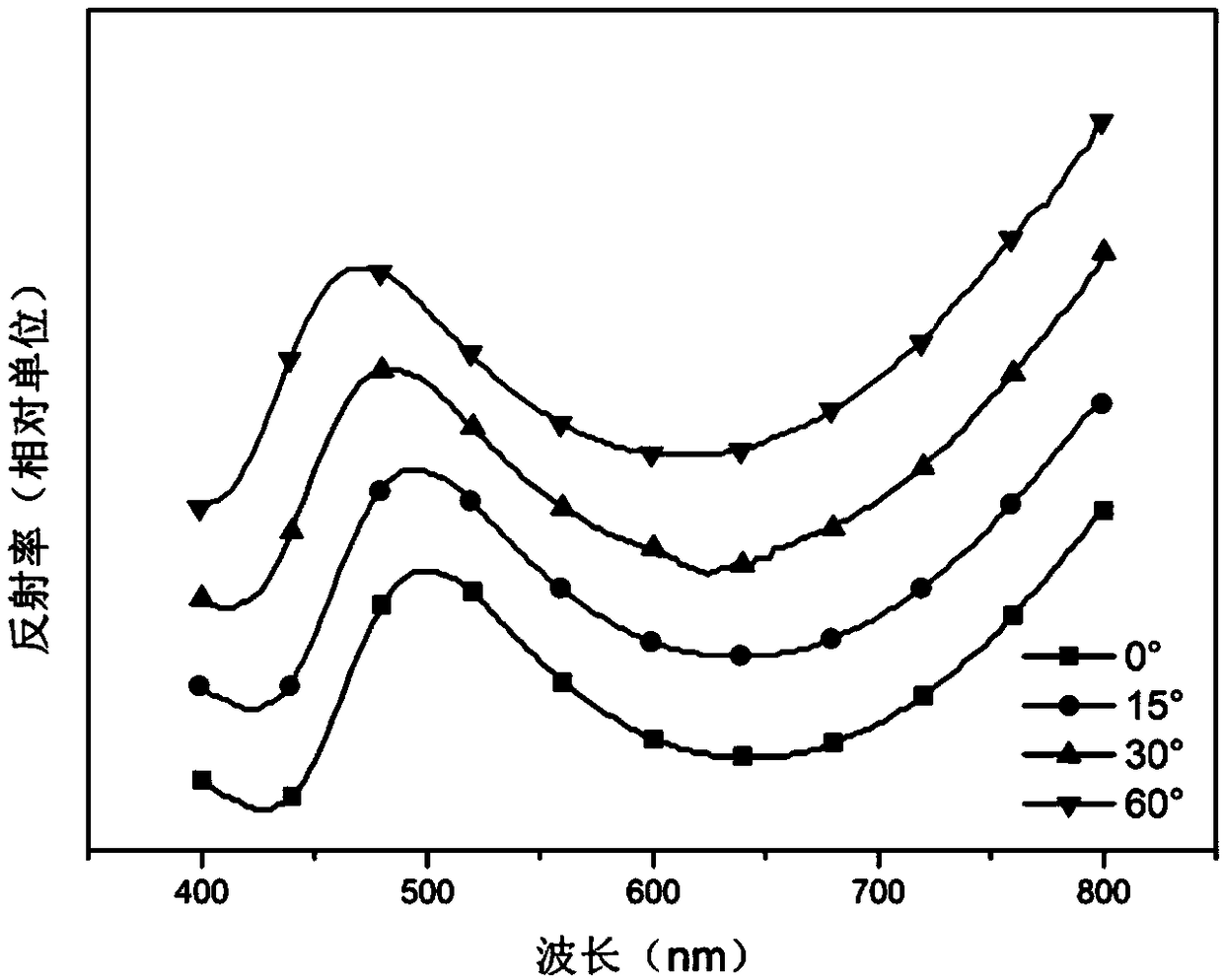

Composite photon structure material with generated color being high in luminance and low in angle dependence and preparation method thereof

An angle-dependent, photon-structured technology, which is applied to devices, coatings, special surfaces, etc. for coating liquid on the surface, can solve the problems of complex preparation process, high cost, and difficulty in large-scale application, and achieve wide application Prospects, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Prepare negatively charged monodisperse polystyrene nanospheres on the surface by soap-free emulsion polymerization. The specific preparation method is: 4g styrene, 1g methacrylic acid, and 100g deionized water are placed in a 250mL four-necked flask In the process, stir at a speed of 300r / min and slowly raise the temperature to 75°C. After the temperature stabilizes, dissolve 0.15g of ammonium persulfate in 5g of deionized water, quickly add it to the aforementioned four-necked flask, and stir for 12 hours. After the reaction, centrifuge and wash 3 times, and finally disperse in deionized water for later use. The particle diameter of the obtained polystyrene nano microsphere is 207nm, and the surface of the particle is negatively charged.

[0035] (2) The polystyrene nano-microspheres obtained in step (1) and the anionic polyurethane dispersion (the anionic polyurethane dispersion used is selected from commercial Dispercoll U53) and carbon black are ①10:1:0.1, ②10:...

Embodiment 2-3

[0042] The negatively charged monodisperse polystyrene nanospheres in Example 1 are replaced with negatively charged silica nanospheres (the silica nanospheres are selected from Zhongke Leiming (Beijing) Technology Co., Ltd., DKSIO200 , particle size 200nm), negatively charged polymethyl methacrylate nano-microspheres (the polymethyl methacrylate nano-microspheres are selected from Shanghai Zhenzhun Biotechnology Co., Ltd., ZZS-MMA200, particle size 200nm), microspheres Mix and disperse with anionic polyurethane dispersion and carbon black at a mass ratio of 10:2:0.1, and other conditions are consistent with Example 1.

[0043] Table 2

[0044]

Embodiment 4-5

[0046] The anionic polyurethane dispersion in Example 1 was replaced by an anionic acrylic emulsion, anionic epoxy resin emulsion, microspheres, anionic polymer emulsion and carbon black were mixed in a mass ratio of 10:2:0.1 and Dispersed, other conditions are consistent with embodiment 1.

[0047] table 3

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com