Method for recovering, treating and closed-loop circulating waste water of papermaking

A closed-circuit circulation technology for papermaking wastewater, applied in water/sewage treatment, water/sludge/sewage treatment, papermaking, etc., can solve problems such as inability to promote, and achieve high recycling profits, simple operation and management, and less land occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

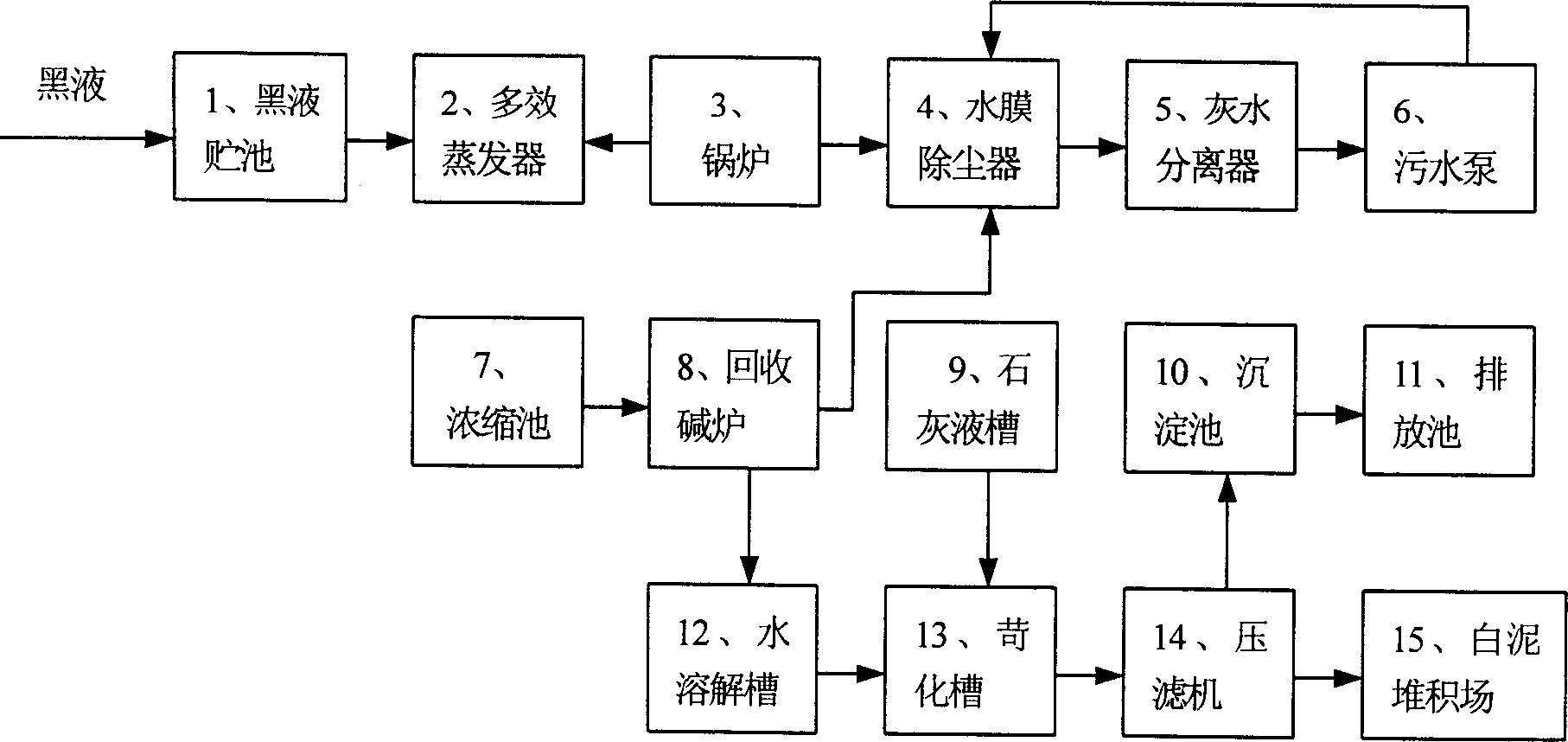

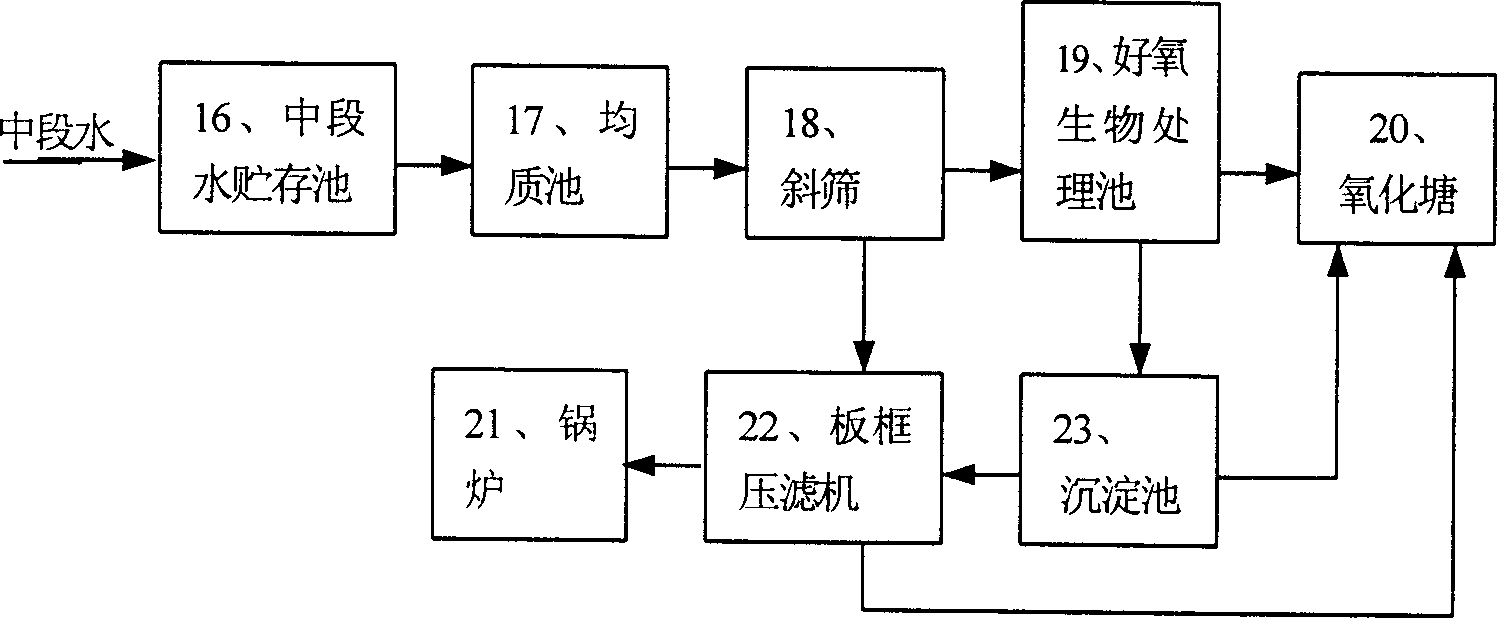

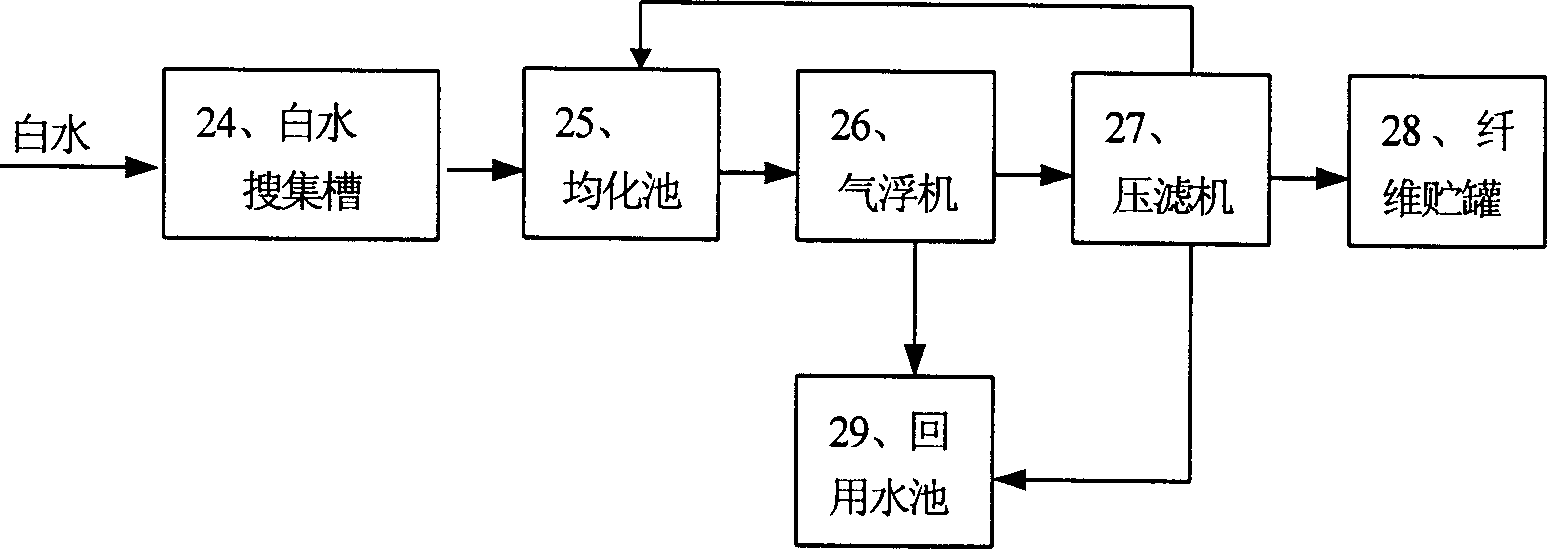

[0036] Combine below Figure 7-Figure 9 Further describe the process of the present invention.

[0037] Papermaking black liquor, recovery of alkali, pulp, fuel and waste water recycling, such as Figure 7 shown, including;

[0038] [71] is the black liquor storage tank, and the uneven water quality and water quantity are homogenized in the regulating tank [72], and the hemifiber and lignin in the black liquor are recycled to [77] by the screen filter [73]. Pulp storage tank, used as papermaking raw material. After the effluent of the screen filter is filtered by the filter device [74], all impurities in the black liquor are intercepted and adsorbed by the filter material in the filter device, and the filter material and the trapped and adsorbed impurities are sent to the boiler [78] for combustion or storage. The used filter material is cheap, with large specific surface area and good chemical stability, such as slag, lignite, coke and other materials, and the particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com