Automobile power supply loop redundancy system

A redundant system, automotive power supply technology, applied in circuit devices, emergency power supply arrangements, circuits or fluid pipelines, etc., can solve the problems of narrow application area, power-off restart of parts, high cost, and improve functional safety level, The effect of solving the limitation of hardware conditions and using a wide area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

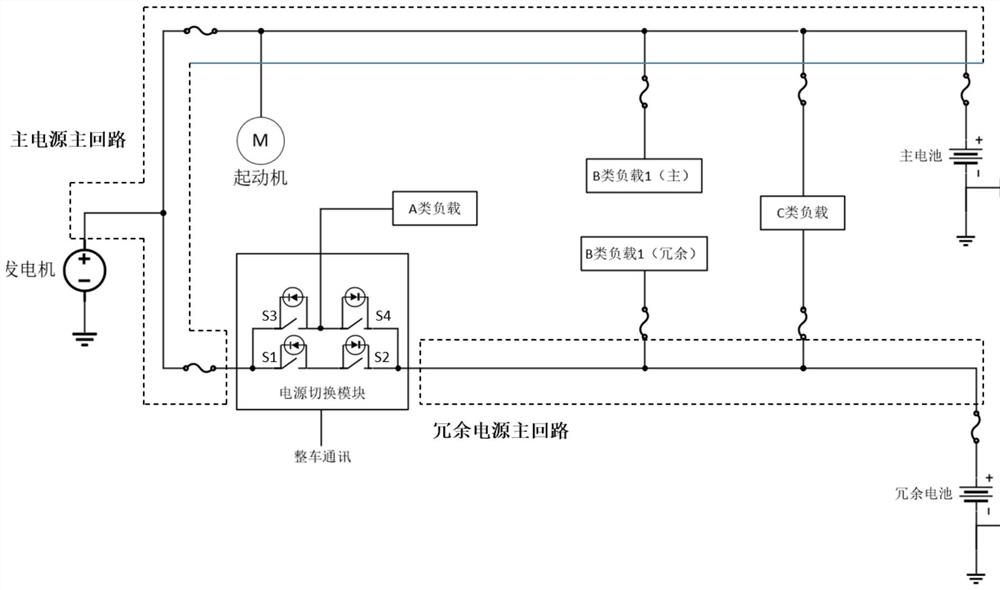

[0023] Such as figure 1As shown, the present invention provides a kind of automotive power circuit redundancy system, including generator, main battery, power switching module, redundant battery, wherein generator and main battery are used as main power supply, and redundant battery is used as redundant power supply; Power generation The positive pole of the generator is electrically connected to the positive pole of the main battery, the negative pole of the generator is grounded to the negative pole of the main battery; The positive electrode of the redundant battery is electrically connected to the A-type load, B-type redundant load and C-type load through the power switching module; the negative electrode of the redundant batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com