Method for smelting high-nitrogen steel at normal pressure by two steps

A high-nitrogen steel, normal pressure technology, applied in the field of smelting high-nitrogen steel, can solve problems such as the lack of commercialized market supply, achieve the effect of easy organization and OEM entrustment, reduced process condition requirements, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

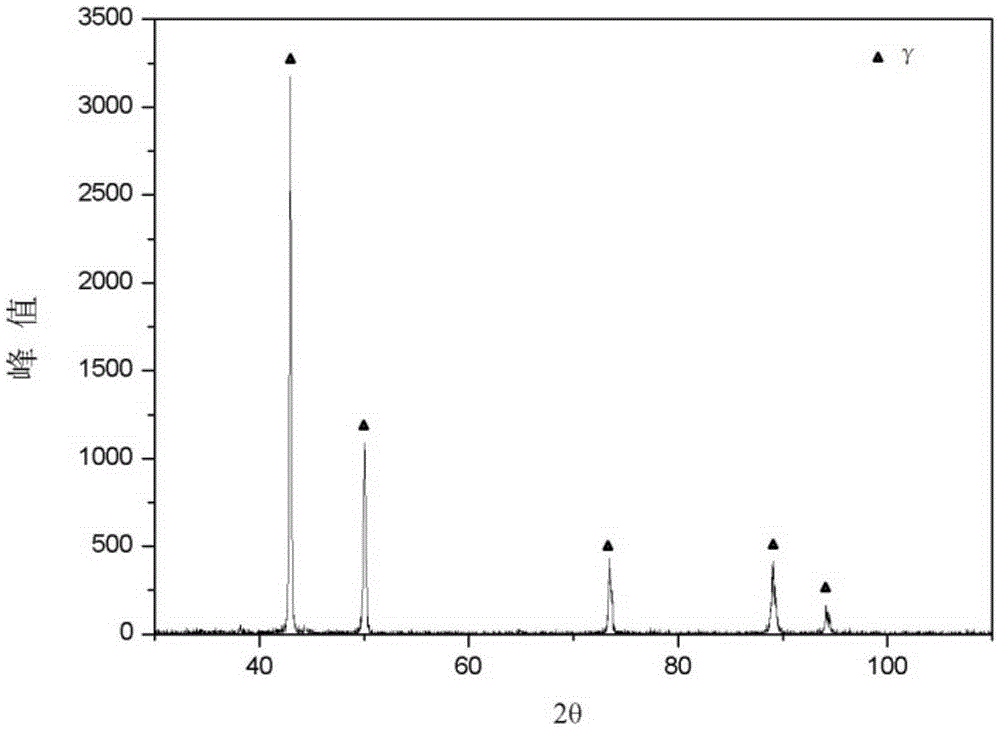

[0023] Take smelting 300kg0Cr21Mn17Mo2.5N0.8 high-nitrogen austenitic stainless steel as an example, the chemical composition of high-nitrogen steel is as follows (%, weight percentage):

[0024]

[0025] Step 1, iron nitride alloy:

[0026] A. Milling

[0027] According to the composition requirements of high-nitrogen steel (as shown in Table 1), after considering metallurgical consumption or burning loss, calculate and purchase ingredients: micro-carbon ferrochromium pellets containing 73% Cr-27% Fe (size about 40-50mm) 200kg, 100kg of 99.9% pure manganese pellets (about 40-50mm in size); 300kg of reduced iron lumps containing 99.9% Fe, 20kg of 99.9% ferromolybdenum.

[0028] Jaw crushers, roller machines, and powerful crushers are used to crush different materials separately. After coarse crushing, medium crushing, and fine crushing, the materials are crushed to a target degree of 20 mesh; various materials are screened to obtain 18-25 The purpose powder, according to ...

Embodiment 2

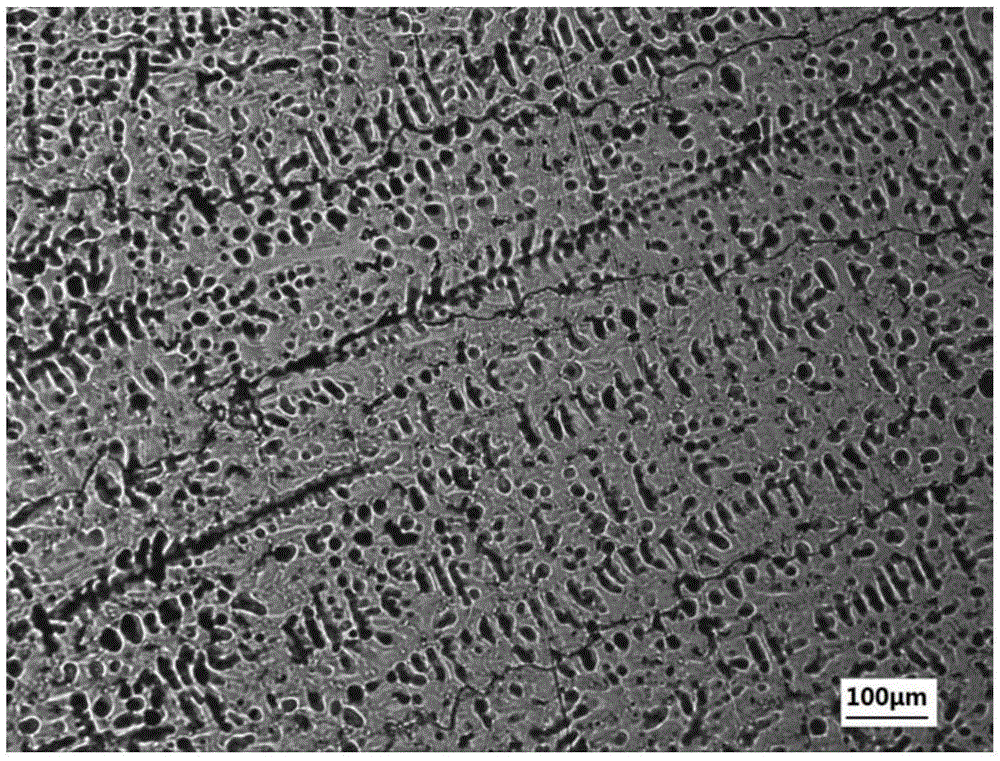

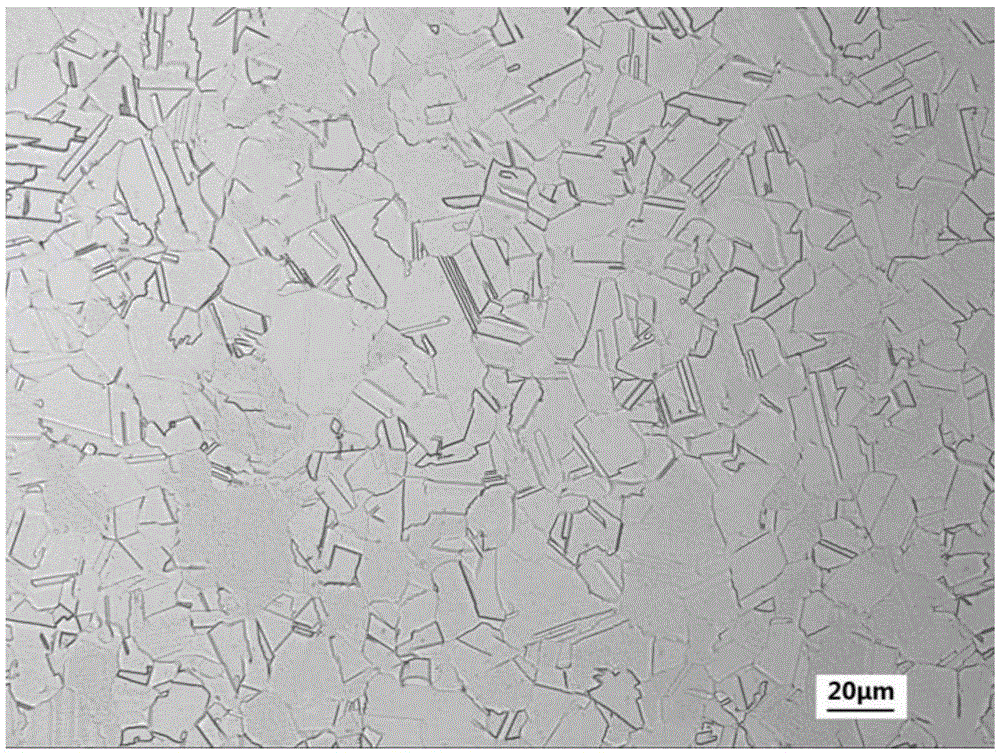

[0058] In order to obtain a steel ingot with a more uniform and dense structure, electroslag remelting can be carried out on the ingot poured by one-time normal pressure melting. Taking the smelting of 150kg0Cr21Mn21Mo2.5N0.9 high-nitrogen austenitic stainless steel as an example, the chemical composition of the high-nitrogen steel is as follows ( %, weight percent):

[0059]

[0060] Step 1, iron nitride alloy:

[0061] A. Milling

[0062] According to the composition requirements of high-nitrogen steel (as shown in Table 1), after considering metallurgical consumption or burning loss, calculate and purchase ingredients: micro-carbon ferrochromium pellets containing 73% Cr-27% Fe (size about 40-50mm) 100kg, 50kg of 99.9% pure manganese pellets (about 40-50mm in size); 150kg of reduced iron lumps containing 99.9% Fe, 10kg of 99.9% ferromolybdenum.

[0063] Jaw crushers, roller machines, and powerful crushers are used to crush different materials separately. After coarse c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com