Hard alloy part with diamond coating and preparation method of hard alloy part

A technology of diamond coating and hard alloy, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the difficult physical property matching degree and coating thermal stress relief, and cannot prevent cobalt For problems such as diamond graphitization and affecting the bonding force between the film and the substrate, it can achieve excellent film-substrate bonding strength, prevent graphitization, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

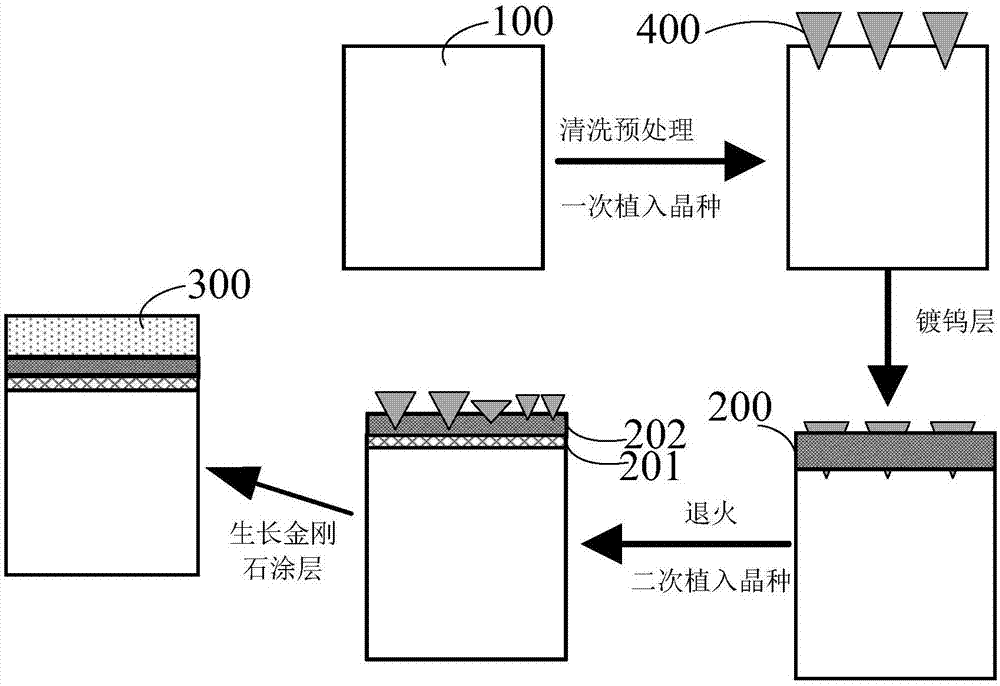

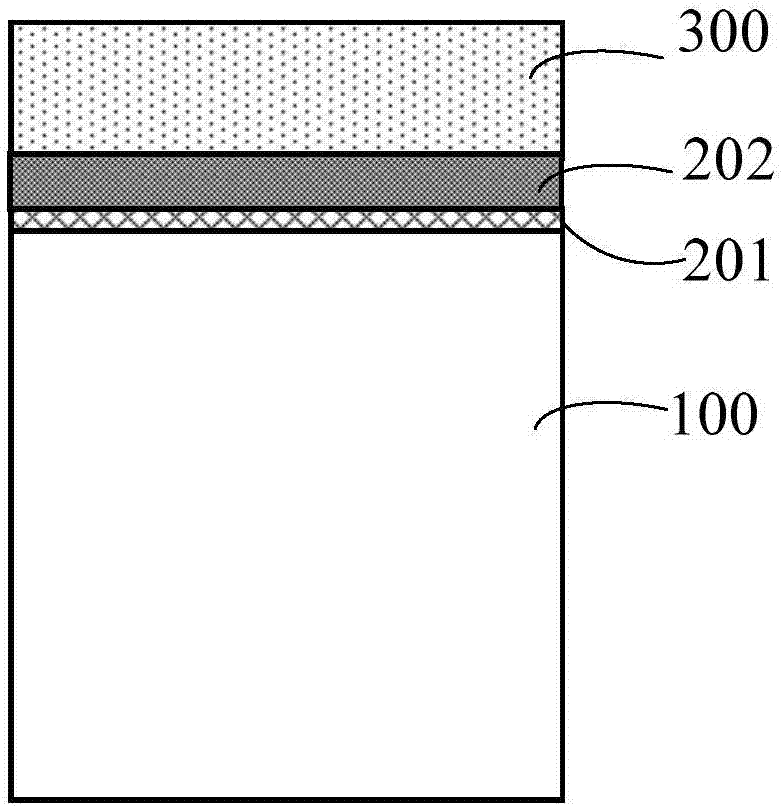

[0048] see figure 1 , a kind of preparation method with the cemented carbide part of diamond coating, comprises the following steps:

[0049] (1) Use the YG6X (WC-6wt.% Co) cemented carbide indexing insert sold in the domestic market as the substrate, and perform cleaning and pretreatment to remove the stains on the surface of the substrate: first place the substrate in acetone for ultrasonic cleaning 30min, the ultrasonic power is 100W, and then put the acetone-cleaned substrate into the ethanol solution, ultrasonically clean at 100W for 2min, and dry;

[0050] (2) Put the cleaned matrix into an acetone suspension containing diamond powder (particle size: 300nm), and perform ultrasonication for 60 minutes at a power of 100W to implant diamond crystal seeds on the surface of the matrix, take it out and clean it with alcohol , and finally blow dry with nitrogen to obtain the inoculated matrix;

[0051] (3) Deposit a metal tungsten layer with a thickness of 100nm on the surfac...

Embodiment 2

[0058] A method for preparing a hard alloy part with a diamond coating, comprising the following steps:

[0059] (1) Use the YG8 (WC-8% Co) cemented carbide end mill sold in the domestic market as the substrate, and carry out cleaning pretreatment to remove the stains on the surface of the substrate: first place the substrate in acetone for ultrasonic cleaning for 40 minutes , the ultrasonic power is 110W, and then the acetone-cleaned substrate is put into an ethanol solution, ultrasonically cleaned at 120W for 1min, and dried;

[0060] (2) Put the cleaned matrix into an acetone suspension containing diamond powder (particle size: 300nm), and perform ultrasonication for 45 minutes at a power of 80W to implant diamond crystal seeds on the surface of the matrix, take it out and clean it with alcohol , and finally blow dry with nitrogen to obtain the inoculated matrix;

[0061] (3) Deposit a metal tungsten layer with a thickness of 150nm on the surface of the substrate after the...

Embodiment 3

[0067] A method for preparing a hard alloy part with a diamond coating, comprising the following steps:

[0068] (1) Use the YT15 (WC-15% TiC, Co) cemented carbide blade sold on the domestic market as the substrate to carry out cleaning pretreatment to remove the surface stains of the substrate: first place the substrate in acetone for ultrasonic cleaning for 60 minutes, The ultrasonic power is 90W, and then the acetone-cleaned substrate is put into an ethanol solution, ultrasonically cleaned at 100W for 5min, and dried;

[0069] (2) Put the cleaned matrix into an acetone suspension containing diamond powder (particle size: 500nm), and perform ultrasonication for 30 minutes at a power of 110W to implant diamond crystal seeds on the surface of the matrix, take it out and clean it with alcohol , and finally blow dry with nitrogen to obtain the inoculated matrix;

[0070] (3) Deposit a metal tungsten layer with a thickness of 200nm on the surface of the substrate after the diamo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com