Method for producing high-purity silver powder by using silver-containing dead catalyst

A waste catalyst and high-purity technology, applied in the direction of improving process efficiency, can solve the problems of high energy consumption, easy entry of silver into the slag phase, low purity, activity and dispersion of silver powder, and achieve the effect of overcoming single performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

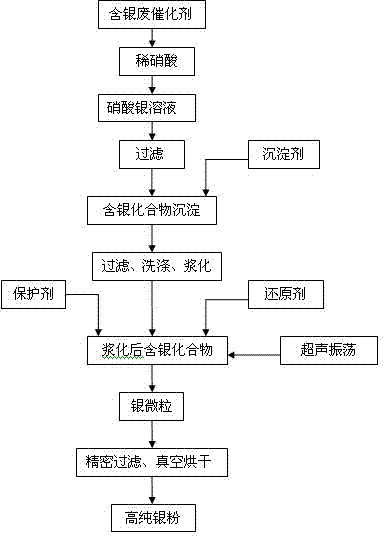

Image

Examples

example 1

[0033] (1) Use 500 grams of silver-containing waste catalyst as raw material, and use 1500 mL of 10% to 30% dilute nitric acid solution to dissolve silver into silver nitrate solution;

[0034] (2) Add 47 grams of precipitating agent to the filtered silver nitrate solution to generate silver-containing compound precipitation;

[0035] (3) The silver-containing compound precipitate is filtered, washed, and then slurried to obtain the slurried silver-containing compound;

[0036] (4) Select hydrogen peroxide and sodium borohydride as the reducing agent, polyvinylpyrrolidone as the protective agent, the amount of the protective agent added is 3% of the silver content, and the pH value is controlled at the same time, the reducing agent is added at a speed of 10mL / min, and the stirring speed is 220rpm , the reaction temperature is 55 ° C, under the condition of ultrasonic vibration, silver ions can be reduced to spherical high-purity silver powder particles.

[0037] (5) The obtai...

example 2

[0039] (1) Use 500 grams of silver-containing waste catalyst as raw material, and use 1500 mL of 10% to 30% dilute nitric acid solution to dissolve silver into silver nitrate solution;

[0040] (2) Add 45 grams of precipitating agent to the filtered silver nitrate solution to generate silver-containing compound precipitation;

[0041] (3) The silver-containing compound precipitate is filtered, washed, and then slurried to obtain the slurried silver-containing compound;

[0042] (4) Select formic acid as the reducing agent, polyethylene glycol as the protective agent, the amount of the protective agent added is 3% of the silver content, the pH value is controlled to be 3, the adding speed of the reducing agent is 30mL / min, the stirring speed is 350rpm, and the reaction The temperature is 45°C, and under the condition of ultrasonic vibration, silver ions can be reduced to flake high-purity silver powder particles.

[0043] (5) The obtained high-purity silver powder is filtered,...

example 3

[0045] (1) Use 500 grams of silver-containing waste catalyst as raw material, and use 1500 mL of 10% to 30% dilute nitric acid solution to dissolve silver into silver nitrate solution;

[0046] (2) Add 45 grams of precipitating agent to the filtered silver nitrate solution to generate silver-containing compound precipitation;

[0047] (3) The silver-containing compound precipitate is filtered, washed, and then slurried to obtain the slurried silver-containing compound;

[0048] (4) Select aliphatic aldehyde as the reducing agent, sodium lauryl sulfate as the protective agent, the amount of the protective agent added is 3% of the silver content, the pH value is controlled to be 13, the adding speed of the reducing agent is 45mL / min, and the stirring speed is 400rpm , the reaction temperature is 45 ° C, under the condition of ultrasonic vibration, silver ions can be reduced to reticular high-purity silver powder particles.

[0049] (5) The obtained high-purity silver powder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com