Method and device for processing sewage water by annular contact oxidation

A technology of oxidation reaction and circular contact, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. The effect of small land area, low operating cost and low investment amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

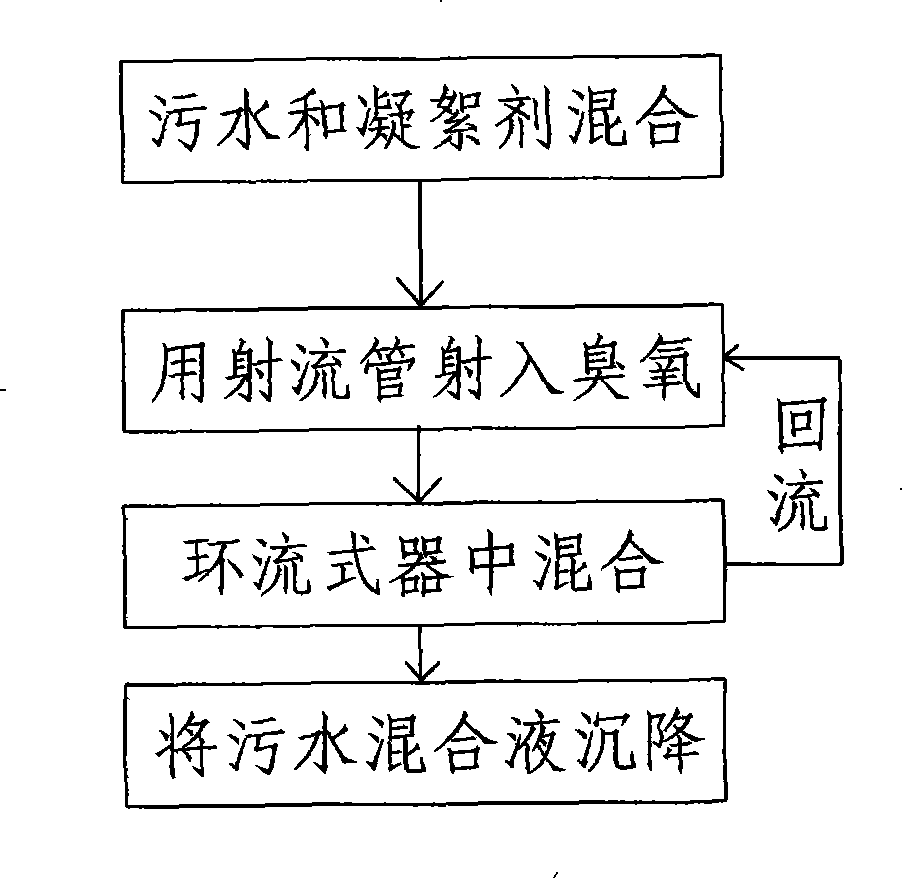

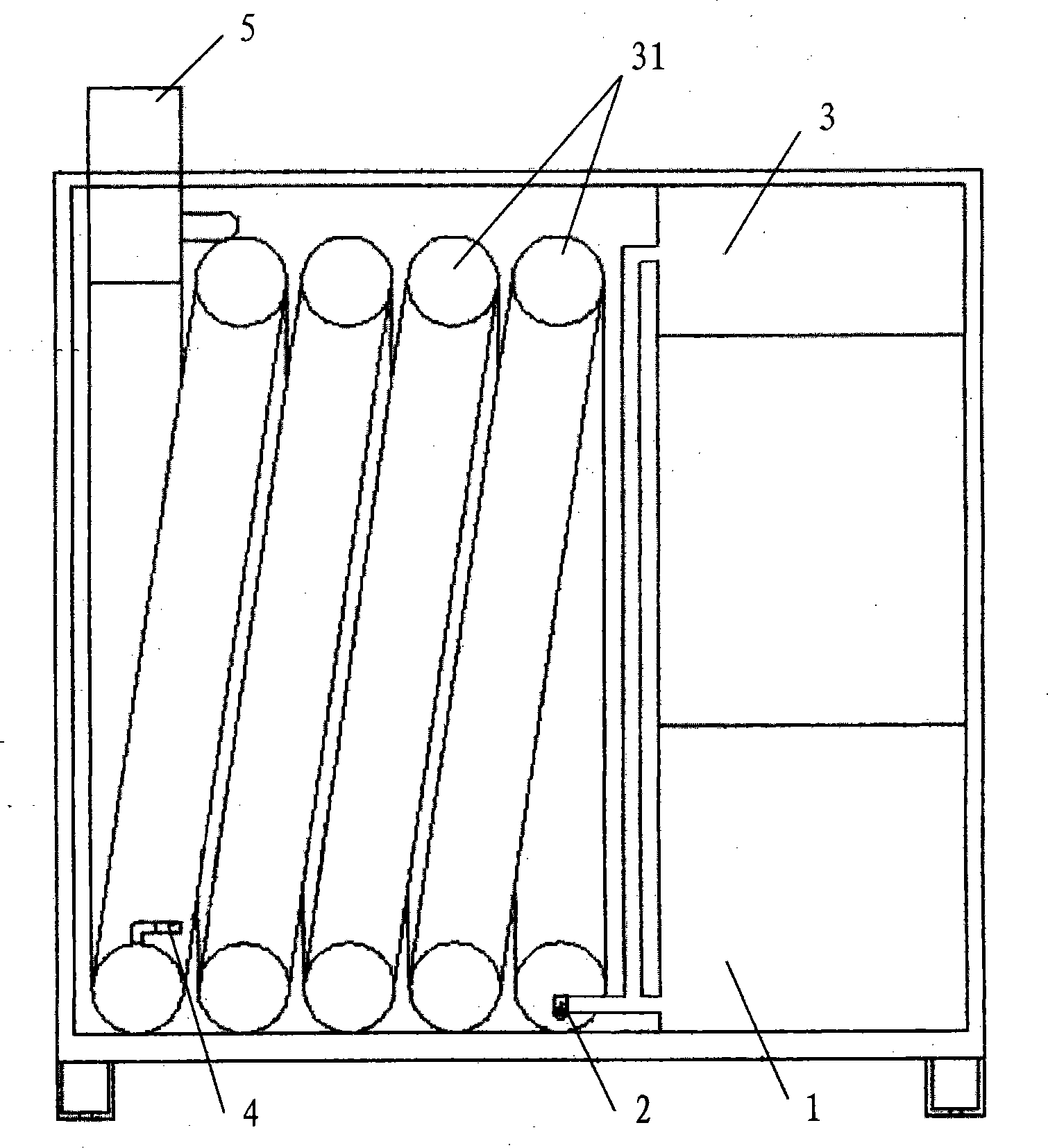

[0014] Such as figure 1 and figure 2 As shown, a method for treating sewage by annular contact oxidation reaction is characterized in that the sewage is first mixed with a flocculant, and then ozone air is injected into the sewage through a jet tube to mix with a pressure above 0.15 MPa, and then mixed. The mixture is mixed in the circulation mixer at a pressure greater than normal pressure, so that the mixture also forms bubble upwelling and waterfall impact mixing in the circulation mixer, so that a certain amount of ozone dissolves and adheres to the flocculated In the sewage of the agent, it is released again, which greatly improves the full contact time and contact area between ozone and organic matter and reducing pollutants in sewage. The above-mentioned mixed liquid uses a reflux device to control a certain amount of reflux to improve the reaction efficiency. The reflux device is used to circulate the reaction liquid multiple times and contact the reaction gas multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com