Plasma enhanced cleaning device and cleaning method

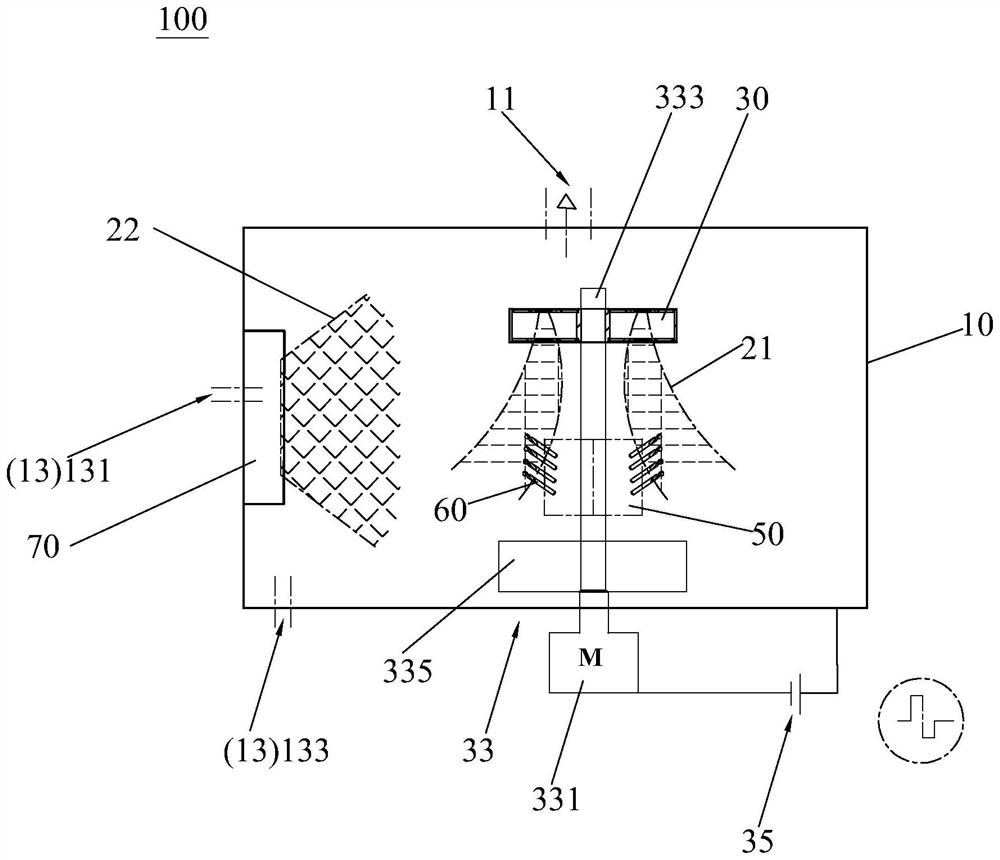

A plasma and cleaning device technology, applied in the field of plasma cleaning, can solve the problems of ion flow divergence, limit, uneven etching, etc., and achieve the effect of improving cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

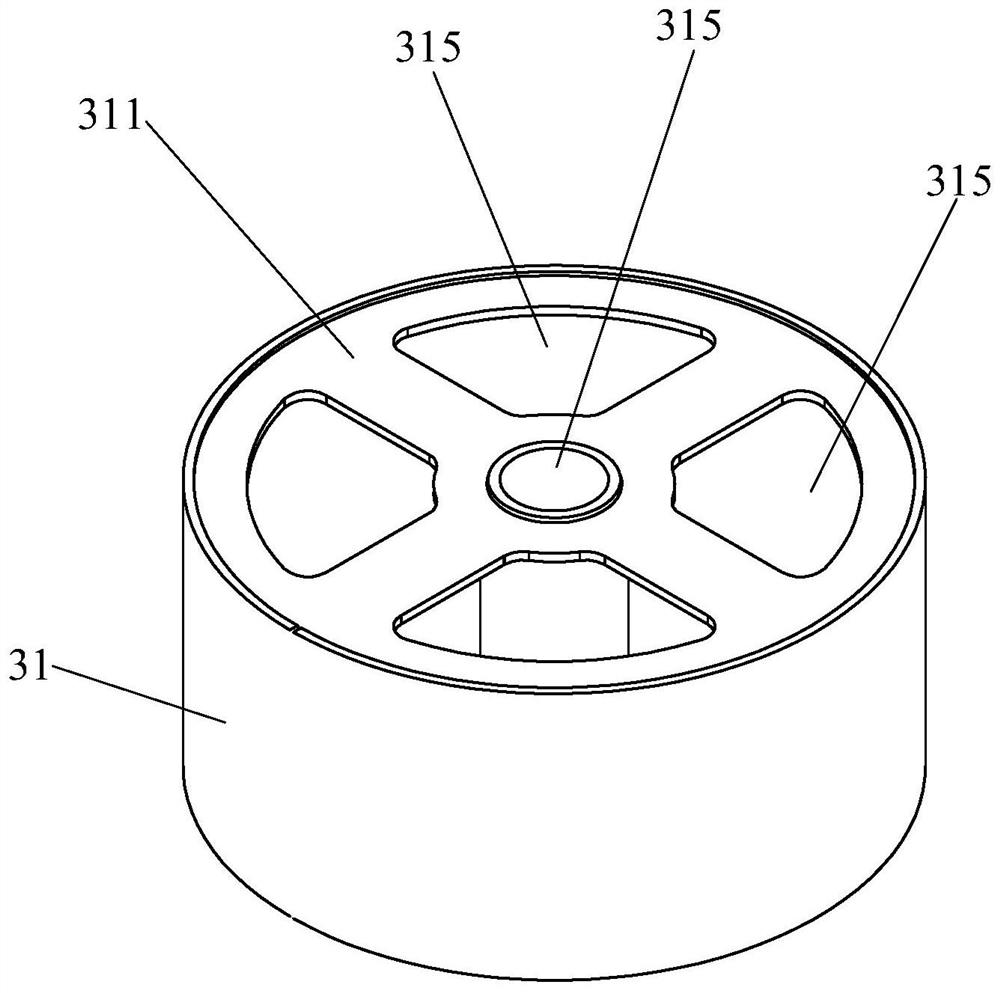

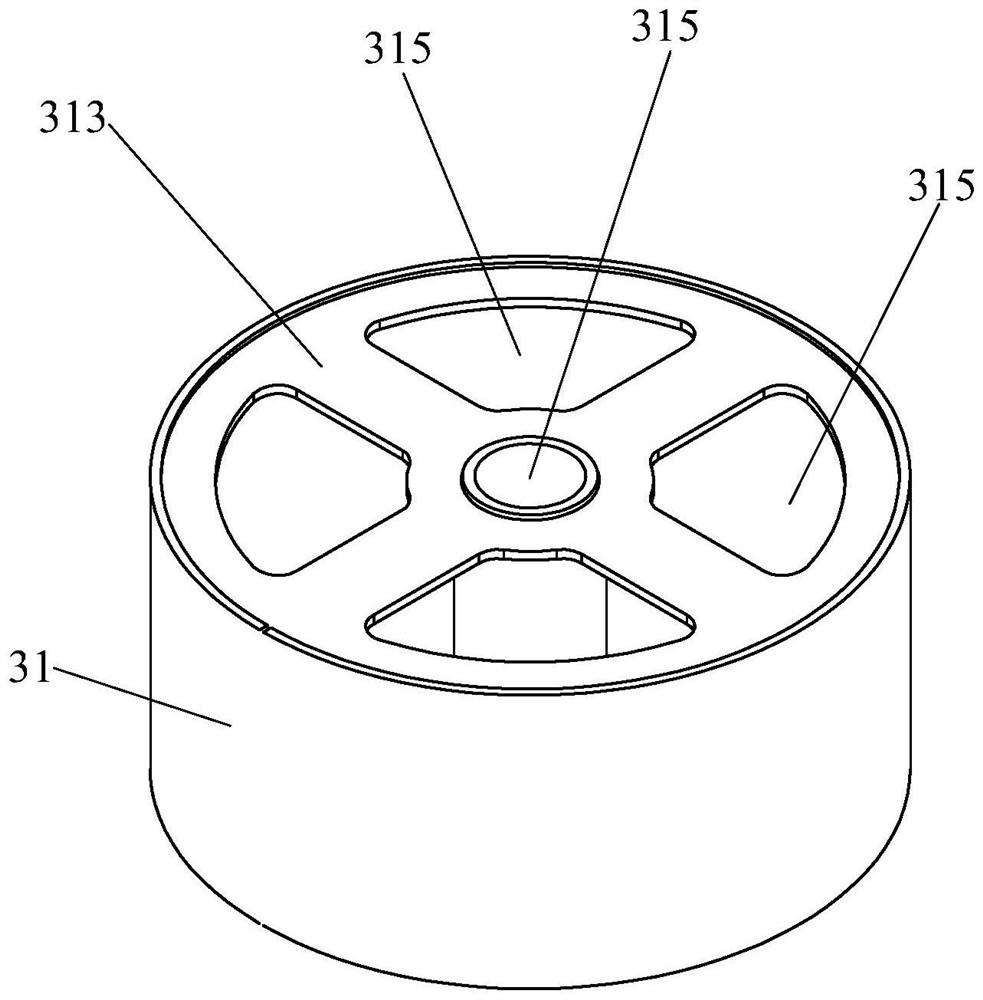

Method used

Image

Examples

Embodiment 1

[0061] The cleaning method using the plasma enhanced cleaning device comprises the steps of:

[0062] (1) The product to be processed is selected from a long-deep sipe tool product, and the long-deep sipe tool product is ultrasonically cleaned and dried;

[0063] (2) Put the product to be processed into the jig and put it into the vacuum chamber, the turntable system drives the product to be processed to rotate synchronously, keep the rotation at a constant speed, the rotation speed is 1.2rpm, pump the vacuum at room temperature, and the vacuum is below 0.02Pa;

[0064] (3) feed the Ar gas of 300sccm, control the exhaust volume of the exhaust port, adjust the gas pressure to be 10.0Pa, apply a pulse bias voltage of 800V to the turntable system and the anode, and the duty ratio is 80%, so that the plasma generator starts, And in the cavity of the body part, an umbrella-shaped arc-shaped glow plasma with fixed frequency flickering is generated, and a slight glow corona appears o...

Embodiment 2

[0071] The cleaning method using the plasma enhanced cleaning device comprises the steps of:

[0072] (1) Select special-shaped jigs for the products to be processed, and perform ultrasonic cleaning and drying on the products with special-shaped jigs;

[0073] (2) Put the product to be processed into the jig and put it into the vacuum chamber, the turntable system drives the product to be processed to rotate synchronously, keep the rotation at a constant speed, the speed is 1rpm, pump the vacuum at room temperature, and the vacuum is below 0.02Pa;

[0074] (3) feed the Ar gas of 500sccm, control the exhaust volume of the exhaust port, adjust the gas pressure to be 28.0Pa, apply a pulse bias voltage of 800V to the turntable system and the anode, and the duty ratio is 70%, so that the plasma generator starts, And in the cavity of the body part, an umbrella-shaped arc-shaped glow plasma with fixed frequency flickering is generated, and a slight glow corona appears on the surface ...

Embodiment 3

[0081] The cleaning method using the plasma enhanced cleaning device comprises the steps of:

[0082] (1) The product to be processed is selected as a porous product, and the porous product is ultrasonically cleaned and dried;

[0083] (2) Put the product to be processed into the jig and put it into the vacuum chamber, the turntable system drives the product to be processed to rotate synchronously, keep the rotation at a constant speed, the speed is 2rpm, pump the vacuum at room temperature, and the vacuum is below 0.008Pa;

[0084] (3) feed the Ar gas of 180sccm, control the exhaust volume of the pumping port, adjust the gas pressure to be 0.2Pa, apply a pulse bias voltage of 600V to the turntable system and the anode, and the duty ratio is 60%, so that the plasma generator starts, And in the cavity of the body part, an umbrella-shaped arc-shaped glow plasma with fixed frequency flickering is generated, and a slight glow corona appears on the surface of the fixture for 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com