Solar cell back electrode passivation layer preparation technology based on surface oxidation method

A technology of surface oxidation and back electrode, which is applied in the field of solar cells, can solve the problems of high deposition energy of Mo thin films and affect the quality of the battery interface, and achieve the effect of improving the combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

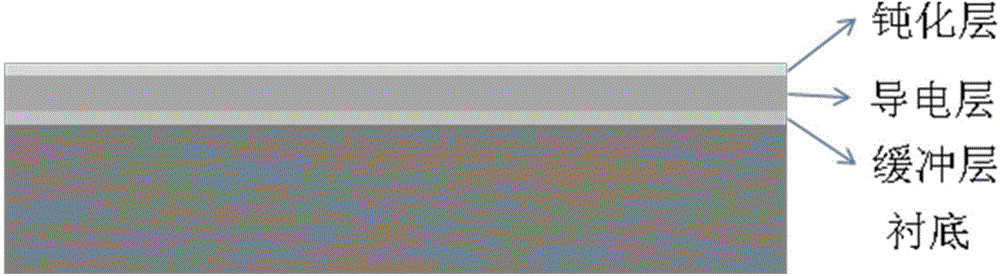

[0020] 1. Put the cleaned substrate into the vacuum chamber of the magnetron sputtering equipment, wait for the background vacuum of DC sputtering to be 3-9E-7mTorr, start the magnetron sputtering process to deposit Mo film, and prepare the substrate buffer layer (2). The Mo buffer layer (2) is deposited with a thickness of 50-500nm under the pressure of 8-12mTorr and the power of 200-400w.

[0021] 2. On the basis of the buffer layer, change the process parameters, and continue to deposit the Mo conductive layer (3) with a thickness of 100-1000 nm.

[0022] 3. After the conductive layer (3) reaches the required thickness, change the working gas to a mixed gas of argon and oxygen, and the flow rate of oxygen is 10-50% of that of argon. A MoO2-doped Mo passivation layer (4) is deposited with a thickness of 30-200 nm.

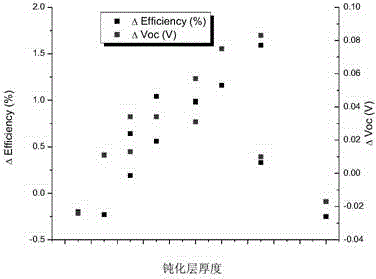

[0023] This composite electrode has good adhesion to the substrate, and at the same time, its sheet resistance is figure 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com