High-flexibility polyester epoxy impregnated resin and preparation method thereof

A technology of impregnating resin and polyester resin, which is applied in the field of highly flexible polyester epoxy impregnating resin and its preparation, can solve the problems of paint film cracking, poor toughness, and high brittleness of cured resin, and achieve good flexibility and excellent Effects of mechanical flexibility and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

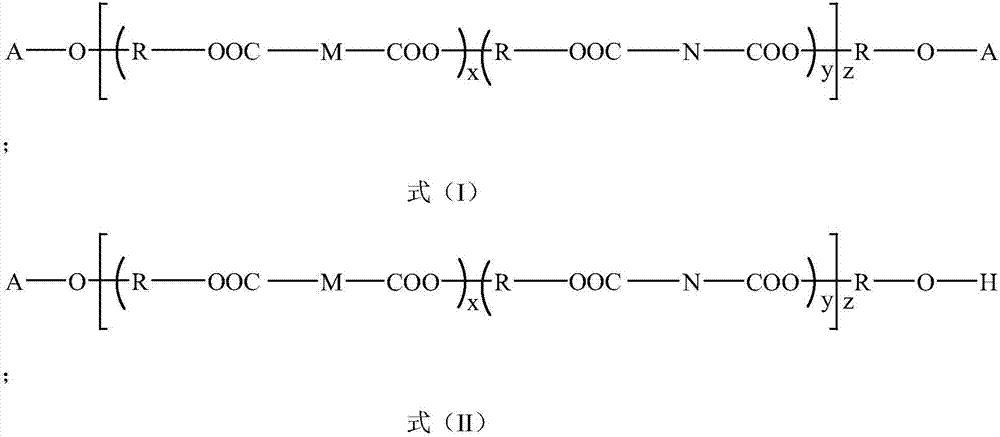

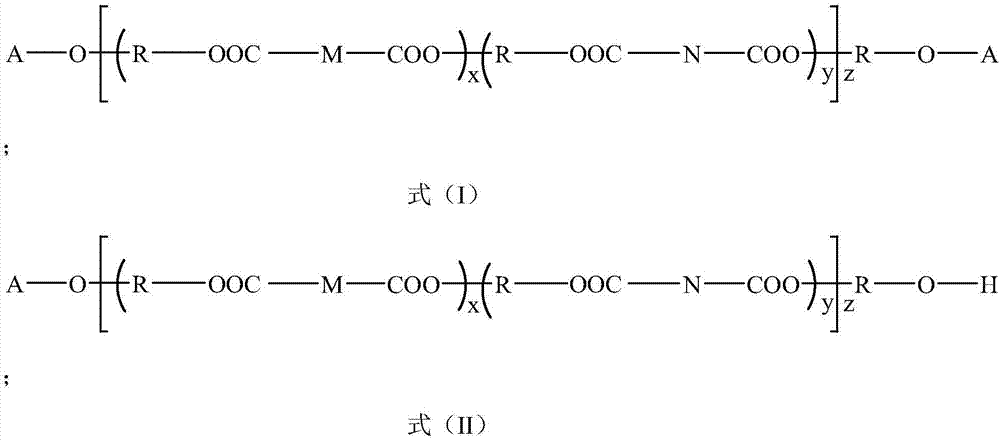

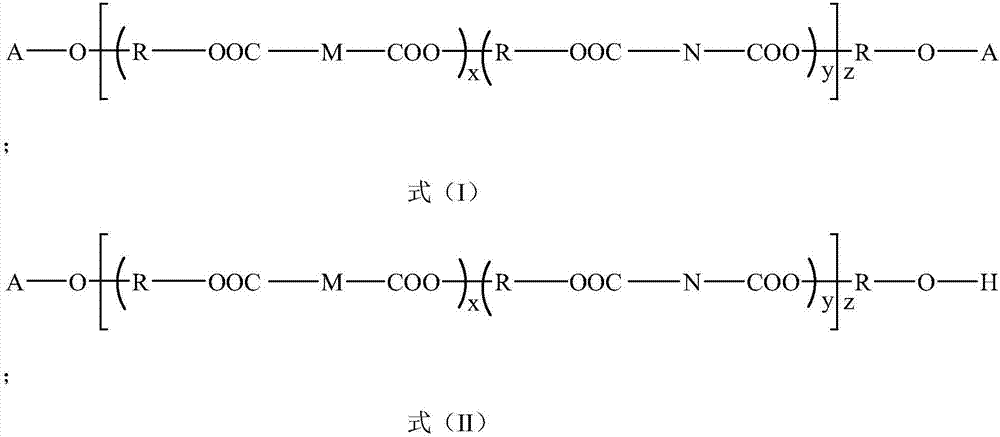

Method used

Image

Examples

Embodiment 1

[0045] A kind of highly flexible polyester epoxy impregnated resin of the present invention, comprises by mass parts: 32 parts of flexible unsaturated polyester resin UP-1, 30 parts of dimeric fatty acid glycidyl esters (NPER-172), 38 parts of environmental protection Type reactive diluent 1,6-hexanediol dimethacrylate, 0.4 parts of polymerization inhibitor (including 0.2 parts of 2,6-di-tert-butyl p-cresol and 0.2 parts of p-tert-butyl catechol), 0.8 parts Free radical initiator dicumyl peroxide, 0.3 parts of latent epoxy curing accelerator (comprising 0.2 part of chromium acetylacetonate and 0.1 part of zinc naphthenate), its specific preparation method comprises the steps:

[0046] (1) Preparation of flexible unsaturated polyester resin: In a dry 1000mL four-necked round-bottomed flask with mechanical stirring, reflux condenser and air guide tube, add 286.0 g of neopentyl glycol and 58.5 g of trihydroxyethane g, 234.0g of dimerized octadecane unsaturated fatty acid, 260.0g ...

Embodiment 2

[0053] A kind of highly flexible polyester epoxy impregnated resin of the present invention comprises by mass parts: 35 parts of flexible unsaturated polyester resin UP-1, 28 parts of dimeric fatty acid glycidyl esters (HyPox DA323), 36 parts of environment-friendly Reactive diluent triethylene glycol dimethacrylate, 0.4 part of polymerization inhibitor (including 0.2 part of p-methoxyphenol and 0.2 part of 2,6-di-tert-butyl p-cresol), 0.8 part of free radical initiator Dicumyl oxide, 0.4 part of latent epoxy curing accelerator (comprising 0.2 part of aluminum acetylacetonate and 0.2 part of cobalt naphthenate), its preparation method may further comprise the steps:

[0054] (1) Preparation of flexible unsaturated polyester resin: In a dry 1000mL four-necked round-bottomed flask with mechanical stirring, reflux condenser and air guide tube, add 286.0 g of neopentyl glycol and 58.5 g of trihydroxyethane g, 234.0g of dimerized octadecane unsaturated fatty acid, 260.0g of maleic ...

Embodiment 3

[0061] A kind of highly flexible polyester epoxy impregnated resin of the present invention comprises: 30 parts of flexible unsaturated polyester resin UP-2, 30 parts of dimeric fatty acid glycidyl esters (NPER-172), 40 parts of environmental protection Type reactive diluent tripropylene glycol dimethacrylate, 0.4 part of polymerization inhibitor (including 0.2 part of p-benzoquinone and 0.2 part of 2,6-di-tert-butyl p-cresol), 0.8 part of free radical initiator diisoperoxide Propylbenzene, 0.4 part of latent epoxy curing accelerator (comprising 0.2 part of aluminum acetylacetonate and 0.2 part of zinc naphthenate), its preparation method may further comprise the steps:

[0062] (1) Preparation of flexible unsaturated polyester resin: In a dry 1000mL four-necked round-bottomed flask with mechanical stirring, reflux condenser and airway tube, add 181.2g of neopentyl glycol and 1,2-propanediol for the first step 114.7g, 120.8g of 1,4-butanediol, 302.0g of dioctadecane unsaturate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com