Porous aluminum foil for lithium ion battery current collector and preparation method and application thereof

A lithium-ion battery, ion battery technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of high cost, slow speed, troublesome operation, etc., and achieve low cost, high efficiency, and short time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

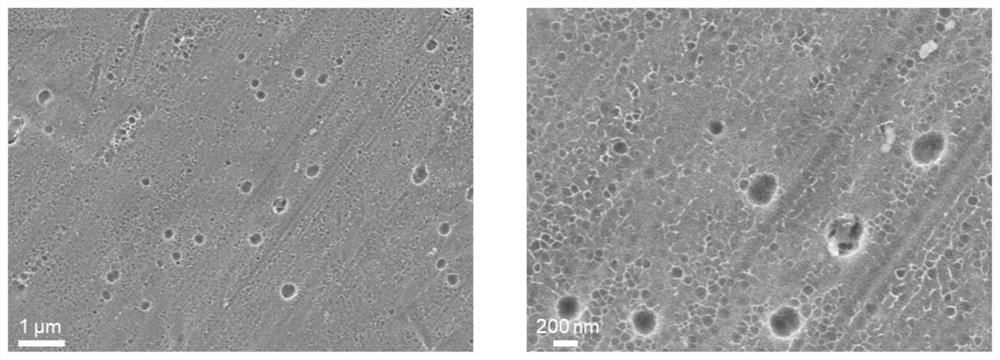

[0040] Dissolve 0.1g of ferric nitrate in 10mL of deionized water and ultrasonically dissolve. Put aluminum foil with a mass of about 8mg into a 30*60mm porcelain boat. 1.5mL of 0.01g / mL ferric nitrate solution was dropped into the porcelain boat to immerse the aluminum foil. The submerged aluminum foil was subjected to microwave reaction for 30 s. The obtained product was observed in the SEM scanning image of the aluminum foil under the condition of 0.01g / mL ferric nitrate solution under the microwave for 30s, and the surface of the aluminum foil only partially had a porous structure, and the quality hardly changed.

Embodiment 2

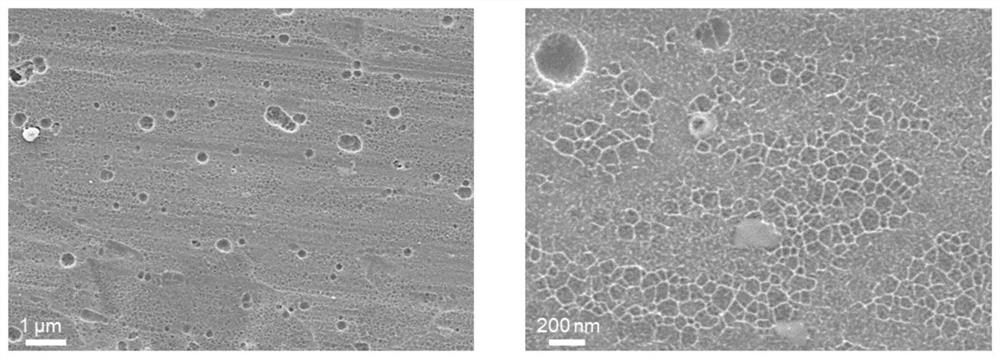

[0042]Dissolve 0.5g of ferric nitrate in 10mL of deionized water and ultrasonically dissolve. Put aluminum foil with a mass of about 8mg into a 30*60mm porcelain boat. 1.5mL of 0.05g / mL ferric nitrate solution was dropped into the porcelain boat to immerse the aluminum foil. The submerged aluminum foil was subjected to microwave reaction for 30 s. The obtained product is observed in the SEM electron microscope scanning image under the condition of 0.05g / mL ferric nitrate solution, and there is a porous structure with uneven particle size on the surface of the aluminum foil microwaved for 30s, which is more porous than the surface of the aluminum foil obtained under the condition of 0.01g / mL ferric nitrate solution. Much porous structure, mass change is negligible.

Embodiment 3

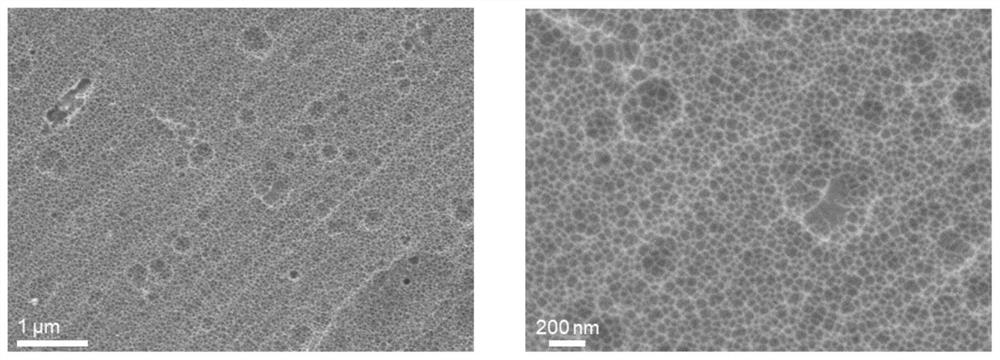

[0044] Dissolve 1.0 g of ferric nitrate in 10 mL of deionized water, and ultrasonically dissolve. Put aluminum foil with a mass of about 8mg into a 30*60mm porcelain boat. 1.5mL of 0.1g / mL ferric nitrate solution was dropped into the porcelain boat to immerse the aluminum foil. The submerged aluminum foil was subjected to microwave reaction for 30 s. The obtained product was observed in the SEM electron microscope scanning image, and a honeycomb porous structure was evenly distributed on the surface of the aluminum foil under the condition of 0.1g / mL ferric nitrate solution under the microwave for 30s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com