Fabrication method of LED device

A technology of LED devices and microspheres, which is applied in the field of lighting, can solve the problems that it is difficult to meet market demand, and that quantum dot-LED devices cannot achieve high luminous efficiency and high light conversion efficiency, so as to maintain luminous performance, excellent mechanical strength, and prevent bursting. The effect of killing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a method for preparing a quantum dot-LED device (QD-LED device) with high luminous efficiency and high light conversion efficiency, comprising the following steps:

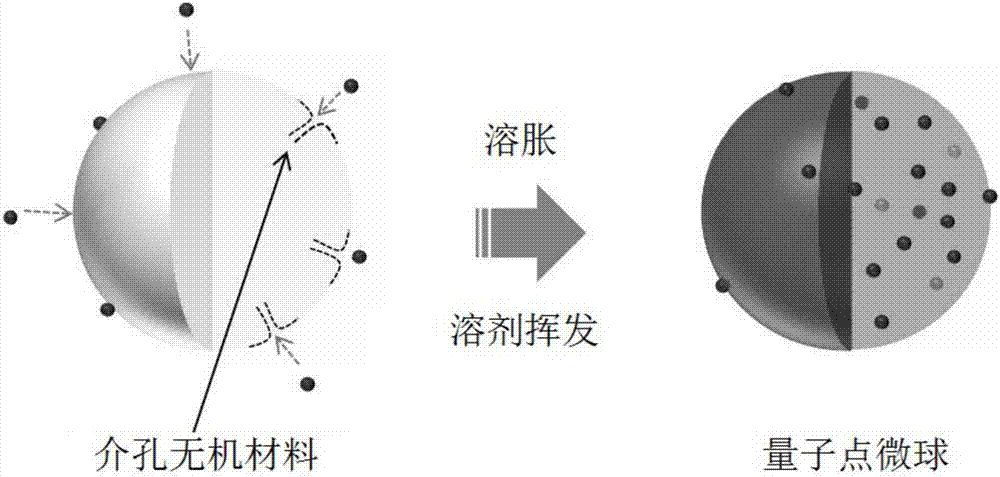

[0033] (1) Preparation of quantum dot microspheres

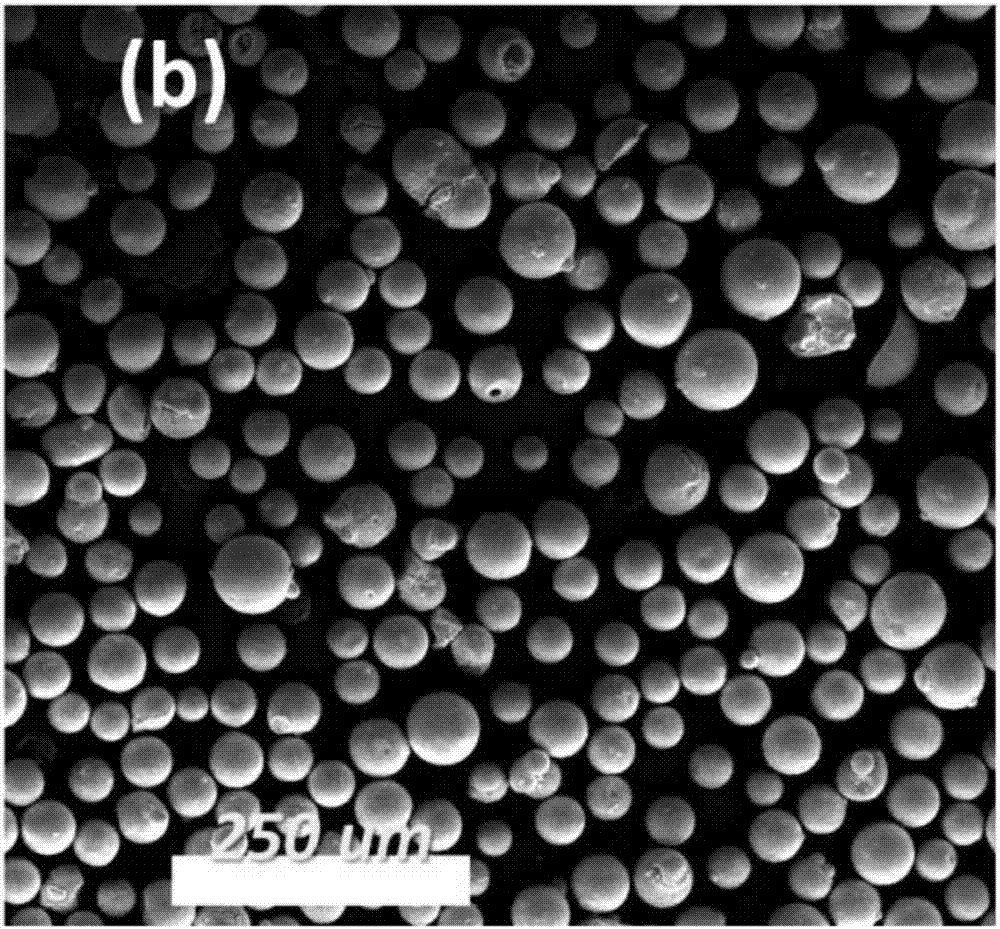

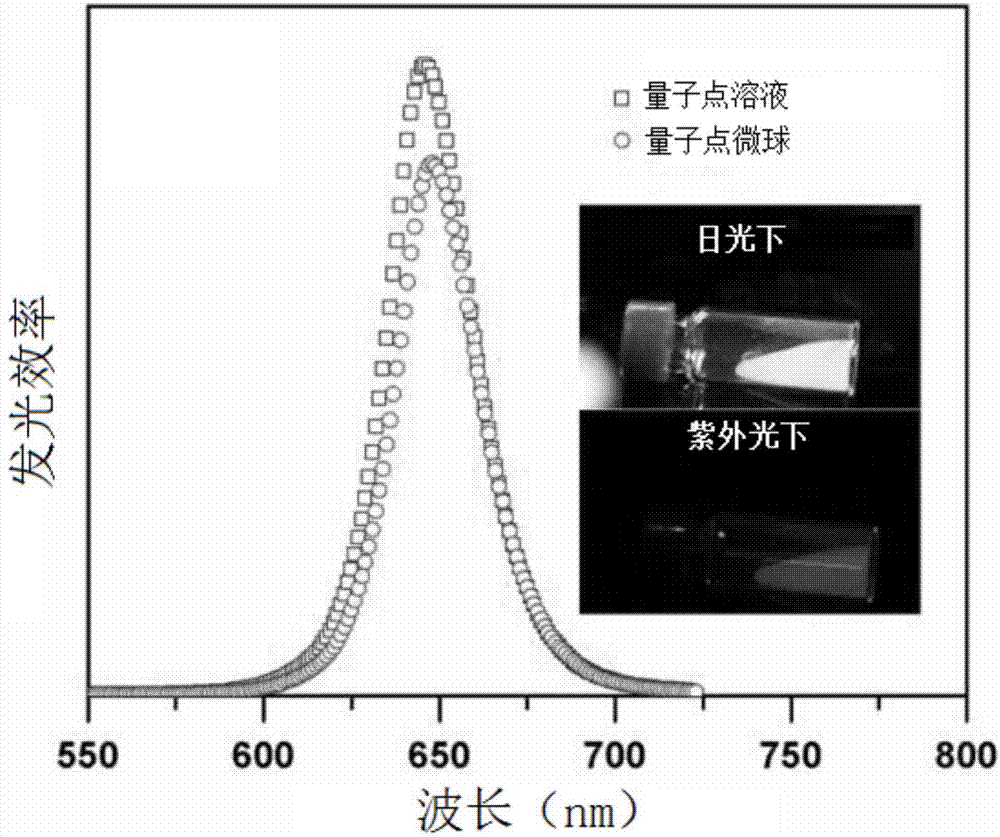

[0034] The schematic diagram of the preparation process of quantum dot microspheres is shown in figure 1 As shown, measure 10mL of solvent and 2mL of quantum dot solution (the quality of which contains quantum dots is 0.5-5mg, preferably 2mg). (Microsphere size can be 1-60μm, mesopore size 5-15nm, preferably 30μm size microspheres, 7nm pore size), act for a certain time at 60°C for 1-4h, heat to remove n-hexane, wash the microsphere powder, n-hexane Alkanes, chloroform, ethanol, methanol and other solvents can be washed, preferably n-hexane, and vacuum-dried to obtain quantum dot microspheres. The electron microscope picture of the quantum dot microspheres is as follows figure 2 As shown, the particle size of the microspheres is ...

Embodiment 2

[0042] Prepare QD-LED devices according to the preparation method described in Example 1, carry out the doping amount test of graphene, control the size of graphene is basically the same, width or length is about 500nm, thickness is 5nm, change the dosing of graphene amount, respectively controlling the mass fraction of the graphene powder in the mixed viscous solution to be 0%, 0.01%, 0.03%, 0.05%, and 0.1%, to prepare QD-LED devices respectively, and to compare the long-term lighting stability Analysis and comparative analysis of the spectral energy distribution of QD-LED devices, the comparative analysis results of spectral energy distribution are shown in Table 1, and the comparative analysis results of long-term lighting stability are as follows Figure 6 shown.

[0043] It can be seen from Table 1 that after adding graphene, the light-emitting characteristics of QD-LED devices are reduced to a certain extent. With the increase of graphene doping concentration, the red ligh...

Embodiment 3

[0050] The invention provides a preparation method of a white light LED device (QD-LED device) with high luminous efficiency and high light conversion efficiency, comprising the following steps:

[0051] (1) Preparation of quantum dot microspheres

[0052] Quantum dot microspheres were prepared by the steps described in Example 1. The mesoporous material microspheres were mesoporous molecular sieves, and the quantum dots were red quantum dots.

[0053] (2) Preparation of quantum dot microsphere solution

[0054] Get 0.5mg of graphene powder and add it to the aqueous solution of ethanol. Graphene is a honeycomb planar film with one or several atomic layer thicknesses. The width or length of graphene powder can be 100nm-2μm, preferably about 500nm, and the thickness is 5nm. Ultrasonic dispersion for 30 minutes, adding 20 mg of quantum dot microspheres prepared above and 25 mg of YAG: Ce yellow fluorescent powder, and then adding 1 g of silicone resin, mixed well, and vacuum def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com