Environment-friendly efficient ferrous sulfide passivant and preparation method thereof

An environmentally friendly ferrous sulfide technology, applied in the field of fine chemicals, can solve problems such as ferrous sulfide spontaneous combustion accidents, damaged equipment, and large accumulations of ferrous sulfide, so as to prolong the service life, avoid the loss of fluid kinetic energy, and The effect of scale inhibition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

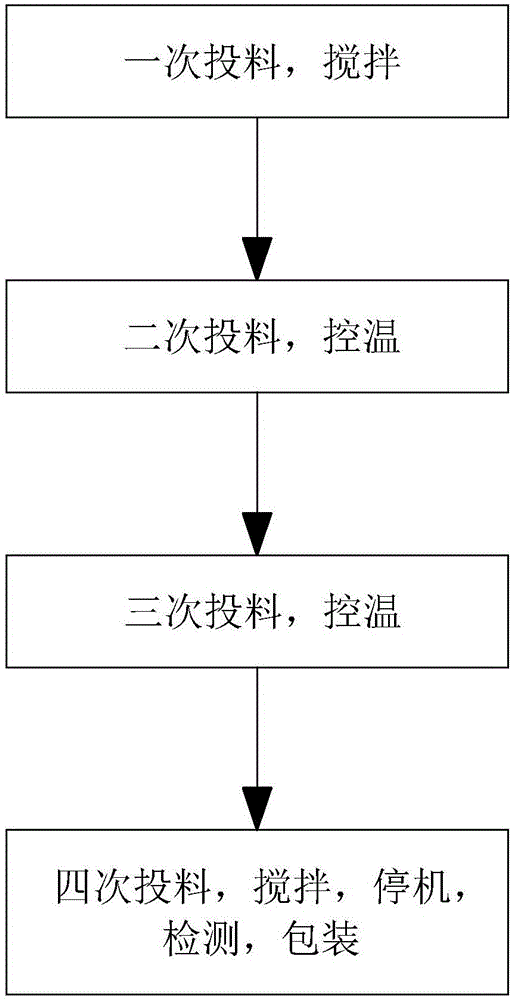

Method used

Image

Examples

Embodiment 1

[0044] Step 1: first feed nitrogen into the mixer, and empty the mixer, add 1kg fatty alcohol polyoxyethylene ether sodium sulfate, 1kg methyloctylacetaldehyde, 2kg methylnonacetaldehyde, 2kg amine oxide, 1kg itacan The acid copolymer is itaconic acid-sodium propylene sulfonate-sodium hypophosphite copolymer, 1kg itaconic acid-ethyl acrylate-acrylic acid copolymer and 89kg water are slowly added into the mixer, start the mixer, record the mixing time, and start the mixer to fatty alcohol polyoxyethylene ether sodium sulfate, methyloctylacetaldehyde, methylnonacetaldehyde, amine oxide, itaconic acid-sodium propylene sulfonate-sodium hypophosphite copolymer and itaconic acid-ethyl acrylate-acrylic acid It takes 15 to 30 minutes for all the copolymers to be fed;

[0045] Step 2: Slowly add 1kg of sodium dodecylbenzenesulfonate and 0.5kg of sodium carbonate under normal pressure, and control the maximum reaction temperature to be less than 75°C. When the reaction temperature rises...

Embodiment 2

[0049] Step 1: first feed nitrogen into the mixer, and empty the mixer, add 2kg fatty alcohol polyoxyethylene ether sodium sulfate, 1.7kg methyl nonacetaldehyde, 3.3kg 7-hydroxy-3,7-dimethyl octane Add aldehyde, 5kg amine oxide, 1kg itaconic acid-sodium propylene sulfonate-sodium hypophosphite copolymer, 2kg itaconic acid-ethyl acrylate-acrylic acid copolymer and 77kg water slowly into the mixer, start the mixer, record the mixing time, From the start of the mixer to the copolymerization of fatty alcohol polyoxyethylene ether sodium sulfate, methylnonacetaldehyde, 7-hydroxy-3,7-dimethyloctylaldehyde, amine oxide, itaconic acid-sodium propylene sulfonate-sodium hypophosphite It takes 15 to 30 minutes to complete the feeding of the compound and itaconic acid-ethyl acrylate-acrylic acid copolymer;

[0050] Step 2: Slowly add 2kg of sodium dodecylbenzenesulfonate and 2kg of sodium carbonate under normal pressure, and control the maximum reaction temperature to be less than 75°C. W...

Embodiment 3

[0054] Step 1: first feed nitrogen into the mixer, and empty the mixer, add 1.6kg fatty alcohol polyoxyethylene ether sodium sulfate, 1kg methyloctylacetaldehyde, 1kg methylnonacetaldehyde, 2kg7-hydroxyl-3, 7-Dimethyloctanal, 3.5kg amine oxide, 1.04kg itaconic acid-sodium propylene sulfonate-sodium hypophosphite copolymer, 1.56kg itaconic acid-ethyl acrylate-acrylic acid copolymer and 83kg water were slowly added to the mixer Inside, turn on the mixer, record the mixing time, from turning on the mixer to fatty alcohol polyoxyethylene ether sodium sulfate, methyloctylacetaldehyde, methylnonacetaldehyde, 7-hydroxy-3,7-dimethyloctylaldehyde, amine oxide 1. Itaconic acid-sodium propylene sulfonate-sodium hypophosphite copolymer and itaconic acid-ethyl acrylate-acrylic acid copolymer all need 15 to 30 minutes to complete feeding;

[0055] Step 2: Slowly add 1.4kg sodium dodecylbenzenesulfonate and 1.3kg sodium carbonate under normal pressure, and control the maximum reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com