A kind of stain-resistant pc/abs alloy and preparation method thereof

A technology of anti-fouling and alloying, which is applied in the field of anti-fouling PC/ABS alloy and its preparation, can solve problems such as long gaps, and achieve the effects of accelerating etching, increasing hydrophobicity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

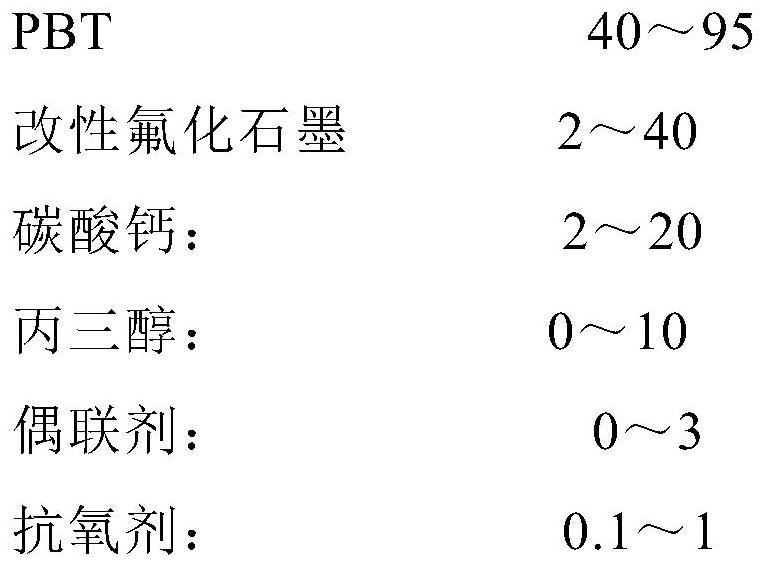

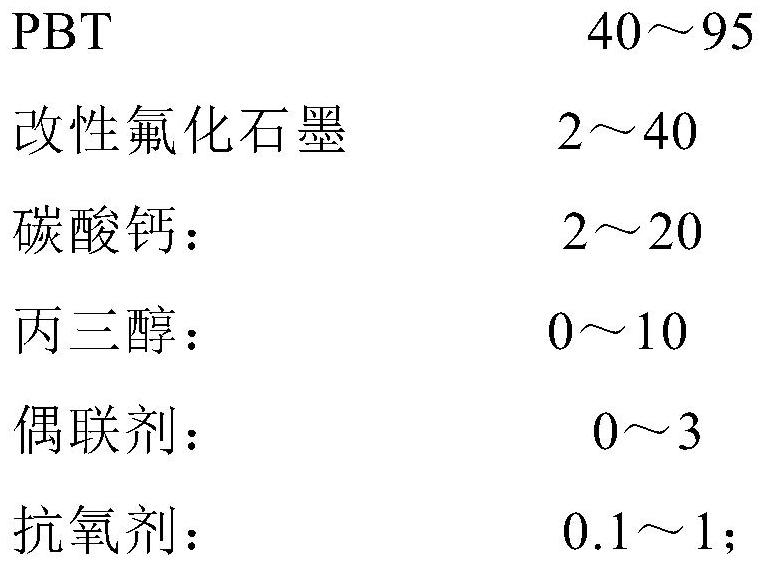

Method used

Image

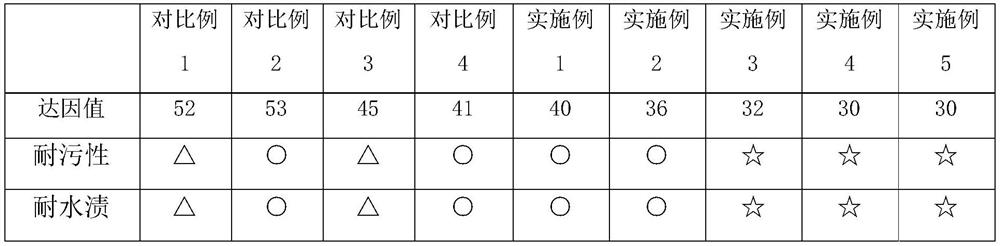

Examples

Embodiment 1

[0079] (1) Weigh each component by weight: graphite fluoride: 95 parts, glycidyl methacrylate 5 parts

[0080] (2) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material

[0081] (3) Put the mixed material in an internal mixer at a temperature of 150-230° C., after internal mixing for 30 seconds to 10 minutes, and granulate to obtain modified graphite fluoride.

[0082] (4) Weigh each component by weight: PBT is (0.9dl / g) 90 parts, modified fluorinated graphite is 9 parts, coupling agent MODIPER@F600 is 1 part, antioxidant 245 is 0.1Kg, Antioxidant 168 is 0.1Kg

[0083] (5) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material

[0084] (6) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the pollution-resistant PBT masterbatch.

[0085] The twin-screw extruder includes 10 t...

Embodiment 2

[0093] (1) Weigh each component by weight: graphite fluoride: 99 parts, glycidyl methacrylate 1 part

[0094] (2) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material

[0095] (3) Put the mixed material in an internal mixer at a temperature of 150-230° C., after internal mixing for 30 seconds to 10 minutes, and granulate to obtain modified graphite fluoride.

[0096] (4) Weigh each component by weight: 80 parts of PBT (0.65dl / g), 15 parts of modified fluorinated graphite, 4 parts of calcium carbonate (5000 mesh), and 1 part of coupling agent MODIPER@F600 , Antioxidant 245 is 0.1Kg, Antioxidant 168 is 0.1Kg

[0097] (5) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material

[0098] (6) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the masterbatch.

[0099] The twin-scre...

Embodiment 3

[0107] (1) Weigh each component by weight: graphite fluoride: 99 parts, glycidyl methacrylate 1 part

[0108] (2) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material

[0109] (3) Put the mixed material in an internal mixer at a temperature of 150-230° C., after internal mixing for 30 seconds to 10 minutes, and granulate to obtain modified graphite fluoride.

[0110] (4) Weigh each component by weight: 40 parts of PBT (0.9dl / g), 47 parts of modified fluorinated graphite, 10 parts of calcium carbonate (8000 mesh), and 3 parts of coupling agent MODIPER@F600 , Antioxidant 245 is 0.1Kg, Antioxidant 168 is 0.1Kg

[0111] (5) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material

[0112] (6) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the masterbatch.

[0113] The twin-scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com