Thermoplastic elastomer for encapsulating PC/ABS, and preparation method thereof

A technology of thermoplastic elastomer and encapsulation, which is applied in the field of thermoplastic elastomer and its preparation, can solve the problem of no way to encapsulate polarity, etc., and achieve the effect of improving the combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

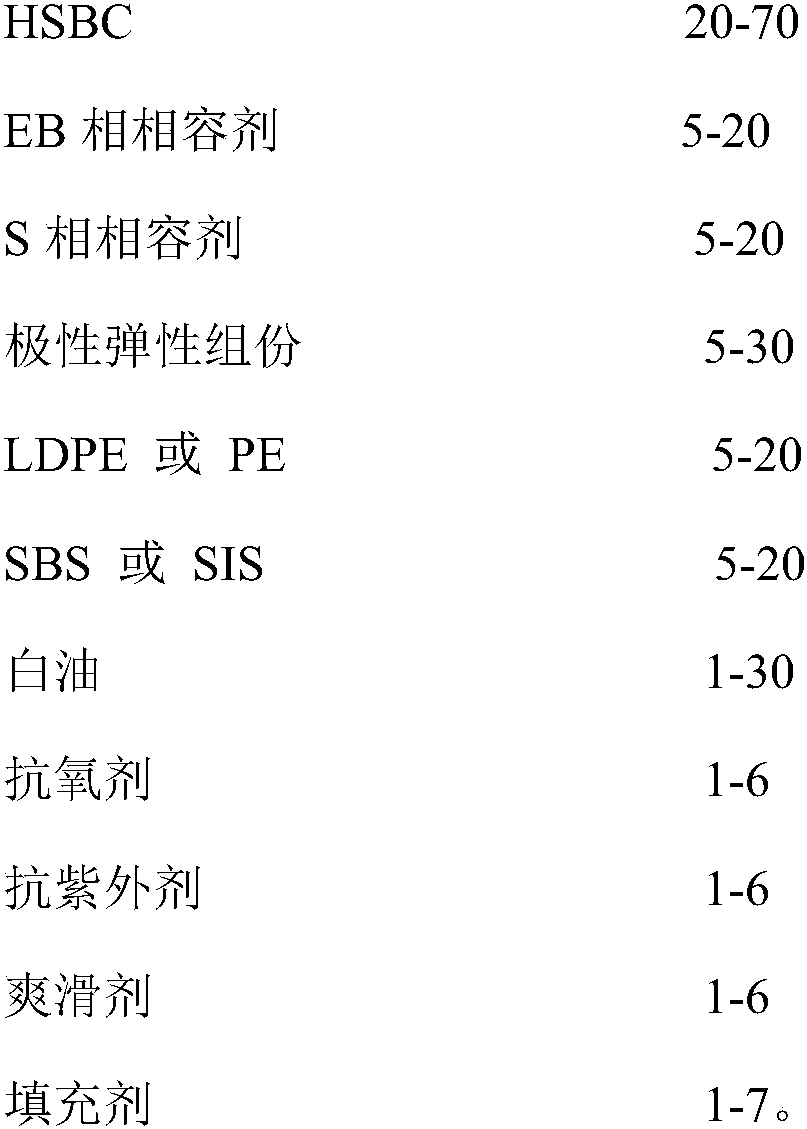

[0023] In order to achieve the purpose of the present invention, in one of the embodiments of the present invention, a thermoplastic elastomer for encapsulating PC / ABS is provided, which is prepared by the following components by weight:

[0024]

[0025]

[0026] Among them, HSBC is at least one of SEBS, SEPS, and SEEPS, the EB phase compatibilizer is at least one of MAH-PE, MAH-PP, and MAH-POE, the S phase compatibilizer is MAH-PS, and the polarity The elastic component is at least one of LA Polymer, TPU, and TPEE.

Embodiment 2

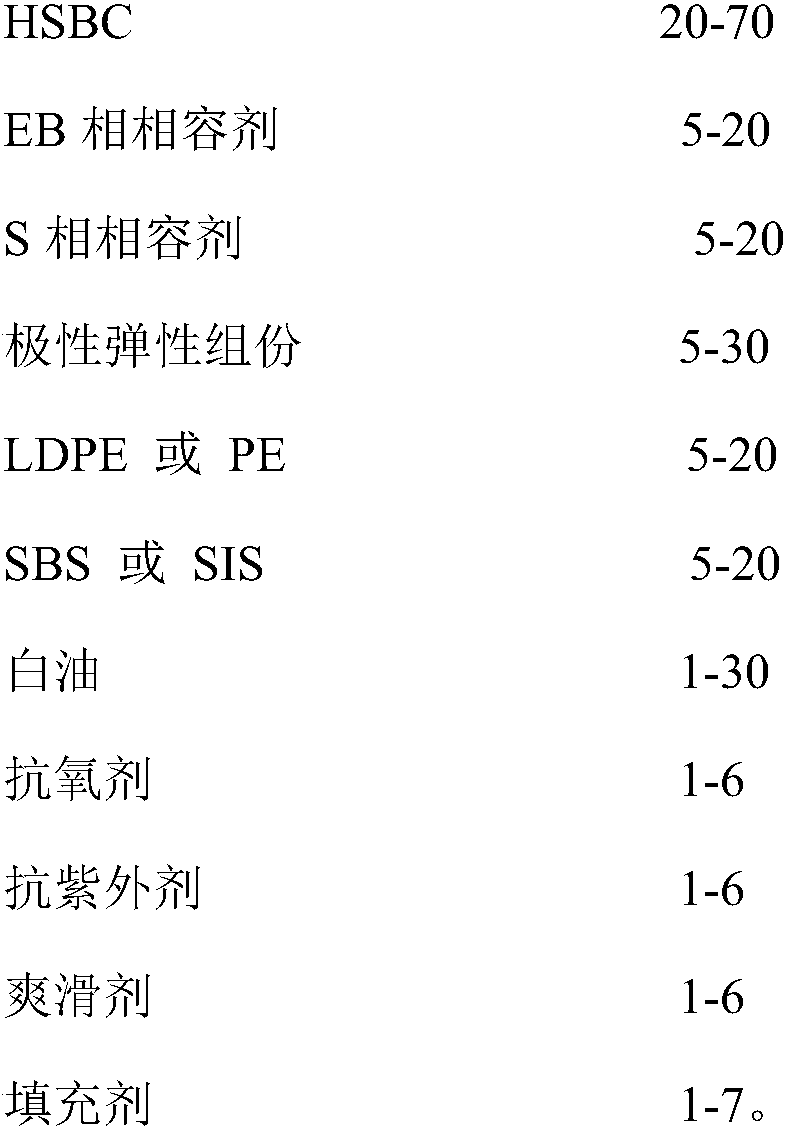

[0028] In order to achieve the purpose of the present invention, in one of the embodiments of the present invention, a thermoplastic elastomer for encapsulating PC / ABS is provided, which is prepared by the following components by weight:

[0029]

Embodiment 3

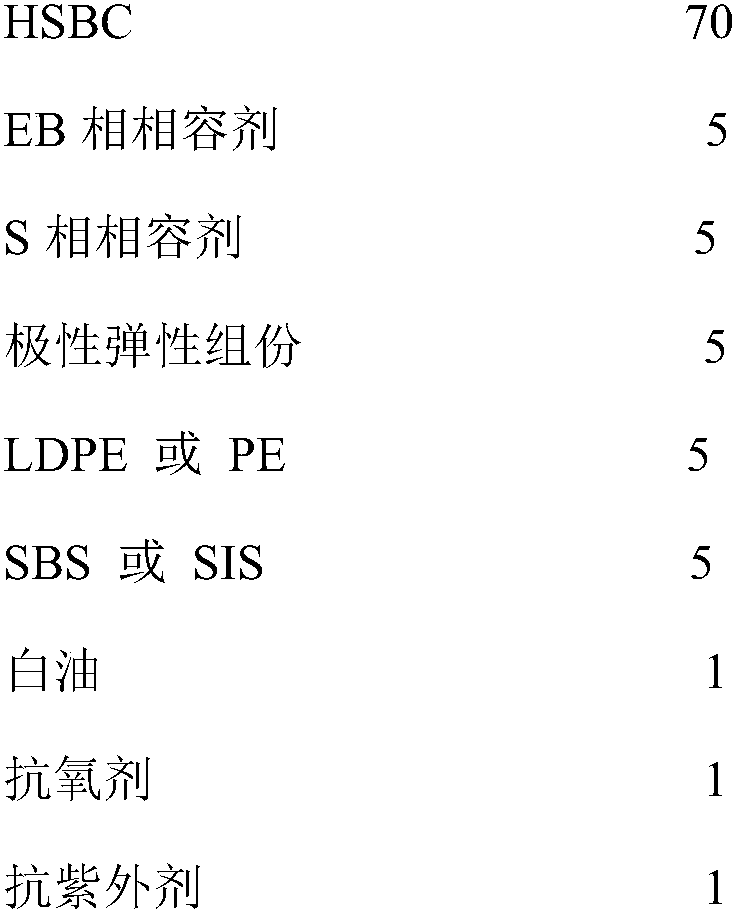

[0031] In order to achieve the purpose of the present invention, in one of the embodiments of the present invention, a thermoplastic elastomer for encapsulating PC / ABS is provided, which is prepared by the following components by weight:

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com