Floatation method for silica-calcium collophane with difficult separation

A technology of silicon-calcium and colloidal phosphate rock, which is applied in the field of flotation technology, can solve the problems that cannot meet the requirements of wet-process phosphoric acid ore, and achieve the effect of low flotation cost, significant economic benefits, and small flotation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

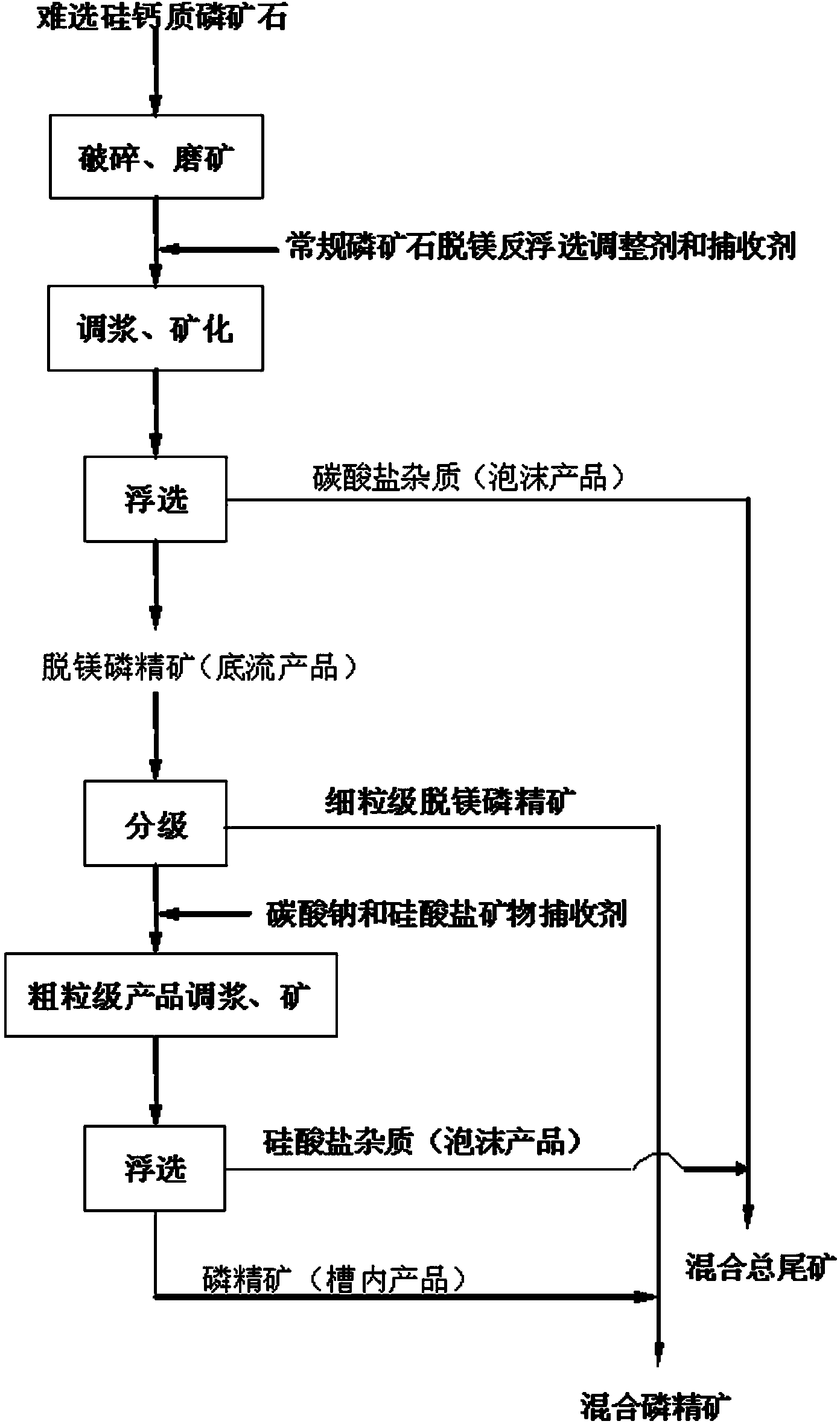

Method used

Image

Examples

Embodiment 1

[0025] Example 2

Embodiment 2

[0027] Example 3

Embodiment 3

[0029] The invention solves the problem that after the removal of carbonate impurities only through single reverse flotation, the content of phosphorus concentrate is not high, but the content of silicate impurities is relatively high and cannot meet the requirements of wet-process phosphoric acid ore, and then the silicate is removed through reverse flotation. In the impurity process, due to the existence of a large amount of slime, the flotation foam is sticky, difficult to defoam, and the fluidity of the pulp is poor. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com