Surface modification method of fluoride luminescent material, and fluoride luminescent material prepared by method

A luminescent material and surface modification technology, applied in luminescent materials, chemical instruments and methods, manganese halide, etc., can solve problems affecting the efficiency of phosphor use, difficulty in using fluoride phosphor, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0066] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0067] Instruments and Equipment

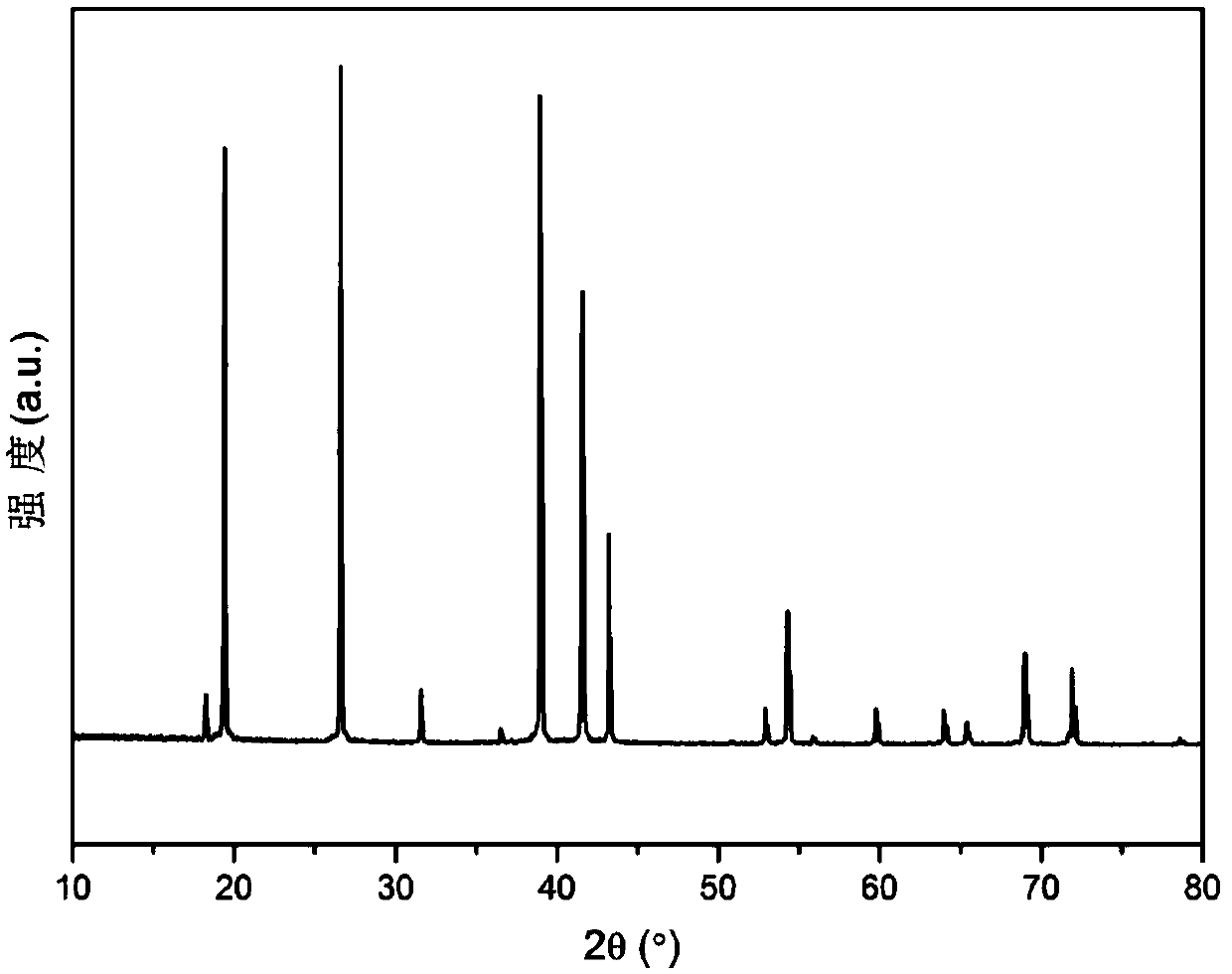

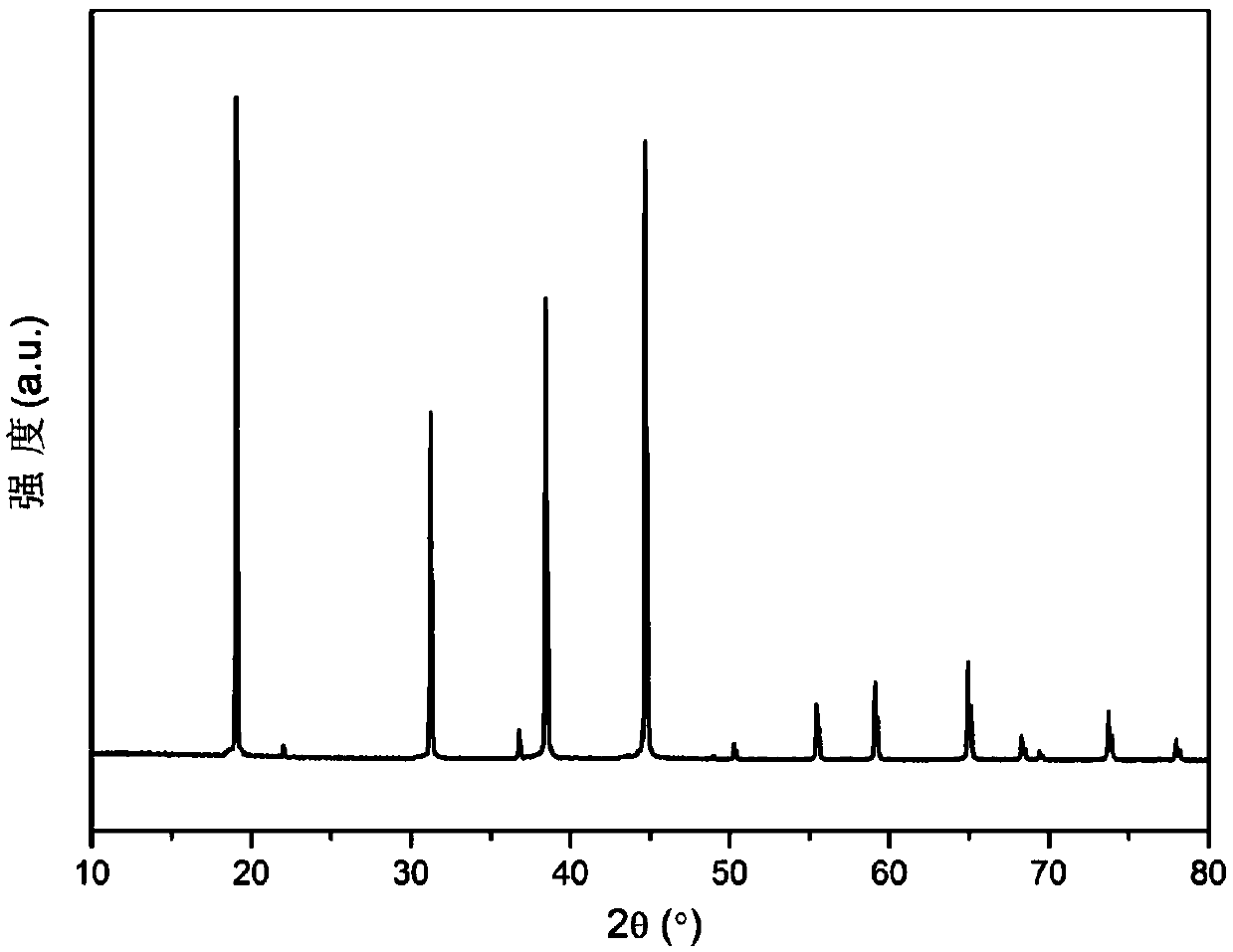

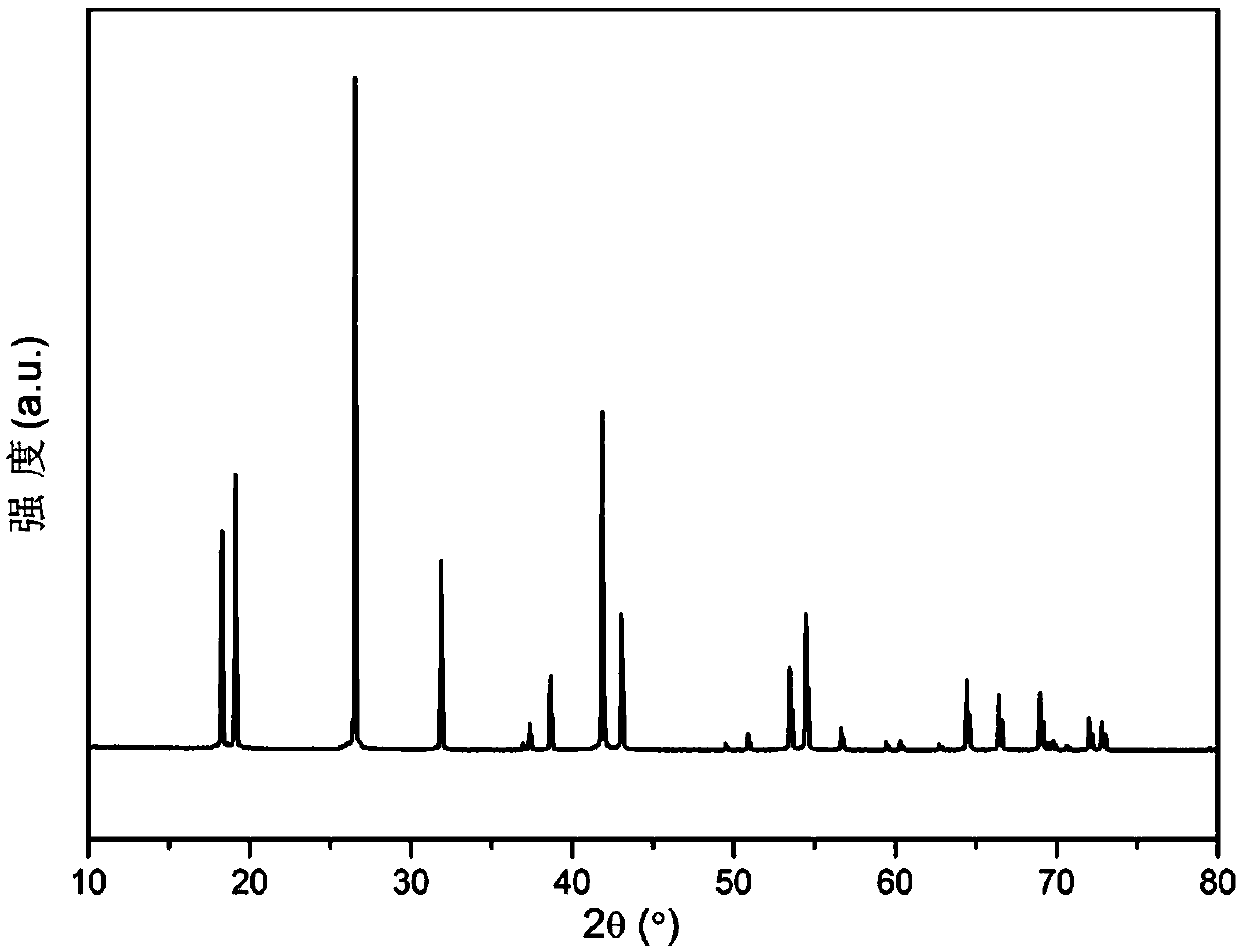

[0068] X-ray powder diffractometer (DMAX 2500PC, Rigaku) was used for phase analysis; field emission scanning electron microscope (FE-SEM, Hitachi SU1510) was used to observe the sample morphology; FLS980 (Edinb...

preparation example 1-3

[0070] Preparation Example 1-3: A 2 MF 6 :Mn 4+ Phosphor powder preparation

preparation example 1

[0071] The synthesis methods of Preparation Examples 1-3 are the same, only differing in the types and amounts of raw materials, and the specific parameters are shown in Table 1 below. Take the K of Preparation Example 1 2 MF 6 :Mn 4+ phosphor as an example, first the K 2 MnF 6 Dissolve in hydrofluoric acid solution, after stirring for 1-10min, A 2 MF 6 Add the powder into the solution, continue to stir at room temperature for 30-90 minutes, and finally filter, then wash with acetone to remove any residual HF, and put it in an oven for 4 hours at 70°C to obtain the final powder. The excitation and emission spectra, fluorescence quantum yield and absorption efficiency of the product were tested by a FLS980 (Edinburgh Instrument) fluorescence spectrometer, and the results are shown in Table 2.

[0072] Table 1. Preparation Example 1-3 Synthetic Technical Parameters

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com