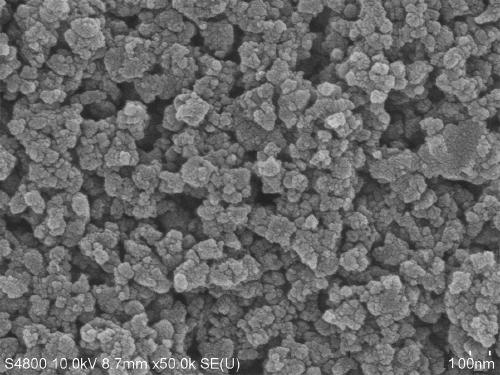

Green synthetic Fe3O4-PdO nanocomposite material, preparation method and application thereof

A nanocomposite material, fe3o4-pdo technology, applied in chemical instruments and methods, water/sludge/sewage treatment, other chemical processes, etc., can solve the problem of time-consuming and other problems, and achieve a simple preparation process, environmental friendliness, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A green synthetic Fe 3 o 4 -The preparation method of PdO nanocomposite material specifically comprises the following steps:

[0033]S1. Weigh 60g of dried and shredded eucalyptus leaves and place them in a container, add 1000mL of deionized water, heat in a water bath at 70°C for 1h, take out and cool to room temperature, vacuum filter, remove the eucalyptus leaf residue and obtain the filtrate as eucalyptus leaf extract; vacuum Buchner funnel was used for suction filtration, and double-layer filter paper was used for suction filtration, and the pore size of the filter paper was 0.45 μm.

[0034] S2, weigh 6.85FeCl 3 ·6H 2 O and 0.0685PdCl 2 Put the solid in a container, add deionized water to dissolve and transfer to a volumetric flask to volume;

[0035] S3, measure 600mL of eucalyptus leaf extract prepared through step S1 and the Fe-containing extract prepared through step S2 3+ with Pd 2+ 300mL of the mixed solution was mixed in a container in a nitrogen atm...

Embodiment 2

[0039] A green synthetic Fe 3 o 4 -The preparation method of PdO nanocomposite material specifically comprises the following steps:

[0040] S1. Weigh 60g of dried and shredded eucalyptus leaves into a container, add 1000mL of deionized water, heat in a water bath at 80°C for 2 hours, take out and cool to room temperature, vacuum filter, and remove the filtrate obtained from eucalyptus leaf residues as eucalyptus leaf extract; Buchner funnel was used for suction filtration, and double-layer filter paper was used for suction filtration, and the pore size of the filter paper was 0.45 μm.

[0041] S2, weigh 6.80FeCl 3 ·6H 2 O and 0.0680PdCl 2 Put the solid in a container, add deionized water to dissolve and transfer to a volumetric flask to volume;

[0042] S3, measure 100mL of eucalyptus leaf extract prepared through step S1 and the Fe-containing extract prepared through step S2 3+ with Pd 2 + 50mL of the mixed solution was mixed in a container in a nitrogen atmosphere, ...

Embodiment 3

[0046] A green synthetic Fe 3 o 4 -The preparation method of PdO nanocomposite material specifically comprises the following steps:

[0047] S1. Weigh 70g of dried and shredded eucalyptus leaves and place them in a container, add 1000mL of deionized water, heat in a water bath at 75°C for 2 hours, take out and cool to room temperature, vacuum filter, and remove the filtrate obtained from eucalyptus leaf residues as eucalyptus leaf extract; Buchner funnel was used for suction filtration, and double-layer filter paper was used for suction filtration, and the pore size of the filter paper was 0.45 μm.

[0048] S2, weigh 6.75FeCl 3 ·6H 2 O and 0.0675PdCl 2 Put the solid in a container, add deionized water to dissolve and transfer to a volumetric flask to volume;

[0049] S3, measure 500mL of eucalyptus leaf extract prepared through step S1 and the Fe-containing extract prepared through step S2 3+ with Pd 2 + 250mL of the mixed solution was mixed in a container in a nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com