Maintenance inspection system for elevator

A technology for inspection systems and elevators, which is applied to elevators, transportation, and packaging in buildings. It can solve the problems that sensors are difficult to detect, the height difference is not large, and the number of sensors is large, so as to prevent the cost from rising.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

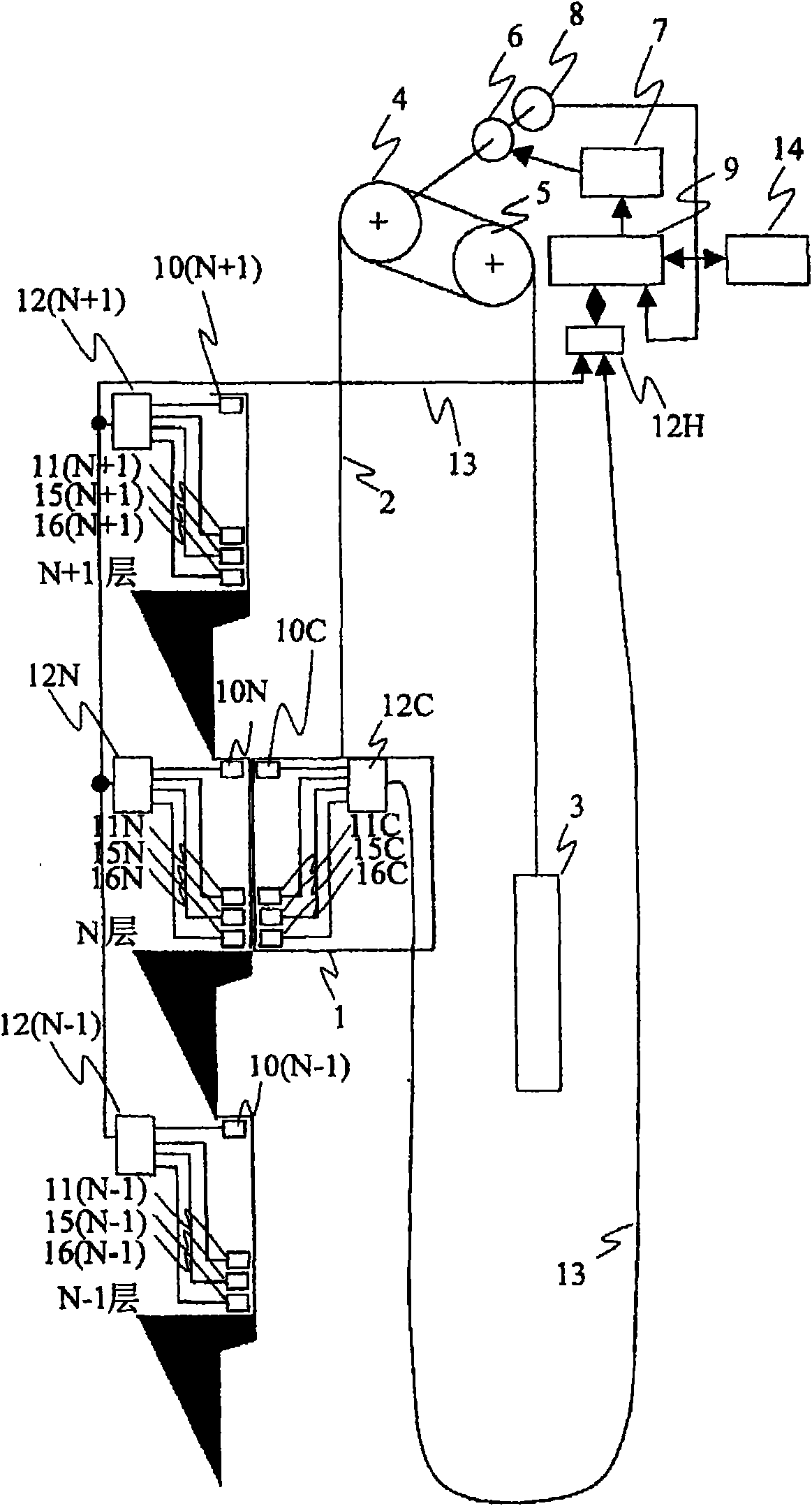

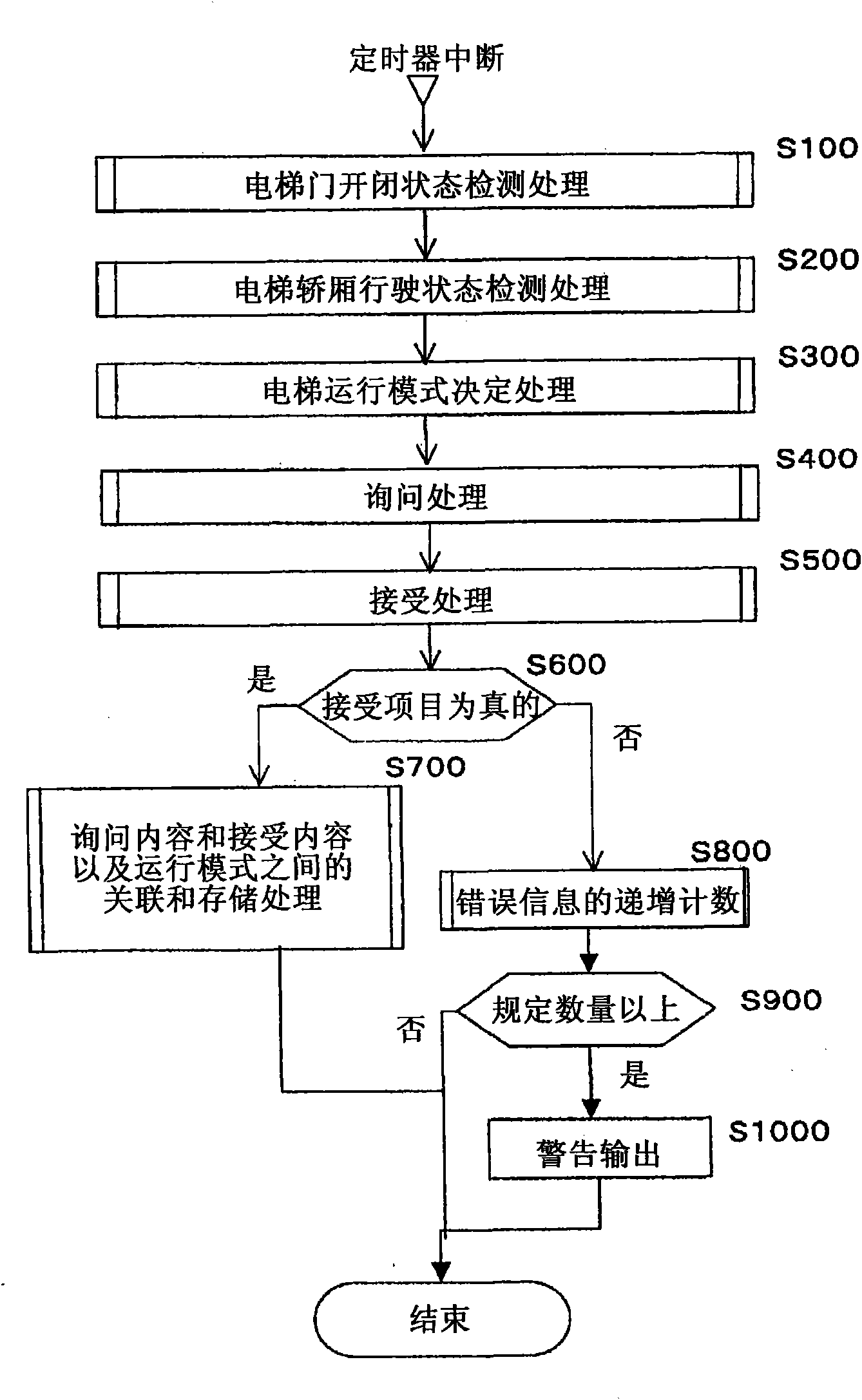

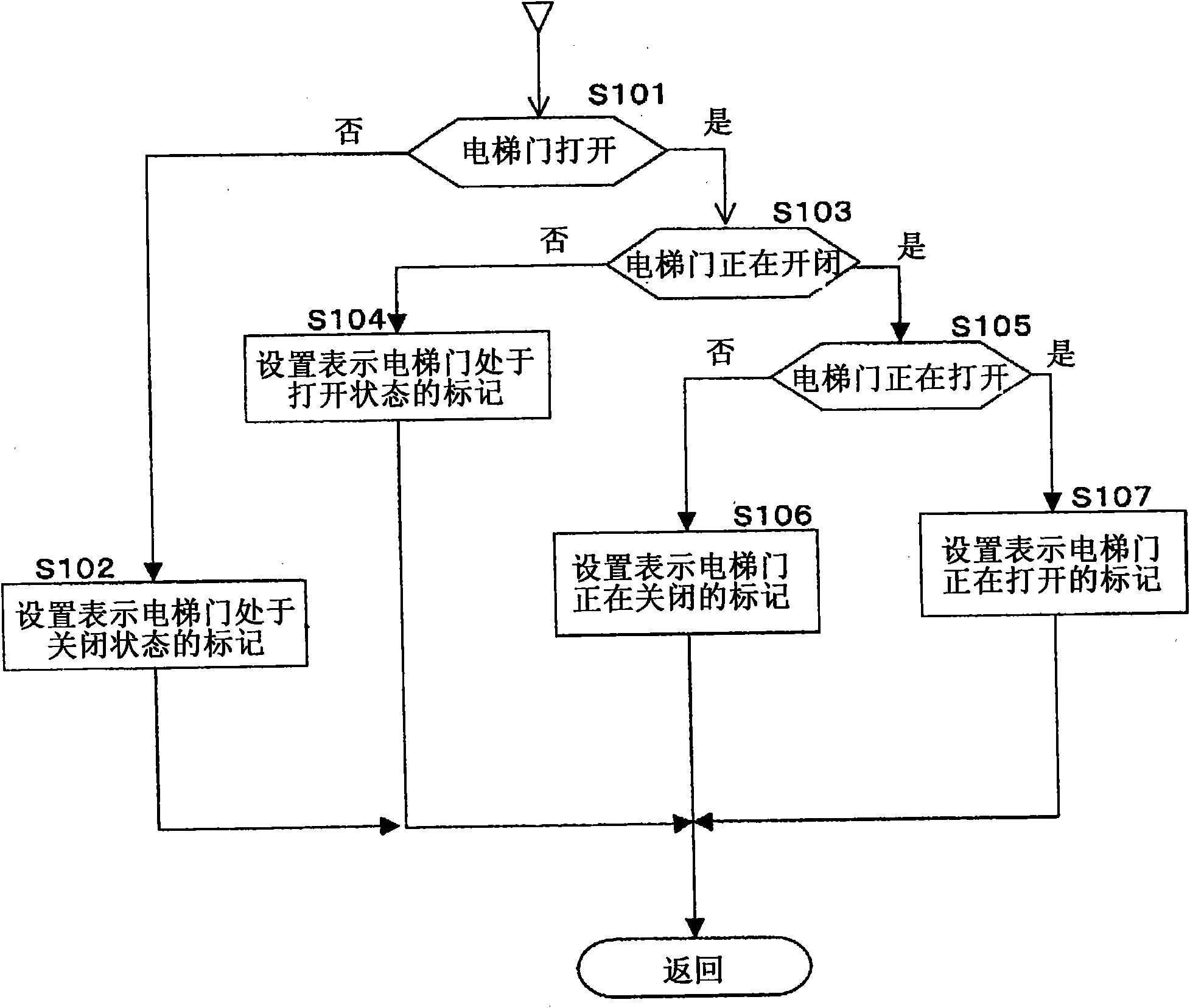

[0051] Refer to the following Figure 1 to Figure 8 An embodiment example of the present invention will be described.

[0052] figure 1 is an overall configuration diagram of the present invention, showing an embodiment example, and refers to the following figure 1 This structure will be described.

[0053] The elevator car 1 carrying passengers and the counterweight 3 are connected to the main rope 2 through a sheave 4 and a deflection pulley 5. of electricity.

[0054] In addition, the motor 6 is equipped with a pulse generator 8, and the pulses generated as the motor rotates are input into the control device 9, and the control device 9 calculates the speed of the elevator car and the vertical position of the elevator car according to the pulses input. Various control data such as position in direction.

[0055] In the elevator car 1, in addition to being provided with known devices such as a display 10C for displaying the position of the elevator car, buttons 11C corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com