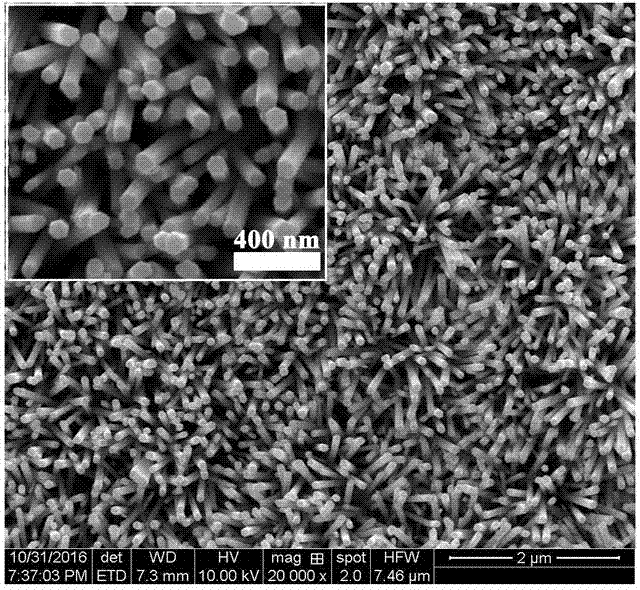

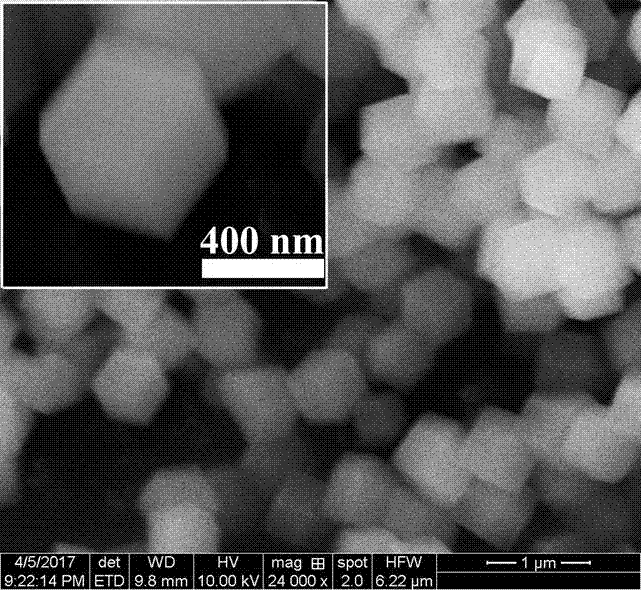

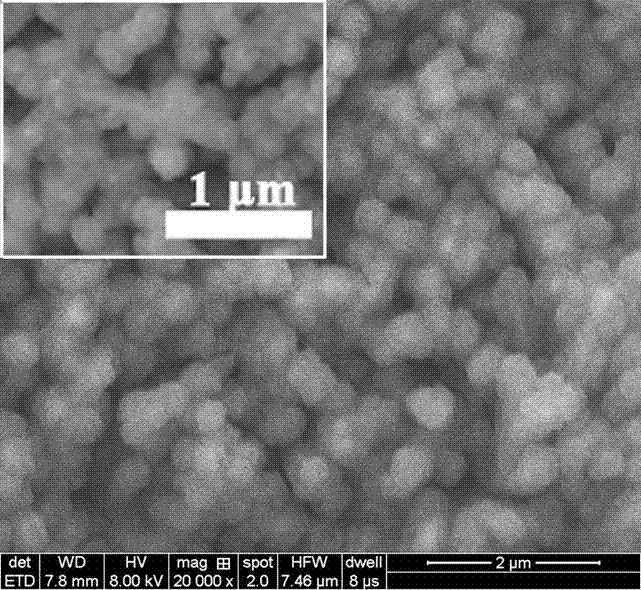

Preparation of rod-like ZnO/ZIF-8 and low temperature H2 sensitive effect of rod-like ZnO/ZIF-8

A ZIF-8, rod-shaped technology, applied in the field of nano-sensor preparation, can solve the problems of complex synthesis operation, large functional loss and high response temperature, and achieve the effects of good repeatability, low power consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] one with H 2 The preparation method of the rod-shaped ZnO / ZIF-8 of sensitive effect has the following steps:

[0028] 1) Preparation of zinc oxide seed layer sol: Weigh 4.4g of zinc acetate dihydrate, dissolve it in 25mL of ethylene glycol methyl ether and stir for 30min, then measure 1.2mL of ethanolamine into the above solution, stir on a magnetic stirrer for 30min to form a transparent Homogeneous sol, stand for 12h for later use;

[0029] 2) Cleaning of flat-plate electrodes: After cleaning the alumina flat-plate electrodes (including interdigitated Ag electrodes) with detergent, put them in acetone, isopropanol, absolute ethanol, and deionized water for ultrasonic cleaning for 30 minutes;

[0030] 3) Spin-coating the aluminum oxide flat electrode to form a film: dry the cleaned aluminum oxide flat electrode and put it on a spin coater, spin at a spin coating speed of 3000rpm / min for 30s, and the number of spin coatings is 3 times. After the completion, remove the...

Embodiment 2

[0040] one with H 2 The preparation method of the rod-shaped ZnO / ZIF-8 of sensitive effect has the following steps:

[0041] 1) Preparation of zinc oxide seed layer sol: Weigh 4.4g of zinc acetate dihydrate, dissolve it in 25mL of ethylene glycol methyl ether and stir for 30min, then measure 1.2mL of ethanolamine into the above solution, stir on a magnetic stirrer for 30min to form a transparent The homogeneous sol was left to stand for 12 hours for later use.

[0042] 2) Cleaning of flat-plate electrodes: After cleaning the alumina flat-plate electrodes (including interdigitated Ag electrodes) with detergent, put them in acetone, isopropanol, absolute ethanol, and deionized water for ultrasonic cleaning for 30 minutes;

[0043] 3) Spin-coating the aluminum oxide flat electrode to form a film: dry the cleaned aluminum oxide flat electrode and place it on a spin coater, spin at a spin coating speed of 5000rpm / min for 30s, and the number of spin coatings is 5 times. After the ...

Embodiment 3

[0048] one with H 2 The preparation method of the rod-shaped ZnO / ZIF-8 of sensitive effect has the following steps:

[0049] 1) Preparation of zinc oxide seed layer sol: Weigh 4.4g of zinc acetate dihydrate, dissolve it in 25mL of ethylene glycol methyl ether and stir for 30min, then measure 1.2mL of ethanolamine into the above solution, stir on a magnetic stirrer for 30min to form a transparent Homogeneous sol, stand for 12h for later use;

[0050] 2) Cleaning of flat-plate electrodes: After cleaning the alumina flat-plate electrodes (including interdigitated Ag electrodes) with detergent, put them in acetone, isopropanol, absolute ethanol, and deionized water for ultrasonic cleaning for 30 minutes;

[0051] 3) Spin-coating the aluminum oxide flat electrode to form a film: dry the cleaned aluminum oxide flat electrode and place it on a spin coater, spin at a spin coating speed of 4000rpm / min for 30s, and the number of spin coatings is 4 times. After the completion, remove t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com