Quantum dot glass phosphor powder as well as preparation method and application thereof

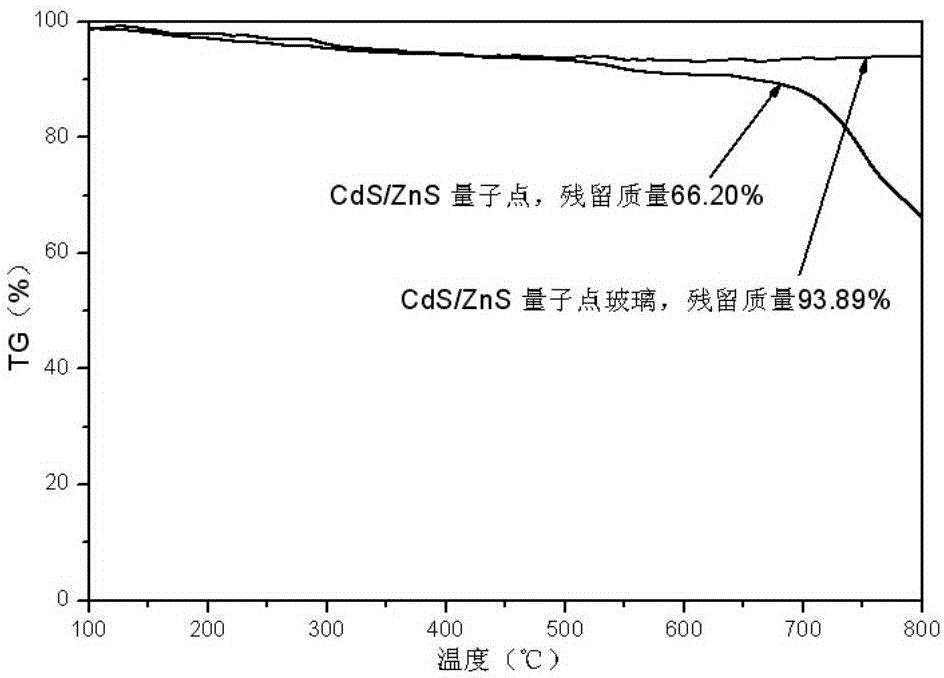

A technology of quantum dot glass and fluorescent powder, which is applied in the field of quantum dot glass fluorescent powder and its preparation, and achieves the effects of simple preparation process, wide application prospects, and good high-temperature luminescence stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

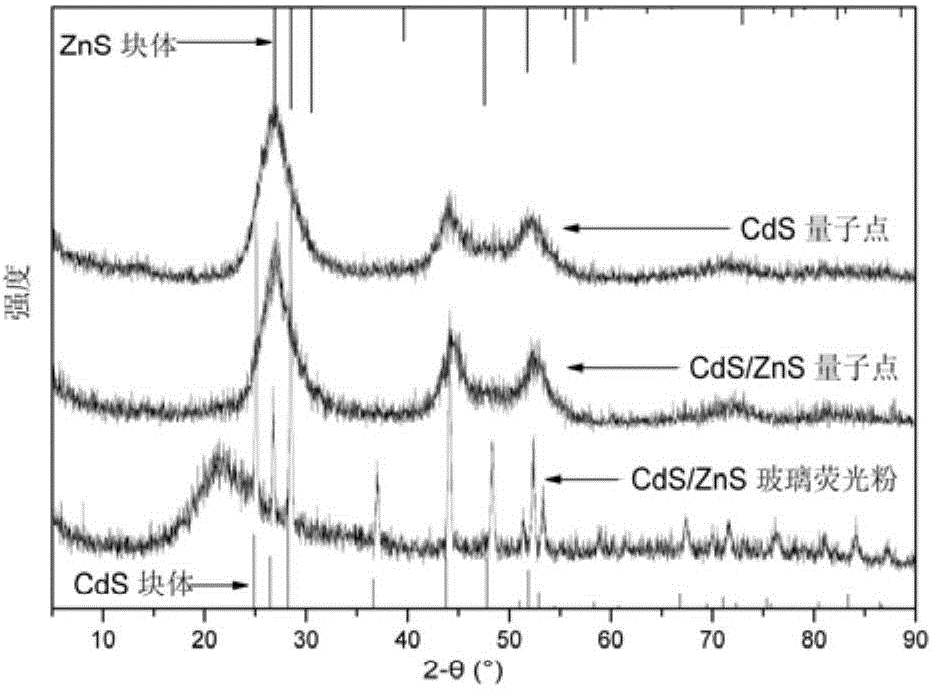

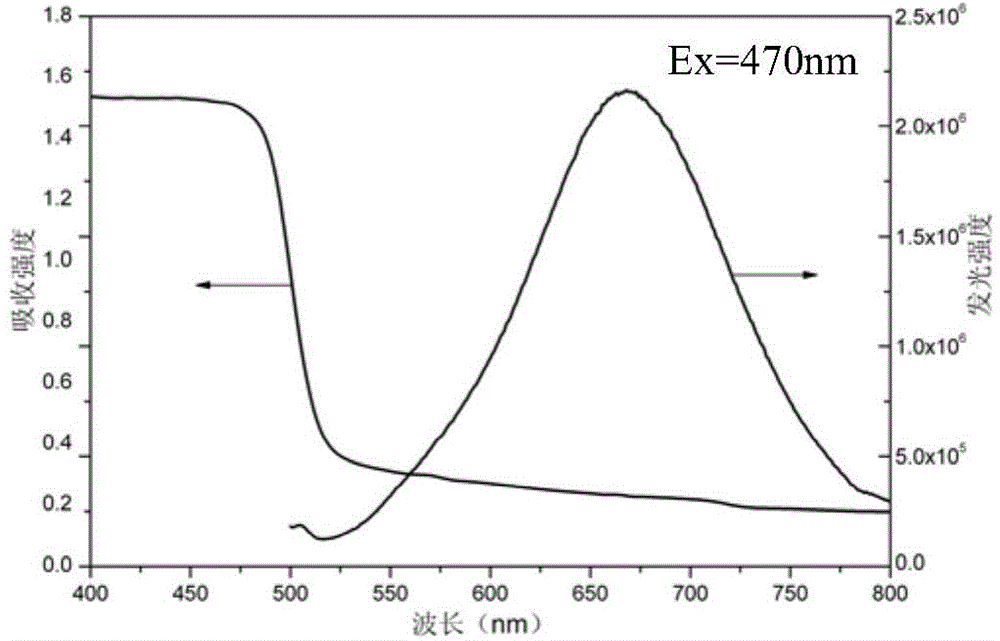

[0034] CdSO 4 ·8H 2 O was dissolved in distilled water, and thioacetamide (TAA) was added dropwise while stirring magnetically. Sonication was performed for 40 minutes after adjustment to pH 12. Drop absolute ethanol into the above solution to produce a yellow flocculent precipitate, and the powder is dissolved in distilled water again after centrifugation. will contain Zn(NO 3 ) 2 ·6H 2 The hot distilled aqueous solution of O and the TAA solution were dropped into the above mixed solution successively. After ultrasonication for 40 minutes, the mixed solution was centrifuged and vacuum-dried at 60° C. to obtain CdS / ZnS quantum dot powder.

[0035] Take polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer (P123) and dissolve it in dilute hydrochloric acid solution, transfer it to a three-necked flask, and place it in an oil bath at 40°C. After a period of time, tetraethyl orthosilicate solution was added dropwise to continue the reaction. The mixed soluti...

Embodiment 2

[0039] Cd(OAc) 2 2H 2 O added containing Na 2 S·9H 2 O in distilled water, magnetically stirred for 12 h, then transferred to a reaction kettle, and reacted at 90° C. for 6 h. Centrifuge the mixed solution and dry it under vacuum at 60°C to obtain CdS quantum dot powder.

[0040] Take polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer (P123) and dissolve it in dilute hydrochloric acid solution, transfer it to a three-necked flask, and place it in an oil bath at 40°C. After a period of time, tetraethyl orthosilicate solution was added dropwise to continue the reaction. The mixed solution was transferred to a reaction kettle, and hydrothermally reacted at 130° C. for 72 hours. After suction filtration and natural air-drying, the white powder was placed in a muffle furnace to heat remove the organic template agent. The specific sintering system was as follows: the heating rate was 1°C / min, the maximum temperature was 550°C, and the temperature was kept for 1...

Embodiment 3

[0044] AgNO 3 , In(NO 3 ) 3 ·H 2 O. Formamide (FA) was sequentially added into the three-necked flask according to a certain molar ratio, and the temperature was raised to 70° C. under the protection of nitrogen with magnetic stirring. After 15 minutes of reaction will contain (NH 4 ) 2 The FA solution of S was added dropwise to the above solution, reacted for 15 minutes and gradually cooled. Directly centrifuge to obtain supernatant, then add absolute ethanol and then centrifuge to obtain AgInS quantum dots.

[0045] Take polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer (P123) and dissolve it in dilute hydrochloric acid solution, transfer it to a three-necked flask, and place it in an oil bath at 40°C. After a period of time, tetraethyl orthosilicate solution was added dropwise to continue the reaction. The mixed solution was transferred to a reaction kettle, and hydrothermally reacted at 130° C. for 72 hours. After suction filtration and natural ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com