Method for implementing transfer of up-conversion nanocrystals from oil phase to aqueous phase

A nanocrystalline and oil-phase technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of different reaction conditions, lack of universality, complex methods, etc., achieve good experimental repeatability, and maintain the effect of luminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

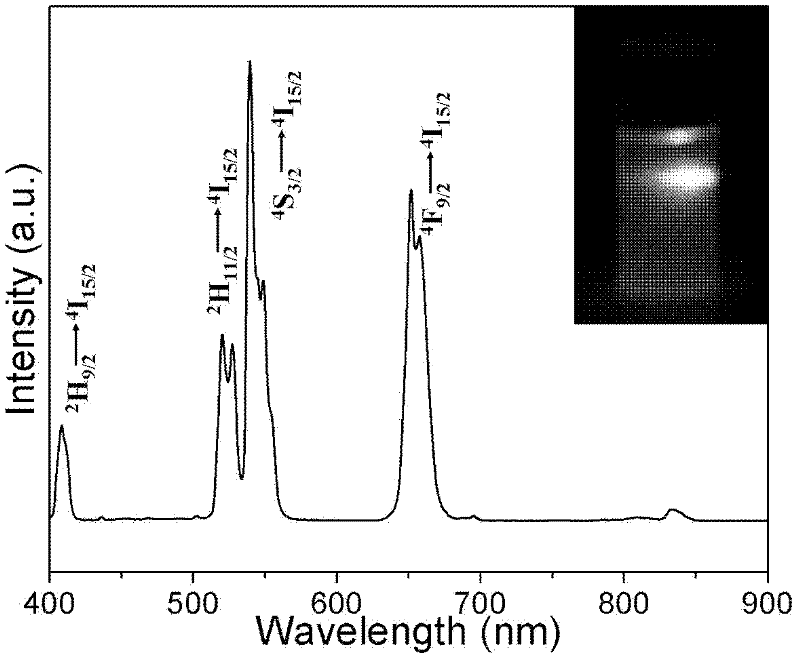

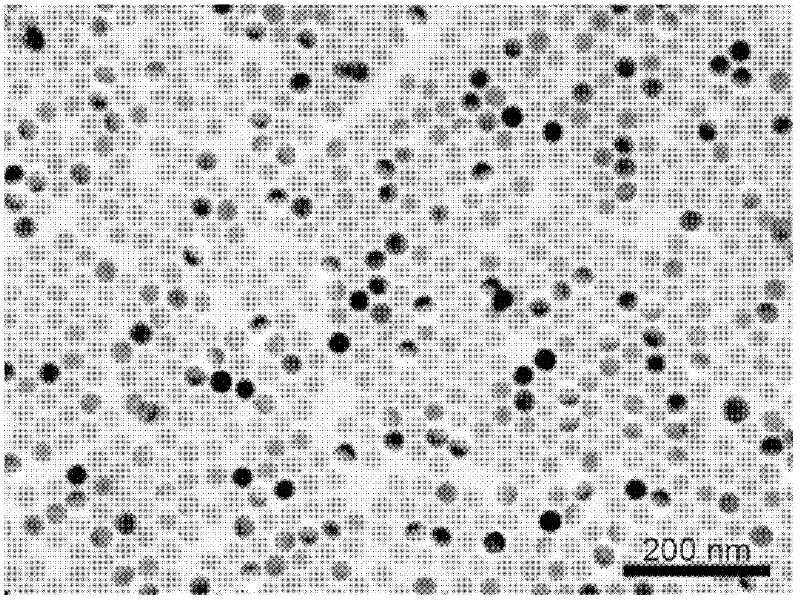

[0025] Add 0.04g of anionic surfactant SDS to 10ml of water, dissolve after stirring to obtain a colorless and transparent solution, then add 2ml with a concentration of 1.9×10 -2 mol / L NaYF 4 (moles 18% Yb, 2% Er,) in chloroform solution; heated to 70 degrees Celsius to volatilize chloroform, cooled to room temperature, and obtained colorless and transparent aqueous phase NaYF 4 (Mole number 18% Yb, 2% Er) solution. As shown in Figure 1(a), the luminescence spectrum of the up-converting nanocrystal is given, which proves that the nanocrystal has the property of up-converting; Figure 1(b) shows the transmission electron microscope photo of the nanocrystal in the chloroform phase, It can be seen from the figure that the size of the nanocrystals is uniform and the dispersion is very good; Figure 1(c) shows the TEM photo of the nanocrystals in the water phase, we can see that the particles are not aggregated and the dispersion is very good, which proves that the oil phase The n...

Embodiment 2

[0027] Add 0.04g cationic surfactant CTAB to 10ml water, dissolve after stirring to obtain a colorless transparent solution, add 2ml concentration to 1.9×10 -2 mol / L NaYF 4 (moles 18% Yb, 2% Er) chloroform solution; heated to 70 degrees Celsius to volatilize chloroform, cooled to room temperature to obtain colorless and transparent aqueous phase NaYF 4 (Mole number 18% Yb, 2% Er) solution. As shown in Figure 1(b), the transmission electron micrograph of the nanocrystals in the chloroform phase is given, figure 2 The transmission electron microscope photos of the nanocrystals in the water phase are given, we can see that the particles are not aggregated, and the dispersion is very good, which proves that the nanocrystals in the oil phase have been successfully transferred to the water phase.

Embodiment 3

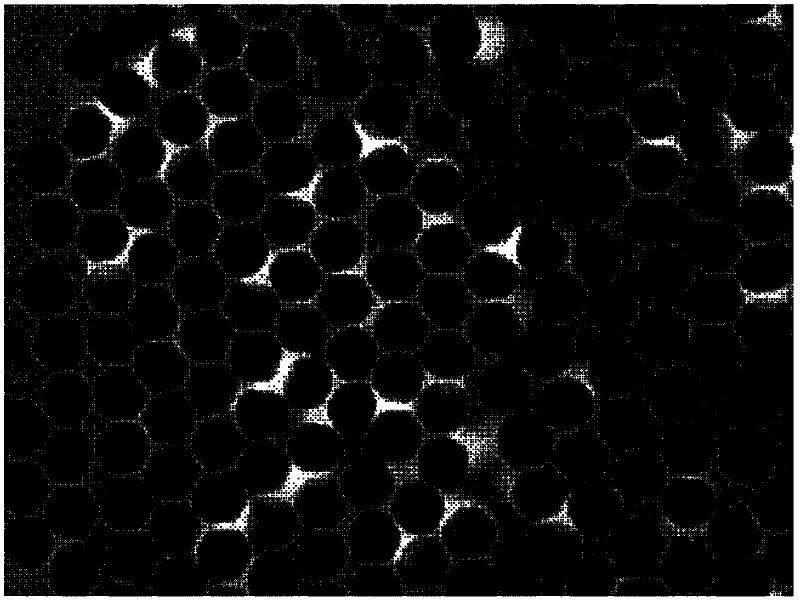

[0029] Add 0.04g cationic surfactant DTAB to 10ml water, dissolve after stirring to obtain a colorless transparent solution, add 2ml concentration to 1.9×10 -2 mol / L NaYF 4 (mole number 18%Yb, 2%Er) chloroform solution; heating to 70 degrees Celsius makes chloroform volatilize, cools to room temperature, obtains colorless and transparent water phase NaYF4 (mole number 18%Yb, 2%Er) solution . As shown in Figure 1(b), the transmission electron micrograph of the nanocrystals in the chloroform phase is given, image 3 The transmission electron microscope photos of the nanocrystals in the water phase are given, we can see that the particles are not aggregated, and the dispersion is very good, which proves that the nanocrystals in the oil phase have been successfully transferred to the water phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com