Color film forming method based on continuous magnetron sputtering

A molding method and magnetron sputtering technology, applied in sputtering coating, ion implantation coating, coating and other directions, can solve the requirements of sputtering deposition film rate are relatively high, difficult to plate oxide targets, The problem of high cost investment can achieve the effect of low equipment configuration requirements, saving coating costs and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

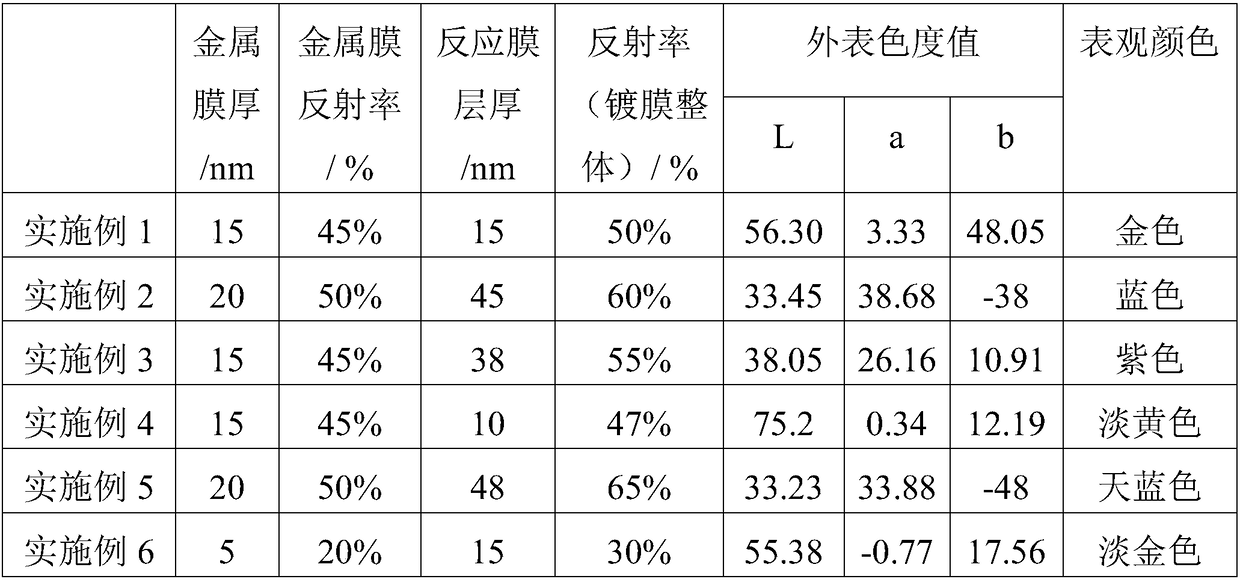

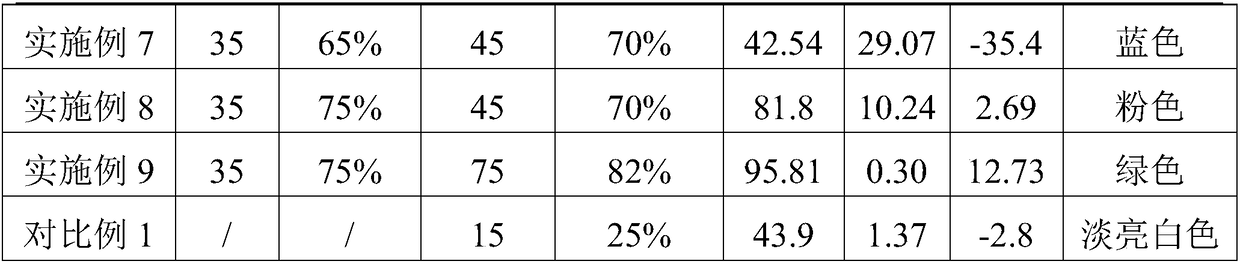

Embodiment 1

[0023] Take a piece of alumina ceramic substrate with a size of 10cm×5cm, and use Youwei IN-LINE continuous sputtering machine as the sputtering equipment. The initial coating vacuum of the process chamber is 5.0E-3pa, and the frequency of the continuous line stroke motor is 20Hz. ;

[0024] No. 1 process chamber process gas argon (120ml / min), sputtering power supply (voltage 385V, current 3.5A) sputtering chromium target;

[0025] Process gas argon (150ml / min) in the second process chamber, reactive gas oxygen (55ml / min), sputtering power supply (voltage 385V, current 4.0A) sputter metal niobium, react with oxygen to form niobium oxide film.

Embodiment 2

[0027] Take a piece of alumina ceramic substrate with a size of 10cm×5cm, and use Youwei IN-LINE continuous sputtering machine as the sputtering equipment. The initial coating vacuum of the process chamber is 5.0E-3pa, and the frequency of the continuous line stroke motor is 20Hz. ;

[0028] No. 1 process chamber process gas argon (120ml / min), sputtering power supply (voltage 395V / current 4A) sputtering chromium target;

[0029] Process gas argon (150ml / min) in the second process chamber, reactive gas oxygen (75ml / min), sputtering power supply (voltage 420v, current 6A) sputter metal niobium, react with oxygen to form niobium oxide film.

Embodiment 3

[0031] Take a piece of alumina ceramic substrate with a size of 10cm×5cm, and use Youwei IN-LINE continuous sputtering machine as the sputtering equipment. The initial coating vacuum of the process chamber is 5.0E-3pa, and the frequency of the continuous line stroke motor is 20Hz. ;

[0032] No. 1 process chamber process gas argon (150ml / min), reactive gas oxygen (65ml / min), sputtering power supply (voltage 400V, current 5A) sputter metal niobium, react with oxygen to form niobium oxide film;

[0033] The process gas of the second process chamber is argon (120ml / min), and the sputtering power supply (voltage 385V, current 3.5A) sputters a chromium target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com