Silicon capacitance pressure sensor

A pressure sensor and silicon capacitor technology, applied in the sensor field, can solve the problems of capacitive signal interference and unfavorable measurement accuracy of capacitive sensors, and achieve the effects of reducing temperature drift, reasonable structure and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

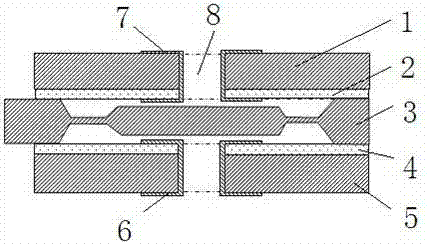

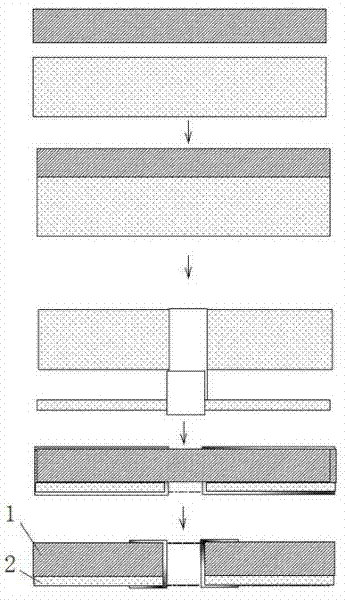

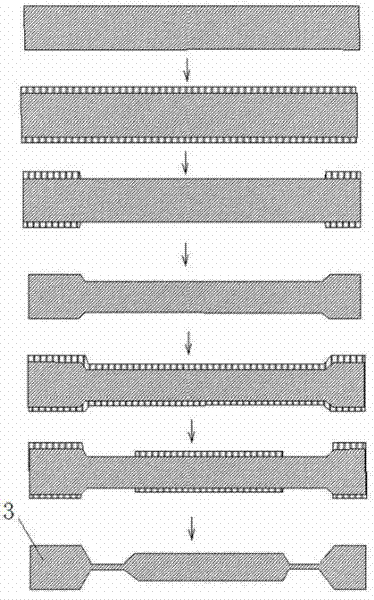

[0026] like Figure 1 to Figure 6 As shown, a silicon fixed pole plate is respectively connected to the upper and lower sides of the silicon center movable pole plate 3 of the island film structure, and the upper silicon fixed pole plate includes the silicon upper pole plate 1 and the glass connecting layer that are electrostatically sealed. 2. The lower silicon fixed plate includes a silicon lower plate 5 and a glass connecting layer 4 that are electrostatically sealed; the middle part of the silicon fixed plate is provided with a central pressure hole 8, which is in the central pressure hole and close to the center. The outer surface of the silicon fixed plate at the upper and lower parts of the press hole is provided with an aluminum film lower electrode 6 and an aluminum film upper electrode 7; thus forming a five-layer sensitive core with "silicon-glass-silicon-glass-silicon" from top to bottom Capacitive pressure sensor with body core structure.

[0027] The core sensit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com