A kind of red fluorescent powder and molecular sieve composite luminescent material and its preparation method and application

A technology of red phosphors and luminescent materials, which is applied in the field of red phosphors, can solve the problems of luminous efficiency attenuation, difficulty in moisture resistance, and decline, and achieve the effects of improving lasting stability, increasing display index, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A red light Cs 2 SiF 6 :Mn 4+ The preparation process of the composite luminescent material with Na-Y type molecular sieve specifically includes the following steps:

[0039] (1) First prepare the Cs-Y molecular sieve material. In this experiment, the concentration of CsF is set to 1mol / L, and the dosing volume is 250mL. Therefore, weigh 37.9750g of CsF reagent with an analytical balance, place it in a 100mL beaker, add deionized water to dissolve it, and wait until it is completely dissolved. Then transfer to a 250mL volumetric flask to prepare a 1mol / L CsF solution. Then use a micropipette to measure 10mL of CsF solution, add 1g of Na-Y molecular sieve, and stir in a 60°C water bath for 12h (stirring speed is 400r / min) to make it fully react. After 12h of reaction, centrifuge (The rotational speed of the centrifuge is 5000r / min, 3min), and the collected product is washed and dried at 70°C for 12 hours. The Cs-Y type molecular sieve can be prepared;

[0040] (2) ...

Embodiment 2

[0047] A red light Cs 2 SiF 6 :Mn 4+ The preparation process of composite luminescent material with Y-type molecular sieve specifically includes the following steps:

[0048] (1) Preparation of Cs-Y molecular sieve material. In this experiment, the concentration of CsF is set to 2mol / L, and the dosing volume is 100mL. Therefore, weigh 30.38g of CsF reagent with an analytical balance, place it in a 500mL beaker, add 100mL of deionized water to dissolve, and wait until it is completely dissolved. After that, a 2mol / L CsF solution was prepared. Then add 10g of Na-Y molecular sieves to the solution, stir in a 60°C water bath for 12h (the rotating speed of stirring is 400r / min), make it fully react, after the 12h reaction finishes, then carry out centrifugation (the rotating speed of centrifugal is 5000r / min) min, 1-3 min), the collected product was washed once with deionized water, then washed again with absolute ethanol and then dried at 70°C for 12 hours. The Cs-Y type mole...

Embodiment 3

[0056] (1) Weigh 0.0484g of K 2 MnF 6 Put the powder in a 50mL plastic beaker, put a stirring bar, add 5mL of H 2 SiF 6 Add 10mL of deionized water to the solution, and stir in a fume hood (stirring speed is 400r / min-450r / min) to completely dissolve it;

[0057] (3) Analytical Balance Accurately weigh 2 g of the Cs-Y molecular sieve prepared in Example 2, after stirring at room temperature for 10 min, take out the stirring bar, centrifuge (centrifugal speed is 5000r / min, 3min), wash, and finally dry dry, and the drying condition is 70 ° C for 6 hours to obtain red light Cs 2 SiF 6 :Mn 4+ Composite luminescent material with Y-type molecular sieve.

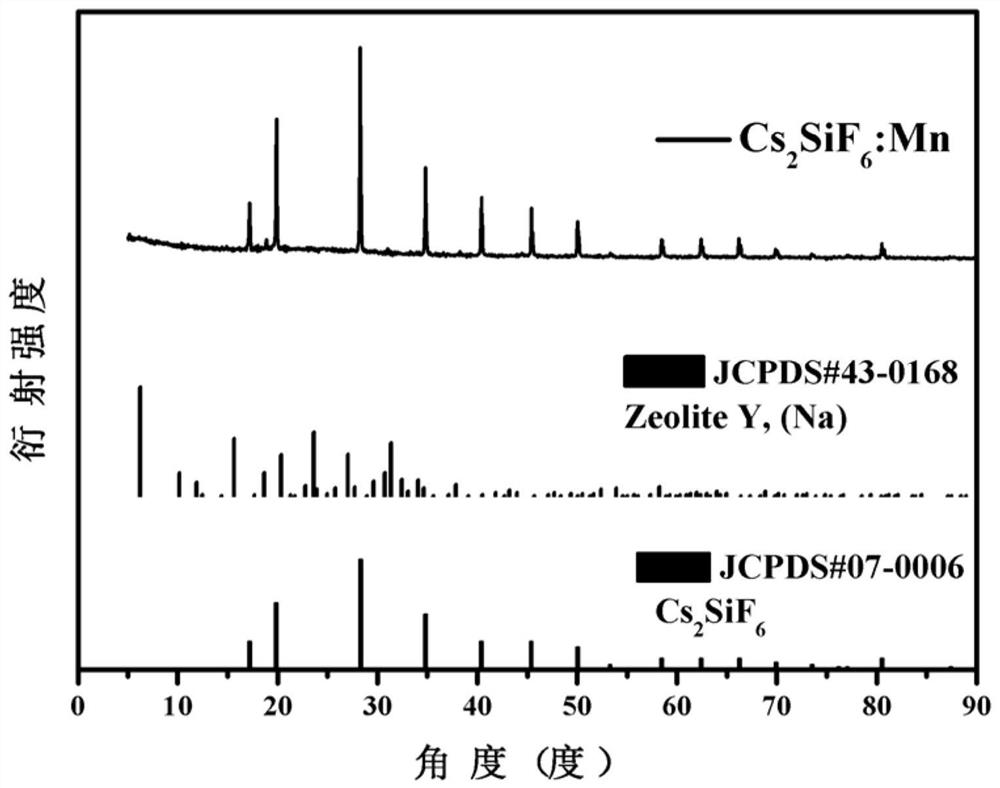

[0058] The XRD diffraction pattern and figure 1 Similarly, it can be seen from the figure that the composite luminescent material maintains the basic structure of the Y-type molecular sieve carrier.

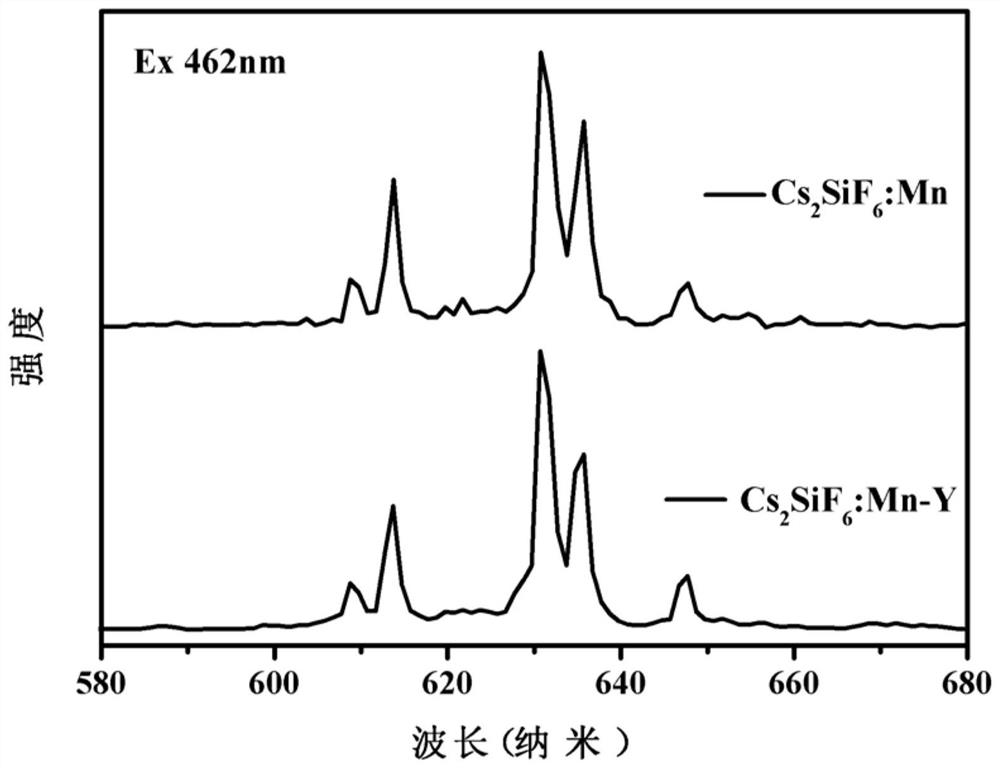

[0059] The emission spectrum of the composite luminescent material prepared in this embodiment and image 3 Similarly, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com