Modified white sugar reducer and preparation method thereof and application thereof in printing and dyeing industry

A technology of reducing agent and sugar, applied in dyeing, textile and papermaking, etc., can solve the problems of poor stability, harmful components, decomposition of the body, etc., and achieve the effects of good stability, small reducing ability and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

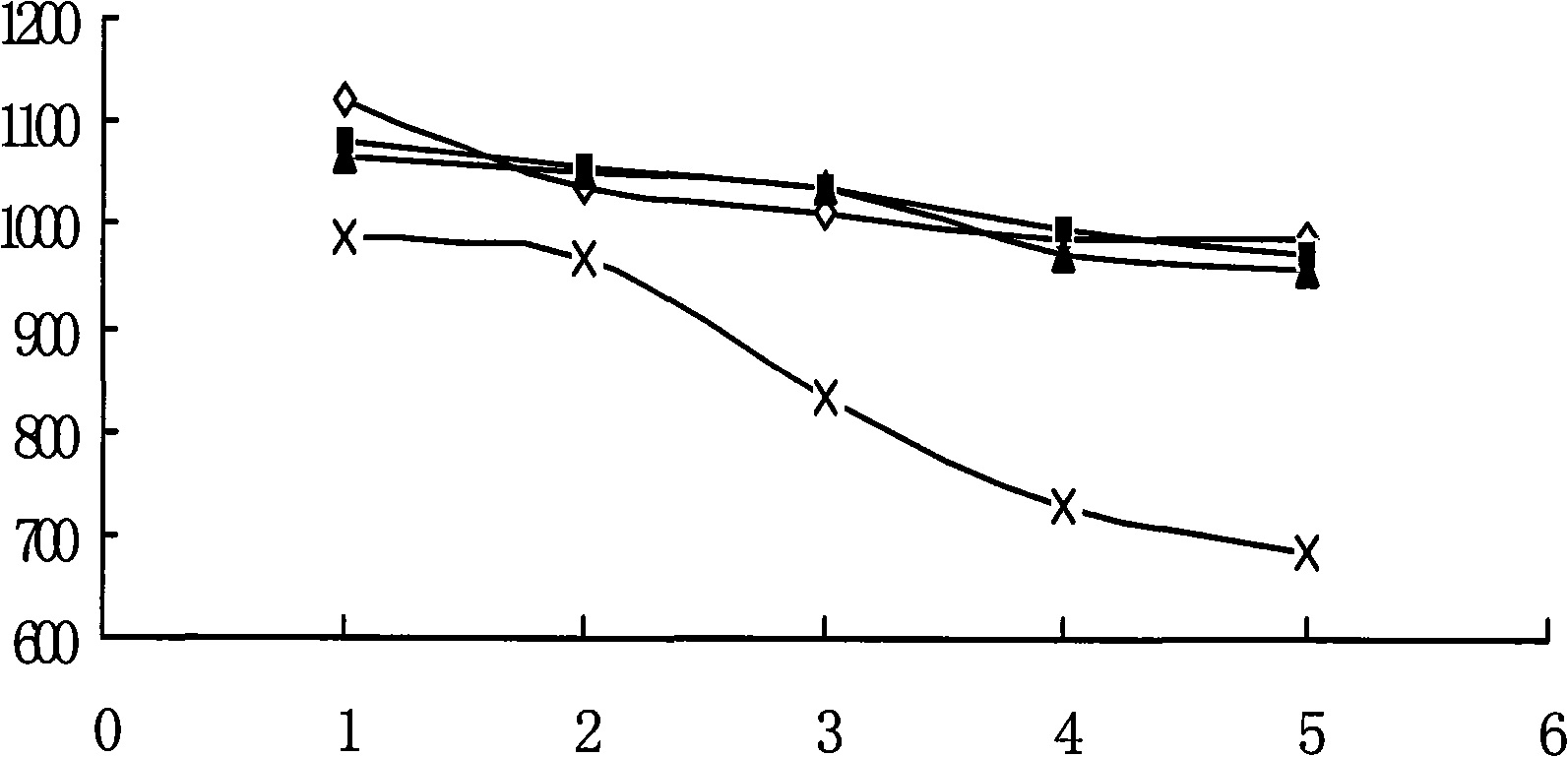

Image

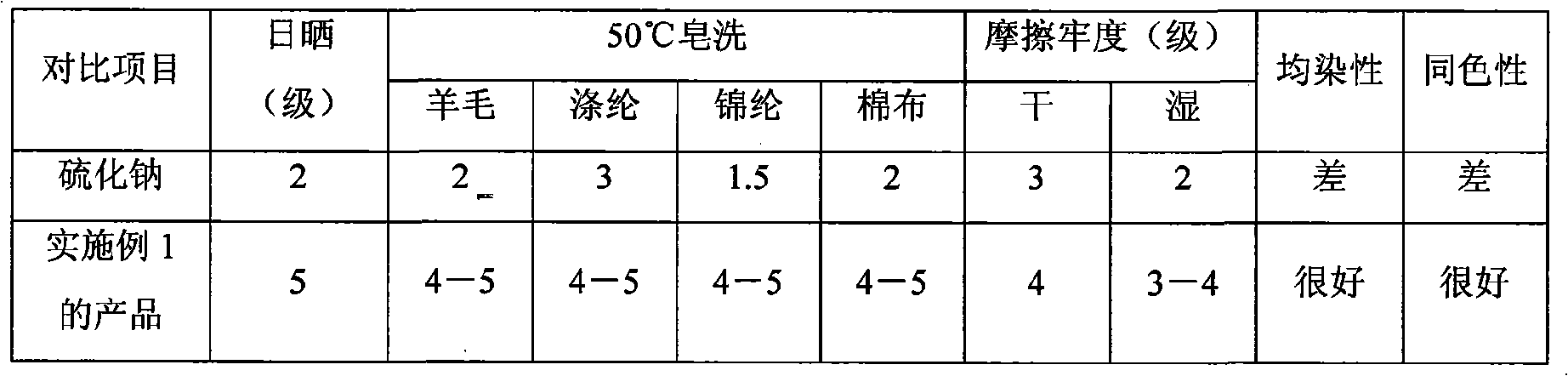

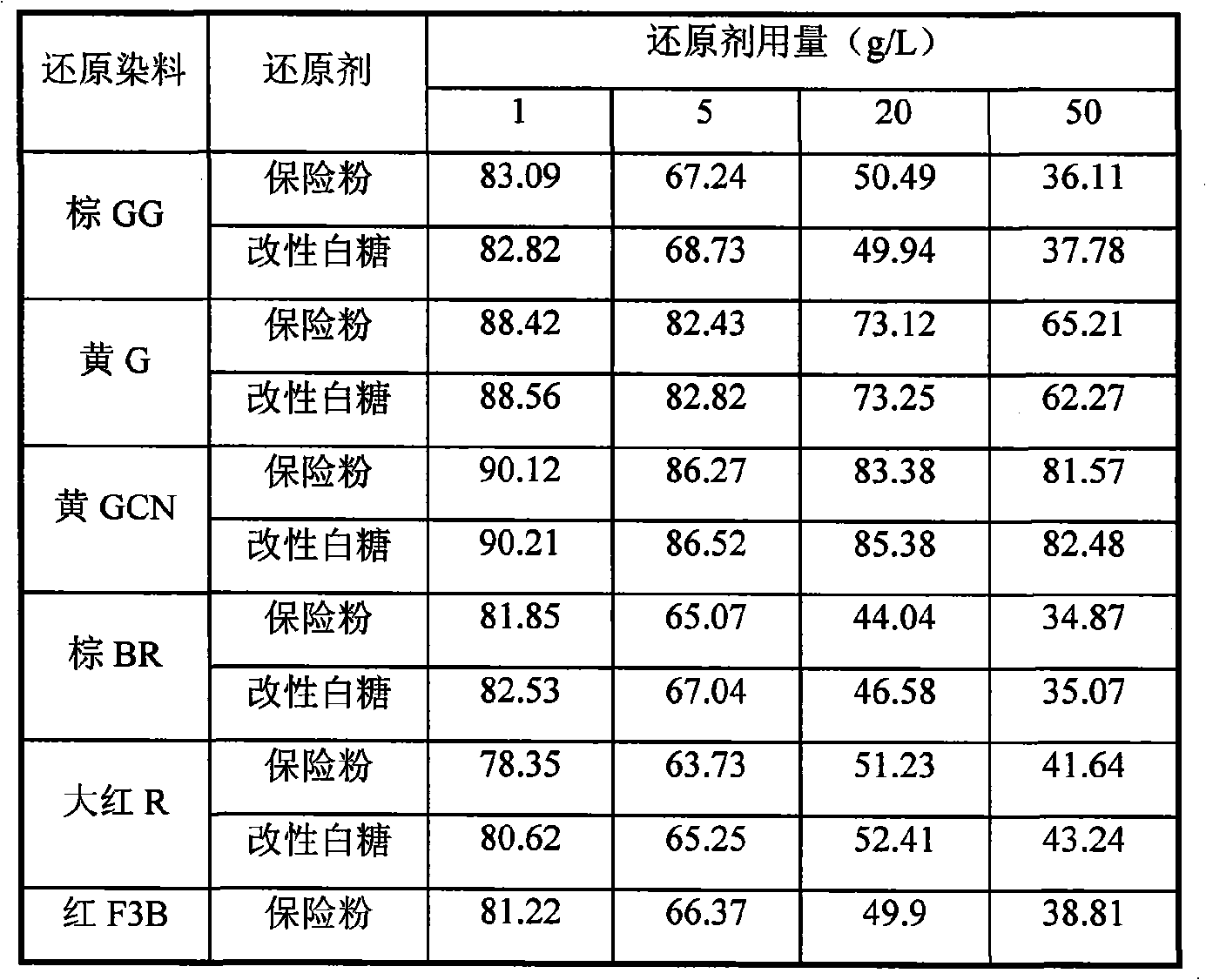

Examples

preparation example Construction

[0032] The preparation method steps are as follows: slowly add fatty aldehyde into the reactor containing sugar, buffer and water, control the mixing reaction temperature below 15°C, and stir at the speed of 50-100r / min. After adding fatty aldehyde, The temperature of the mixing reaction is raised to 20-80℃ at a rate of 1~5℃ / min. After mixing and reacting for 30min~120min, add the sulfonating agent. During the feeding process, the mixing reaction temperature is 20~80℃. After the chemical agent, the mixing reaction temperature is increased to 90-150°C at a heating rate of 1 to 5°C / min. After mixing and reacting for 30-210 minutes, the temperature of the mixing reaction is lowered to 80-90°C, and stabilizers and accelerators are added. After mixing and reacting for 20-60 minutes, dry to obtain a white or light yellow powdery mixture product.

[0033] For the application of the modified sugar reducing agent prepared above in the printing and dyeing industry, the reduction potential o...

Embodiment 1

[0034] Example 1 The raw material quality ratio of the present invention is as follows:

[0035] Sugar: 54.2 kg

[0036] Formaldehyde: 5.5 kg

[0037] Sodium metabisulfite: 15 kg

[0038] Sodium hydroxide: 0.1 kg

[0039] Erythorbic acid: 0.1 kg

[0040] Ethylenediaminetetraacetic acid divalent iron double salt: 0.1 kg

[0041] H 2 O: 25 kg.

[0042]The preparation method of the present invention has the following steps: slowly add formaldehyde (concentration 37%-40%) to the reactor containing sugar, sodium hydroxide and water, control the mixing reaction temperature below 15°C, stir at a speed of 50r / min, and add After the formaldehyde is finished, the mixing reaction temperature is raised to 20°C at a heating rate of 1°C / min. After 30 minutes of reaction, sodium metabisulfite is added. The mixing reaction temperature during the addition is 20°C. After the sulfonating agent is added, the temperature is 1°C. The temperature of the mixed reaction is raised to 90℃ with a heating rat...

Embodiment 2

[0043] Example 2 The raw material quality ratio of the present invention is as follows:

[0044] Raw materials and formula (unit-kg):

[0045] Sugar: 50.8 kg

[0046] Paraformaldehyde: 12.1 kg

[0047] Sodium bisulfite: 15.4 kg

[0048] Sodium acetate: 0.3 kg

[0049] Ascorbic acid: 0.9 kg

[0050] Ethylenediaminetetraacetic acid disodium divalent iron double salt: 0.6 kg

[0051] H 2 O: 19.9 kg.

[0052] The preparation method of the present invention has the following steps: slowly add paraformaldehyde (concentration: 95%-97%) to the reactor containing sugar, sodium acetate, and water, control the mixing reaction temperature below 15°C, and stir at 60r / min After the addition of fatty aldehydes, the temperature of the mixing reaction was raised to 30℃ at a temperature increase rate of 1℃ / min, and sodium bisulfite was added after the mixing reaction for 40 minutes. The mixing reaction temperature during the addition was 30℃, and the sulfonation was completed. After the preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com