Display device and light source correction method for display device

A light source correction and light source technology, applied in the field of light source correction, can solve problems such as deviation when correction is not taken into account, interpretation error, and the tendency of brightness of display units to dim, and achieve the effect of solving brightness reduction and color deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

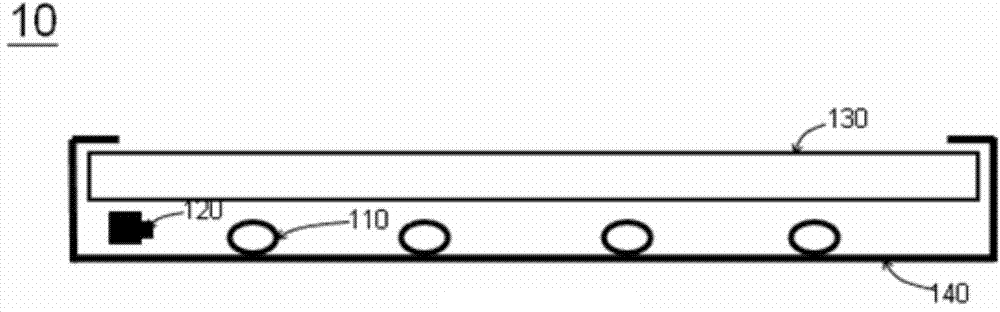

[0026] Please refer to figure 1The structure schematic diagram of the display device 10 of the present invention, the structure of the display device 10 includes: a liquid crystal module 130 , a back cover 140 , a light source 110 and a sensing module 120 . The light source 110 can be an LED light source module with three primary colors of red, blue, and green. When adjusting the light source, the power supply of the light source with three primary colors of red, blue, and green can be adjusted. In addition, the light source 110 can also use an LED light source module packaged by red and blue LED chips and green phosphor powder. When adjusting the light source, only the red and blue light sources can be adjusted for power supply. In the present invention, as long as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com