A kind of pollution-resistant pc/pet alloy and its preparation method

A technology of anti-fouling and alloy, applied in the field of anti-fouling PC/PET alloy and its preparation, can solve the problems of inability to meet the performance requirements of engineering plastics, limited application area, etc., and achieve convenient processing, high anti-fouling performance and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

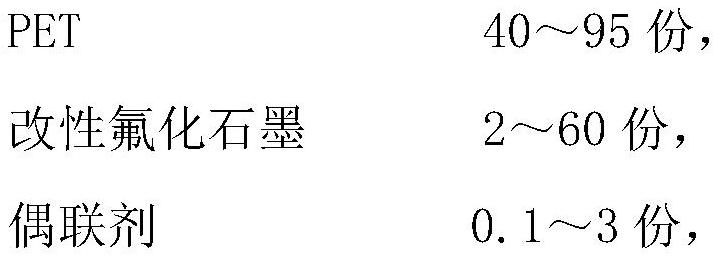

Method used

Image

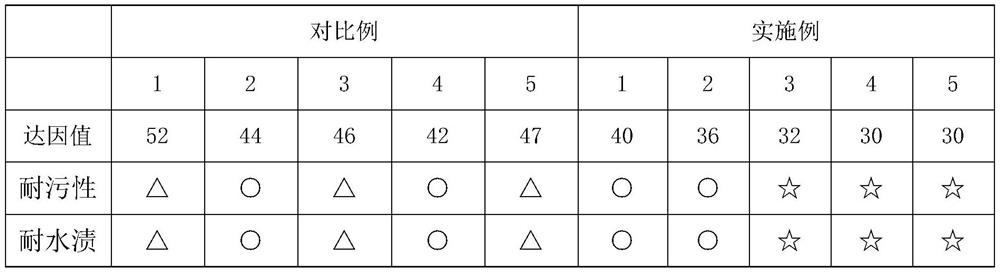

Examples

Embodiment 1

[0079] (1) Take each component by weight: fluorinated graphite: 95 parts, 5 parts of glycidyl methacrylate;

[0080] (2) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material;

[0081] (3) Put the mixed material in an internal mixer at a temperature of 150-230° C., after internal mixing for 30 seconds to 10 minutes, and granulate to obtain modified graphite fluoride.

[0082] (4) Weigh each component by weight: PET is (0.9dl / g) 90 parts, modified fluorinated graphite is 9 parts, coupling agent MODIPER@F600 is 1 part, antioxidant 245 is 0.1 part, Antioxidant 168 is 0.1 part;

[0083] (5) Put the other components of the prepared material in the mixer, and mix for 5-30 minutes to obtain the mixed material;

[0084] (6) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the pollution-resistant PET masterbatch.

[0085] The twin-screw extrud...

Embodiment 2

[0093] (1) Take each component by weight: fluorinated graphite: 99 parts, 1 part of glycidyl methacrylate;

[0094] (2) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material;

[0095] (3) Put the mixed material in an internal mixer at a temperature of 150-230° C., after internal mixing for 30 seconds to 10 minutes, and granulate to obtain modified graphite fluoride.

[0096] (4) Weigh each component by weight: PET is (0.65dl / g) 80 parts, modified fluorinated graphite is 19 parts, coupling agent MODIPER@F600 is 1 part, antioxidant 245 is 0.1 part, Antioxidant 168 is 0.1 part;

[0097] (5) Put the other components of the prepared material in the mixer, and mix for 5-30 minutes to obtain the mixed material;

[0098] (6) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the pollution-resistant PET masterbatch.

[0099] The twin-screw extrude...

Embodiment 3

[0107] (1) Take each component by weight: graphite fluoride: 99.5 parts, glycidyl methacrylate 0.5 part;

[0108] (2) Put the other components of the prepared material in the mixer and mix for 5-30 minutes to obtain the mixed material;

[0109] (3) Put the mixed material in an internal mixer at a temperature of 150-230° C., after internal mixing for 30 seconds to 10 minutes, and granulate to obtain modified graphite fluoride.

[0110] (4) Weigh each component by weight: PET is (0.9dl / g) 40 parts, modified fluorinated graphite is 57 parts, coupling agent MODIPER@F600 is 3 parts, antioxidant 245 is 0.1 part, Antioxidant 168 is 0.1 part;

[0111] (5) Put the other components of the prepared material in the mixer, and mix for 5-30 minutes to obtain the mixed material;

[0112] (6) Put the mixed material into a twin-screw extruder, control the screw speed to 500rpm, melt and extrude, and granulate to obtain the pollution-resistant PET masterbatch.

[0113] The twin-screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com