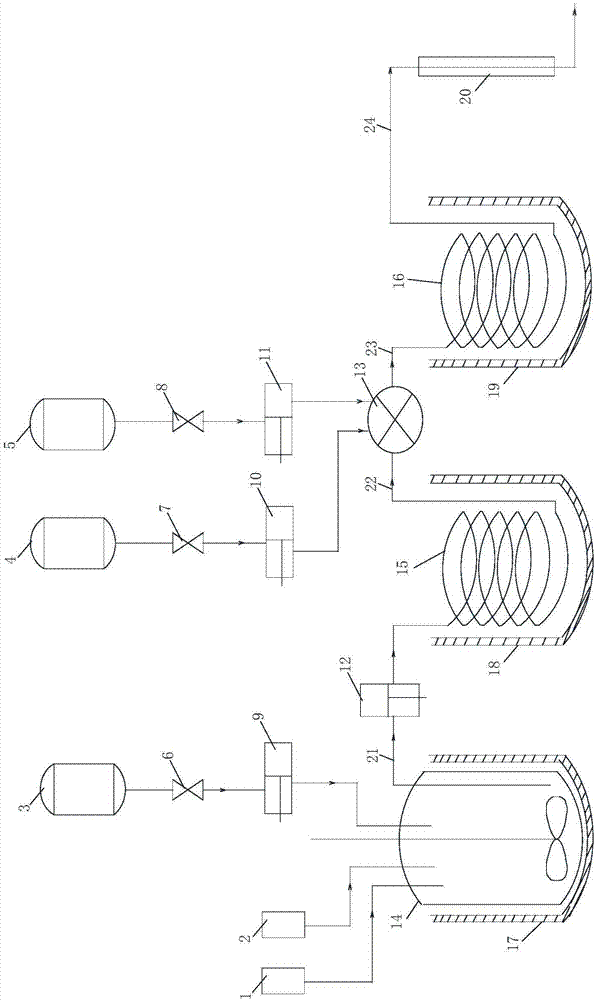

[0028] A special device for preparing graphene oxide (such as figure 1 shown), comprising a mixing tank 14, a first pipeline reactor 15, a second pipeline reactor 16, a mixer 13, a condenser 20 and an aftertreatment system, the output end of the mixing tank 14 and the first The input end of the pipeline reactor 15 is connected by the first conduit 21, the fourth metering pump 12 is arranged on the first conduit 21, the output end of the first pipeline reactor 15 and the input end of the mixer 13 pass through the second Conduit 22 is connected, and the output end of described mixer 13 is connected with the input end of second pipeline reactor 16 by the 3rd conduit 23, and the output end of described second pipeline reactor 16 is connected with the input end of condenser 20 Connected via a fourth conduit 24, the output of the condenser 20 is connected to the aftertreatment system.

[0029] Wherein, the tube length of the first tube reactor 15 is 30 m, and the tube diameter is 6...

Embodiment 2

[0038] A special device for preparing graphene oxide, comprising a mixing tank 14, a first pipeline reactor 15, a second pipeline reactor 16, a mixer 13, a condenser 20 and an aftertreatment system, the mixing tank 14 The output end of the first pipeline reactor 15 is connected by the first conduit 21, the first conduit 21 is provided with the fourth metering pump 12, the output end of the first pipeline reactor 15 is connected with the mixer 13 The input end of described mixer 13 is connected by the second conduit 22, and the output end of described mixer 13 is connected with the input end of second pipeline reactor 16 by the 3rd conduit 23, and the output end of described second pipeline reactor 16 is connected with The input end of the condenser 20 is connected through a fourth conduit 24 , and the output end of the condenser 20 is connected with the aftertreatment system.

[0039] Wherein, the tube length of the first tube reactor 15 is 30 m, and the tube diameter is 6 mm;...

Embodiment 3

[0047] A special device for preparing graphene oxide, comprising a mixing tank 14, a first pipeline reactor 15, a second pipeline reactor 16, a mixer 13, a condenser 20 and an aftertreatment system, the mixing tank 14 The output end of the first pipeline reactor 15 is connected by the first conduit 21, the first conduit 21 is provided with the fourth metering pump 12, the output end of the first pipeline reactor 15 is connected with the mixer 13 The input end of described mixer 13 is connected by the second conduit 22, and the output end of described mixer 13 is connected with the input end of second pipeline reactor 16 by the 3rd conduit 23, and the output end of described second pipeline reactor 16 is connected with The input end of the condenser 20 is connected through a fourth conduit 24 , and the output end of the condenser 20 is connected with the aftertreatment system.

[0048] Wherein, the tube length of the first tube reactor 15 is 20 m, and the tube diameter is 6 mm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com