A kind of fluorine-containing surfactant compound and its preparation method and application

A technology of surfactants and compounds, which is applied in the petrochemical field to improve the recovery of shale gas, can solve the problems of easy plugging of porous media in reservoirs, difficult biodegradation of polymers, and reduced permeability of reservoirs, etc. The effect is good, the operation is simple, and it is beneficial to the effect of on-site promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A kind of preparation of fluorine-containing surfactant compound, the steps are as follows:

[0069] (1) Take 138g (1.2mol) of n-heptylamine and 4.8g (0.06mol) of pyridine in a round-bottomed flask equipped with a magnet, use absolute ethanol as a solvent, and slowly drop it with a constant pressure dropping funnel under an ice bath Add 259 g (0.6 mol) of perfluorooctanoyl chloride, after the dropwise addition is complete, react for 2 hours and then raise the temperature to 75°C, react in an oil bath for 8 hours, filter with suction, remove the solvent, and dry to obtain the compound of formula II.

[0070] (2) Take 153g (0.3mol) of the compound of formula II prepared in step (1) in a round-bottomed flask equipped with a magnet, use an appropriate amount of acetone as a solvent, heat up to 55°C, and after dissolving, drop the liquid with a constant pressure Slowly drop 49.2 g (0.3 mol) of chloroheptanoic acid into the funnel, after the dropwise addition, react in oil fo...

Embodiment 2

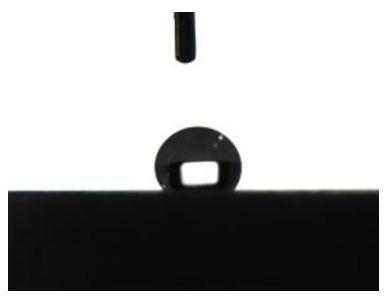

[0076] The preparation of the fluorine-containing surfactant is as described in Example 1, the difference is: the prepared fluorine-containing surfactant is added with deionized water to make a 0.7% solution, soak the rock core with it for 48 hours, place it at room temperature after drying 8 hours, measured the contact angle of water phase and oil phase on the core surface after treatment, and its water phase contact angle was 125 ° (as image 3 shown), the oil phase contact angle is 95° (as Figure 10 shown).

Embodiment 3

[0078] The preparation of the fluorine-containing surfactant is as described in Example 1, the difference is: the prepared fluorine-containing surfactant is added with deionized water to make a 1.0% solution, soak the rock core with it for 48 hours, place it at room temperature after drying 8 hours, measured the contact angle of water phase and oil phase on the rock core surface after treatment, and its water phase contact angle was 128 ° (as Figure 4 shown), the oil phase contact angle is 108° (as Figure 11 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com