Zn-Co-MOF/PVDF nanofiltration membrane, preparation method and application

A nanofiltration membrane and solution technology, applied in the field of membrane separation, can solve the problems of hydrophobic and oleophobic and difficult to process, and achieve the effect of ensuring the economy of production cost, not easy to stick and block, and good hydrophobic and oleophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

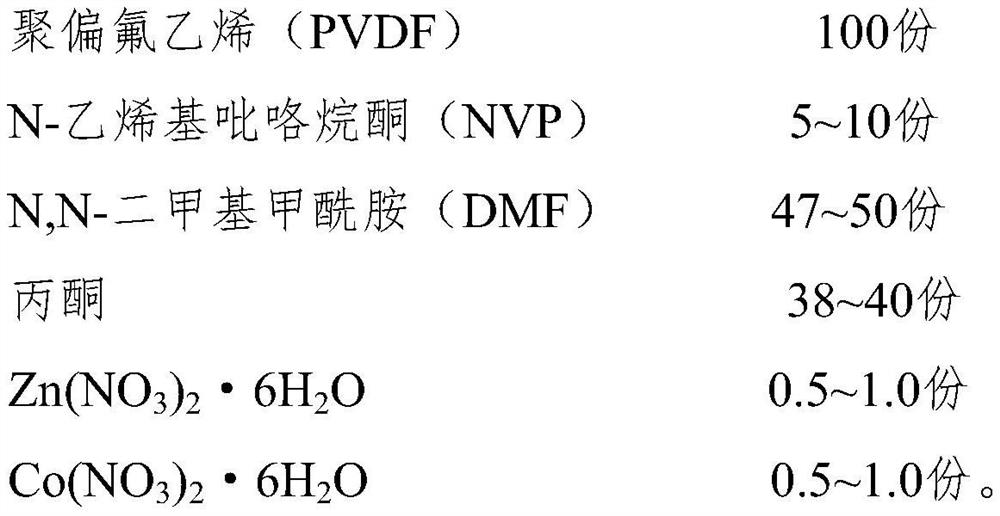

[0023] A Zn-Co-MOF / PVDF nanofiltration membrane, comprising the following weight components:

[0024]

[0025] The preferred technical solution is that the polyvinylidene fluoride (PVDF) is a linear polymer formed by homopolymerization or copolymerization of vinylidene fluoride monomers.

[0026] The preparation method of above-mentioned a kind of Zn-Co-MOF / PVDF nanofiltration membrane, comprises the steps:

[0027] S1: Weigh polyvinylidene fluoride (PVDF), N-vinylpyrrolidone (NVP), N,N-dimethylformamide (DMF) and acetone according to the above parts by weight, and mix N,N-di Methylformamide (DMF) is divided into two parts, polyvinylidene fluoride (PVDF), N-vinylpyrrolidone (NVP) is dissolved in one part of the mixture of N,N-dimethylformamide (DMF) and acetone solution, and at 60°C, magnetically stirred for 12 hours to form solution A;

[0028] S2: Zn(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in another part of N,N-dimethylformamide (DMF) to form a cle...

Embodiment 2

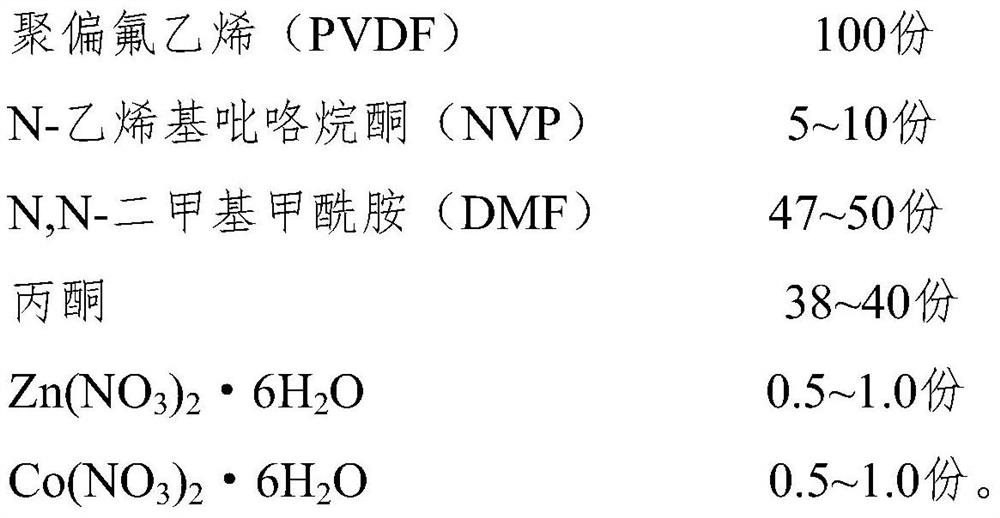

[0033] A Zn-Co-MOF / PVDF nanofiltration membrane, comprising the following weight components:

[0034]

[0035] The preferred technical solution is that the polyvinylidene fluoride (PVDF) is a linear polymer formed by homopolymerization or copolymerization of vinylidene fluoride monomers.

[0036] The preparation method of above-mentioned a kind of Zn-Co-MOF / PVDF nanofiltration membrane, comprises the steps:

[0037] S1: Weigh polyvinylidene fluoride (PVDF), N-vinylpyrrolidone (NVP), N,N-dimethylformamide (DMF) and acetone according to the above parts by weight, and mix N,N-di Methylformamide (DMF) is divided into two parts, polyvinylidene fluoride (PVDF), N-vinylpyrrolidone (NVP) is dissolved in one part of the mixture of N,N-dimethylformamide (DMF) and acetone solution, and under the condition of 65°C, magnetically stirred for 13h to form solution A;

[0038] S2: Zn(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in another part of N,N-dimethylformamide (DMF...

Embodiment 3

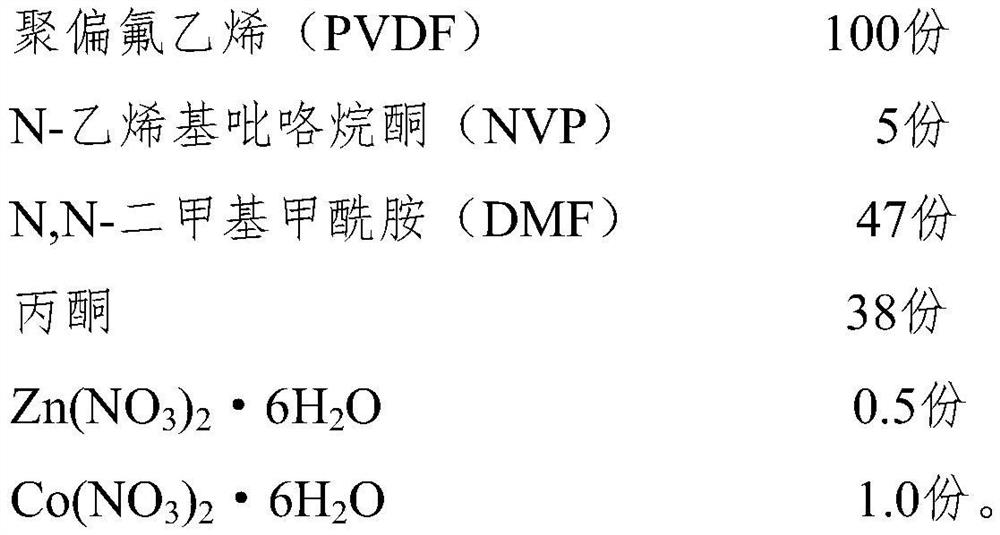

[0043] A Zn-Co-MOF / PVDF nanofiltration membrane, comprising the following weight components:

[0044]

[0045] The preferred technical solution is that the polyvinylidene fluoride (PVDF) is a linear polymer formed by homopolymerization or copolymerization of vinylidene fluoride monomers.

[0046] The preparation method of above-mentioned a kind of Zn-Co-MOF / PVDF nanofiltration membrane, comprises the steps:

[0047] S1: Weigh polyvinylidene fluoride (PVDF), N-vinylpyrrolidone (NVP), N,N-dimethylformamide (DMF) and acetone according to the above parts by weight, and mix N,N-di Methylformamide (DMF) is divided into two parts, polyvinylidene fluoride (PVDF), N-vinylpyrrolidone (NVP) is dissolved in one part of the mixture of N,N-dimethylformamide (DMF) and acetone solution, and at 70°C, magnetically stirred for 14h to form solution A;

[0048] S2: Zn(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in another part of N,N-dimethylformamide (DMF) to form solution B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com