Control method of diatomite ore scrubbing process

A control method, diatomite mining technology, applied in the direction of solid separation, etc., to achieve continuous production, improve the effect of scrubbing, and avoid the effect of excessive dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

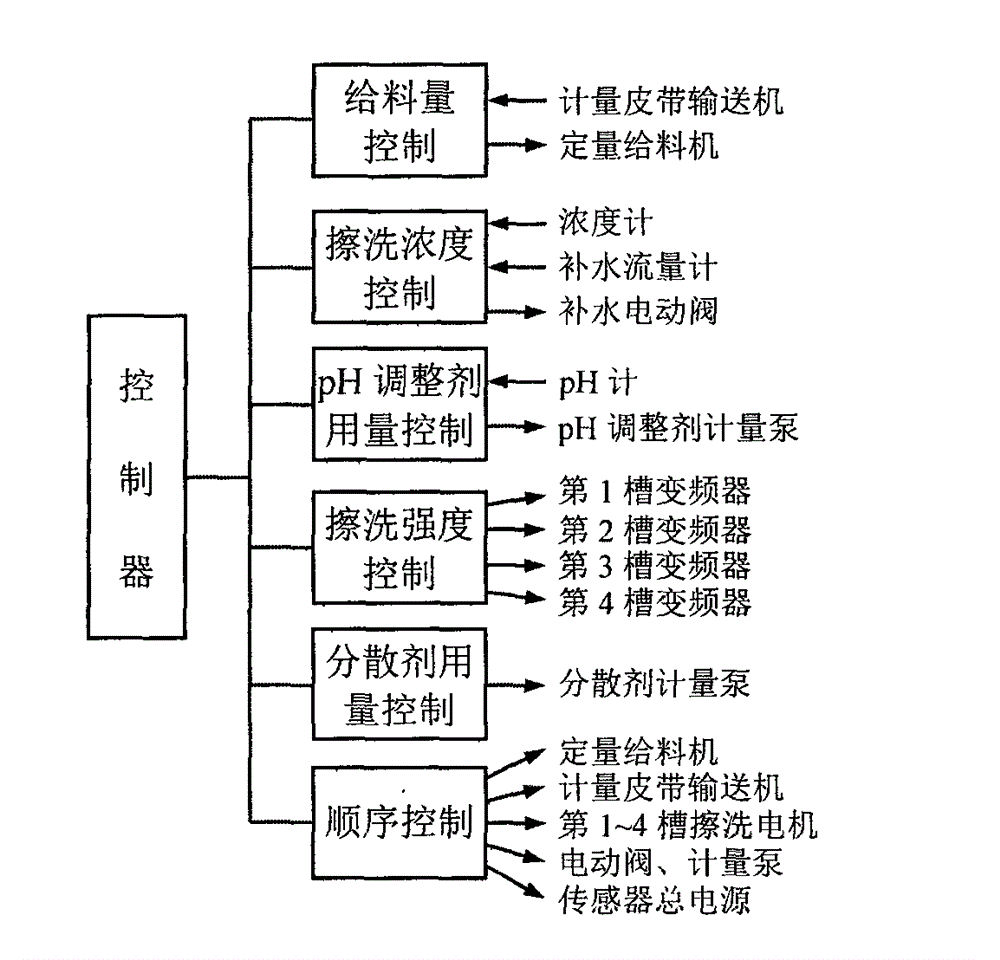

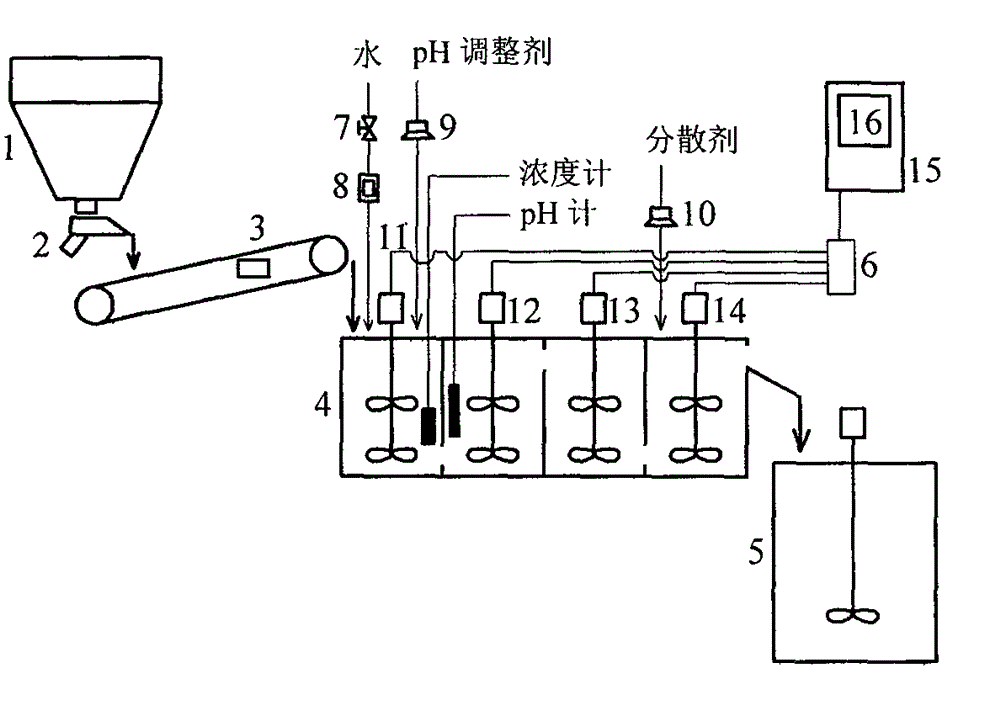

[0020] figure 1It is a functional block diagram of a control method of a diatomite ore scrubbing process of the present invention, specifically including feeding amount control, scrubbing concentration control, pH regulator dosage control, scrubbing intensity control, dispersant dosage control, sequence control and a controller, The described feed rate control, scrub concentration control, pH adjuster dosage control, scrub strength control, dispersant dosage control and sequence control are respectively connected with the described controller, and according to the diatom content of diatomite raw ore, determine the given The amount of material, based on this, adjust the electric valve for water replenishment, control the scrubbing concentration to 30% to 35%, and adjust the metering pump of the pH regulator to make the pH value in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com