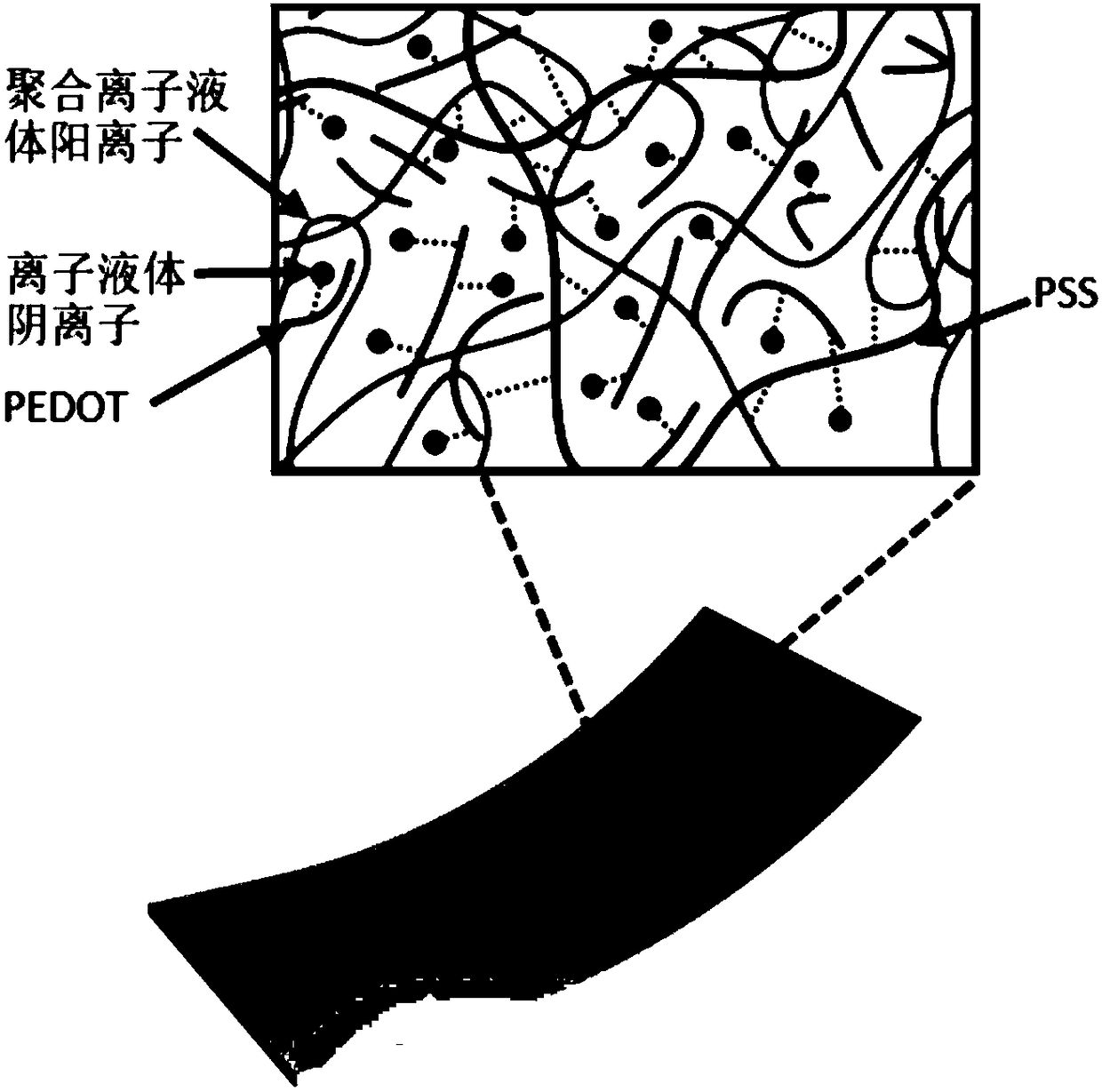

Manufacturing method of PEDOT:PSS@ ionic liquid gel composite self-supporting flexible transparent electrode

A technology of ionic liquid and transparent electrode, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., to achieve the effect of easy control, simple equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation method of transparent PEDOT:PSS film

[0034] The PEDOT:PSS solution was spin-coated on a glass slide to form a PEDOT:PSS film, which was used in the next step to prepare a PEDOT:PSS@polyionic liquid composite transparent electrode.

[0035] (2) Electrostatic interaction between PEDOT:PSS and ionic liquid prepolymerization

[0036] A solution (1-vinyl-3- The mass ratio of ethylimidazole dinitrile amine salt and N-methylimidazolium bisulfate / potassium persulfate / N,N-methylenebisacrylamide is 1000 / 10 / 10) coated to the formed in step (1) On the transparent PEDOT:PSS film, a composite PEDOT:PSS film was obtained.

[0037] (3) Preparation of PEDOT:PSS@polyionic liquid composite transparent electrode

[0038] The PEDOT:PSS film in step (2) was heated at 80°C for 10min, rinsed with distilled water several times, and heated at 120°C for 10min to obtain a PEDOT:PSS@polyionic liquid composite flexible transparent electrode with excellent conductivity and stabil...

Embodiment 2

[0042] (1) Preparation method of transparent PEDOT:PSS film

[0043] The PEDOT:PSS solution was spin-coated on a glass slide to form a PEDOT:PSS film, which was used in the next step to prepare a PEDOT:PSS@polyionic liquid composite transparent electrode.

[0044] (2) Electrostatic interaction between PEDOT:PSS and ionic liquid prepolymerization

[0045] A solution (N- The mass ratio of vinylpyridine tetrafluoroborate and N-methylimidazole bis(trifluoromethanesulfonyl)imide / potassium persulfate / N,N-methylenebisacrylamide is 1000 / 10 / 10) Apply to the transparent PEDOT:PSS film formed in step (1) to obtain a composite PEDOT:PSS film.

[0046] (3) Preparation of PEDOT:PSS@polyionic liquid composite transparent electrode

[0047] The PEDOT:PSS film in step (2) was irradiated with 255nm ultraviolet light for 1h, rinsed with distilled water several times, and heated at 120°C for 10min to obtain a PEDOT:PSS@polyionic liquid composite flexible transparent electrode with excellent co...

Embodiment 3

[0051] (1) Preparation method of transparent PEDOT:PSS film

[0052] The PEDOT:PSS solution was spin-coated on a glass slide to form a PEDOT:PSS film, which was used in the next step to prepare a PEDOT:PSS@polyionic liquid composite transparent electrode.

[0053] (2) Electrostatic interaction between PEDOT:PSS and ionic liquid prepolymerization

[0054] Contain tributylvinylammonium (trifluoromethanesulfonyl) imide salt, 1-vinyl-3-ethylimidazole dinitrile amine salt, benzoyl peroxide, polyethylene glycol dimethacrylate Solution (tributylvinylammonium (trifluoromethanesulfonyl)imide salt and 1-vinyl-3-ethylimidazole dinitrile amine salt / benzoyl peroxide / polyethylene glycol dimethacrylate The mass ratio is 1000 / 10 / 10) and coated on the transparent PEDOT:PSS film formed in step (1) to obtain a composite PEDOT:PSS film.

[0055] (3) Preparation of PEDOT:PSS@polyionic liquid composite transparent electrode

[0056] The PEDOT:PSS film in step (2) was heated at 80°C for 10min, ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com