Patents

Literature

66results about How to "Solve brightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for detecting moving objects

ActiveCN101739550ARealize detectionFix image shakeImage analysisCharacter and pattern recognitionAnomaly detectionBackground image

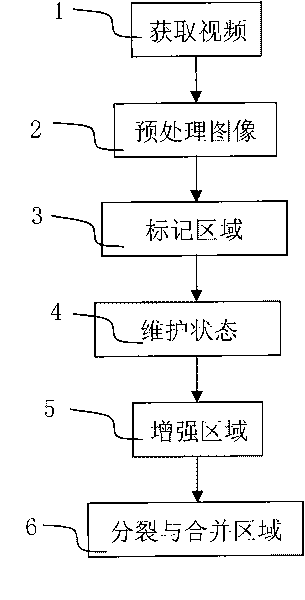

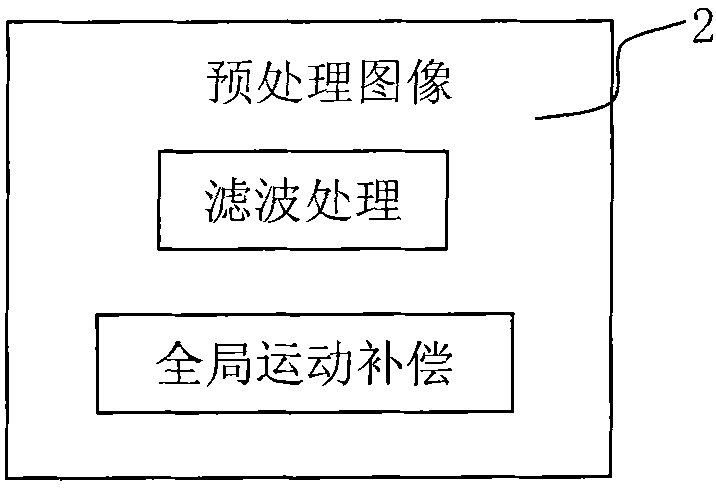

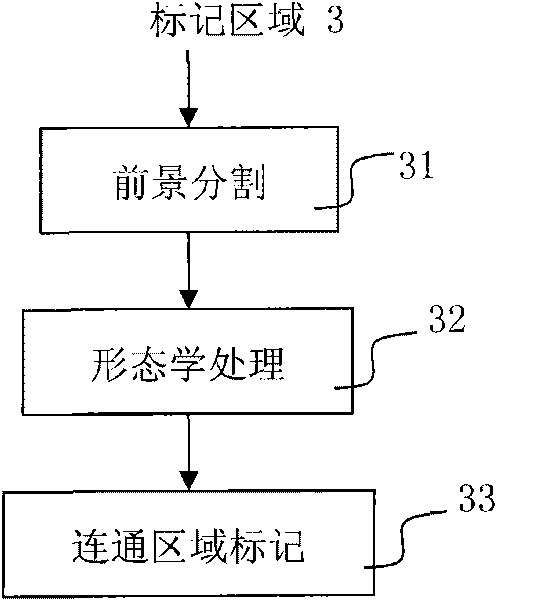

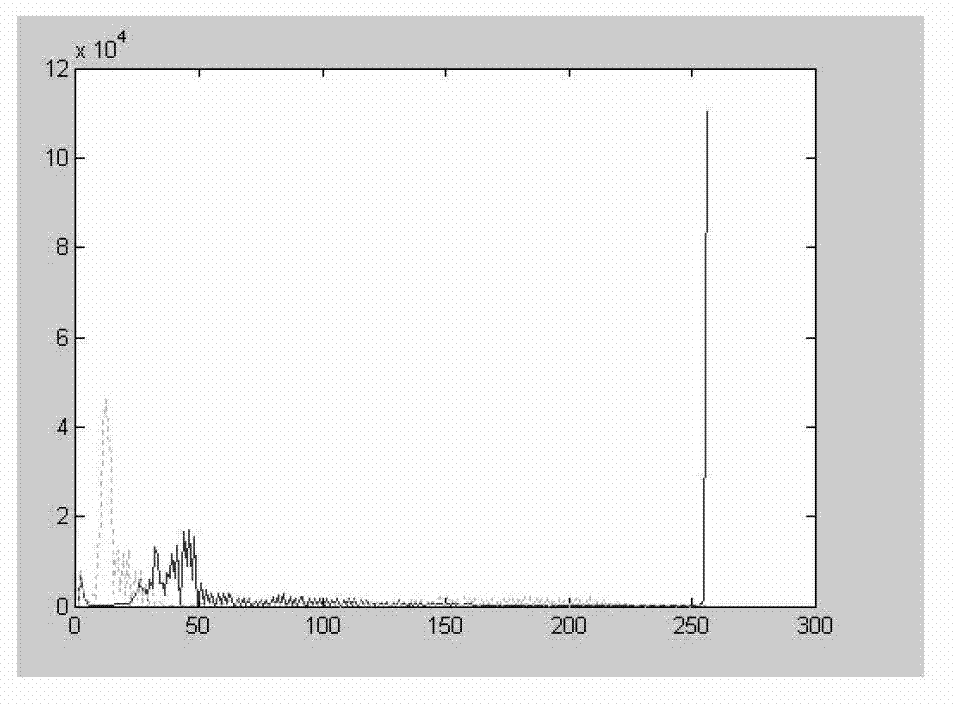

The invention provides a method and a system for detecting moving objects. The method for detecting the moving objects comprises the following steps: acquiring video, namely acquiring video contents to obtain a scene image, and establishing a background model; preprocessing the image to eliminate the influence of the background image on the background model; marking areas, namely partitioning a foreground from the scene image according to the background model, and marking communicated areas; maintaining a state, namely judging the current state of a moving object detection system, performing corresponding processing, and performing abnormal detection if necessary; enhancing the areas, namely removing the false areas of shadow, high brightness and leaf swing by using shadow detection, high brightness detection and tree filter; and splitting and merging the areas, namely splitting and merging the areas by using the restriction provided by the background model and the priori knowledge of human and vehicle models to solve the problem of over partition and mutual shading of the objects. The method and the system detect the moving objects, and solve the problems of image jitter, brightness change, shadow, leaf swing and the like.

Owner:NETPOSA TECH

Image processing method and image processing device

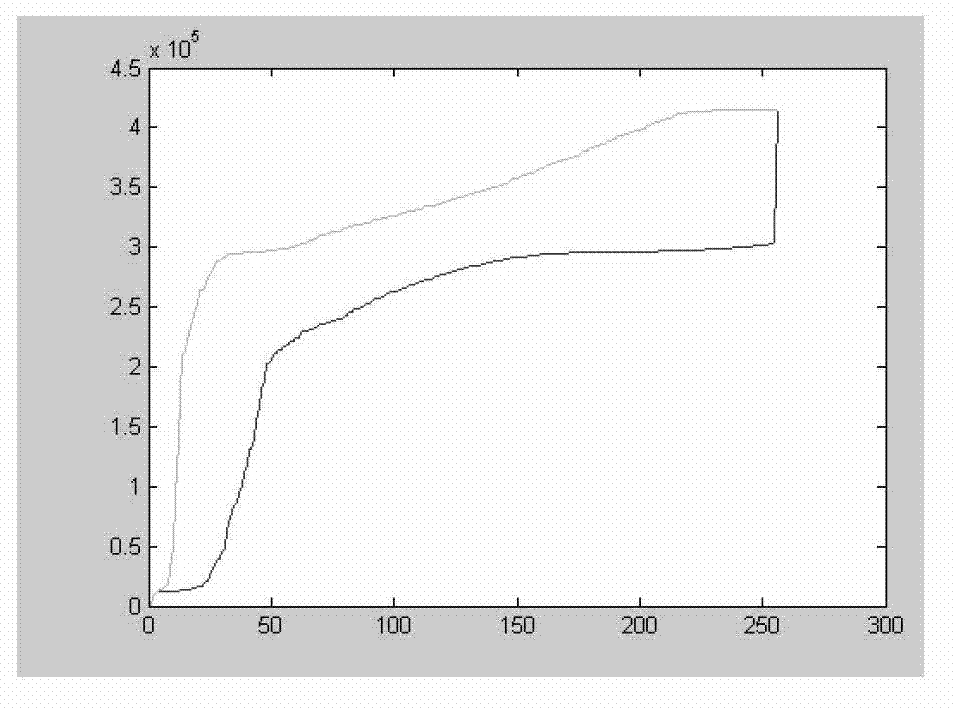

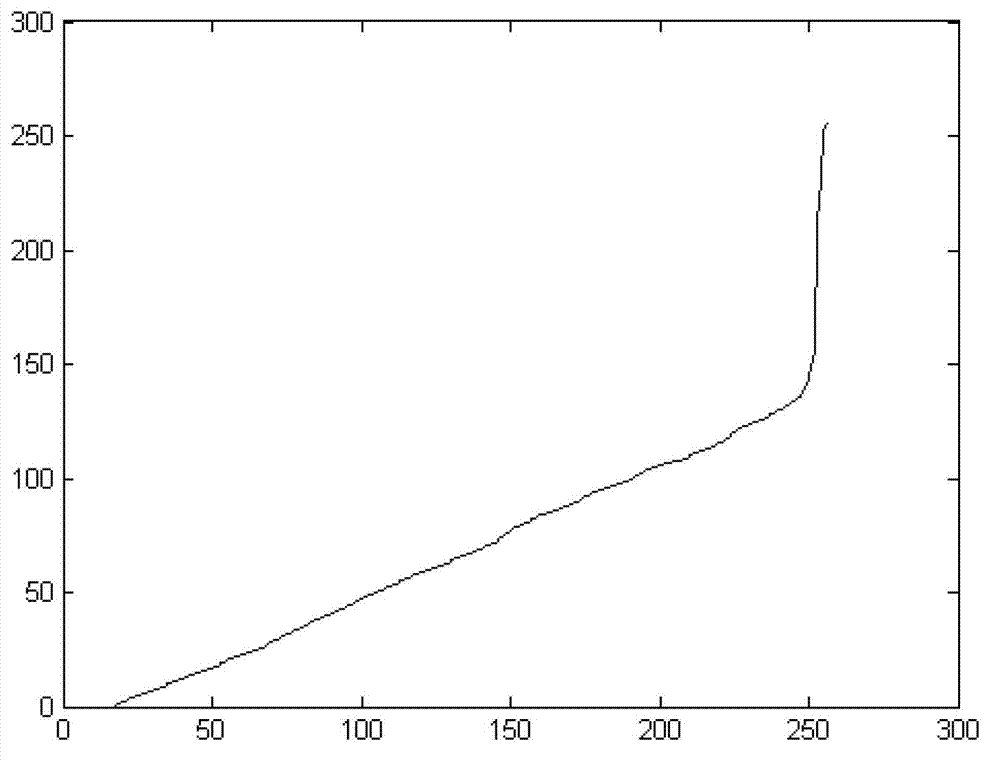

ActiveCN102970549AResolve colorSolve brightnessTelevision system detailsImage enhancementImaging processingExposure Elapsed Time

The invention provides an image processing method and an image processing device. The image processing method comprises steps of collecting at least two exposure frames of different brightness of the same scene in different exposure times; for every exposure frame, combining raw data units which are subjected to repeated permutation in the exposure frame, and obtaining the combined first brightness data; and acquiring correction parameters of all exposure frames in accordance with all first brightness data, conducting weighting for all exposure frames in accordance with correction parameters, and obtaining a High Dynamic Range (HDR) image of corrected raw data. By the aid of the method, the problem of serious distortion of color, brightness and contrast of the image acquired from Raw data through the prior art is solved.

Owner:HUAWEI TECH CO LTD

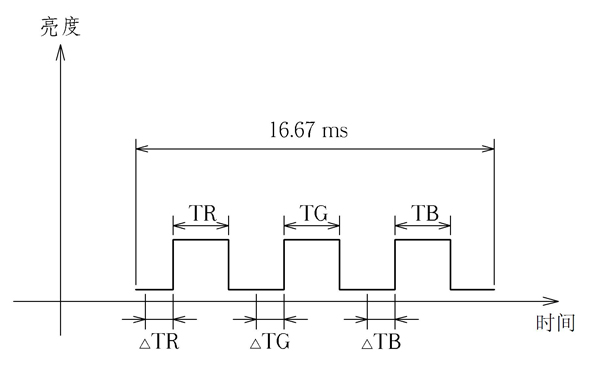

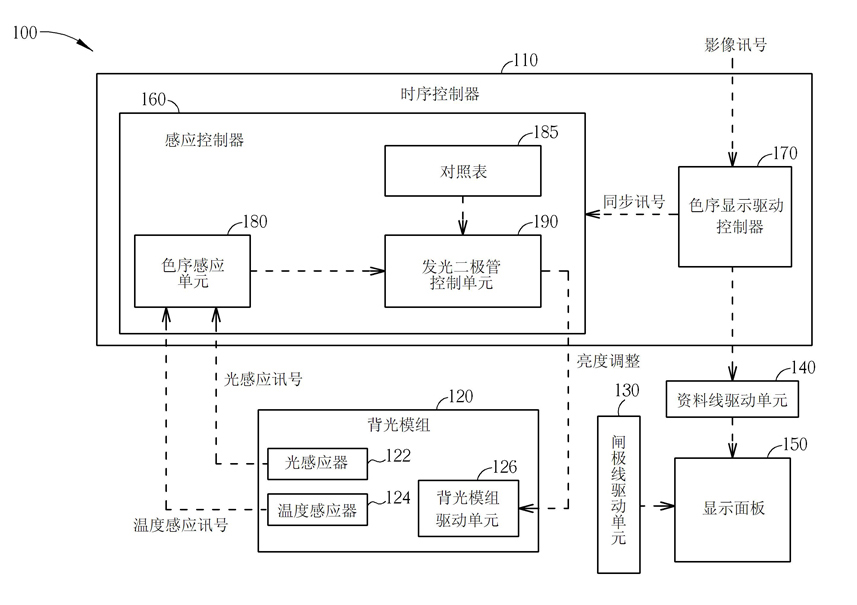

Method for adjusting luminosity of display and related backlight module

InactiveCN101833928ASolve brightnessStable brightnessStatic indicating devicesLuminosityDisplay device

The invention relates to a method for adjusting the luminosity of a display and a related backlight module. The standard luminosity is found according to the detected temperature and actual luminosity of the backlight module and a target luminosity value used by the display. In addition, when the actual luminosity is adjusted, the influence caused by ambient light is also considered, so that the adjusted actual luminosity is not interfered by the ambient light. The method solves the problem of the luminance of the common color sequence type display is insufficient when the luminance of the light-emitting diode of the backlight module is non-linearly changed and the light-emitting diode is aged caused by the factors such as the increment of service time, the change of the temperature and the like.

Owner:HUAYING OPTOELECTRONICS

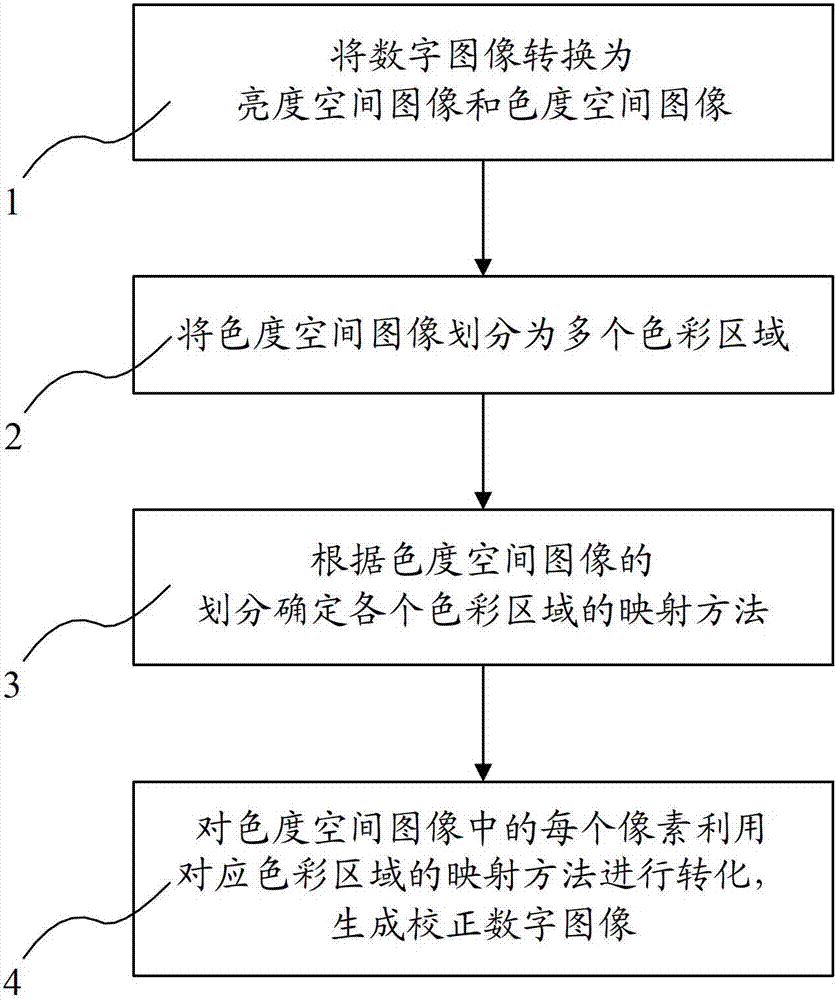

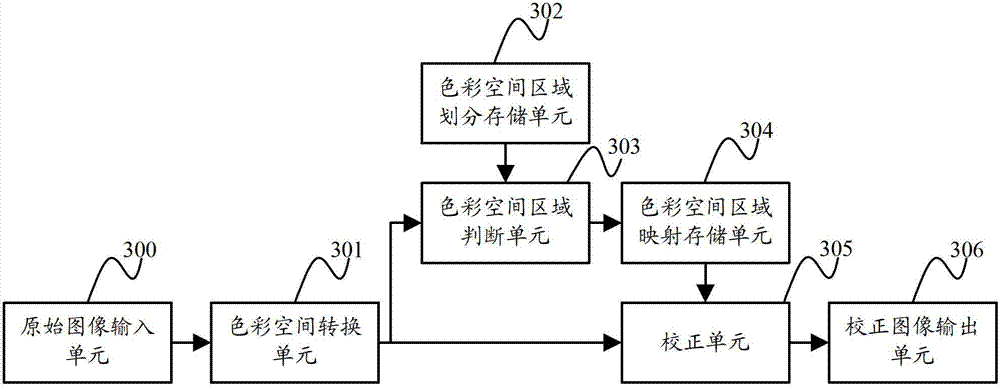

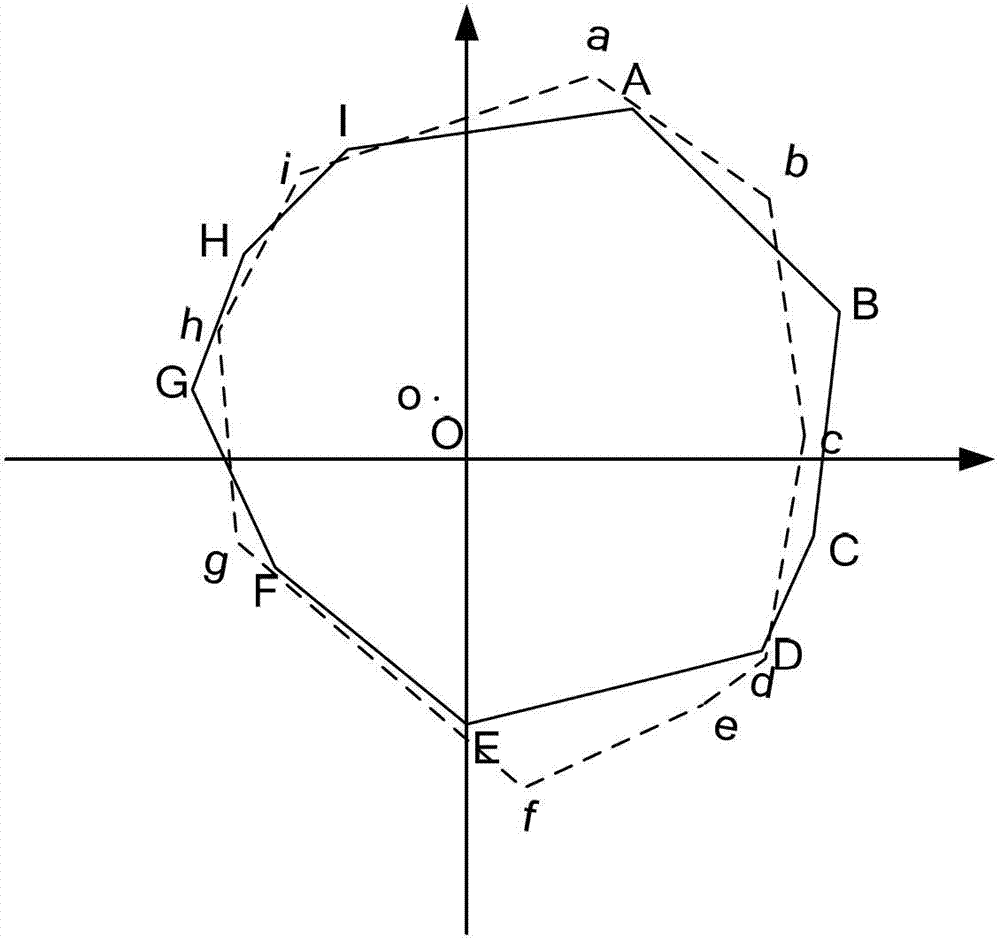

Digital image color correcting method and realizing device

The invention relates to a digital image color correcting method and a realizing device which belong to the technical field of digital image processing. The digital image color correcting method includes firstly converting a digital image into a luminance space image and a hue space image; diving the hue space image into multiple color areas; dividing and determining a mapping method of each color area according to the hue space image; converting pixel of the corresponding color area by the determined mapping method, and finally generating a corrected digital image. The problem that only some color areas can be corrected by a linear correcting method is solved by the method and the device, and meanwhile, the problems of high operational difficulty and possible change of input image luminance are solved. The digital image color correcting method and the realizing method can correct color of the image on the premise without changing the input image luminance and is fine in correcting effect, low in complexity, convenient in realizing ways, low in realizing cost and wider in application range.

Owner:SHANGHAI FULLHAN MICROELECTRONICS

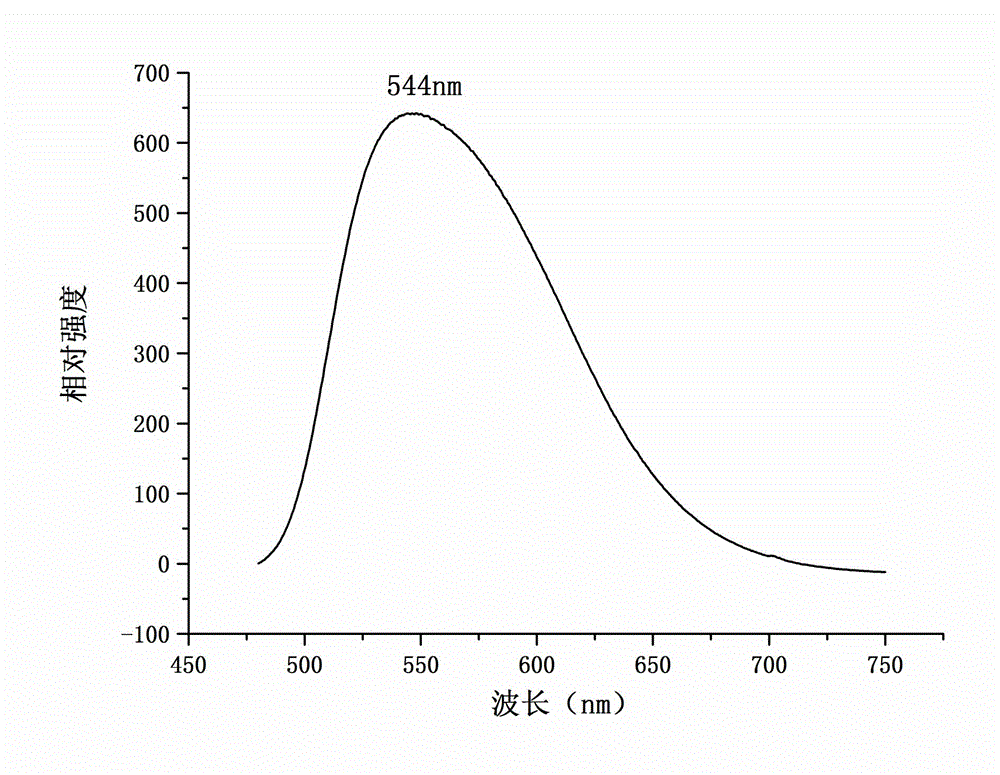

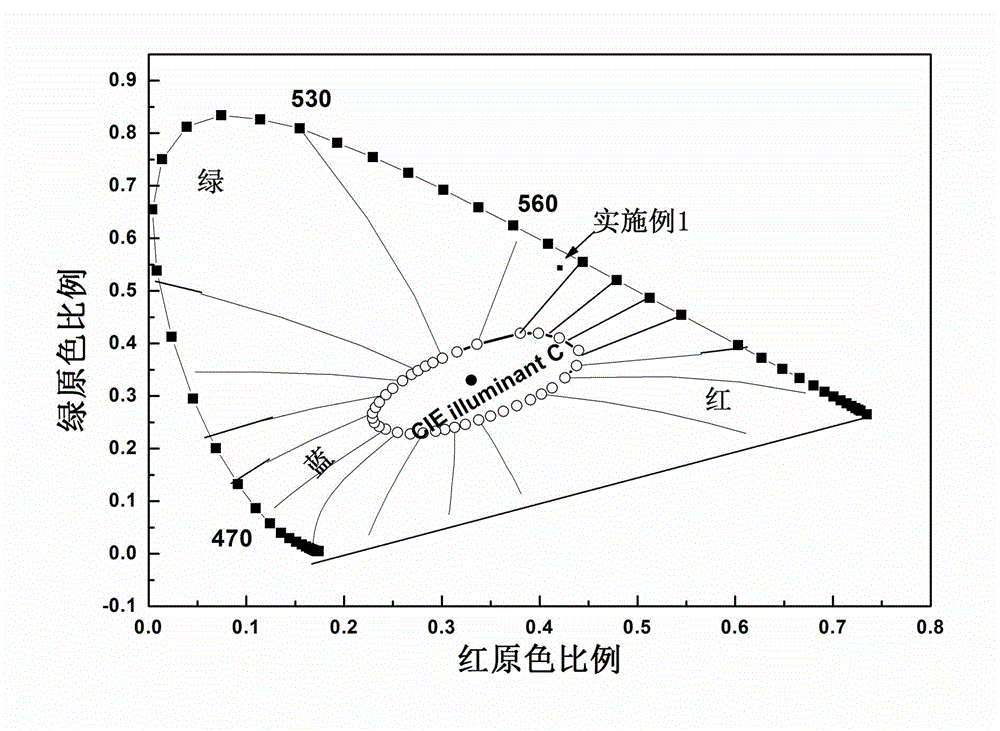

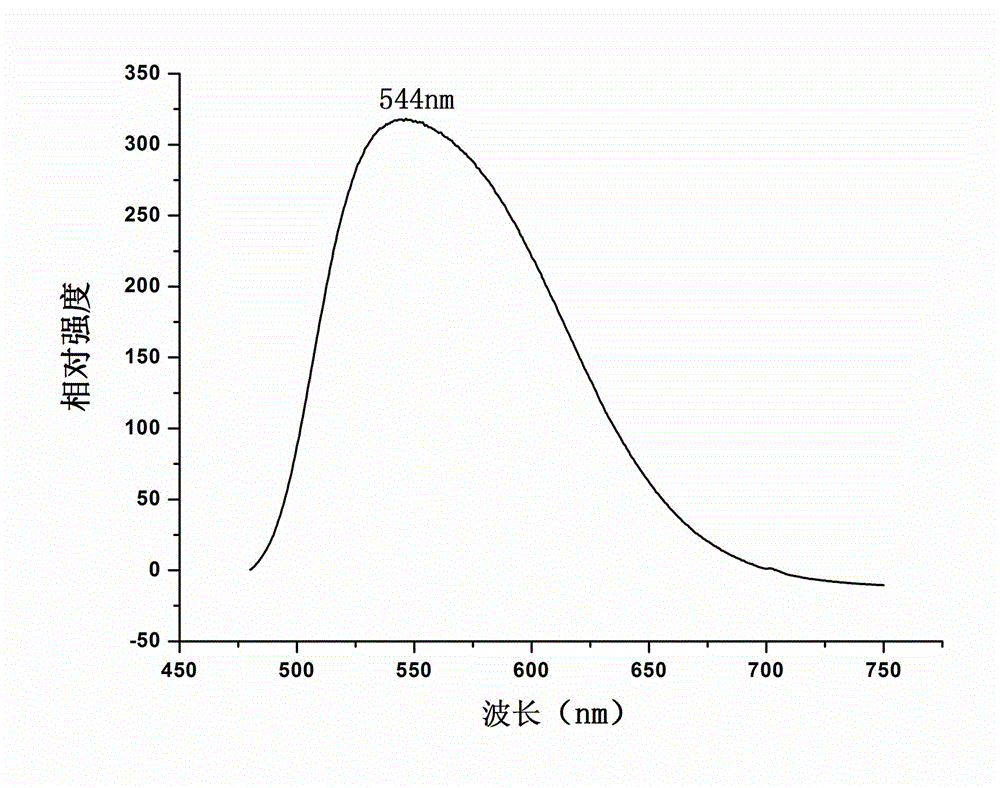

Composite phosphor luminescent glass and preparation method for same

InactiveCN102745893AImprove luminous performanceGood chemical stabilityPhotochemistryComposite material

The invention relates to a composite phosphor luminescent glass and a preparation method for the same. The ingredients of the composite phosphor luminescent glass is ~~~ glass powder and phosphor, wherein the ~~glass powder accounts for 80-95% by mass, and the phosphor accounts for 5-20% by mass. The preparation method for the composite phosphor ~~ luminescent glass comprises a first step of preparing ~~glass by using high temperature fusion technique, and a second step of mixing the glass powder and the phosphor uniformly for sintering to obtain the composite phosphor luminescent glass. The composite phosphor luminescent glass of the invention has good luminescent properties, and is mainly used to solve the problems that the phosphor is easily dampened during the use of LED devices, and resin is prone to aging during the packaging of the LED devices.

Owner:WUHAN UNIV OF TECH

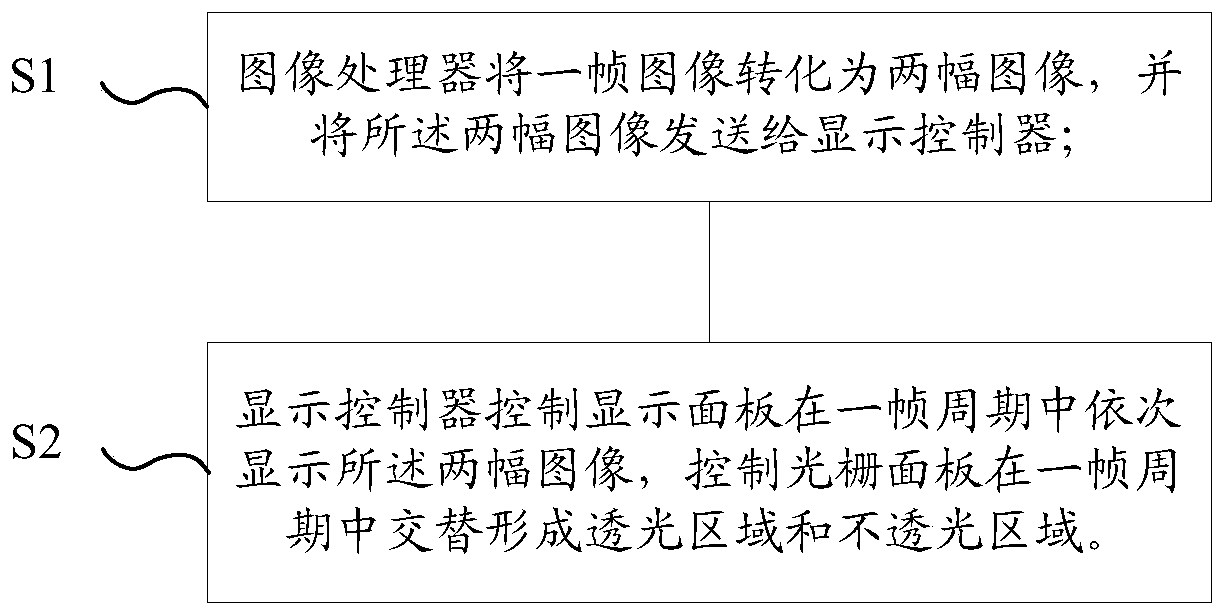

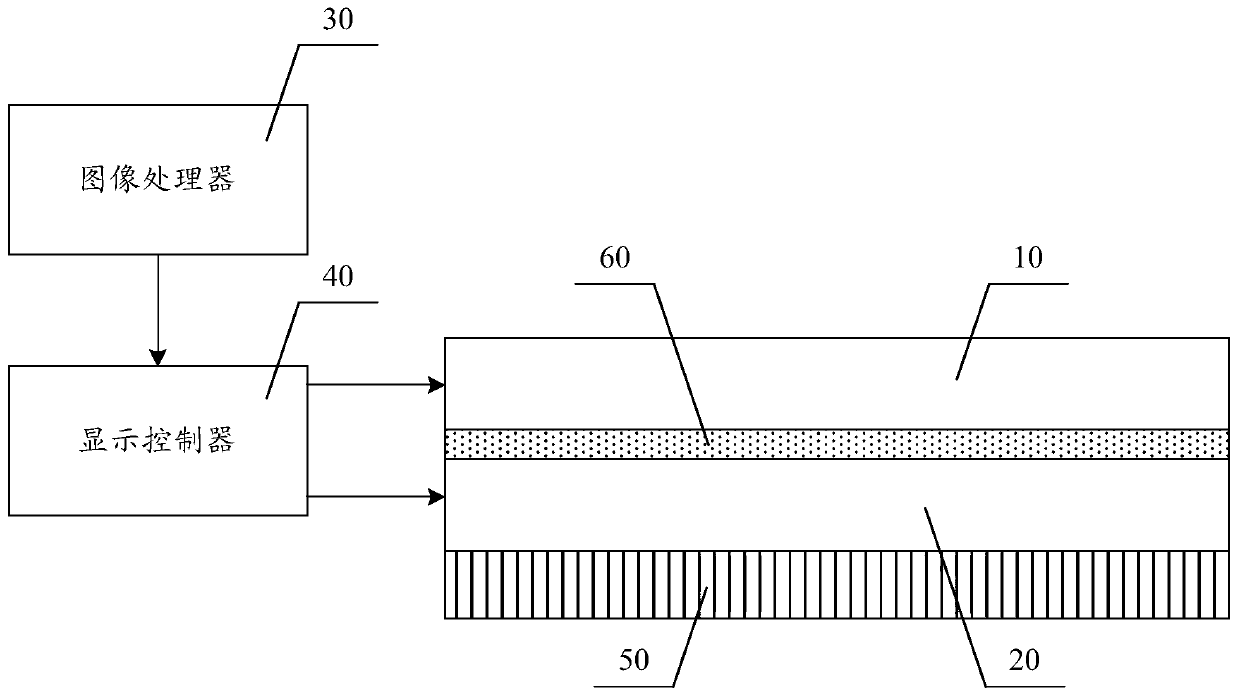

Display device and control method thereof

ActiveCN110264967ANo lossSolve brightnessStatic indicating devicesSteroscopic systemsImage resolutionTime-sharing

The embodiment of the invention provides a display device and a control method thereof. The control method of the display device comprises the steps that an image processor divides a frame of image into M images and sends the M images to a display controller, wherein the M is an even number larger than or equal to 2; and the display controller controls the display panel to sequentially display the M images in a frame period, and controls the grating panel to sequentially form grating patterns corresponding to the M images in the frame period. The invention discloses a double-layer panel structure based on a grating panel and a display panel. A frame of image is displayed in multiple times in a frame period, and grating patterns corresponding to the images displayed for multiple times are formed in sequence through time-sharing control, peep-proof display is achieved, switching between the peep-proof display mode and the shared display mode is achieved, and the display device has the advantages of being small in brightness loss, high in display resolution ratio, free of loss of peep-proof display state images and the like.

Owner:BOE TECH GRP CO LTD +1

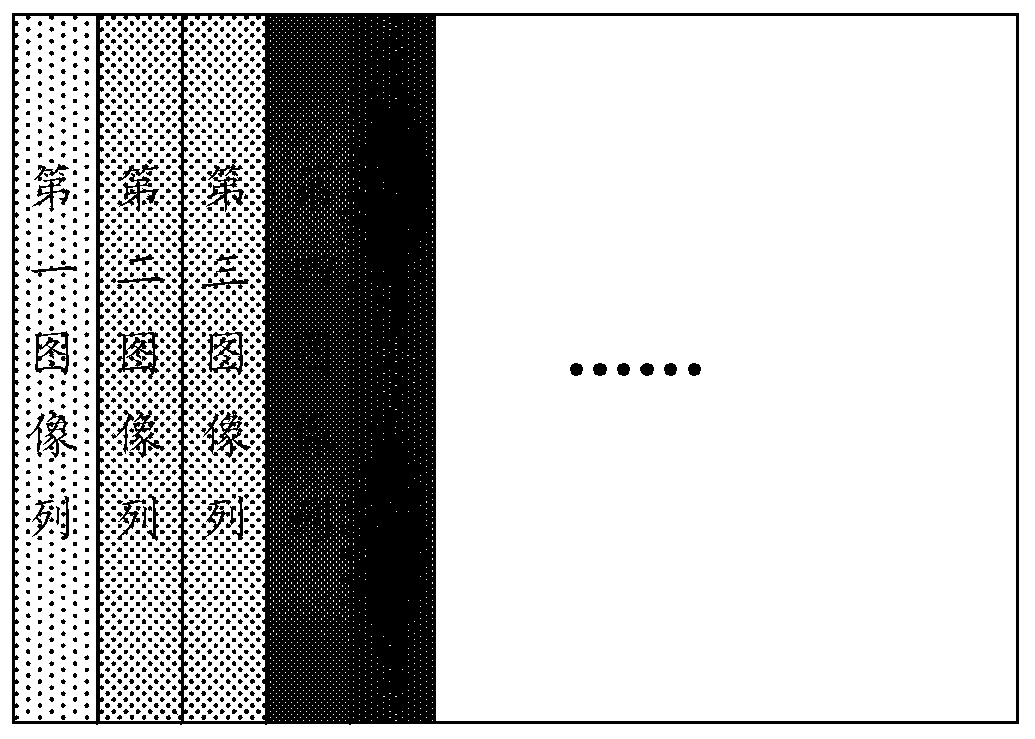

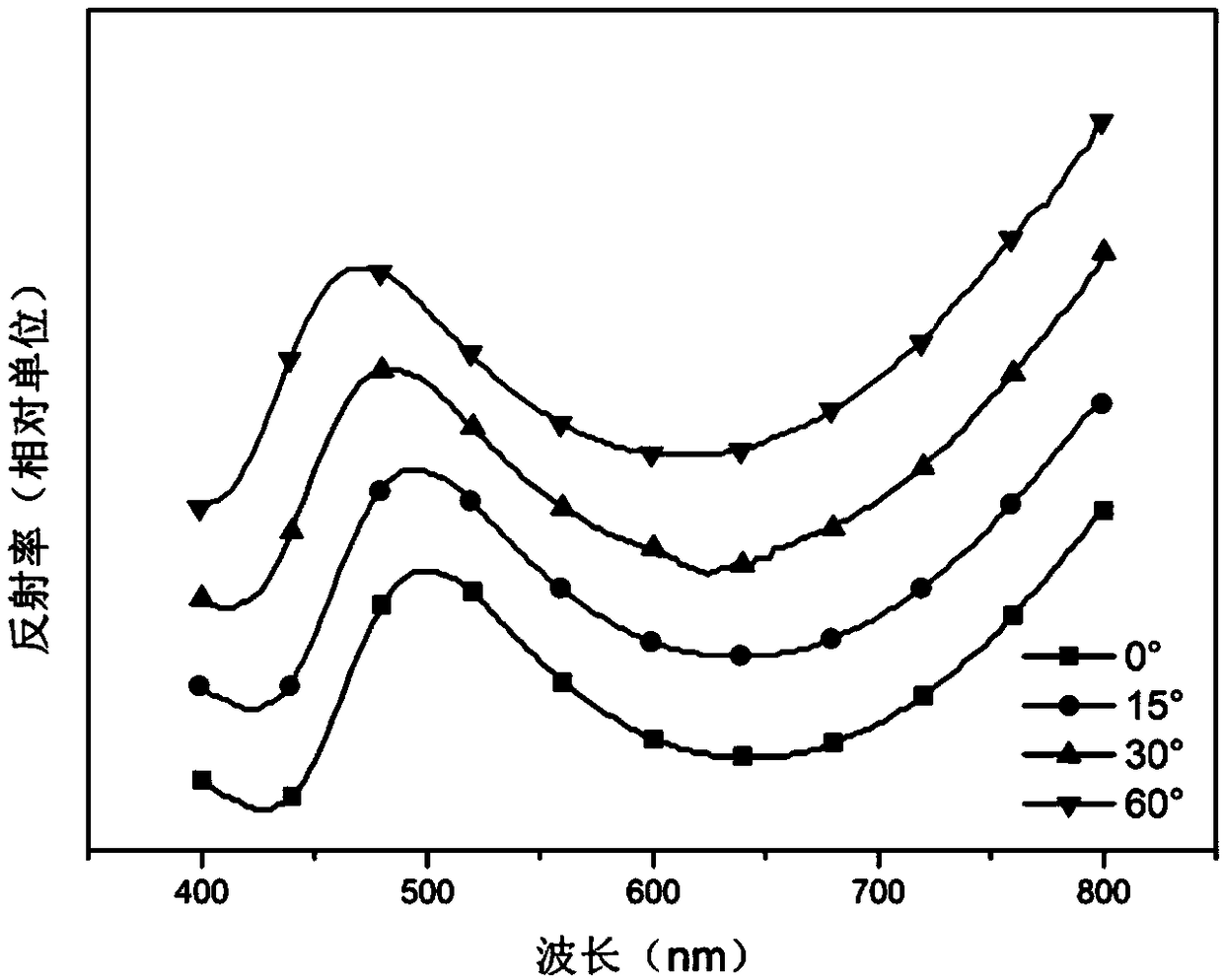

Composite photon structure material with generated color being high in luminance and low in angle dependence and preparation method thereof

ActiveCN109201438AIncrease brightnessSolve brightnessSpecial surfacesCoatingsAngle dependencePhotonic crystal

The invention discloses a composite photon structure material with generated color being high in luminance and low in angle dependence and a preparation method thereof. The method comprises the step that monodispersed nano microspheres, polymer emulsion with the same electric charge as the microspheres, and black light absorption substances are mixed and subjected to self-assembly under the heat-aiding condition, so that a composite structure photonic crystal film with the surface being in long-range order and the interior being unformed is obtained, wherein the prepared photonic crystal filmhas the structure color being high in luminance and low in angle dependence. The preparation method is simple in process, environmentally friendly and non-toxic and has the wide application prospect in the fields such as color display, coatings, textiles and ceramic.

Owner:SOUTH CHINA UNIV OF TECH

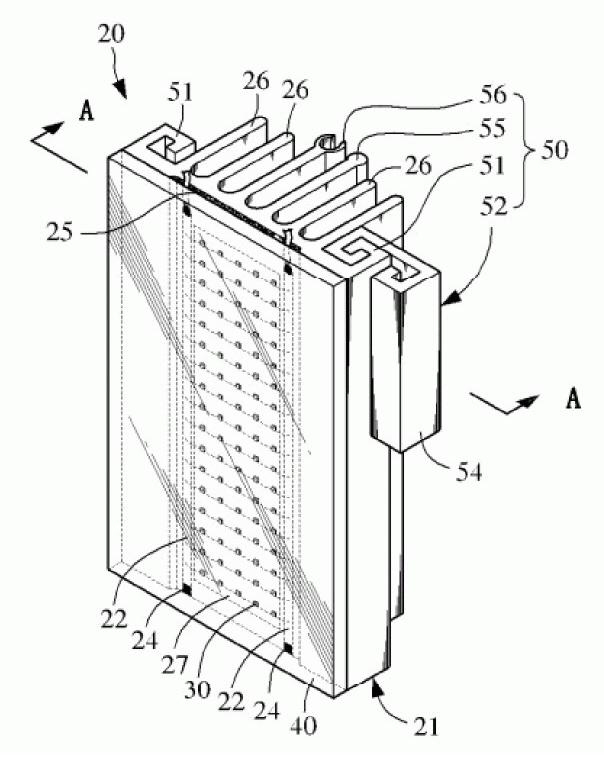

High-power light emitting diode with radiating substrate made of diamond-like film-copper composite material

InactiveCN102354725ABoth have cooling effectIncrease contact areaSolid-state devicesSemiconductor devicesJunction temperatureEngineering

The invention discloses a high-power light emitting diode with a radiating substrate made of a diamond-like film-copper composite material. The diode comprises an LED (Light Emitting Diode) chip, a lens, a reflection cup and the radiating substrate made of the diamond-like film-copper composite material, wherein the LED chip is positioned in the reflection cup; the lens is positioned above the reflection cup; the lower surface of the cooling substrate directly contacts with air; and the LED chip is directly placed on the upper surface of the cooling substrate by die attaching resin or metal eutectic welding. The composite material disclosed by the invention extracts heat from high-power LED via a shortest path, and directly emits heat to the air so as to effectively lower the junction temperature of the LED. Because the composite material can lower the thermal resistance of the whole LED packaging structure, the composite material can be used for cooling single high-power LED and an LED module by combining with an optimized structural design, thereby realizing high-luminance shining for a long term.

Owner:SOUTH CHINA NORMAL UNIVERSITY

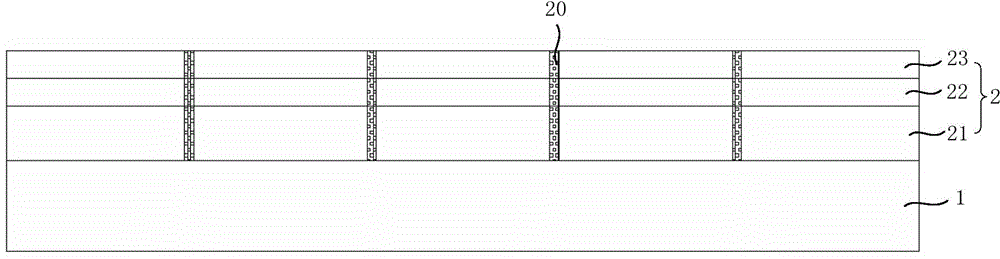

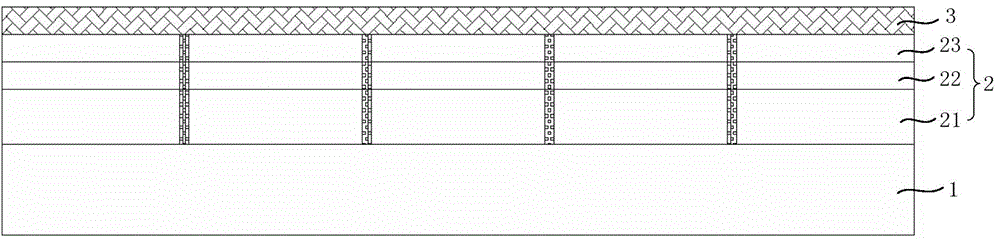

Vertical LED structure and manufacturing method thereof

ActiveCN104409585AReduce manufacturing costSolve brightnessSemiconductor devicesLead structureEngineering

The invention provides a vertical LED structure and a manufacturing method thereof. The manufacturing method comprises the following steps: cutting an epitaxial layer into a plurality of insulated and separated independent light emitting semiconductor layers through the ion implantation technique to replace the traditional complex processes of firstly manufacturing an isolation groove and then filling an insulated material, forming an independent contact layer on each independent light emitting semiconductor layer, then forming a net-shaped-structure DBR reflection layer on each independent contact layer to replace a silver specular reflection layer, and then forming an independent metal function layer on the net-shaped-structure DBR reflection layer. According to the invention, the net-shaped-structure DBR reflection layer is arranged on the independent contact layer to replace the silver specular reflection layer, and the cheap independent metal function layer is arranged on the net-shaped-structure DBR reflection layer, the production cost of an LED is reduced while the problems of brightness improvement and heat dissipation are solved, and the manufacturing method is suitable for large-scale commercialized production.

Owner:HANGZHOU SILAN AZURE

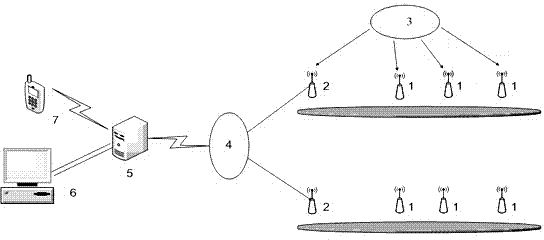

Method and device for intelligently controlling street lamps based on internet of things

InactiveCN103974514AReal-time monitoring of working conditionsSolve real-timeNetwork topologiesElectric light circuit arrangementGeneral Packet Radio ServiceThe Internet

The invention discloses a method and device for intelligently controlling street lamps based on an internet of things. The method comprises the following steps: centralizing street lamps on a street lamp center node for controlling by adopting a radio frequency communication mode, transmitting a control instruction to a server by utilizing terminal equipment, and transmitting the control instruction to the street lamp center node to realize remote control by the server. A street lamp control node is arranged on each street lamp, the street lamp control node and the street lamp center node form a wireless sensor network by virtue of a radio frequency module, the street lamp center node communicates with a remote terminal control system by virtue of a general packet radio service (GPRS) wireless communication module, intelligent wireless sensor network street lamp control based on the internet-of-things technology is realized, the lighting intensity can be adaptively adjusted, the operating conditions of the street lamps are monitored in real time, street lamp fault type alarm, fault site notification and other functions can be provided, a street lamp manager can remotely monitor, analyze, manage and optimize all street lamps by virtue of the remote terminal control system, and the defects that the traditional street lamp management system is low in real-time interactivity, the lighting intensity cannot be adaptively adjusted and the like can be overcome.

Owner:GUIZHOU UNIV

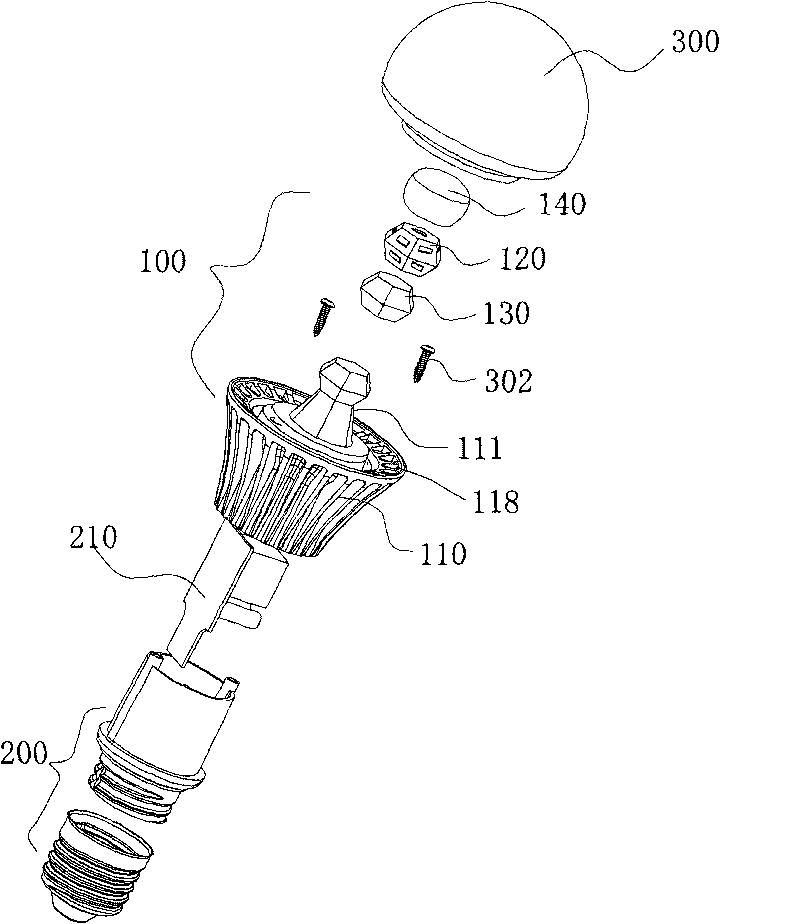

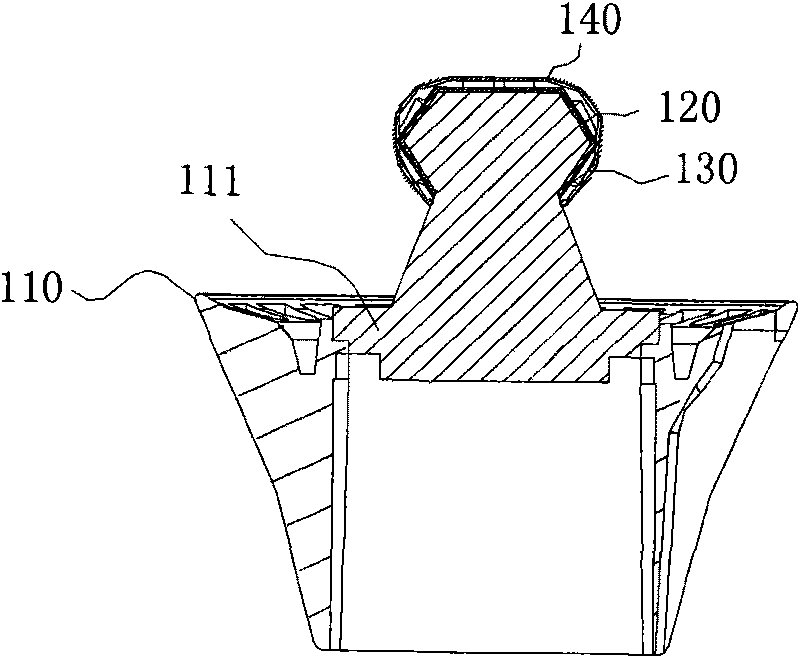

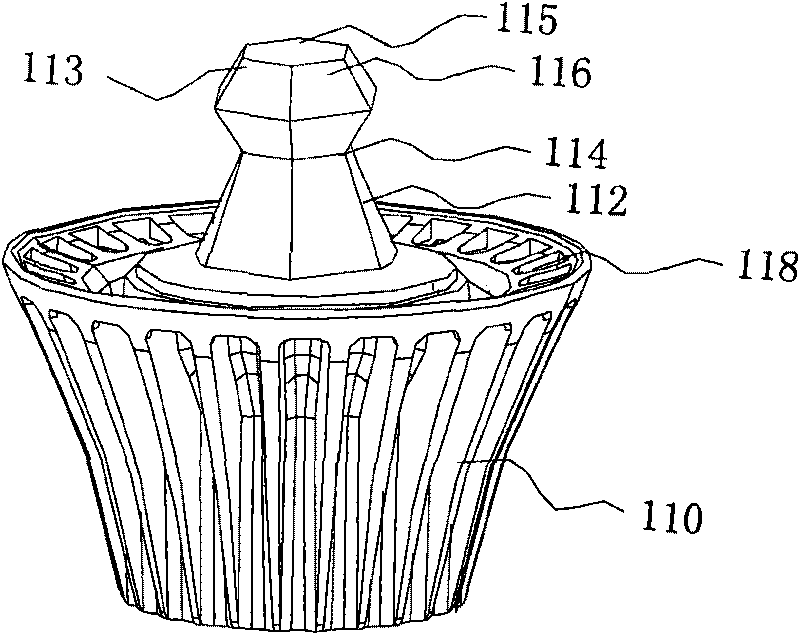

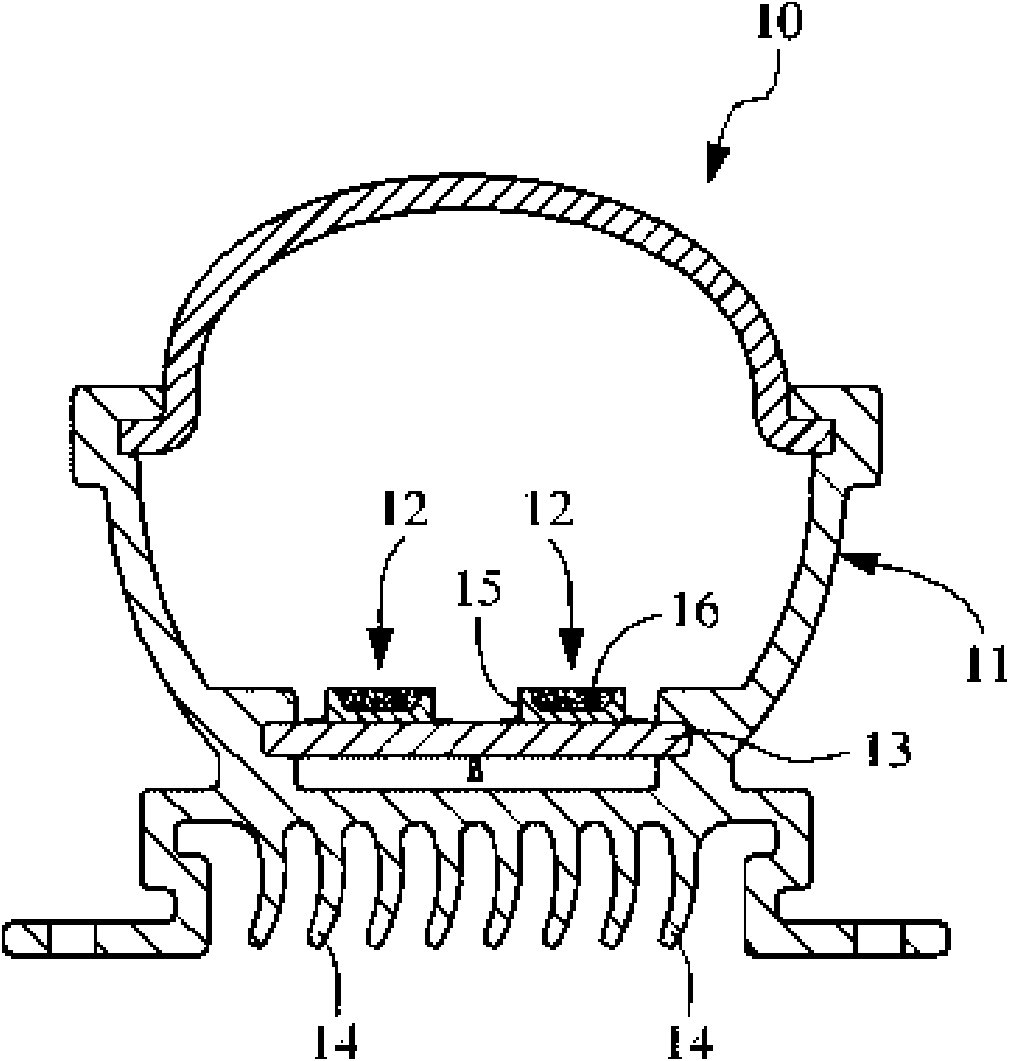

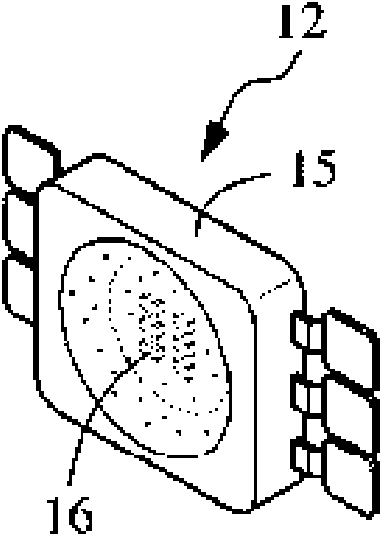

LED three-dimensional light source

InactiveCN101718398AReduce thermal resistanceImprove cooling effectPoint-like light sourceElectric circuit arrangementsEngineeringColor temperature

The invention relates to an LED three-dimensional light source, which comprises a lamp body, a base fixedly connected with the bottom of the lamp body and a lampshade fixedly connected with the top of the lamp body, and generates light of different color temperatures by using LEDs with two or more color temperatures. The lamp body comprises a heat dissipation seat with a lamp post, and a light source plate which is fixedly connected with the LED, matched with the lamp post and made of a bendable material; and the inside of the base is provided with a driving power supply. The LED three-dimensional light source has the advantages of convenient production and manufacture, large luminous angle, capability of dimming and adjusting color, safe use and stable performance.

Owner:CIVILIGHT SHENZHEN SEMICON LIGHTING

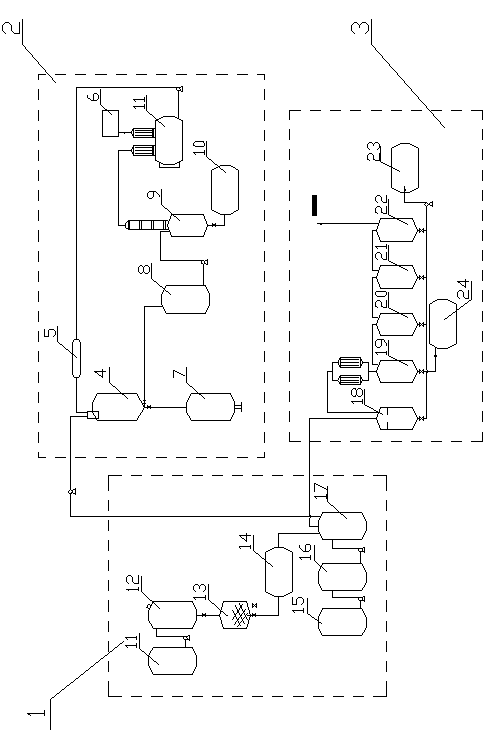

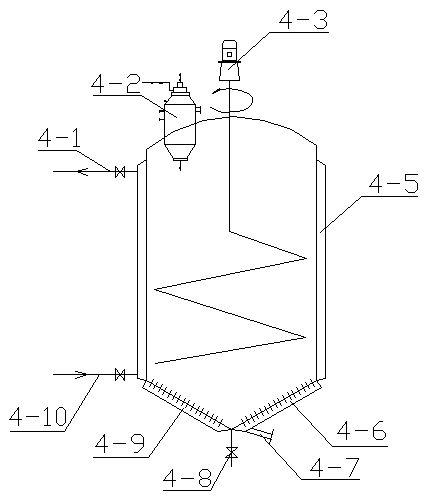

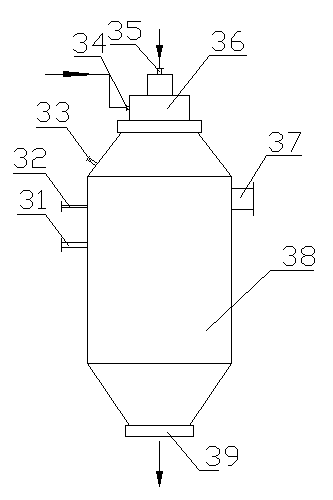

Totally enclosed clean production system for rubber vulcanization accelerator 2-mercaptobenzothiazole

A totally enclosed clean production system for rubber vulcanization accelerator 2-mercaptobenzothiazole, includes a high-pressure synthesis system (1), a crude product purification system (2) and an exhaust gas processing system (3), the crude product purification system comprises an extraction autoclave (4), 2-mercaptobenzothiazole crude product is directly pumped from a high-pressure synthesis autoclave (17) into the extraction autoclave (4), the extraction autoclave (4) has a 2-mercaptobenzothiazole outlet connected to a drying machine and a mother liquor outlet connected to a mother liquor storage tank (8), the mother liquor storage tank (8) is connected to a rectification column (9), the top of the rectification column (9) is connected to a toluene storage tank (11), recovered toluene is connected to the extraction autoclave (4) via a toluene metering tank (5), and the bottom discharge port of the rectification column (9) is connected to a resin storage tank (10). The invention overcomes the environment pollution and hazard of the operator caused by exposed cooling and exposed leaching, overcomes the drawbacks of extraction and drying by artificial feeding and discharge, fully realizes enclosed discharge, enclosed extraction, and enclosed filtration and drying, and realizes fully enclosed leak-free continuous production without organic gas emission.

Owner:HENAN HENGRUI RUBBER PLASTIC SCI & CO LTD

Baking powder and preparation method thereof

InactiveCN103239367ASolve the problem that the coloring is not bright enoughSolve the low consumption of pearlescentCosmetic preparationsMake-upMonoglycerideTG - Triglyceride

The invention provides a baking powder. The baking powder contains silicon processed talcum powder, nylon powder, magnesium aluminosilicate, a xanthan gum, mica powder, silica, polydimethylsiloxane, triglyceride, a coloring agent, ethylhexyl glyceride, sodium benzoate and monoglyceride. The invention also provides a preparation method of the baking powder. The baking powder is suitable for making makeup products comprising eye shadow / pressed powder / rouge / bronzer powder and the like. The baking powder made through adopting the method solves technical problems comprising insufficient coloring brightness, low pearlescent application amount, insufficient resplendent effect, bad color saturation, and bad luster brightness of the baking powder made through a routine method. In the invention, large amounts of pearlescent powder and mica can be added, so the color is bright, the pearlescent effect is resplendent and stereo, and the baking powder is close to skins; and the baking powder made through the method provided by the invention is better than the baking powder made through the routine method in appearance structure, color saturation, luster brightness, powder condensation, and break and shake resistances.

Owner:上海露凡西化妆品有限公司 +1

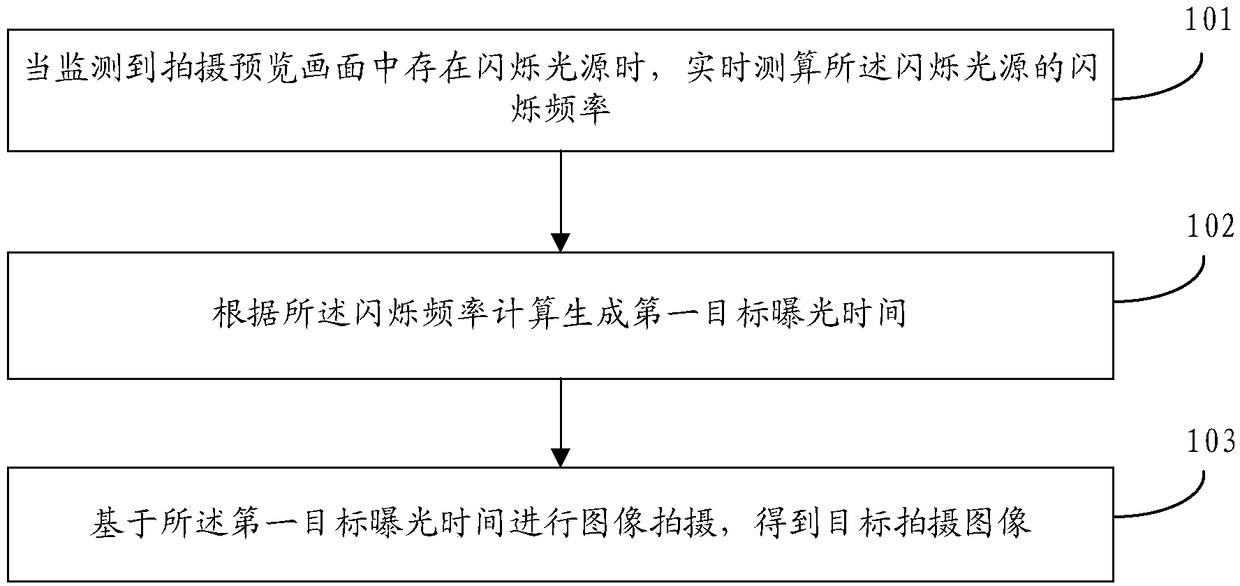

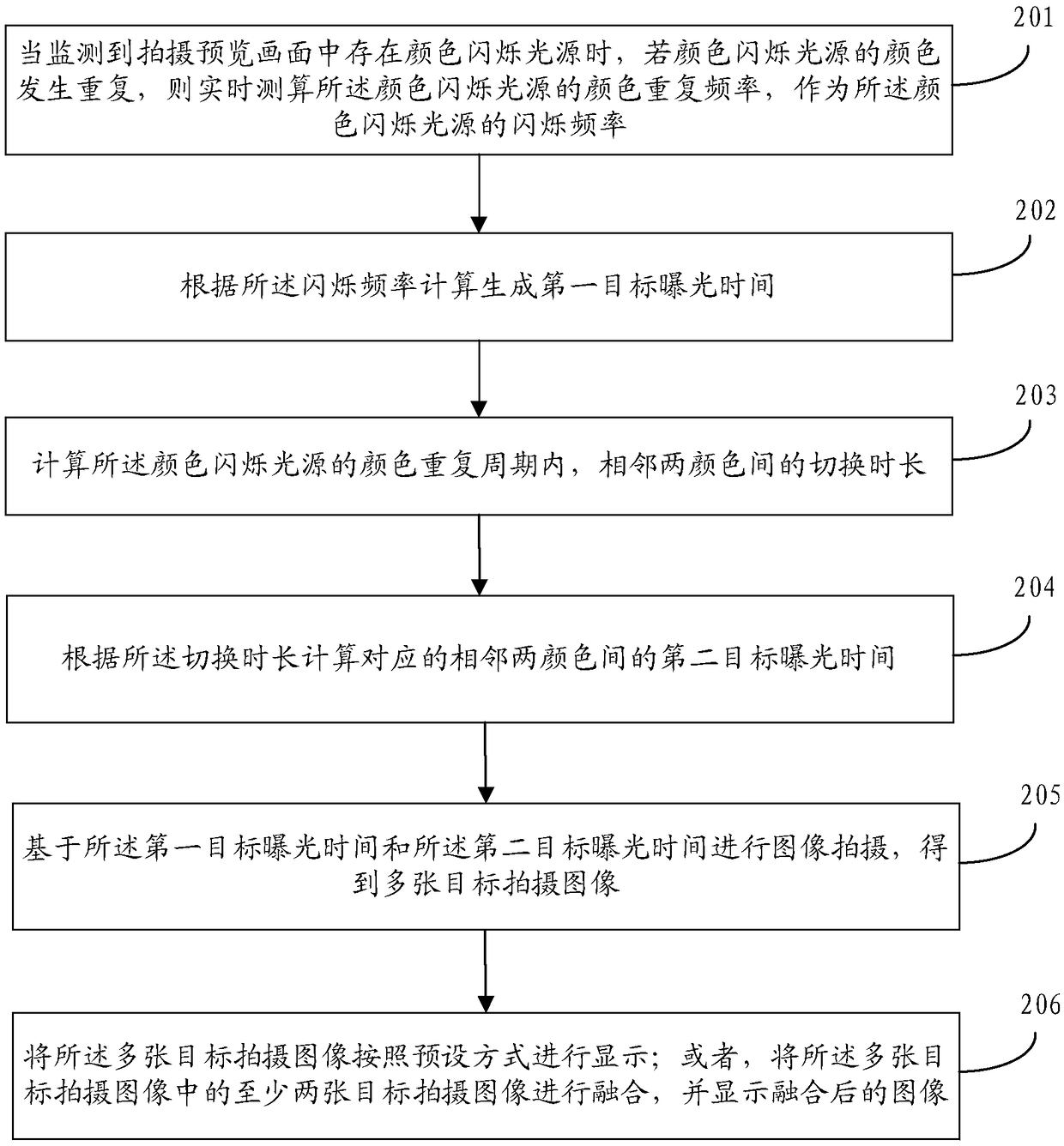

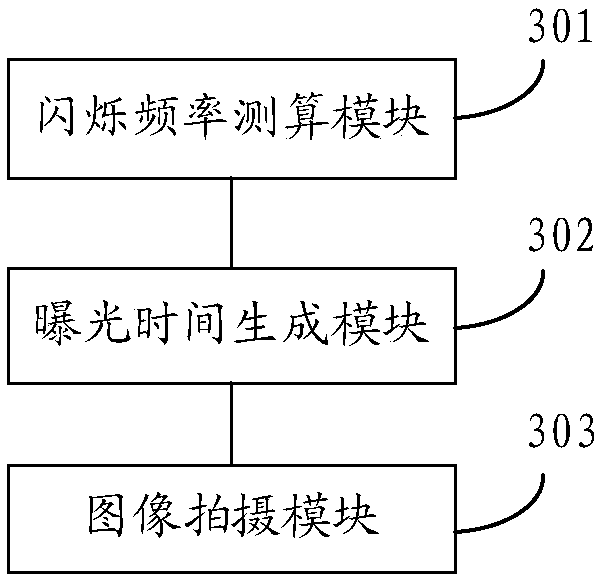

Photographing method and device, storage medium and mobile terminal

ActiveCN109120863AAvoid Space TexturesQuality improvementTelevision system detailsColor television detailsFlickering lightComputer terminal

The embodiment of the invention discloses a photographing method and device, a storage medium and a mobile terminal. The photographing method comprises the steps of calculating the flicker frequency of a flicker light source in real time when it is monitored that there is a flicker light source in a photographing preview image; calculating and generating first target exposure time according to theflicker frequency; and performing image photographing based on the first target exposure time to obtain a target photographed image. By adopting the above technical scheme, the embodiment of the invention can reasonably determine the target exposure time according to the flicker frequency of the flicker light source and photograph a photographing subject containing the flicker light source basedon the target exposure time, thereby not only effectively solving a problem of brightness and color distortion, which is caused by the flicker of the flicker light source, of the photographed image, but also being capable of avoiding the spatial texture caused by the flicker light source in the photographed image, and being capable of effectively improving the quality of the photographed image.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Pixel unit, display panel and display equipment

ActiveCN110428740AAlleviate the problem of excessSolve brightnessCasings with display/control unitsPhotovoltaic energy generationDark stateImaging quality

The invention discloses a pixel unit, a display panel and display equipment, relates to the technical field of display and aims at reducing a dark state region of an image displayed by stretchable display equipment so as to improve the image quality. The pixel unit comprises a peripheral pixel region, a middle pixel region and a first-class stretching regulating hole distribution region, wherein the peripheral pixel region is positioned in the peripheral direction of the middle pixel region; and the first-class stretching regulating hole distribution region is positioned between the peripheralpixel region and the middle pixel region. The display panel comprises the pixel unit adopting the technical scheme. The pixel unit provided by the invention is used in display.

Owner:BOE TECH GRP CO LTD

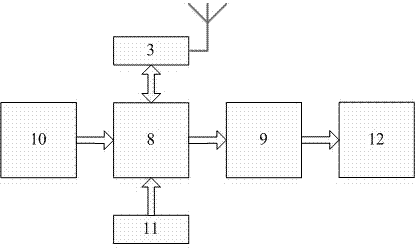

Superaqueous searching controller with ultra-high luminescence lightness

InactiveCN101402395AQuick responseEasy flash controlVessel signalling devicesAutomatic controlSearch and rescue

The invention relates to an overwater super-bright luminous search and rescue controller. The invention discloses the overwater super-bright luminous search and rescue controller, which is characterized by comprising a buoyant air bag and a controller box, wherein at least two luminous strips which are formed by more than two OLED lumistors, and a photosensitive tube are hermetically embedded on the facade of the buoyant air bag, and are connected with an optical detecting unit and a power drive unit in the controller box through leads; the controller box comprises a water resistance detecting unit, the optical detecting unit, a microprocessor, the power drive unit and a high-capacity battery; the water resistance detecting unit, the optical detecting unit and the power drive unit are coupled to the microprocessor respectively; and the high-capacity battery respectively supplies power for the microprocessor and the power drive unit. The overwater super-bright luminous search and rescue controller has obvious luminous effect, large visual angle and far visual range, has the functions of automatic control and GPS positioning, has the operating time of more than 5 days, is particularly suitable for environments with insufficient light, and is greatly convenient to rescue people who are fallen into water.

Owner:NAVY MEDICINE RES INST OF PLA

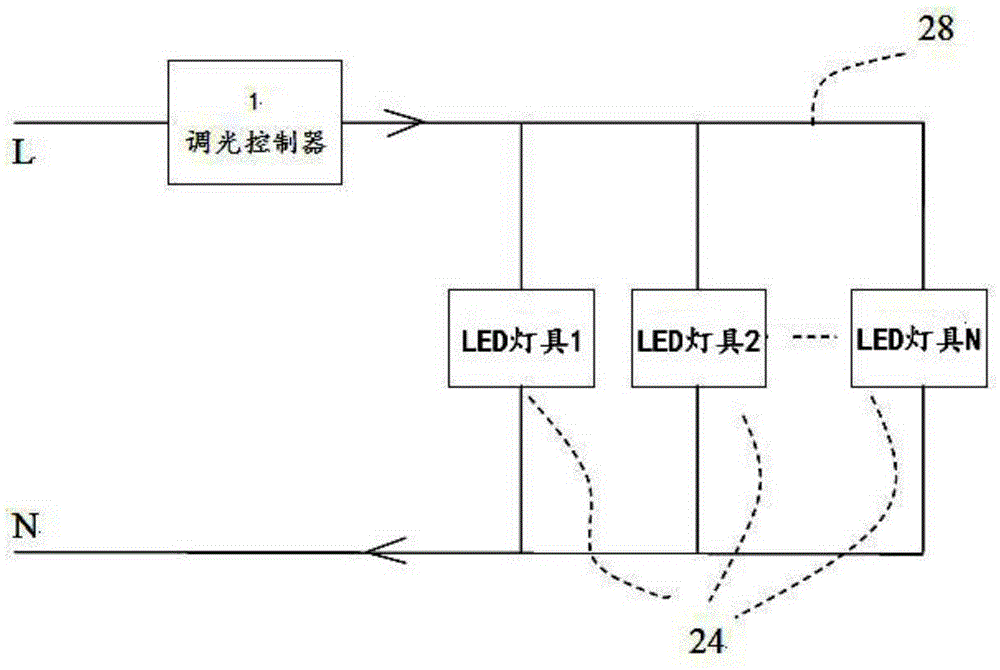

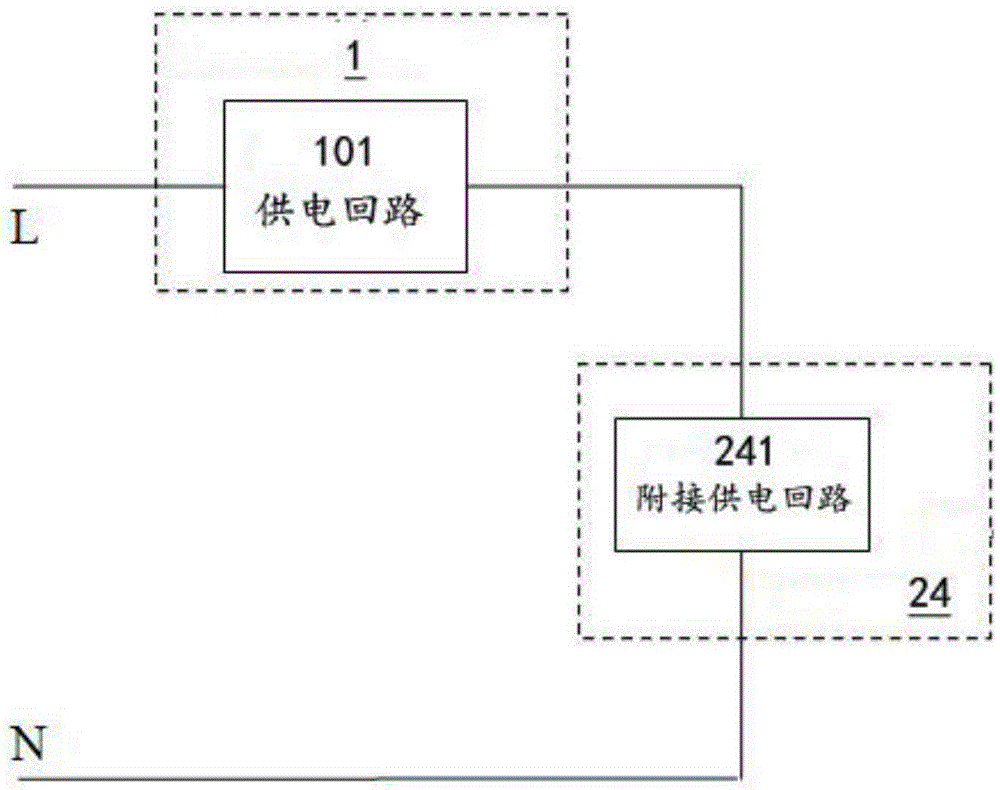

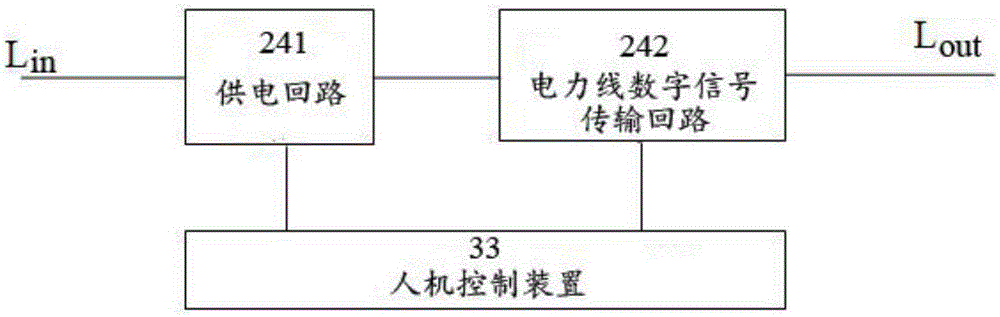

Dimming system and method

InactiveCN105323926ASolve brightnessSolve the color temperatureElectric light circuit arrangementEngineeringDigital control

A dimming system is designed. The dimming system comprises a dimming controller and an LED lamp that are serially connected through a load power line, wherein the dimming controller is configured to send a digital control instruction to the LED lamp through the load power line, and a single-line type power supply loop is formed by the dimming controller and the LED lamp based on the load power line. The dimming system, under the conventional electrical wiring requirement, realizes the control of the luminance, the color temperature and the color of the LED lamp in the single firing line loop, and the control of the luminance, the color temperature and the color of the LED lamp in the single firing line loop cannot be realized by the conventional switch and the dimming switch.

Owner:PUTIAN INTELLIGENT LIGHTING INST

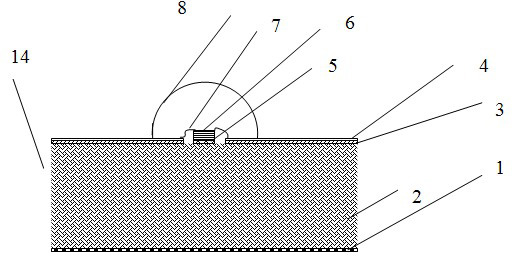

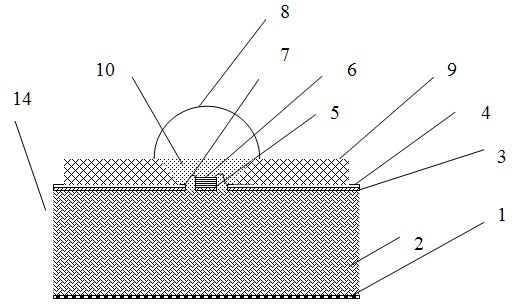

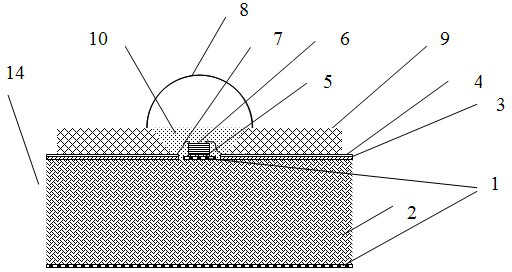

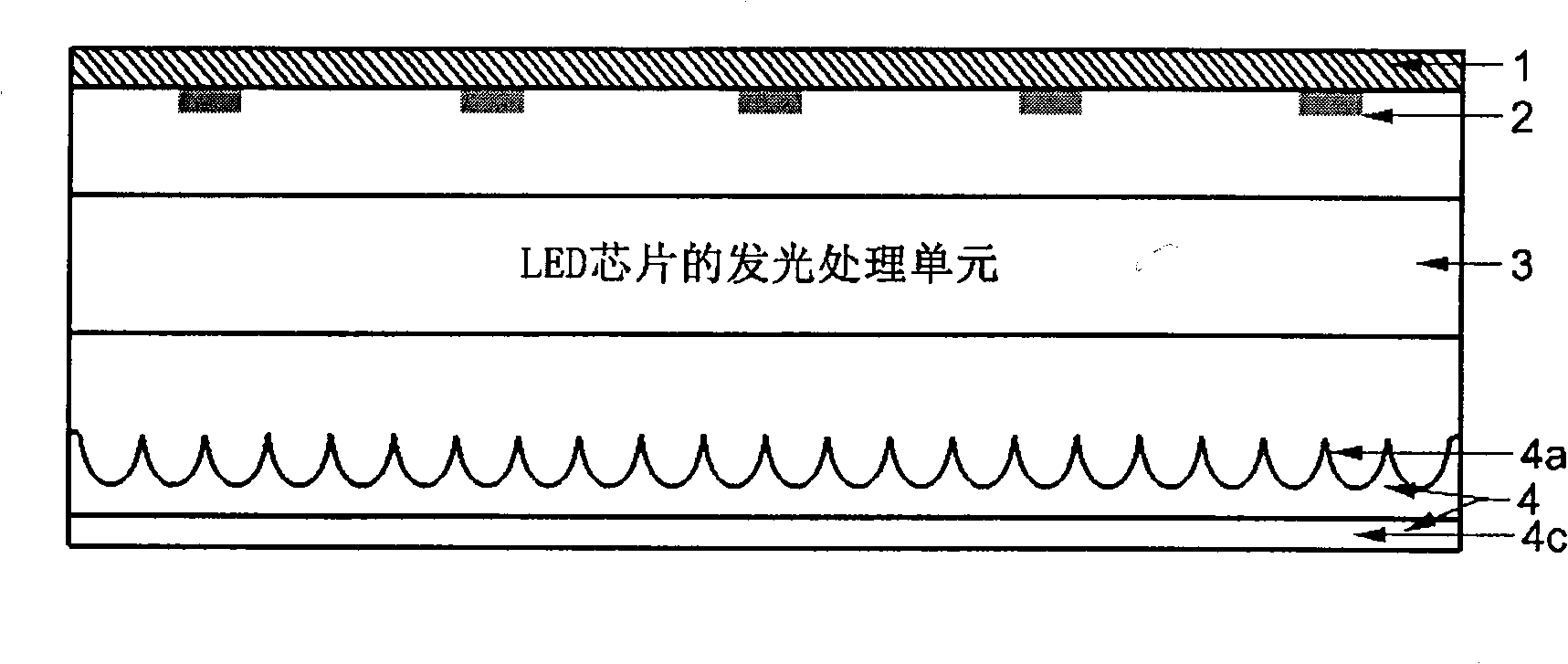

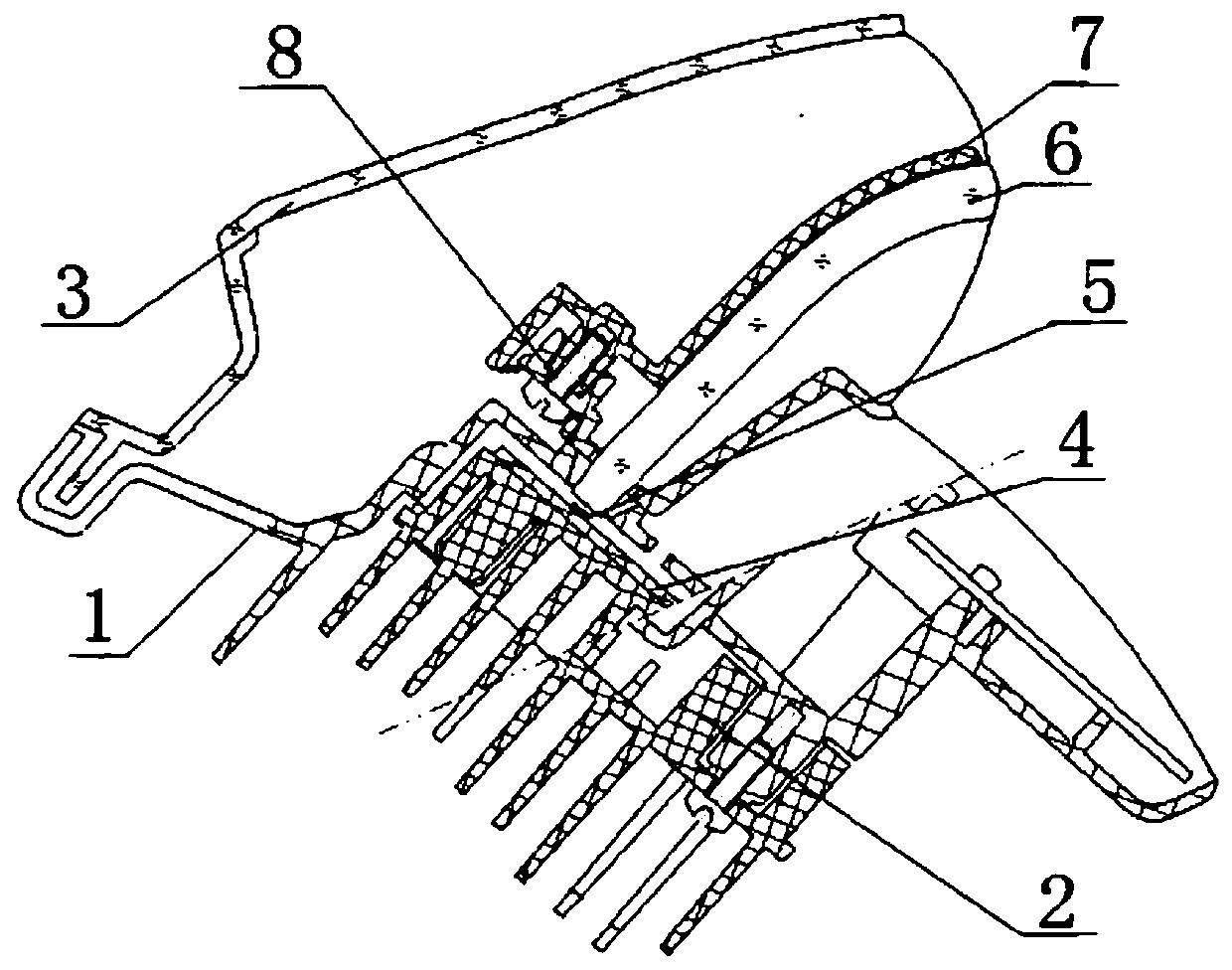

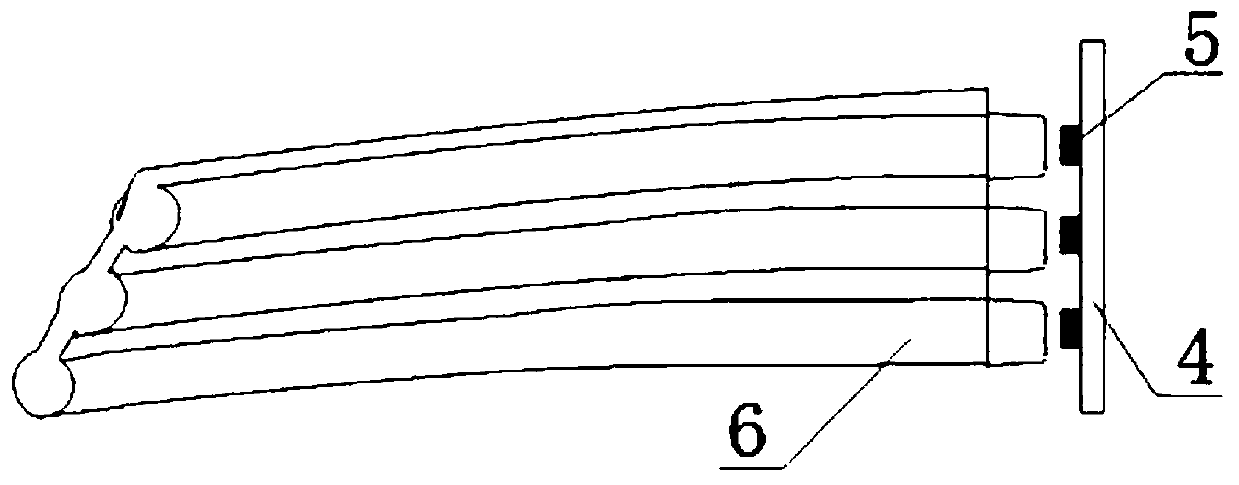

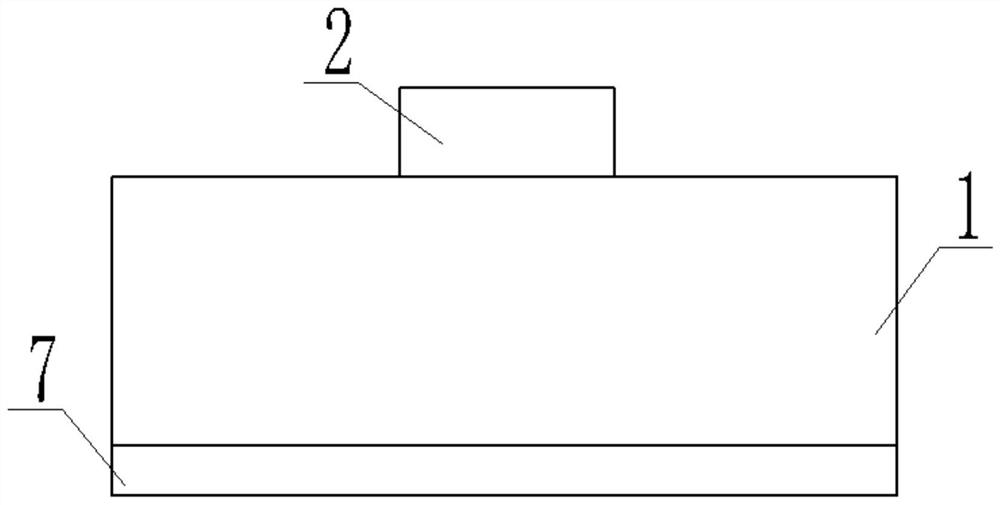

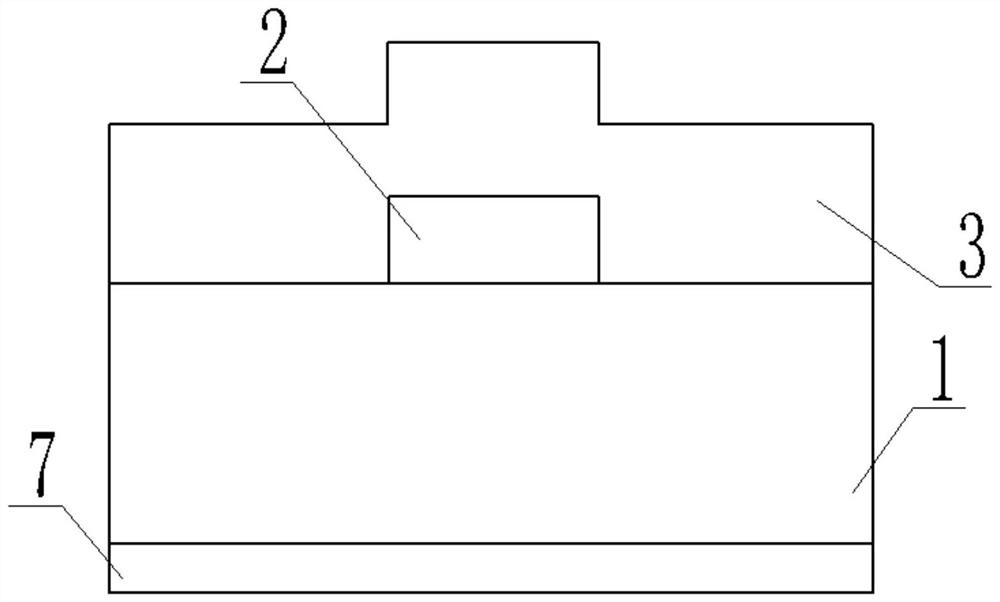

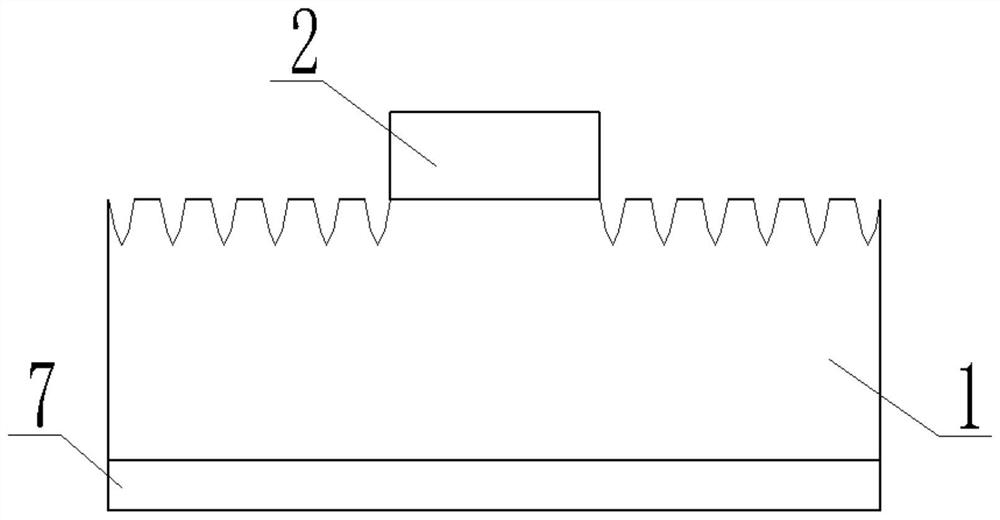

Light source structure based on LED

InactiveCN101493210ASolve UtilizationSolve brightnessPoint-like light sourceRefractorsLight-emitting diodeStructure based

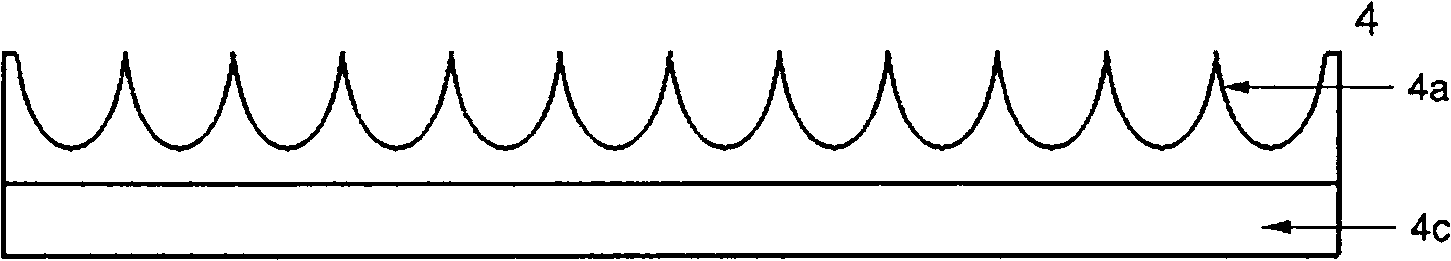

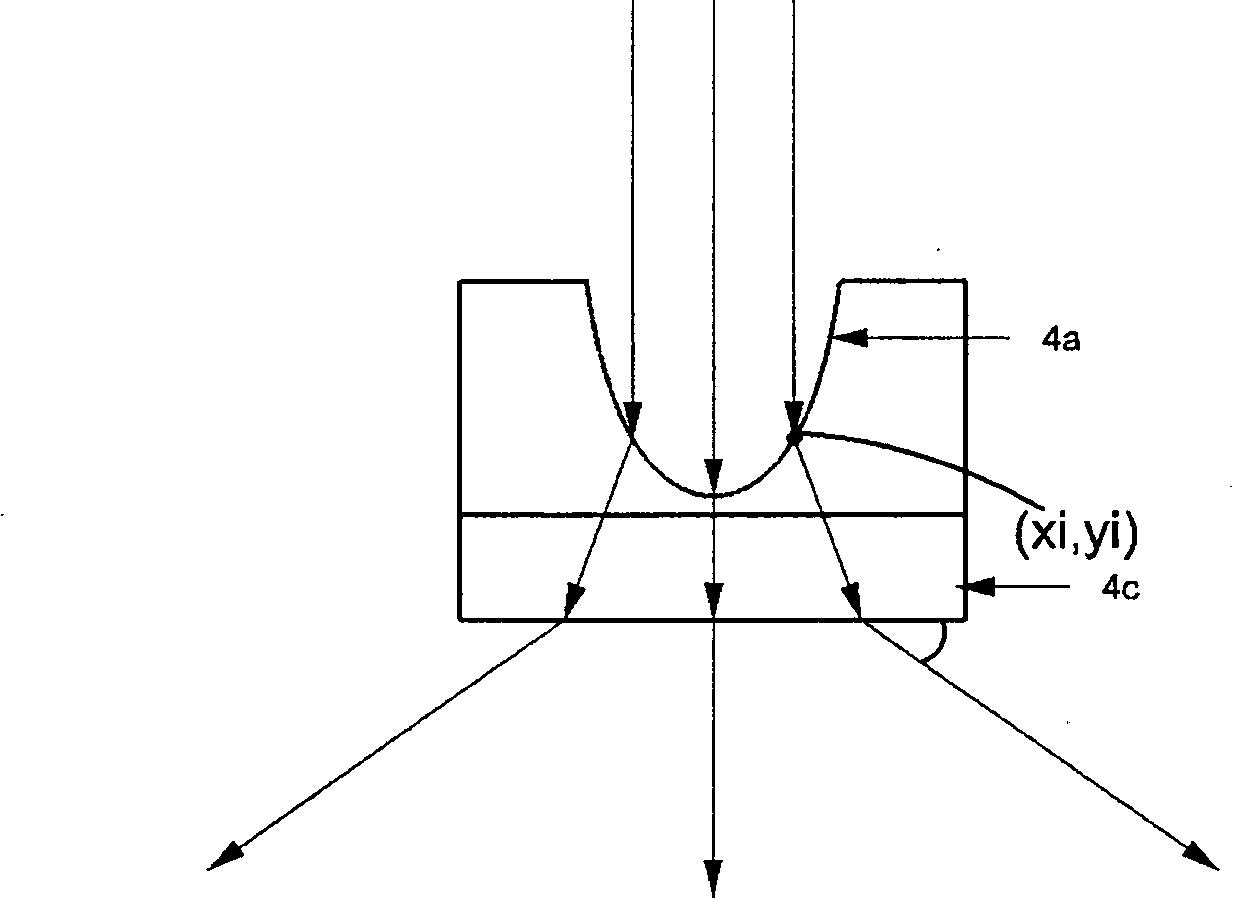

The invention relates to a light source structure based on a light emitting diode (LED), which belongs to the technical field of LED application. The light source structure at least comprises a baseplate 1, an LED chip 2, a light-emitting processing unit 3 of the LED chip and an optical light scattering plate 4 designed by nonimaging optics, wherein, the LED chip 2 fixed on the baseplate 1 is the light-emitting source, the optical field distribution is processed by the light-emitting processing unit 3 of the LED chip including but not limited to on and then transmitted to the inner surface of the optical light scattering plate 4; at least one side of the optical light scattering plate 4 comprises a microstructure designed by nonimaging optics, the microstructure ensures the incident light to scatter, thus a light source structure with uniform luminance is formed. The light source structure provided by the invention has the advantages of comfort for human eyes, friendly environment and high utilization rate of the LED luminous energy; the structure can be made into flat shapes including but not limited to squareness, roundness, ellipse, sphericity, spheroidicity, and the like, and non-flat shapes including but not limited to spherical surface, ellipsoidal surface, cylindrical surface and the like, which can realize infinite extension.

Owner:TSINGHUA UNIV

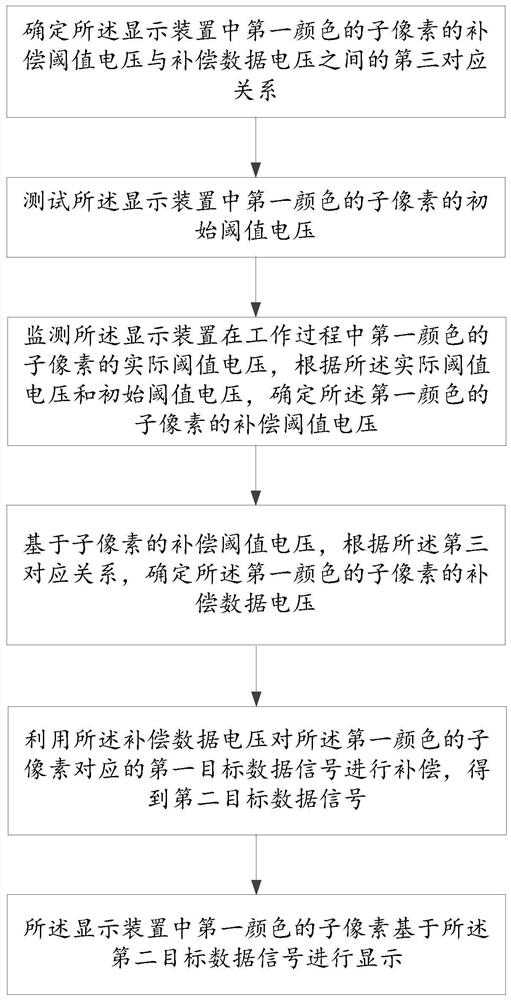

Display compensation method, display compensation device and display device

ActiveCN112951156AAchieve compensationSolve for uniformityStatic indicating devicesDisplay deviceGrey level

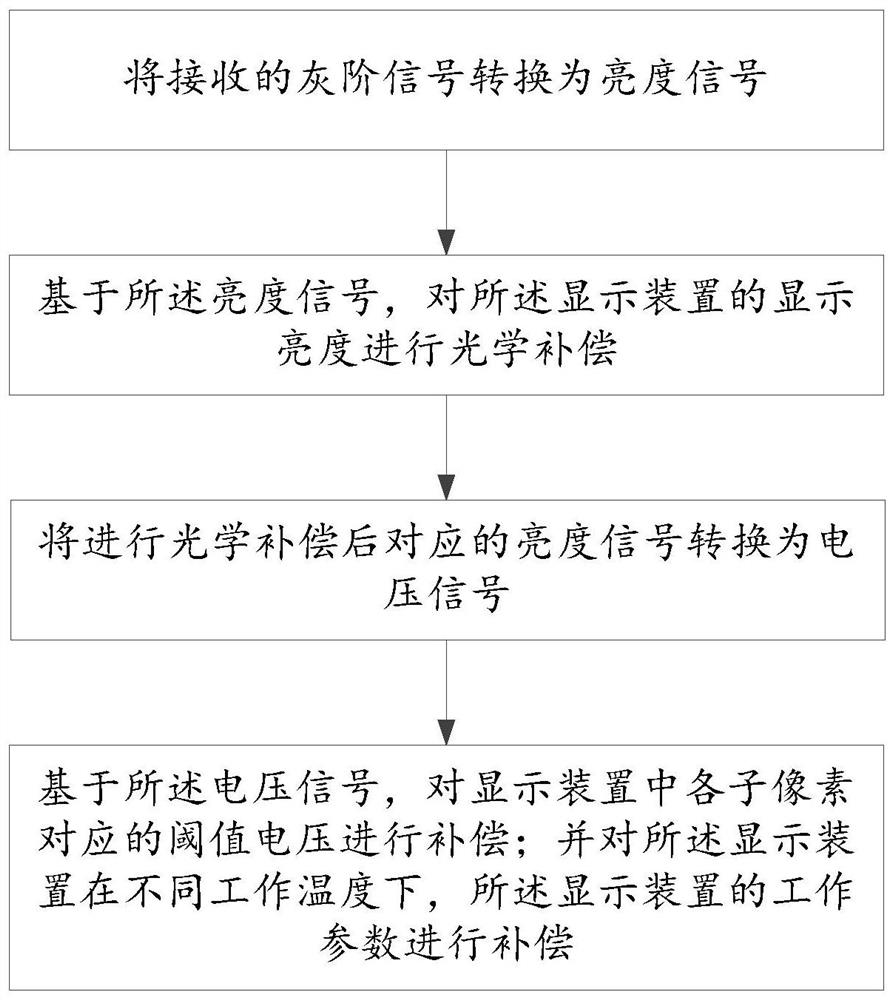

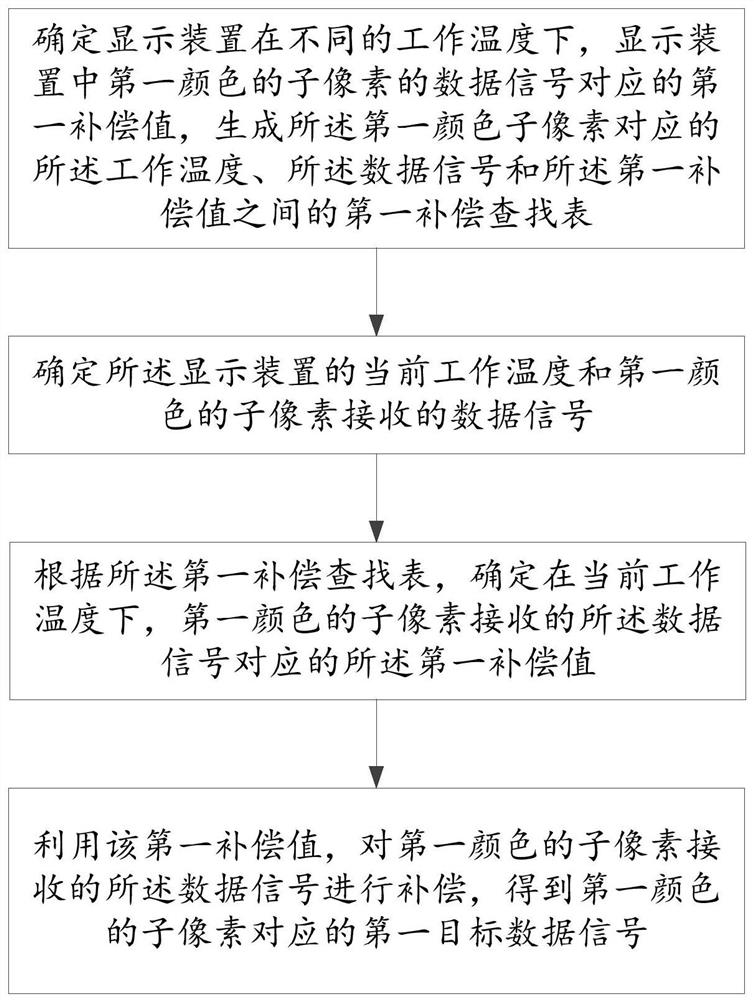

The invention provides a display compensation method, a display compensation device and a display device, and relates to the technical field of display. While the display precision is guaranteed and the cost is reduced, the problems that the uniformity of a display screen is poor, the sub-pixel gray scale relation is changed due to the change of the environment temperature, and the brightness of the screen is influenced due to the aging offset of the threshold voltage corresponding to the sub-pixels are solved. The display compensation method is applied to the display device. The display compensation method comprises the following steps: converting a received gray-scale signal into a brightness signal; performing optical compensation on the display brightness of the display device based on the brightness signal; converting the corresponding brightness signal after optical compensation into a voltage signal; based on the voltage signal, compensating threshold voltage corresponding to each sub-pixel in the display device; and compensating for the working parameters of the display device when the display device is at different working temperatures.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

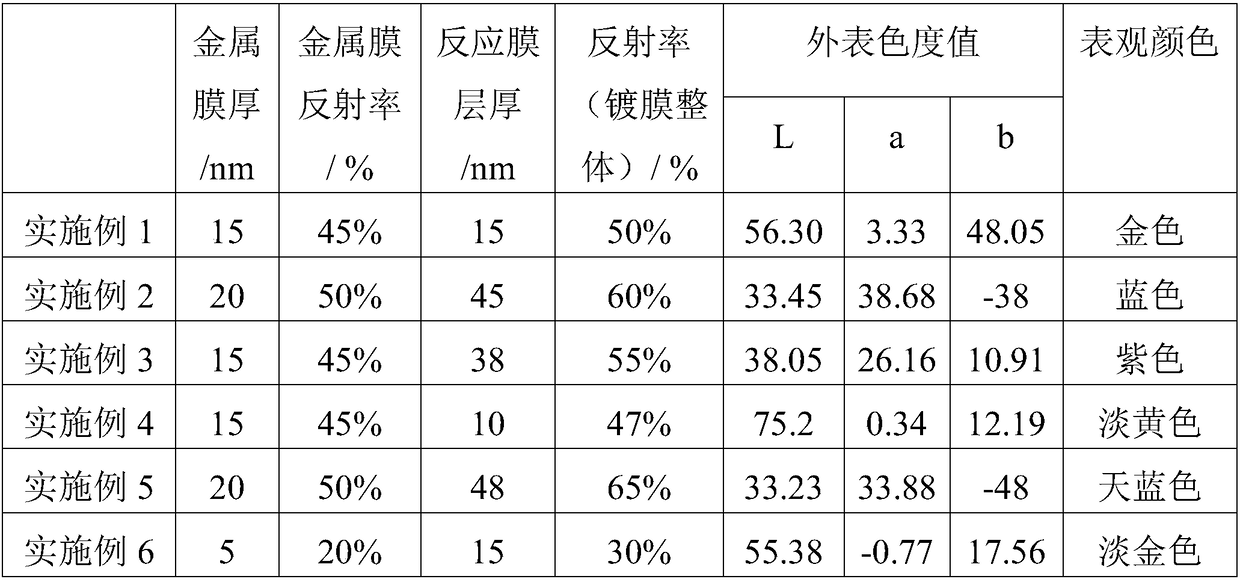

Color film forming method based on continuous magnetron sputtering

InactiveCN108118298AAvoid rising costsSolve the color is too singleVacuum evaporation coatingSputtering coatingSputteringReactive gas

The invention relates to the magnetron sputtering film forming technique and particularly relates to a color film forming method based on continuous magnetron sputtering. The method comprises the steps of carrying out sputtering coating on the surface of a to-be-coated base material so as to form one or more metal film layers, and coating the surface of the outermost metal film layer with one or more reaction film layers, or firstly carrying out sputtering coating on the surface of the to-be-coated base material so as to form one or more reaction film layers, and coating the surface of the outermost reaction film layer with one or more metal film layers, wherein the reaction film layers are prepared by reaction of metal target materials sputtered in vacuum cavities with reactant gas and depositing, the thickness of the metal film layers is 5nm-35nm, the average visible light reflectivity is 20%-75%, and the introduction amount of reactant gas is 30ml / min-80ml / min. By virtue of mutual cooperation between the metal film layers and the reaction film layers, the preparation of multiple color films is realized, the film coating process is stable and simple, and the coating film with relatively high brightness can be prepared without excessively increasing the thickness of the reaction film layers.

Owner:池州市正彩电子科技有限公司

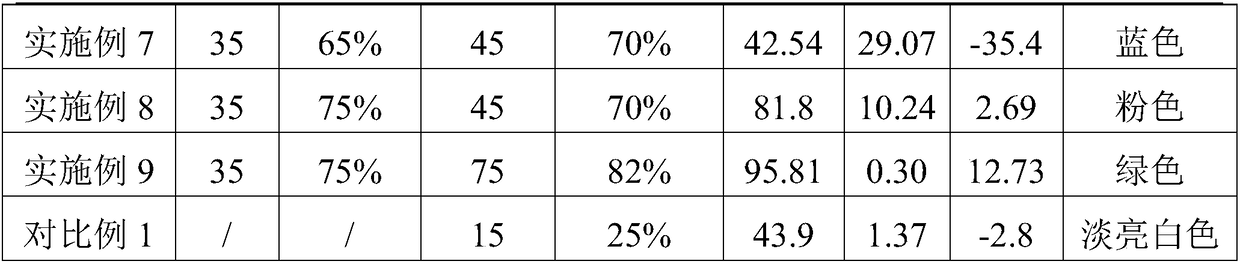

Induced pluripotent stem cell colony quality automatic evaluation method and device

ActiveCN112102232AImprove accuracySolve brightnessImage enhancementImage analysisHuman Induced Pluripotent Stem CellsMirror image

The invention provides an induced pluripotent stem cell colony quality automatic evaluation method and device; image preprocessing is carried out through adaptive gamma transformation, so the problemsof poor image brightness and contrast caused by objective reasons in the image acquisition process are solved; and based on rotation invariance of iPSCs colonies, the data set amplification is carried out through image rotation, mirroring and affine transformation; more comprehensive characteristic value information of iPSCs bacterial colony images is obtained by fusing characteristic informationof seven different sources, the classification performance is improved, the bacterial colony quality evaluation performance is improved, characteristic learning is carried out through a dimension reduction algorithm, the cost is saved, and application and popularization are facilitated.

Owner:SHENZHEN UNIV

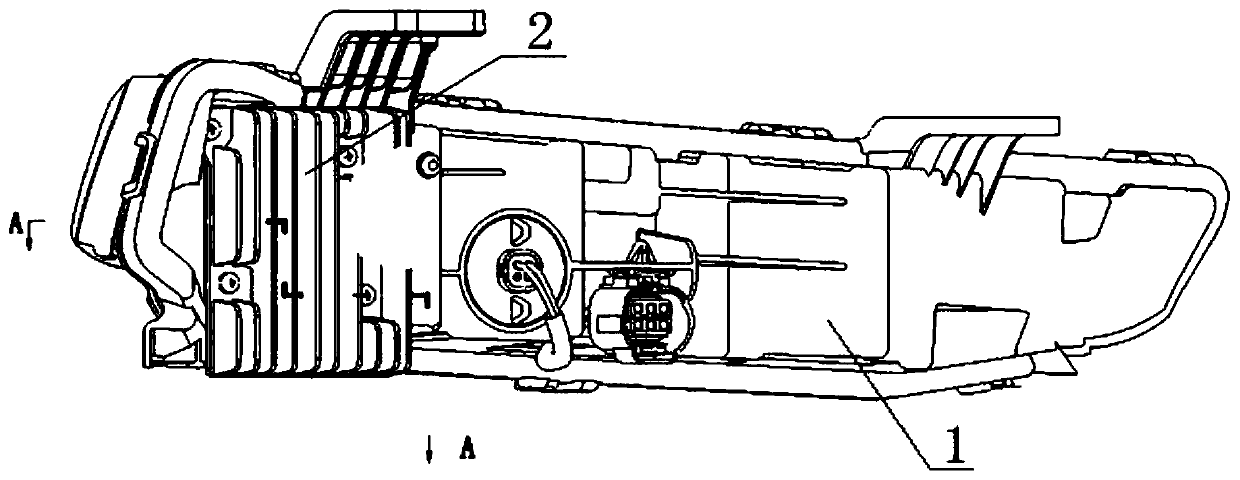

Novel LED (Light Emitting Diode) position lamp

InactiveCN109812777ASolution to short lifeSolution volumeElectric circuit arrangementsOptical signallingLight guideEffect light

The invention provides a novel LED (Light Emitting Diode) position lamp which comprises a lamp shell, a lampshade, a heat radiator, an LED circuit board, an LED light source, a light guide fixing rackand a light guide, wherein the lampshade is arranged at the front end of the lamp shell in a covering manner; a light emitting cavity is formed between the lampshade and the lamp shell; a lamp grooveis formed rightwards in the left end of the lamp shell in a concave manner; the heat radiator and the LED circuit board positioned in front of the heat radiator are arranged in the lamp groove; the LED light source is arranged on the LED circuit board; the LED circuit board is connected with an external power supply through a power supply wire; the light guide fixing rack is arranged in the lightemitting cavity; the light guide is arranged on the light guide fixing rack; the LED light source corresponds to the left end of the light guide; light through holes are formed between the LED lightsource and the light guide in the lamp shell. After light emission of the LED light source of the novel LED position lamp, a bright light band can be formed through conduction of the light guide, an automobile outline lighting requirement can be met, and the novel LED position lamp is simple in structure, easy to assemble, stable in performance, few in fault, long in service life and energy-savingand environmentally friendly.

Owner:南宁燎旺车灯股份有限公司

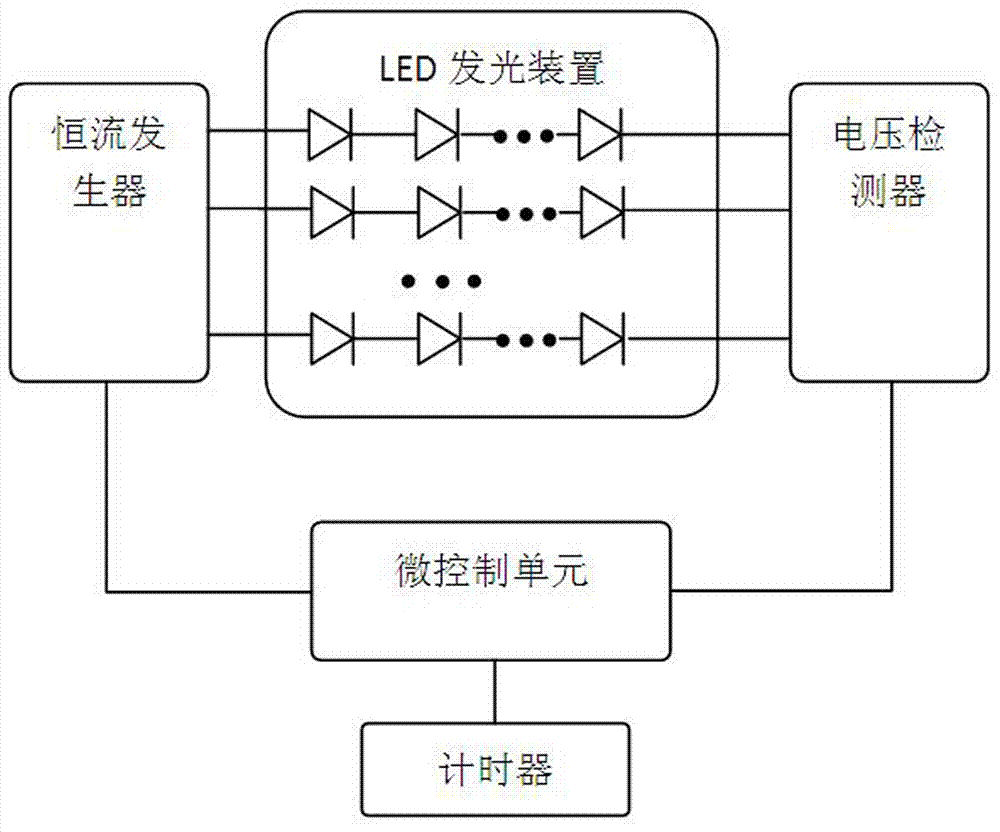

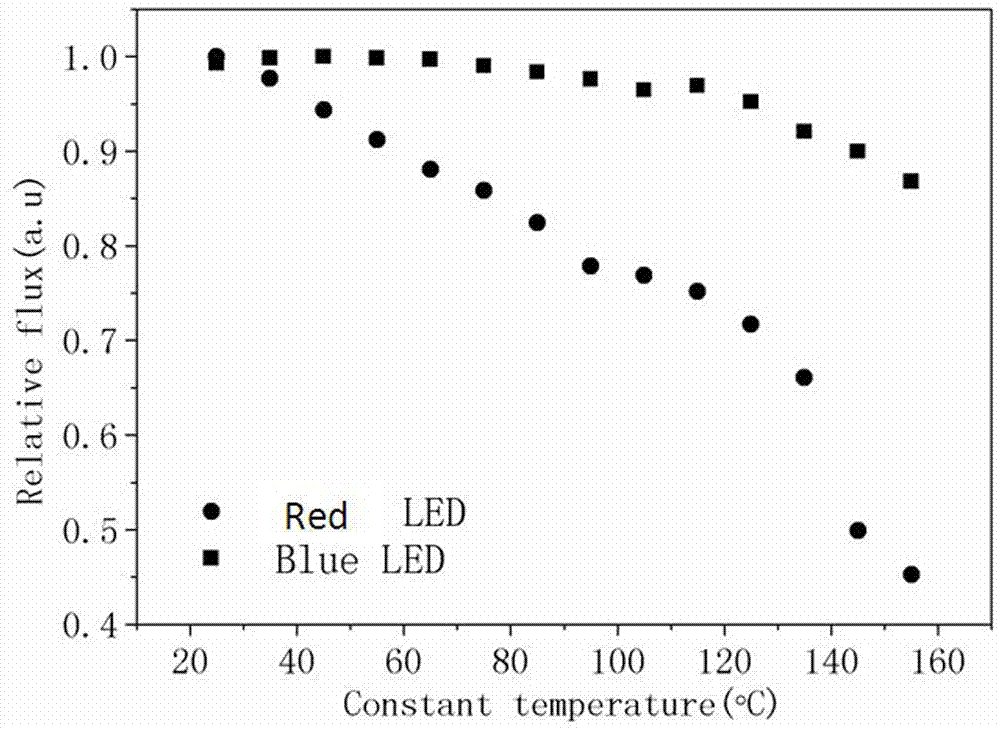

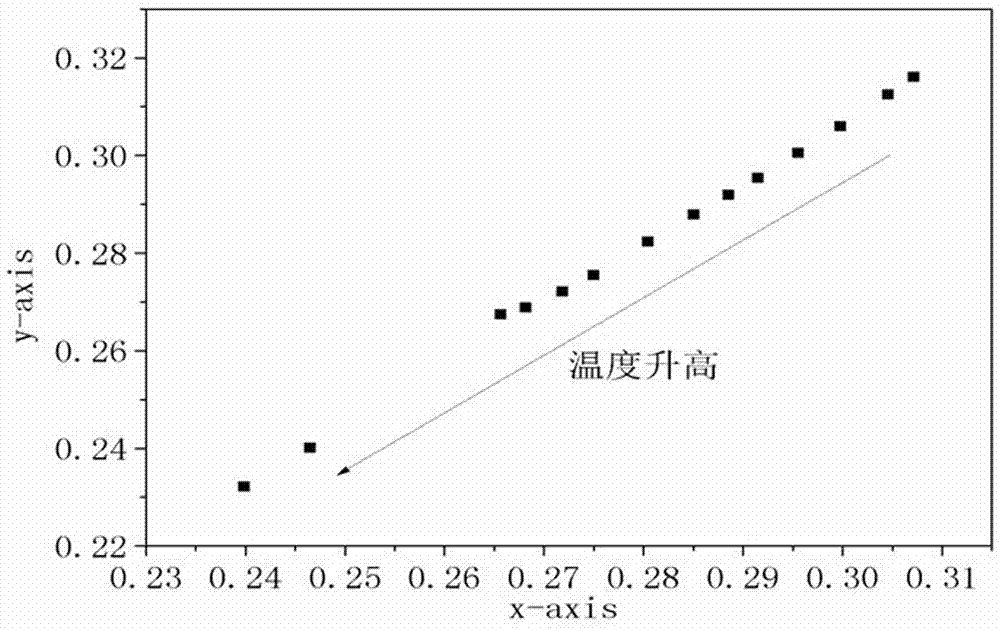

LED light source with stable light color

PendingCN107222948ASolve brightnessSolve the problem of color changeElectrical apparatusElectroluminescent light sourcesElectricityLight source

An LED light source with stable light color comprises an LED luminous device, a constant current generator, a micro-control unit, a voltage detector and a timer, wherein the micro-control unit is electrically connected with the constant current generator, the voltage detector and the timer, the constant current generator is electrically connected with an input end of the LED luminous device, the voltage detector is electrically connected with an output end of the LED luminous device, the micro-control unit is used for storing a change relation of brightness and color coordinates of each color of LED in the LED luminous device with a junction temperature and working time in advance and adjusting a duty ratio of each path of constant current output from the constant current generator after the change condition of the brightness and color coordinates of each color of LED is acquired by reading data of the voltage detector and the timer and calculating, so that hybrid light with stable color and brightness is emitted from the LED luminous device all the way. The LED light source is simple in structure and low in manufacturing cost, and the problem of change on the brightness and the chromaticity of the LED light source caused by reasons such as temperature change, current change and bead aging can be effectively solved.

Owner:GUANGDONG INST OF SEMICON IND TECH

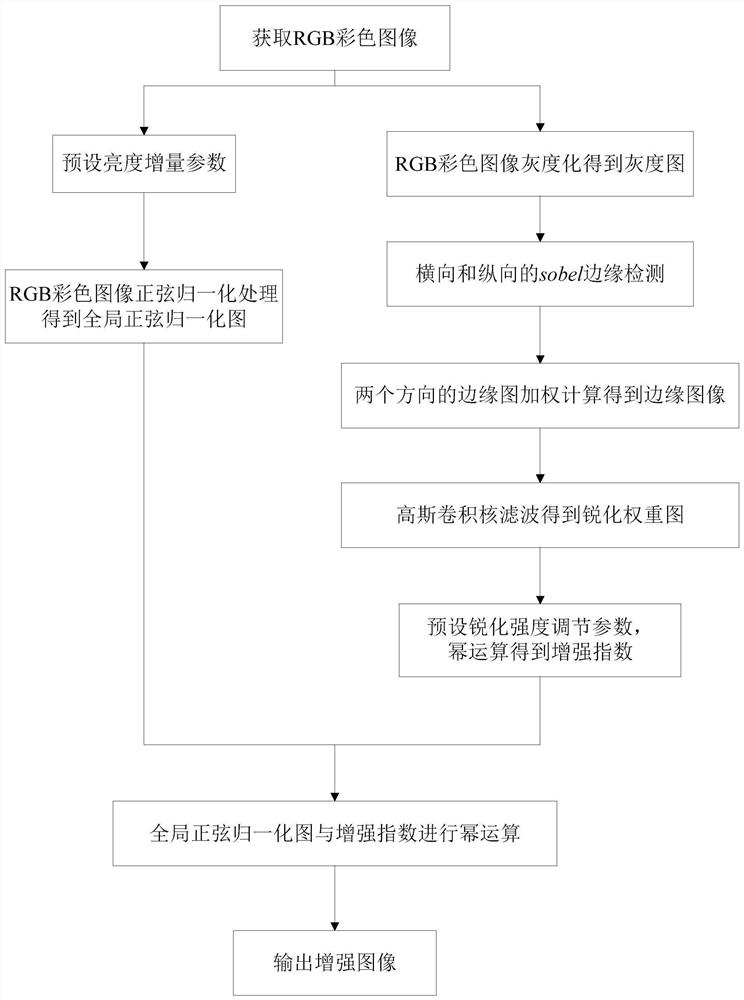

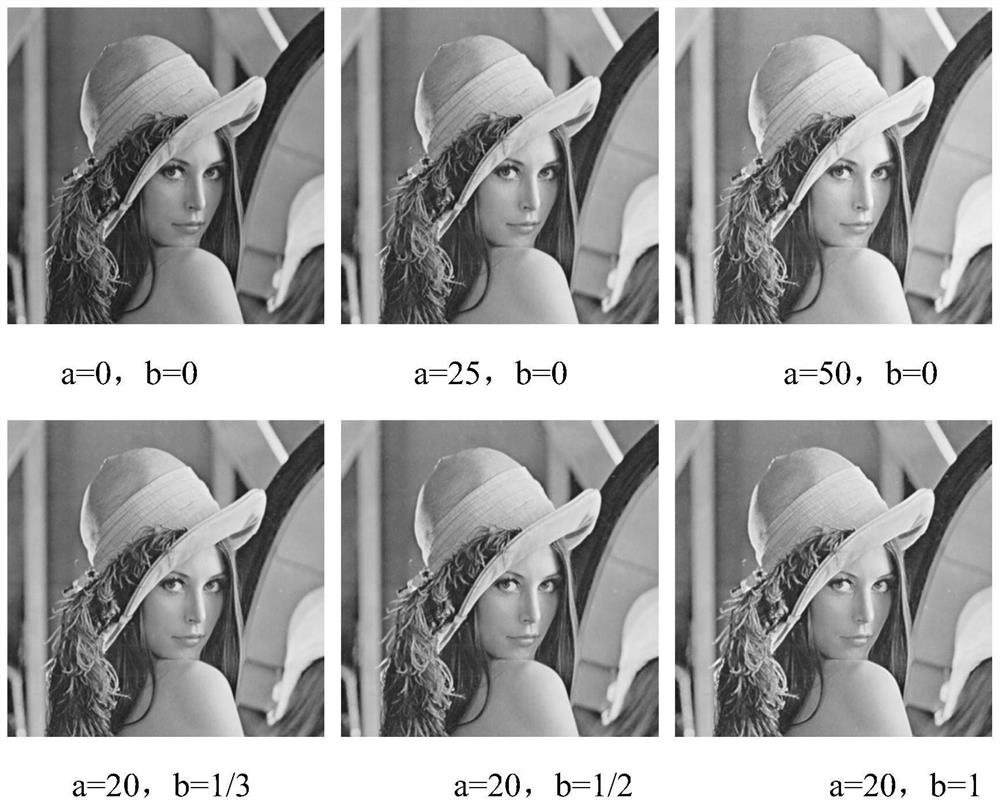

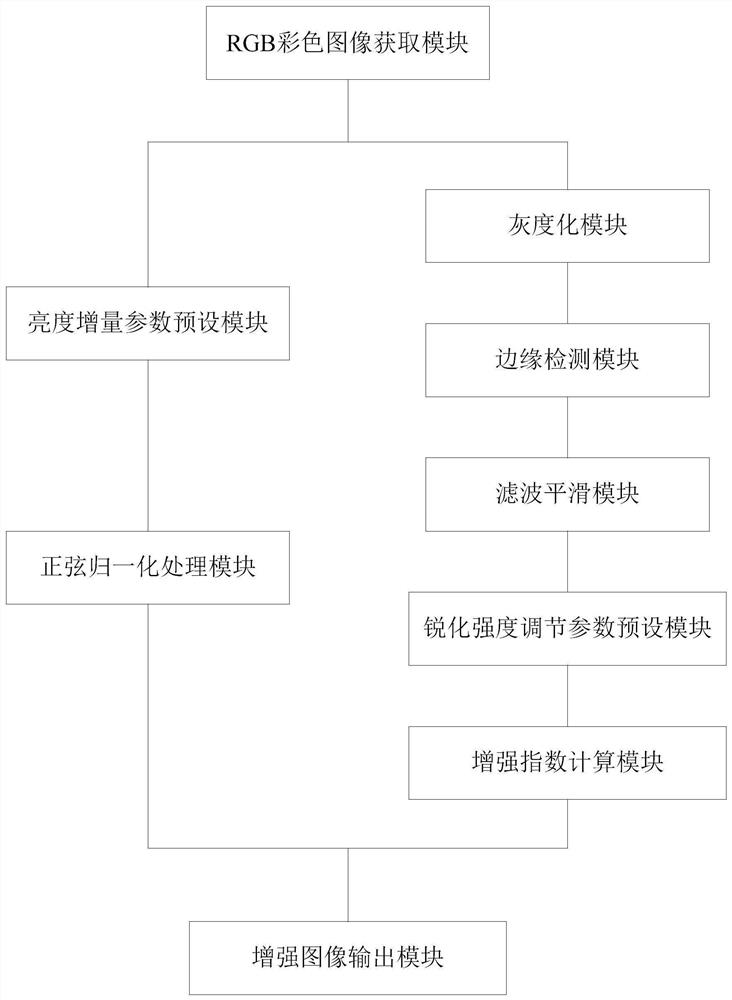

Image enhancement method based on sine curve change and application thereof

PendingCN113450272ASolve brightnessSolve the problem of contrast ratioImage enhancementImage analysisPattern recognitionColor image

The invention discloses an image enhancement method based on sine curve change and application thereof, and the method comprises the following steps: obtaining an RGB color image, presetting a brightness increment parameter, and carrying out the sine normalization processing of the RGB color image, thereby obtaining a global sine normalization image; graying the RGB color image to obtain a grey-scale map, carrying out Sobel edge detection, respectively and independently carrying out convolution on the grey-scale map in the x direction and the y direction by adopting a transverse difference operator and a longitudinal difference operator, and carrying out weighted merging to obtain an edge image; and performing Gaussian convolution kernel filtering smoothing on the edge image, performing convolution on a Gaussian convolution kernel and the edge image, presetting a sharpening intensity adjustment parameter, performing exponentiation according to the sharpening intensity adjustment parameter to obtain an enhancement index, and performing exponentiation on the global sine normalized image and the enhancement index to obtain an enhanced image. According to the method, the image brightness increment is in normal distribution, so that smooth adjustment is realized, the image is sharpened to different degrees by adopting the edge sharpening weight, and a better image enhancement effect is obtained.

Owner:广州方图科技有限公司

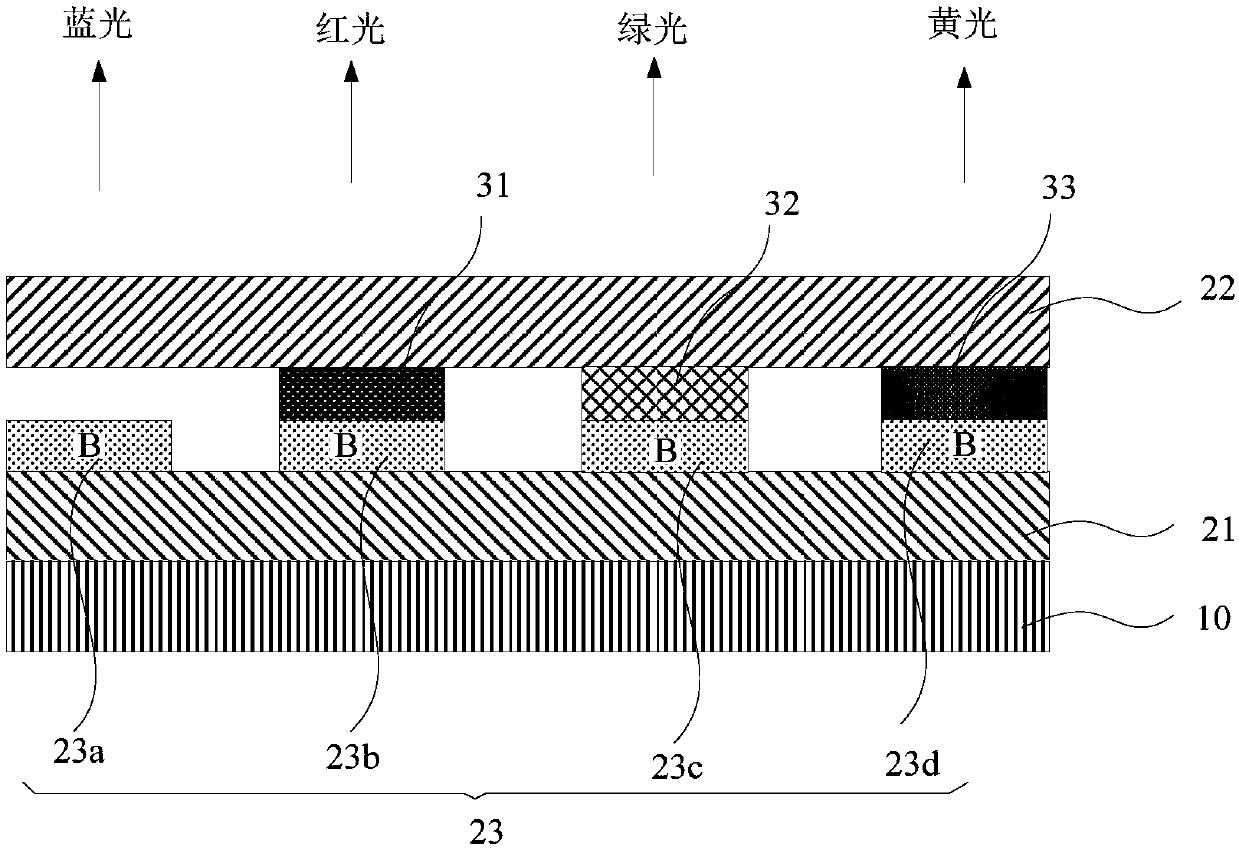

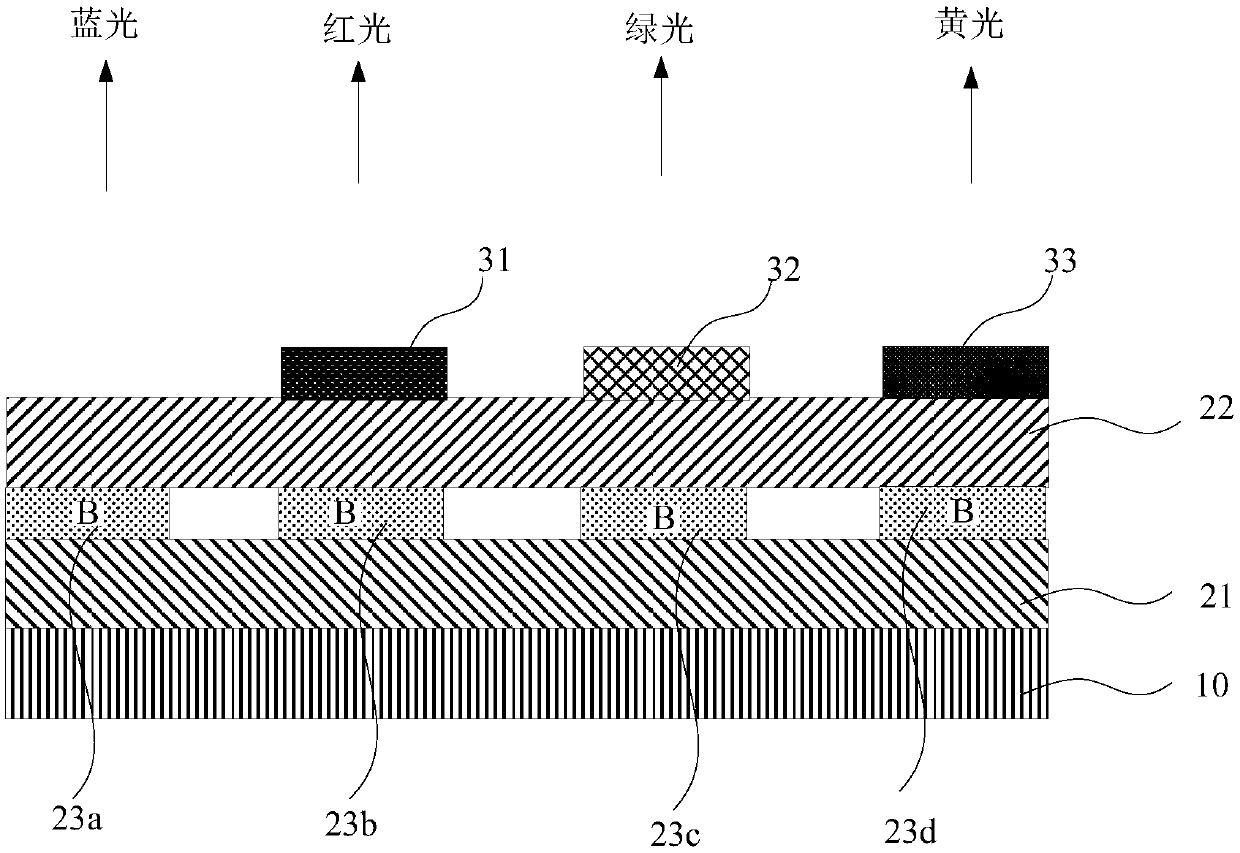

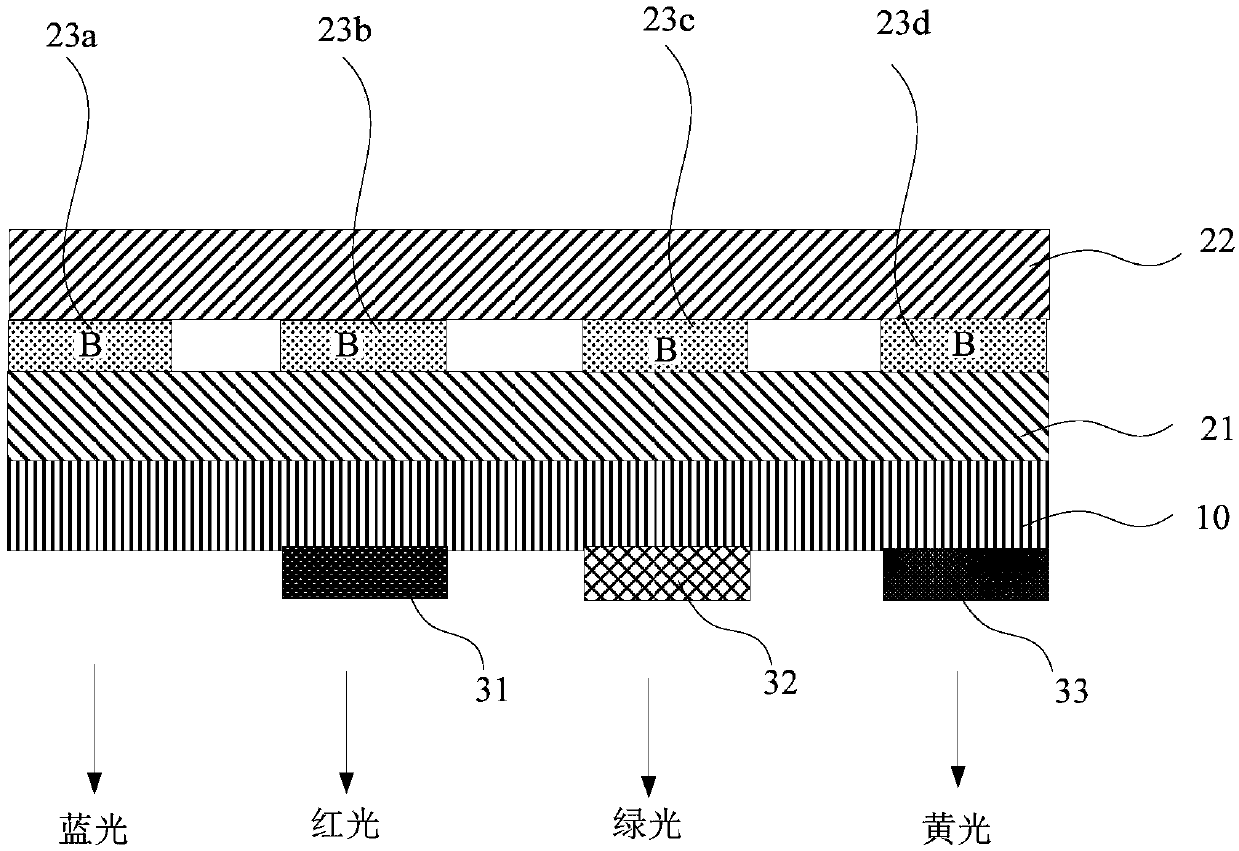

Display panel and display device

PendingCN111261666AImprove color gamutIncrease brightnessSolid-state devicesSemiconductor devicesGamutDisplay device

The invention provides a display panel and a display device. The display panel comprises a plurality of light-emitting units arranged on an array substrate. Each light-emitting unit comprises a firstelectrode layer, an organic light-emitting layer and a second electrode layer which are sequentially arranged on the array substrate in a stacked mode. The organic light-emitting layer includes four sub-pixels, and at least two blue sub-pixels are arranged in the four sub-pixels; a yellow quantum dot layer is arranged on the light-emitting side of the organic light-emitting layer; the yellow quantum dot layer is used for converting blue light emitted by one of the blue sub-pixels into yellow light; or the four sub-pixels comprise at least two red sub-pixels, the yellow quantum dot layer is used for converting red light emitted by one of the red sub-pixels into yellow light. The display panel solves the problems that in the prior art, during three-color display, the color gamut is small, and the overall display brightness is low.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

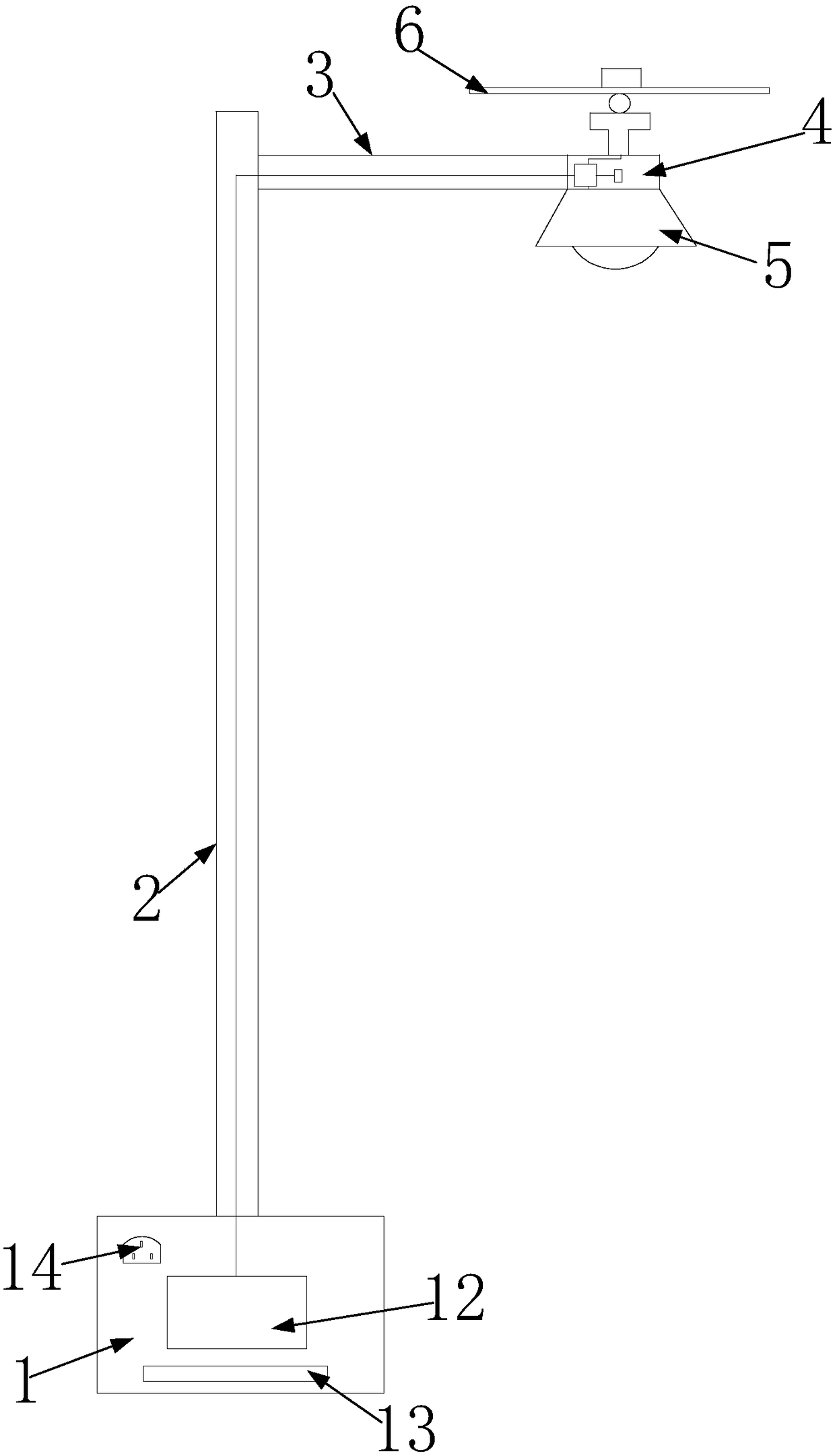

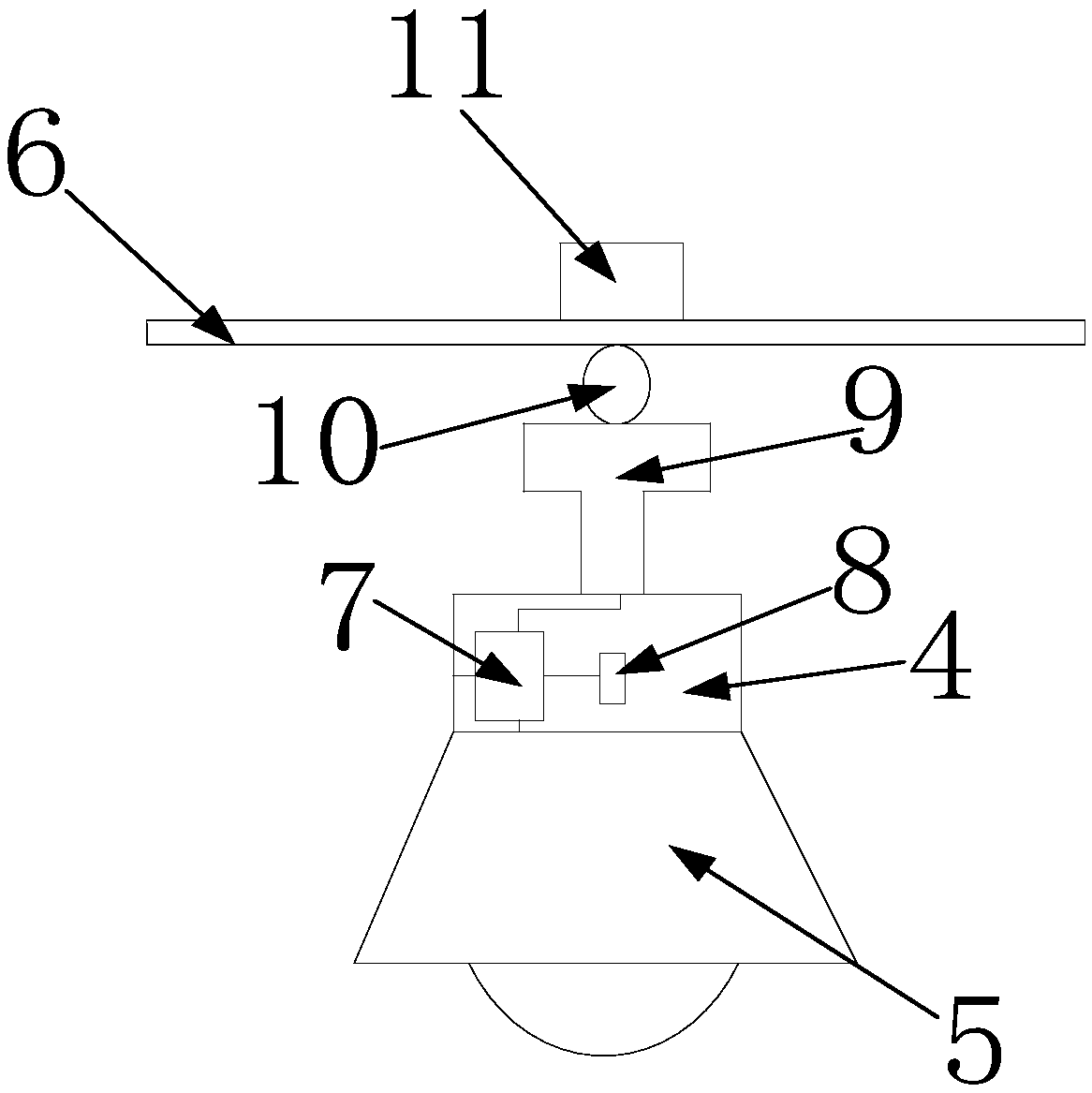

Solar street lamp controller capable of rotating along with solar rays

InactiveCN108105728ASolve brightnessSolve the problem of low batteryElectric circuit arrangementsEnergy efficient lightingSolar street lightSolar cell

The invention discloses a solar street lamp controller capable of rotating along with solar rays. The solar street lamp controller comprises a base, a supporting rod is arranged on the base, a connecting rod is arranged at the end, far away from the base, of the supporting rod, an object carrying table is arranged at the end, far away from the supporting rod, of the connecting rod, a street lamp is arranged at the bottom of the object carrying table, an angle adjusting device is arranged at the top of the object carrying table, a solar cell panel is arranged at the top of the angle adjusting device, and a photoelectric position sensor is arranged at the geometric center of the upper surface of the solar cell panel. By means of the solar street lamp controller, the problem that in the priorart, a solar collecting plate is fixed to the top of the street lamp, the solar energy collecting efficiency is low due to the fact that the solar collecting plate cannot be moved, and consequently asolar street lamp cannot be better used is solved, the solar street lamp controller capable of rotating along with the solar rays is provided, when the solar street lamp controller is used, the solarrays are detected through the photoelectric position sensor, then the solar cell panel is moved to the sun perpendicular incidence position, the solar collection efficiency is guaranteed, and the sufficient electric quantity and the sufficient luminance of the solar street lamp are further guaranteed.

Owner:成都瑞普欧光电有限公司

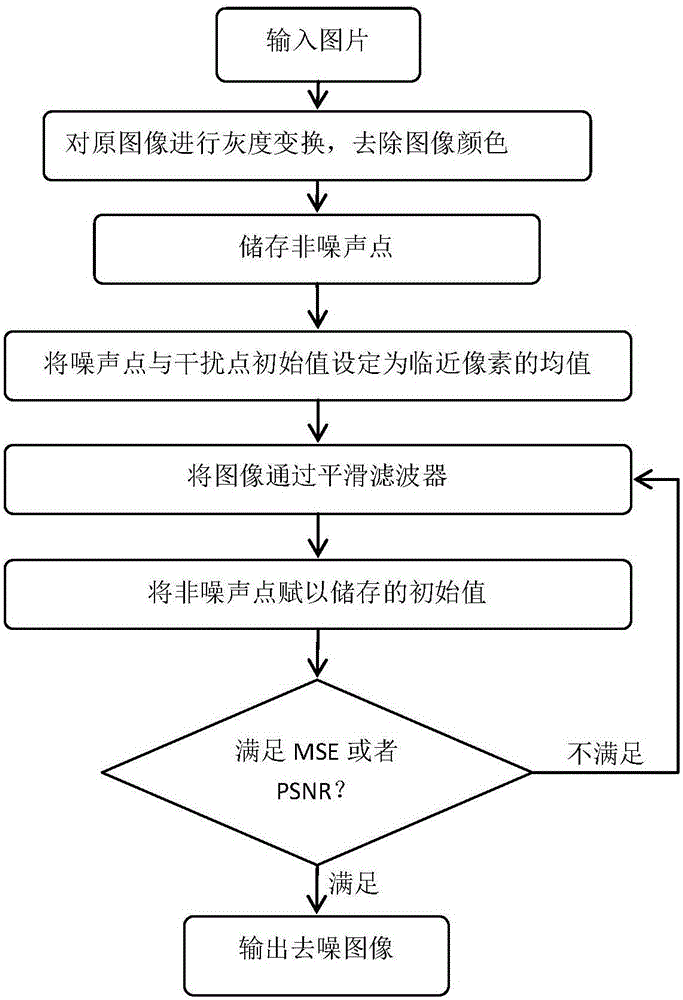

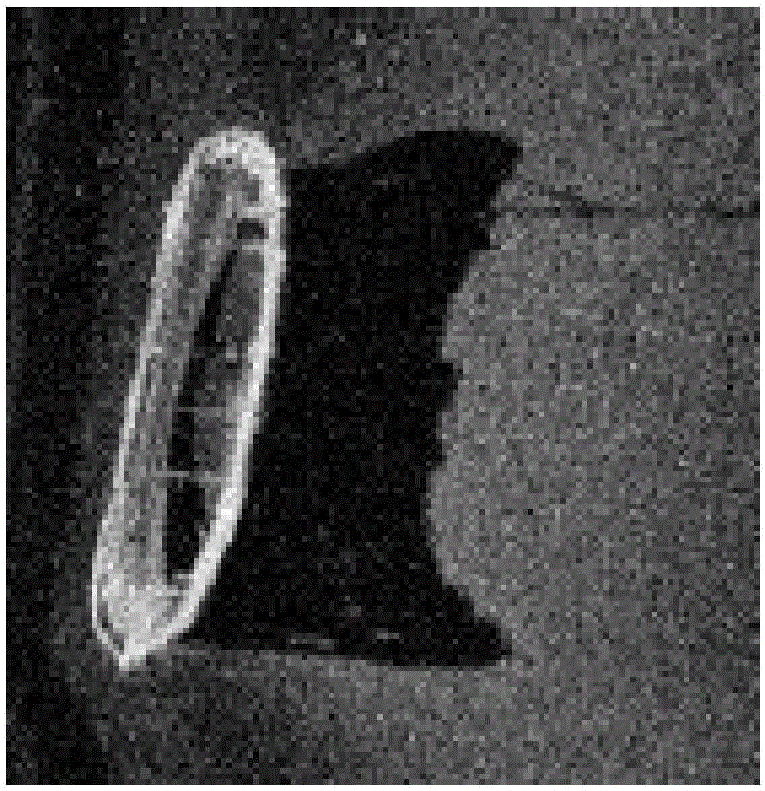

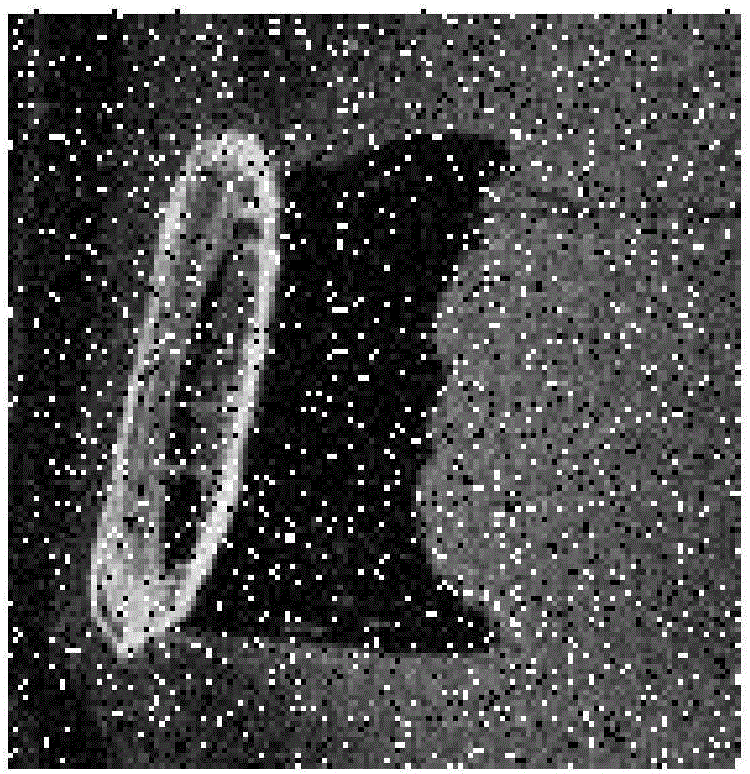

Improved P-G rapid method for removing interference noise

InactiveCN105957021AResolve blurSolve brightnessImage enhancementImage analysisDigital signal processingPattern recognition

The present invention belongs to the field of the digital image processing, and relates to an improved P-G rapid method for removing interference noise. The method comprises: performing gray conversion of an original image, and removing the color of the image; performing marking of the non-noise point in the image; storing the non-noise point into the number group; setting the original value of the noise points and other interference points in the image as a mean value; and setting a cut-off frequency according to the frequency domain of the image, replacing an original frequency domain low pass filter with a smooth frequency domain low pass filter, and maintaining partial high-frequency information. The Improved P-G rapid method for removing interference noise is applied to the field of image denosing to maintain the partial high-frequency information through designing the smoother filter and improve the condition of the reduced signal energy in the filtering process so as to solve the deficiencies of the original P-G algorithm of fuzzy edge and dark brightness after restoration.

Owner:HARBIN ENG UNIV

LED lamp structure

InactiveCN101813249ASolve power problemsSolve brightnessPoint-like light sourceElectric circuit arrangementsManufacturing cost reductionMetal foil

The invention relates to an LED lamp structure which comprises a lamp body, a plurality of LED chips and a lamp shade, wherein the front end of the lamp body is provided with a groove, an anode and cathode conducting circuit and a metal foil, and the back end of the lamp body is provided with a plurality of cooling fins; the LED chips are loaded on the metal foil, electrically connected with the anode and cathode conducting circuit by a line throwing mode and also electrically connected with a wire connecting point, and finally, a packaging material is filled to complete packaging; and the lamp shade is arranged at the front end of the lamp body. The lamp structure not only can reduce power consumption and manufacturing cost, but also can prolong service life.

Owner:简孝伦

Method for manufacturing GaP rough surface of GaAs-based LED wafer

ActiveCN112397624AUniformly roughened surfaceEasy to controlSemiconductor devicesRough surfaceWafering

The invention discloses a method for manufacturing a GaP rough surface of a GaAs-based LED wafer, and the method comprises the steps: preparing a wafer epitaxial layer, carrying out the roughening corrosion of a GaP window layer of the epitaxial layer, dissolving photoresist and roughening corrosion liquid together through a surfactant, forming corrosion sol with a roughening corrosion effect, coating the surface of the GaP window layer with the corrosion sol, baking at a constant temperature of 40-60 DEG C, removing a corrosion film layer and a silicon dioxide layer by using solvents such asacetone and the like, and continuously preparing to obtain an independent tube core; the process method designed by the invention is simple and easy to operate, does not need to introduce special equipment, is lower in cost, is more uniform in coarsening corrosion of the surface of the epitaxial layer, is higher in corrosion controllability, is good in coarsening effect, and solves the problems that the coarsening corrosion is more difficult to control and the coarsening brightness is not improved greatly when a solution is used at present. When the method provided by the invention is used forcoarsening, the light extraction efficiency can be improved by 25-30 percent, and the method has higher practicability.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

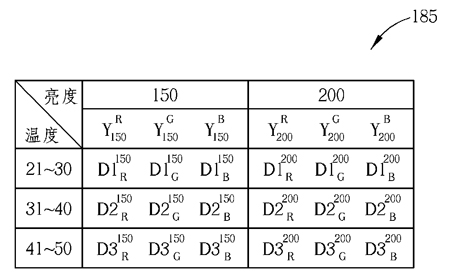

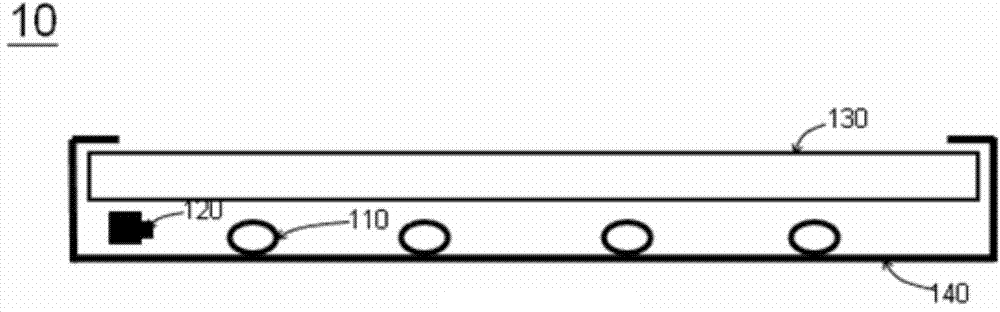

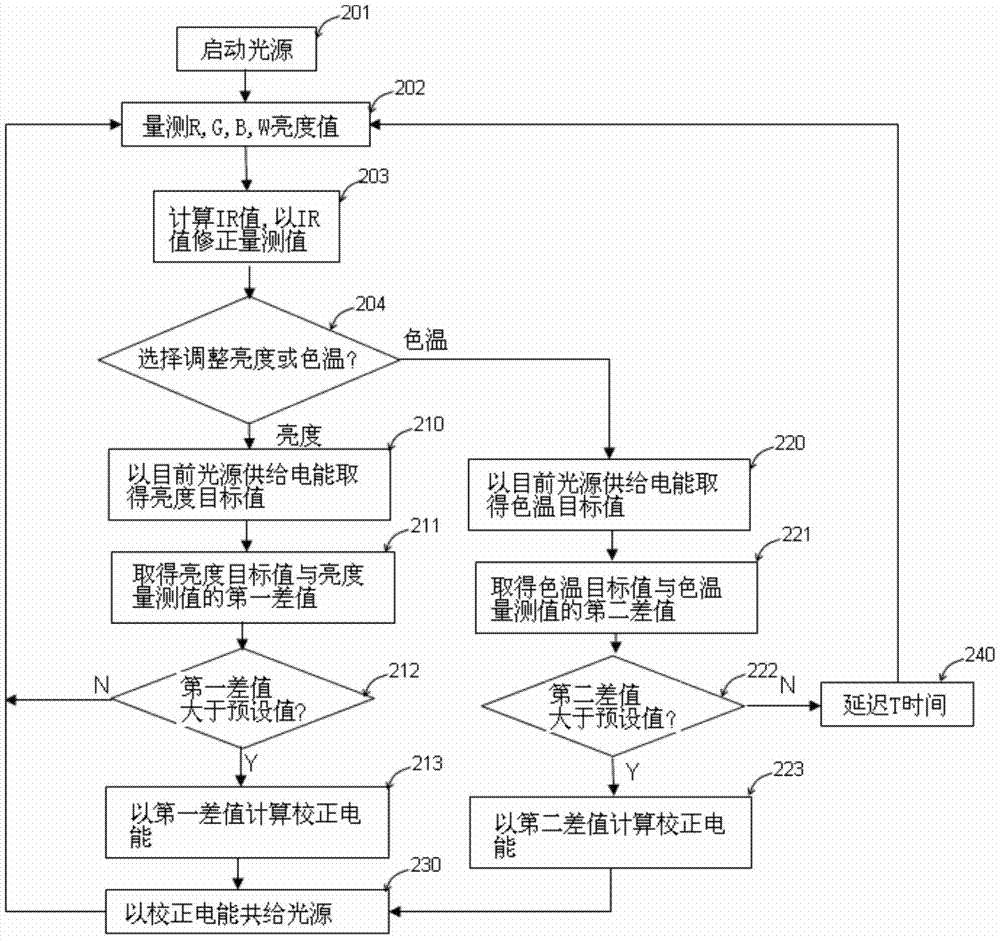

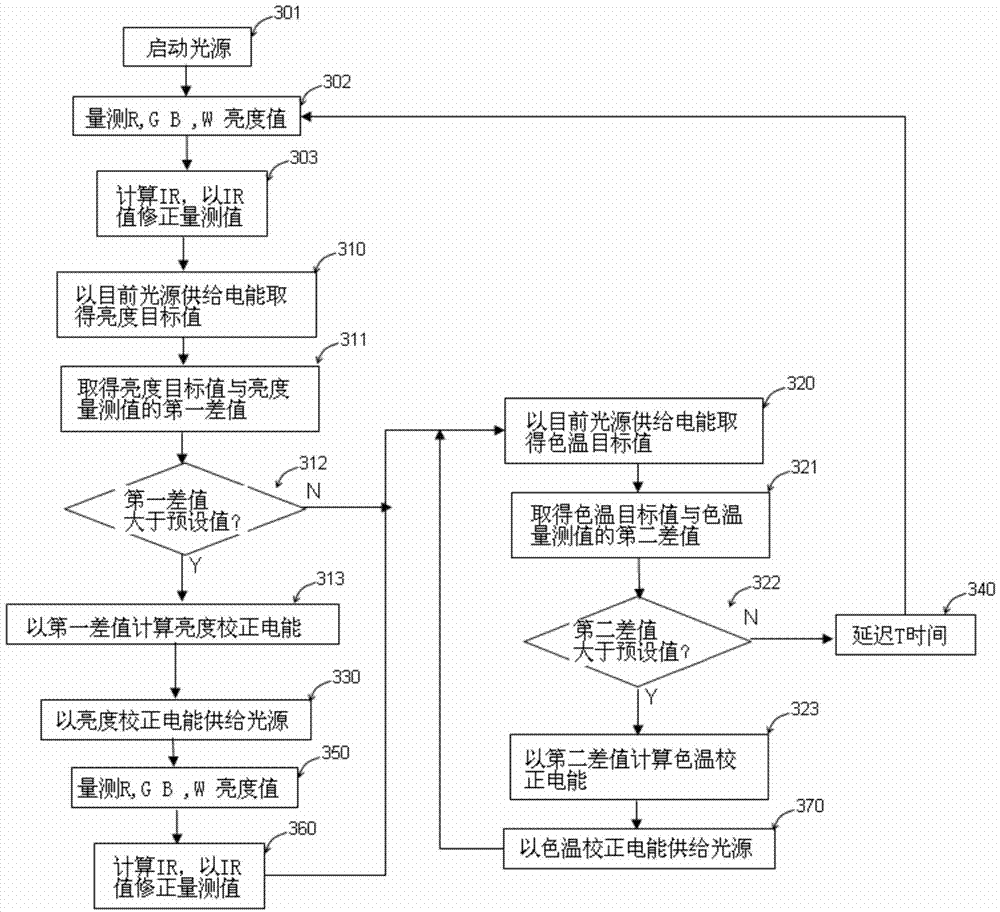

Display device and light source correction method for display device

ActiveCN104776351ASolve brightnessSolve the problem of color castStatic indicating devicesSpectral modifiersElectric energyCorrection method

The invention provides a display device and a light source correction method for the display device. The display device comprises a liquid crystal module, a back cover, light sources and a sensing module; the sensing module is used for measuring red light values, blue light values, green light values and white light values of the light sources; the light sources and the sensing module are arranged between the liquid crystal module and the back cover; the light source correction method comprises the following steps of starting the light sources, and measuring a first red light value, a first blue light value, a first green light value and the white light value of the light sources; calculating an infrared light value according to the first red light value, the first blue light value, the first green light value and the white light value, and subtracting the infrared light value from one of the first red light value, the first blue light value and the first green light value for correcting the supplied electric energy of the light sources. According to the display device and the light source correction method for the display device, provided by the invention, in consideration of the influences of infrared rays on measured values, the problems of bright reduction and color bias of the display device in the prior art are solved.

Owner:QISDA SUZHOU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com