Light source structure based on LED

A technology of light-emitting diodes and light sources, which is applied in the direction of light sources, point light sources, components of lighting devices, etc., can solve problems such as difficult to achieve uniform light-emitting mode, serious loss of light energy, uneven brightness, etc., to achieve the solution of LED light-emitting energy Low utilization rate, easy to clean, solve the effect of uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

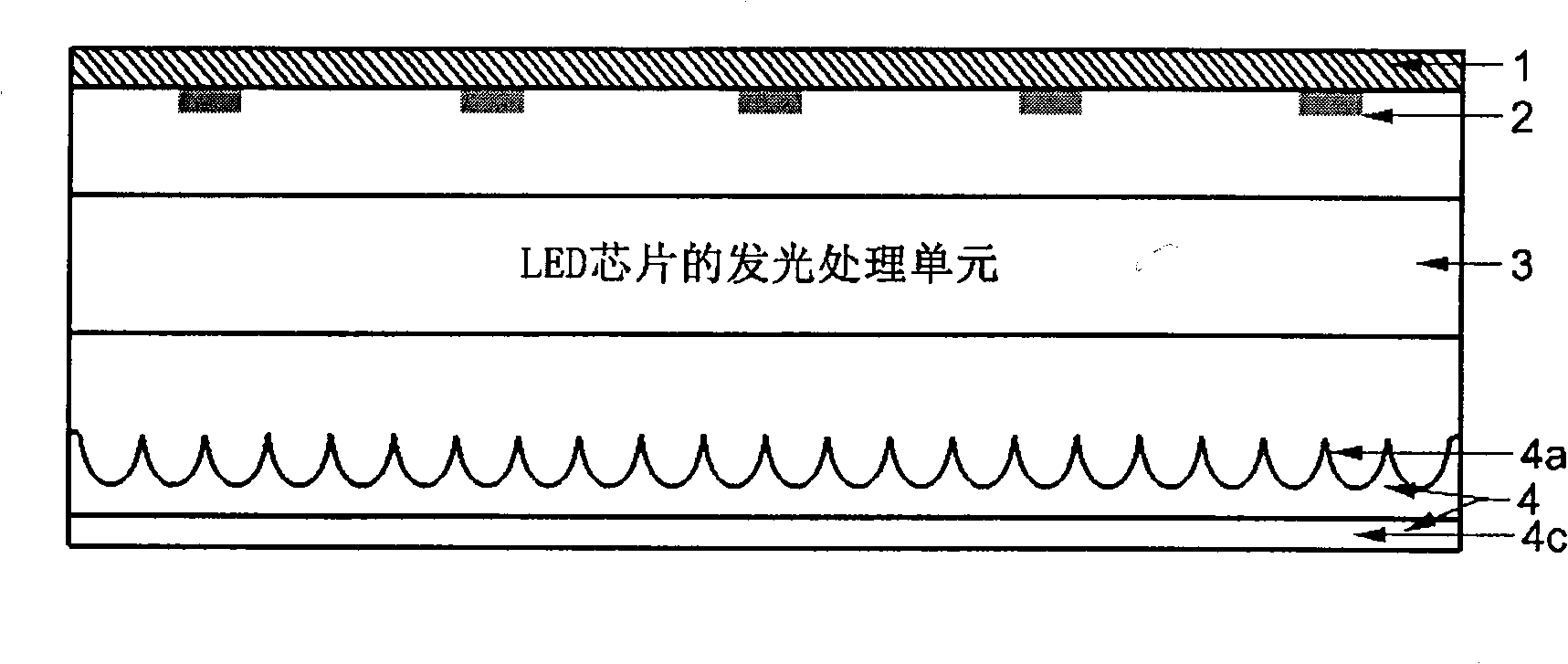

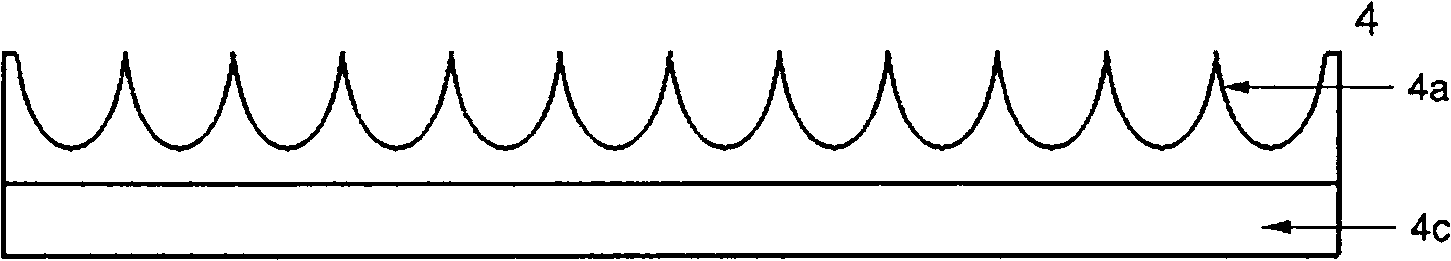

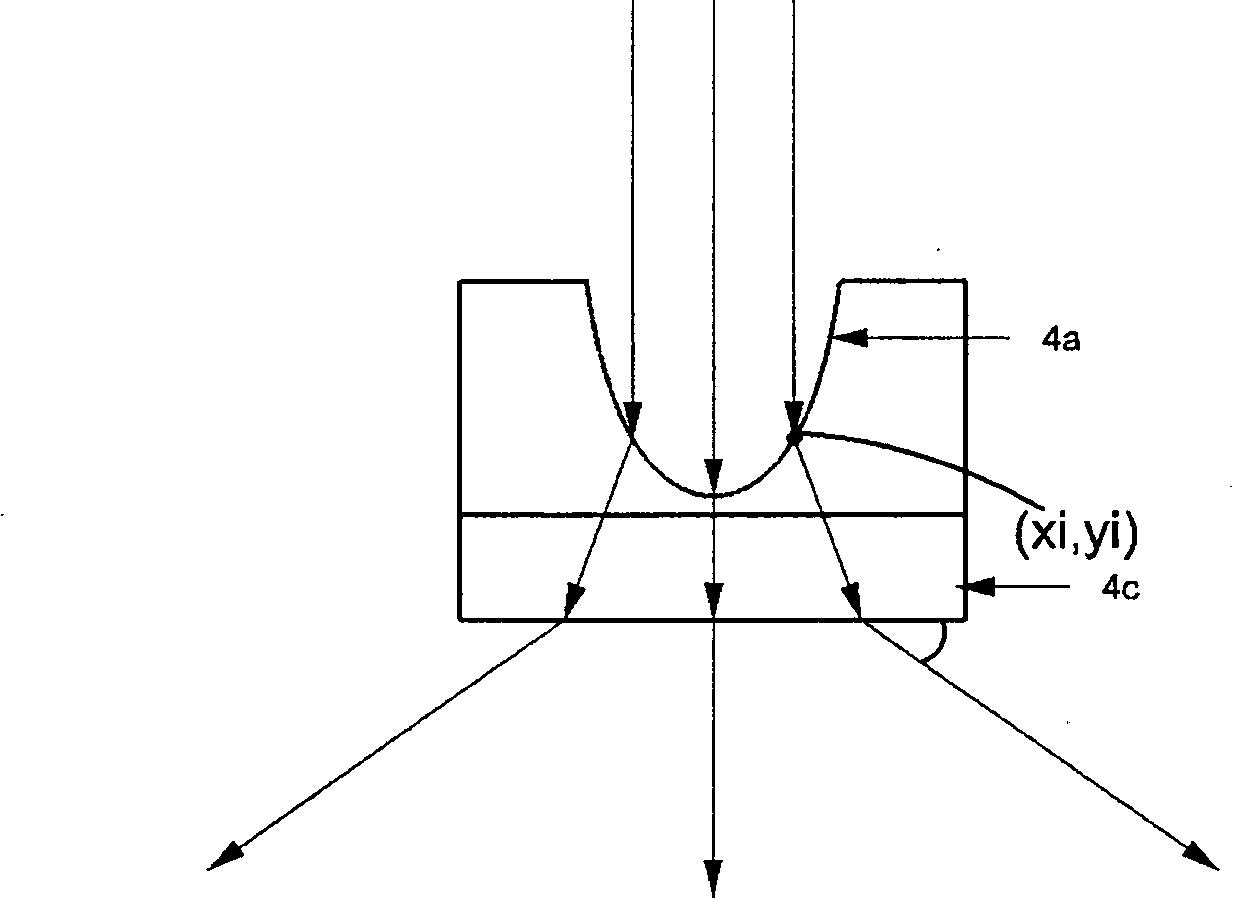

[0045] The basic structure of the light source structure device disclosed in the present invention is as follows: figure 1 shown. The light source structure at least includes a substrate 1, an LED chip 2, a light emitting processing unit 3 of the LED chip, and an optical diffuser plate 4 with non-imaging optical design. The LED chip 2 fixed on the substrate 1 is a light source, and its light field distribution is transmitted to the inner surface of the optical astigmatism plate 4 after being processed by the light emission processing unit 3 of the LED chip, including but not limited to collimation; the optical astigmatism plate 4 At least one side contains engineered microstructures that scatter incident light to form a light source structure of uniform brightness.

[0046] At least one side of the optical astigmatism plate of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com