LED lamp structure

A technology of LED lamps and LED chips, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve problems such as increased costs, and achieve the effects of prolonging service life and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

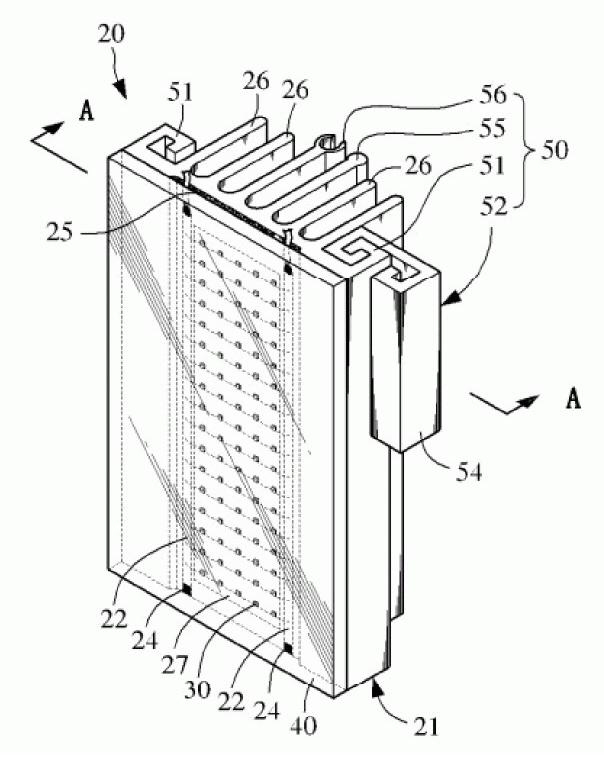

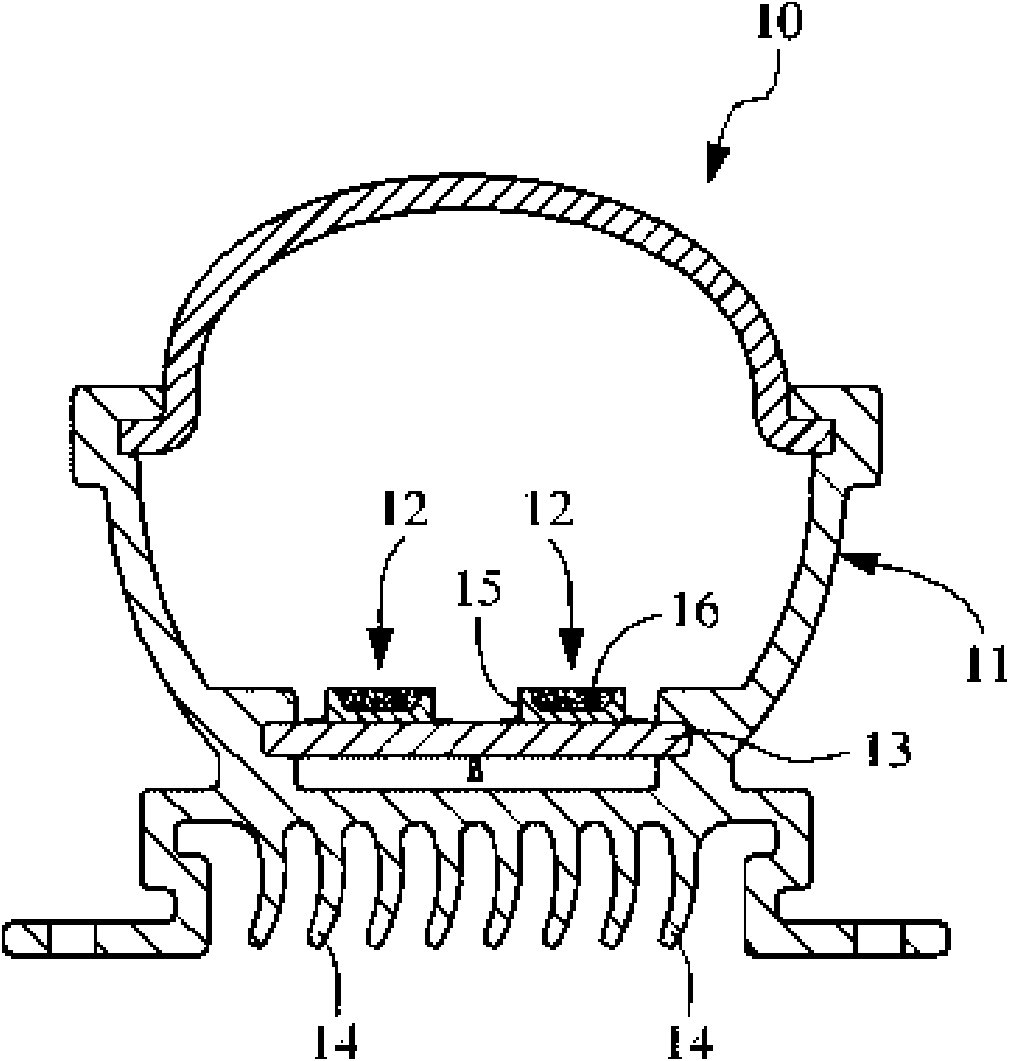

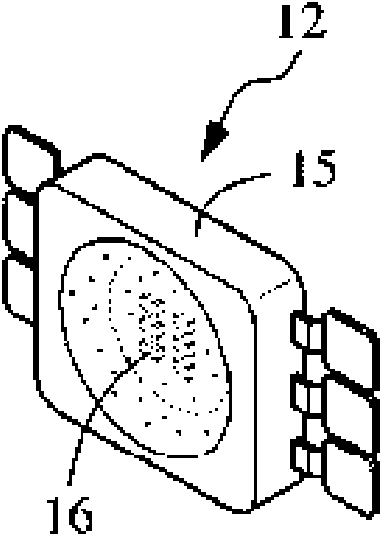

[0034] As shown in FIGS. 3 to 5 , the LED lamp structure 20 of the present invention includes a lamp body 21 , several LED chips 30 , a lampshade 40 and an extension structure 50 . The lamp body 21 is made of a material with better heat dissipation. The front end of the lamp body 21 is provided with a groove 23 , on which are provided a positive and negative conductive circuit 22 and a metal foil 27 , and the metal foil 27 is located between the positive and negative conductive circuit 22 . Several LED chips 30 are mounted on the metal foil 27, connected in series and parallel, and electrically connected to the positive and negative conductive lines 22 by wire bonding, so that the LED chips 30 and the connection point 24 are electrically connected, Finally, the encapsulation material 25 is filled on the groove 23 to complete the encapsulation, and the light source emitted by the LED chip 30 can be emitted through the encapsulation material 25 . Because the LED chip 30 is emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com