Polylactic acid material for fused deposition molding and preparation method of polylactic acid material

A fused deposition modeling and polylactic acid material technology, which is applied in the field of 3D printing technology and plastic processing to achieve the effect of promoting dispersion, realizing large-scale popularization and production, and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

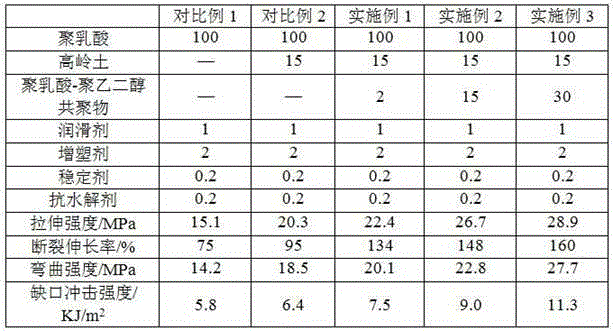

Examples

preparation example Construction

[0032] The preparation method of polylactic acid material for fused deposition modeling comprises the following steps:

[0033] (1) Processing of raw materials: prepare various raw materials, and dry polylactic acid, polylactic acid-polyethylene glycol copolymer and inorganic fillers;

[0034] (2) Mixing of reagents and raw materials: first put polylactic acid, polylactic acid-polyethylene glycol copolymer and inorganic filler into the mixer, and then add lubricant after stirring for 1 minute, and then add plasticizer after stirring for 3 minutes, and stir until The surface of the particles is evenly liquid and bright, that is, they are stirred evenly. After the mixing is completed, a stabilizer and an anti-hydrolysis agent are added for subsequent mixing, and the mixing is continued for 2 minutes, and finally the mixed raw material is obtained.

[0035] (3) Heated extrusion: Add the mixed raw materials into the twin-screw extruder, and keep the feeding speed uniform and smoot...

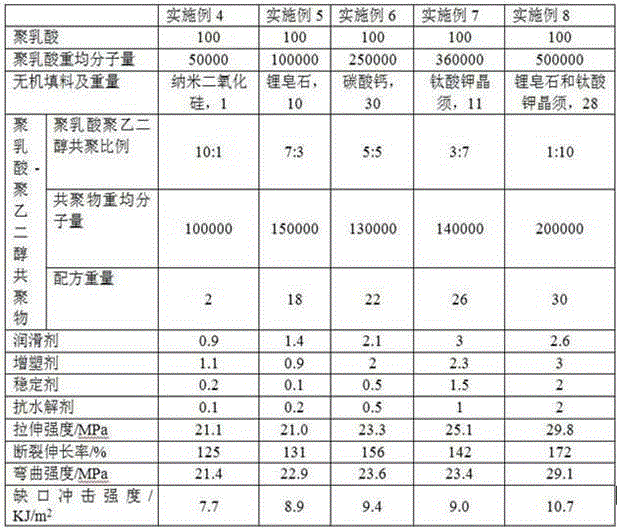

Embodiment 4

[0048] A polylactic acid material for fused deposition molding, which is made of the following raw materials: 100 g of polylactic acid with a weight average molecular weight of 50,000, 1 g of inorganic filler (nano-silica), and polylactic acid-poly Ethylene glycol copolymer (the mass ratio of polylactic acid to polyethylene glycol is 10:1) 2g, lubricant (polyethylene wax) 0.9g, plasticizer (dioctyl phthalate) 1.1g, stabilizer (antioxidant 1010, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) 0.2 g, anti-hydrolysis agent (carbodiimide compound) 0.1 g.

[0049] The preparation method of the polylactic acid material for fused deposition molding in this embodiment, the steps are as follows:

[0050] (1) Processing of raw materials: prepare various raw materials, and dry polylactic acid, polylactic acid-polyethylene glycol copolymer and inorganic fillers;

[0051] (2) Mixing of reagents and raw materials: first put polylactic acid, polylactic acid...

Embodiment 5

[0055] A polylactic acid material for fused deposition molding, which is made of the following raw materials: 100 g of polylactic acid with a weight average molecular weight of 100,000, 10 g of inorganic filler (hectorite), and polylactic acid-polyethylene with a weight average molecular weight of 150,000. Glycol copolymer (the mass ratio of polylactic acid and polyethylene glycol is 7:3) 18g, lubricant (oleic acid amide) 1.4g, plasticizer (epoxidized soybean oil) 0.9g, stabilizer (antioxidant 168, tris[2.4-di-tert-butylphenyl] phosphite) 0.1g, anti-hydrolysis agent (polyurethane) 0.2g.

[0056] The preparation method of the polylactic acid material for fused deposition molding in this embodiment is the same as that in Embodiment 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com