Preparation method of copper-coated tungsten composite powder

A technology of composite powder and tungsten powder, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of poor wettability of powder sintering, poor uniformity of mechanical mixing, poor working conditions, etc. , to achieve the effect of improving tissue uniformity, uniform coating thickness and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

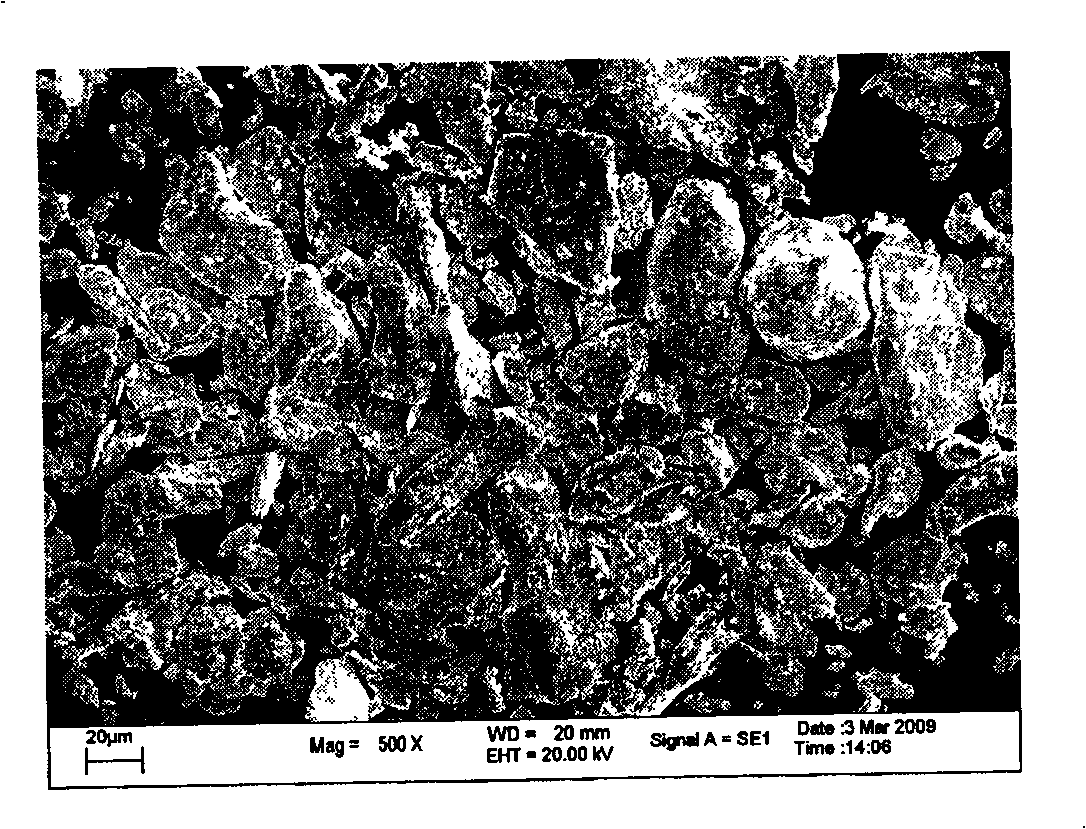

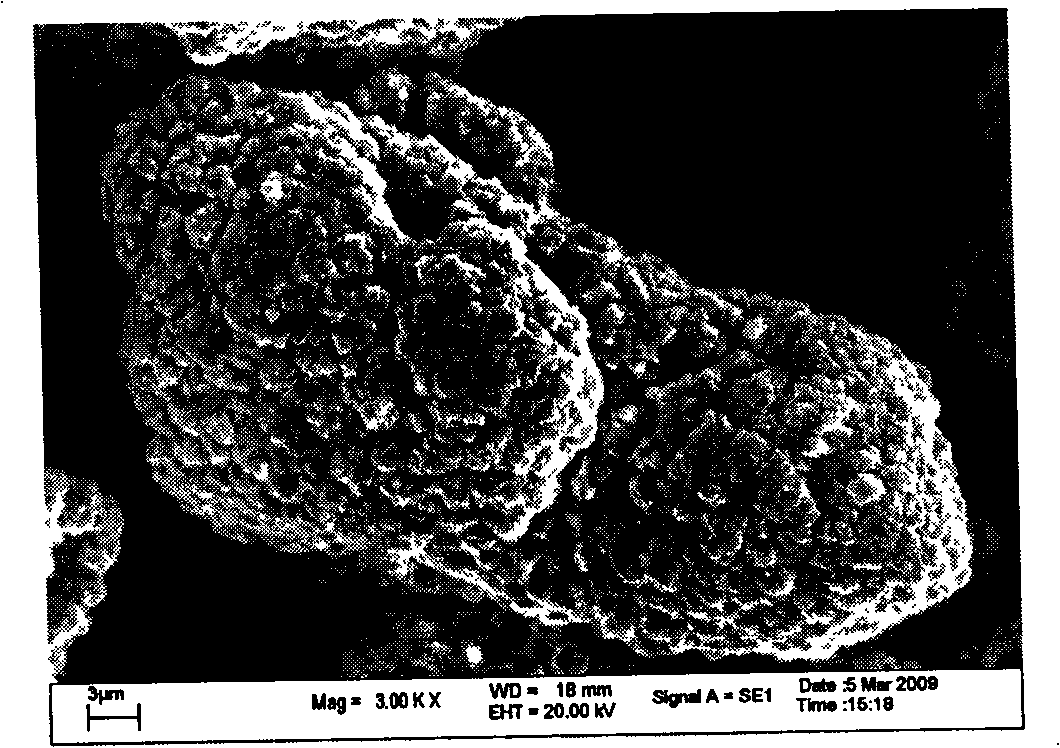

[0023] Prepare 100gW-10Cu composite powder. Take 90g of 30μm tungsten powder. First soak with 10g / L NaOH for 10 minutes, then remove the upper solution and wash with deionized water. Then soak the tungsten powder with 10% HCl for 20 minutes, then remove the upper solution and wash the tungsten powder.

[0024] Get 38.9g copper sulfate pentahydrate, and dissolve with deionized water, be made into the copper sulfate solution of 13g / L. Get 156g of potassium sodium tartrate and dissolve it with deionized water. Then the copper sulfate solution was slowly added to the sodium potassium tartrate solution under stirring to obtain a light blue suspension. At this time, NaOH was dissolved and added to the above light blue suspension, the solution turned dark blue, and the pH value was adjusted to 12. And 0.03 g of bipyridine was added. At this time, tungsten powder and 60ml of formaldehyde were added to the above dark blue solution. Heat it in a constant temperature water bath at ...

example 2

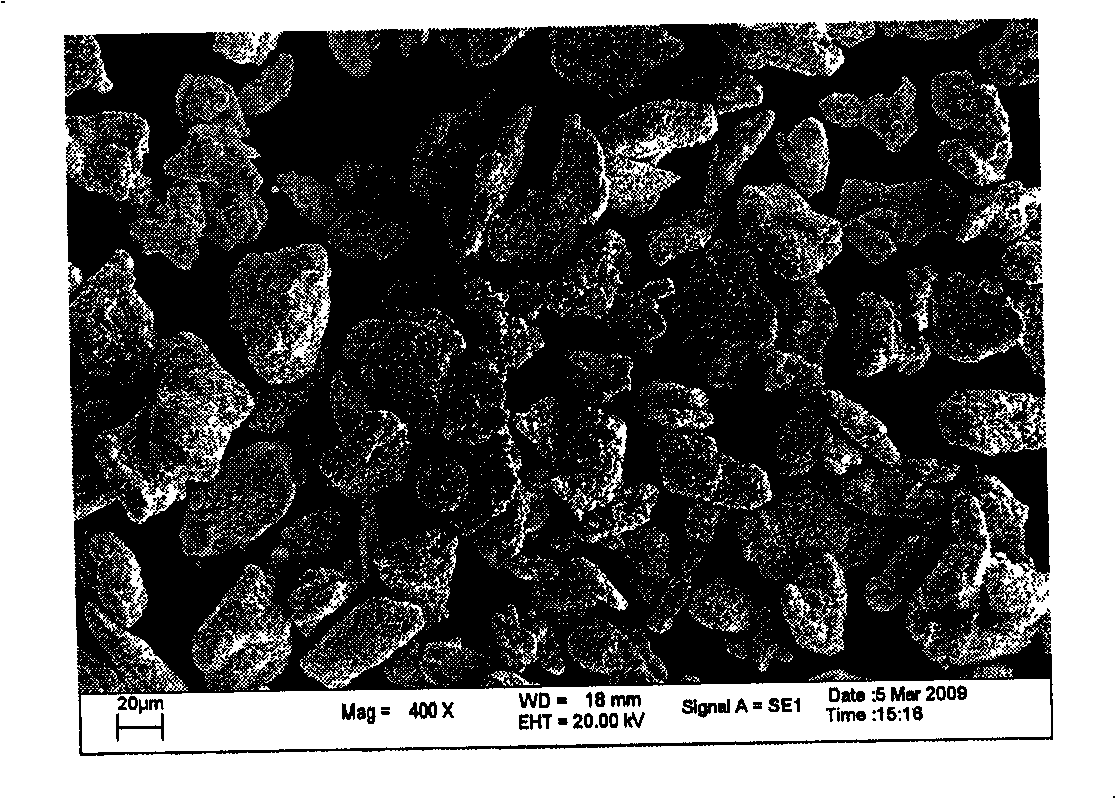

[0026] Prepare 200gW-10Cu composite powder. Take 180g of 30μm tungsten powder. First soak with 10g / L NaOH for 10 minutes, then remove the upper solution and wash with deionized water. Then soak the tungsten powder with 10% HCl for 20 minutes, then remove the upper solution and wash the tungsten powder.

[0027] Get 77.8g copper sulfate pentahydrate, and dissolve with deionized water, be made into the copper sulfate solution of 13.5g / L. Get 311g of potassium sodium tartrate and dissolve it with deionized water. Then the copper sulfate solution was slowly added to the sodium potassium tartrate solution under stirring to obtain a light blue suspension. At this time, NaOH was dissolved and added to the above light blue suspension, the solution turned dark blue, and the pH value was adjusted within the range of 12.5. And 0.11 g of bipyridine was added. At this time, tungsten powder and 86.4ml formaldehyde were added to the above dark blue solution. Heat in a constant temperat...

example 3

[0029] Prepare 100gW-15Cu composite powder. Take 85g of 10μm tungsten powder. First soak with 10g / L NaOH for 10 minutes, then remove the upper solution and wash with deionized water. Then soak the tungsten powder with 10% HCl for 20 minutes, then remove the upper solution and wash the tungsten powder.

[0030] Get 58.35g copper sulfate pentahydrate, and dissolve with deionized water, be made into the copper sulfate solution of 14g / L. Get 233g of potassium sodium tartrate and dissolve it with deionized water. Then the copper sulfate solution was slowly added to the sodium potassium tartrate solution under stirring to obtain a light blue suspension. At this time, NaOH was dissolved and added to the above light blue suspension, the solution turned dark blue, and the pH value was adjusted to 13. And 0.12 g of bipyridine was added. At this time, tungsten powder and 75.1 ml of formaldehyde were added to the above dark blue solution. Heat in a constant temperature water bath at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com