Three dimensional graphene oxide foamed material preparation method through natural drying of solution

A technology of graphene foam and natural drying, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of in-situ molding preparation, long preparation cycle, difficult operation, etc., and achieve low cost and short cycle , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

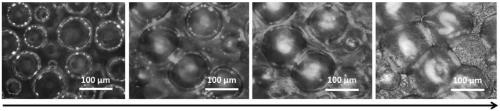

[0029] (1) 10 mL mass fraction of 20% alkyl glycoside (2 g) solution is added to 90 mL concentration of graphene oxide aqueous solution (average particle diameter of graphene oxide is 10 μm) of 16 mg / mL, first with 100 r / min Stir at a slow speed for 2 minutes to mix the alkyl glucoside solution and the graphene oxide aqueous solution evenly, then stir and foam at a speed of 2500r / min, stir for 5 minutes so that the volume of the solution after foaming is 2.0 times the volume of the solution before foaming, and obtain a foam Bubbled graphene oxide viscous solution;

[0030] (2) adopt scraping method to tile the graphene oxide viscous solution of foaming on the aluminum plate base, and the average thickness of the graphene oxide viscous solution of the foaming of the substrate is 5mm, then naturally dry, in A three-dimensional graphene oxide foam material with a thickness of 2.3mm is obtained on the substrate;

[0031] (3) spread the foamed graphene oxide viscous solution prepa...

Embodiment 2

[0036] (1) Add 10 mL of alkyl glycoside solution with a mass fraction of 20% to 90 mL of graphene oxide aqueous solution (average particle size of graphene oxide is 15 μm) with a concentration of 12 mg / mL, and stir slowly at a speed of 100 r / min Mix the alkyl glucoside solution and the graphene oxide aqueous solution evenly for 2 minutes, then stir and foam at a speed of 2500r / min, stir for 5 minutes so that the volume of the solution after foaming is 2.0 times the volume of the solution before foaming, and obtain the foamed oxide Graphene viscous solution;

[0037] (2) adopt scraping method to tile the graphene oxide viscous solution of foaming on the aluminum plate substrate, and the average thickness of the graphene oxide viscous solution of the foaming of substrate is 3mm, then naturally dry, in A three-dimensional graphene oxide foam material with a thickness of 1.5mm is obtained on the substrate.

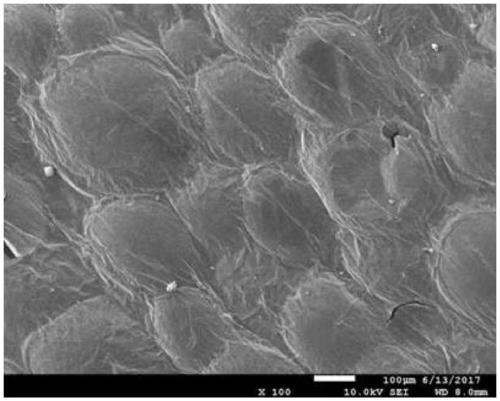

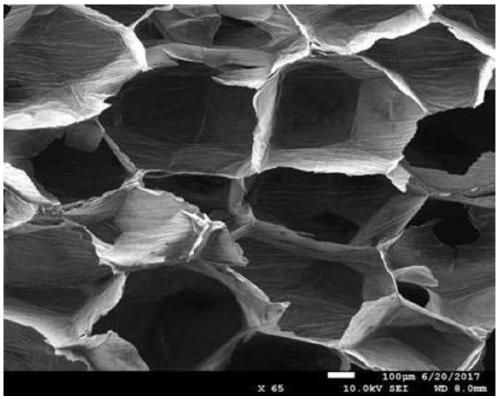

[0038] The prepared three-dimensional graphene oxide foam material was c...

Embodiment 3

[0040] (1) Add 8 mL of alkyl glycoside solution with a mass fraction of 20% to 72 mL of graphene oxide aqueous solution (average particle size of graphene oxide is 10 μm) with a concentration of 16 mg / mL, and stir slowly at a speed of 100 r / min Mix the alkyl glucoside solution and the graphene oxide aqueous solution evenly for 2 minutes, then stir and foam at a speed of 2500r / min, stir for 5 minutes so that the volume of the solution after foaming is 2.5 times the volume of the solution before foaming, and obtain the foamed oxide Graphene viscous solution;

[0041] (2) adopt scraping method to tile the graphene oxide viscous solution of foaming on the aluminum plate base, and the average thickness of the graphene oxide viscous solution of the foaming of the substrate is 5mm, then naturally dry, in A three-dimensional graphene oxide foam material with a thickness of 2.7 mm was obtained on the substrate.

[0042] The prepared three-dimensional graphene oxide foam material was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com