Manufacturing method of crystalline silicon solar cell resistant to PID effect

A technology of solar cells and manufacturing methods, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as accelerated aging of components and plastic pipelines, white spots on the appearance of batches, and ozone is harmful to the human body, and achieve low surface state Density, raw materials are non-toxic, and the effect of improving passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

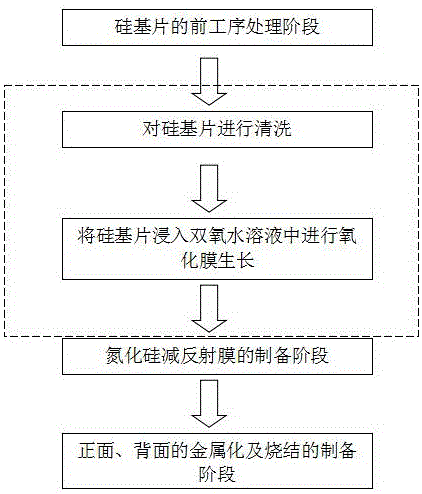

[0047] A kind of method using hydrogen peroxide to prepare anti-PID film, its step comprises:

[0048] (1) Etch and remove the edge of the diffused silicon wafer, wash and remove the phosphosilicate glass layer; the solution used for cleaning is hydrofluoric acid aqueous solution, the mass concentration of hydrofluoric acid aqueous solution is 8%, the solution temperature is 25 ° C, and the cleaning solution is The time is 50s;

[0049] (2) After 10 minutes, immerse the silicon wafer in a hydrogen peroxide solution to grow an oxide film. The temperature of the solution is 25°C, the concentration of hydrogen peroxide is 3%, the treatment time is 4 minutes, and the thickness of the ozone oxide layer is 2nm;

[0050] (3) After 10 minutes, deposit a silicon nitride film on the silicon wafer to be processed; the thickness of the silicon nitride film is 84 nm, and the refractive index is 2.08.

Embodiment 2

[0052] A kind of method using hydrogen peroxide to prepare anti-PID film, its step comprises:

[0053] (1) Etch and remove the edge of the diffused silicon wafer, wash and remove the phospho-silicate glass layer; use hydrofluoric acid aqueous solution for cleaning, the mass concentration of hydrofluoric acid aqueous solution is 5%, the solution temperature is 20°C, and the cleaning time is 150s;

[0054] (2) After 20 minutes, immerse the silicon wafer in a hydrogen peroxide solution to grow an oxide film. The temperature of the solution is 40°C, the concentration of hydrogen peroxide is 6%, the treatment time is 2 minutes, and the thickness of the formed silicon dioxide oxide layer is 4nm;

[0055] (3) After 30 minutes, deposit a silicon nitride film on the silicon wafer to be processed; the thickness of the silicon nitride is 81 nm, and the refractive index is 2.07.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com