Light-emitting diode (LED) epitaxial structure and manufacturing method thereof

A technology of light-emitting diodes and epitaxial structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem that the performance and electrode structure of MQW and P-GaN materials are not enough to meet high-performance applications, and improve the ability to resist ESD, improve ESD level, the effect of avoiding ESD breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

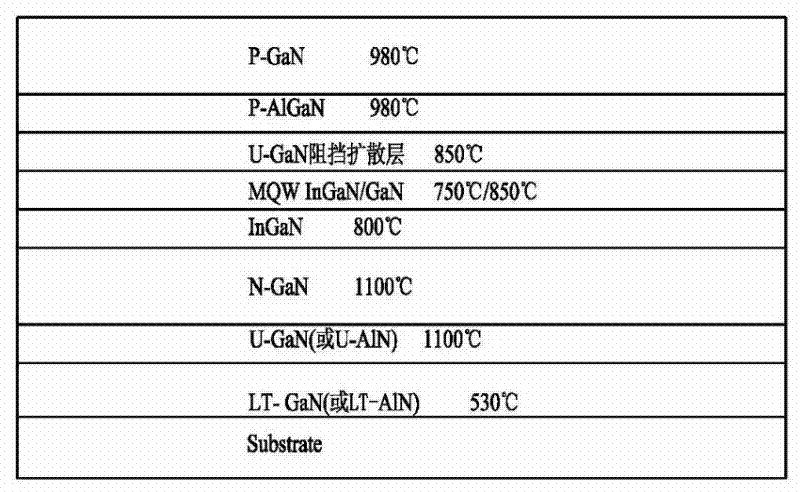

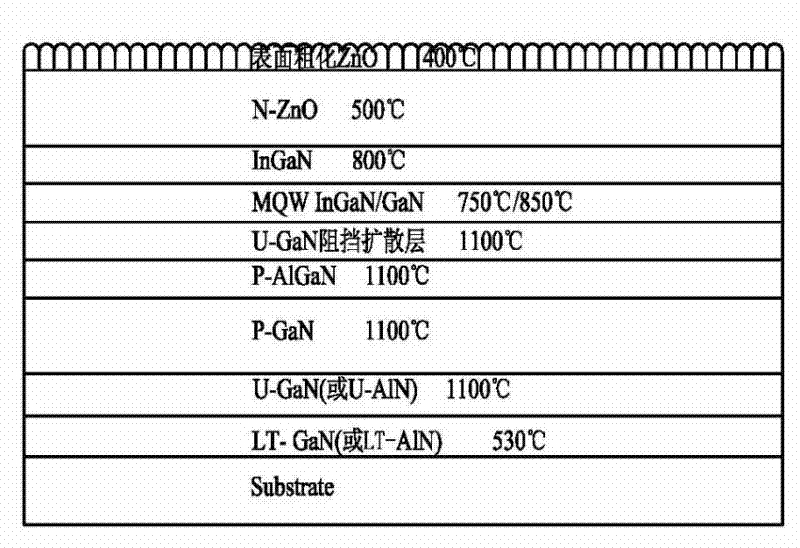

[0048] The purpose of this specific embodiment is to provide a novel light-emitting diode epitaxial structure and its manufacturing method. In short, the method uses an N-ZnO layer to replace the N-GaN layer in the existing light-emitting diode epitaxial structure, The LED epitaxial structure manufactured by this method is as image 3 As shown, its structure includes: low-temperature gallium nitride (LT-GaN) or aluminum nitride (AlN) nucleation layer grown sequentially on the epitaxial substrate material (Substrate layer), high-temperature non-doped gallium nitride or aluminum nitride Buffer layer (U-GaN layer or U-AlN layer), P-type gallium nitride layer (P-GaN layer), P-type gallium aluminum nitride layer (P-AlGaN layer), barrier diffusion layer of P layer and light emitting layer (U-GaN Barrier space layer), multi-quantum well light-emitting layer (MQW InGaN / GaN), InGaN current spreading layer (n-InGaN layer), N-type zinc oxide (N-ZnO) layer and surface roughened N-ZnO lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com