Preparation method for semitransparent YAG fluorescent ceramic sheet

A fluorescent ceramic and translucent technology, applied in the field of preparing translucent fluorescent ceramics, can solve the problems of affecting LED light efficiency and light intensity distribution, difficult to control the quality of finished products, and reducing the refractive index of silica gel, and achieve excellent luminous performance and low production cost. , The effect of meeting the lighting needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

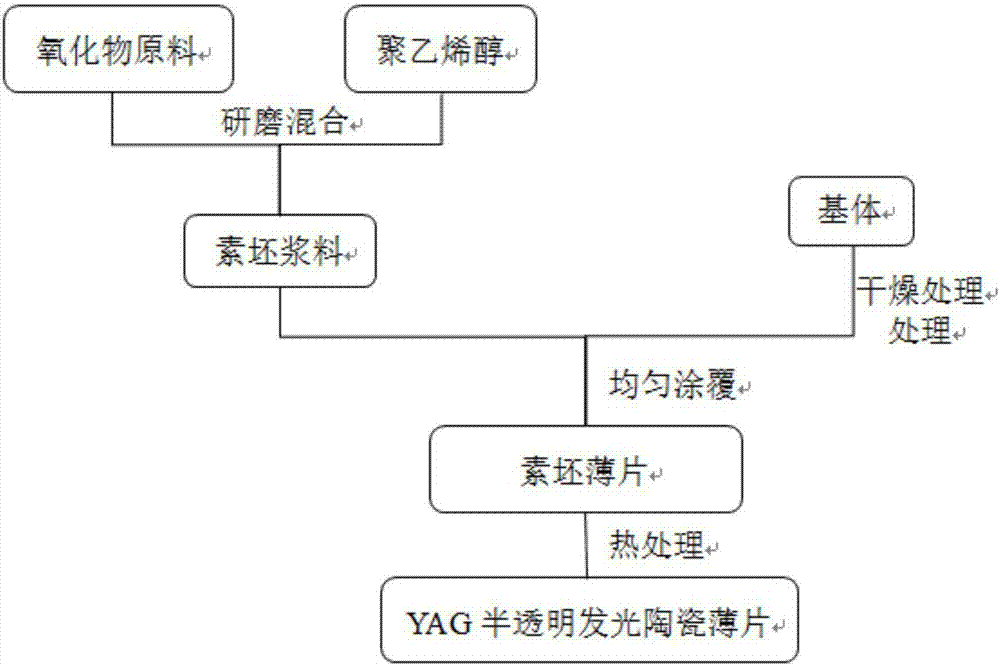

[0036] Such as figure 1 The flow chart of the preparation of the translucent YAG fluorescent ceramic sheet is shown, and the preparation process is as follows:

[0037] A, diyttrium trioxide (Y 2 o 3 ) 1.5mol, aluminum oxide (Al 2 o 3 ) 2.5mol are uniformly mixed, and the mixed material is placed in a ball mill for ball milling for 1 hour to obtain a YAG phosphor precursor;

[0038] B, adding 1 mol of polyvinyl alcohol and 2 mol of distilled water to 16 mol of the YAG phosphor precursor prepared in step A, to obtain the green body slurry;

[0039] C. After adding 2 mol of polyvinylimine and 2 mol of boric acid to the green body slurry prepared in step B, inject the green body slurry mixture into a mold and solidify in situ at room temperature for 3 hours, and dry to obtain a green sheet. The size of the blank is 2cm×2cm×0.1cm. The surface of the mold is cleaned with distilled water first, and then rinsed and disinfected with ethanol. The drying process includes the first st...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that in step A, the rare earth oxide (RE 2 o 3 ) powder and diyttrium trioxide (Y 2 o 3 ) powder mixture 3mol, aluminum oxide (Al 2 o 3 ) powder 5mol evenly mixed, in which the rare earth oxide (RE 2 o 3 ) powder and diyttrium trioxide (Y 2 o 3 ) The mole fraction ratio of powder is 1:1.

Embodiment 3

[0045] The difference between Example 3 and Example 1 is that in Step C, 2.5 mol of tetraethylenepentamine curing agent is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com