Acrylic ester modified high-weatherability paint and preparation thereof

An acrylate, high weather-resistant technology, used in polyester coatings, polyurea/polyurethane coatings, epoxy resin coatings, etc., can solve the problems of decreased mechanical properties of materials, easy fading of color layers, uneven light and heat aggregation, etc. To achieve the effect of soft color, realize technological innovation and leap-forward development, and easy to achieve the process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

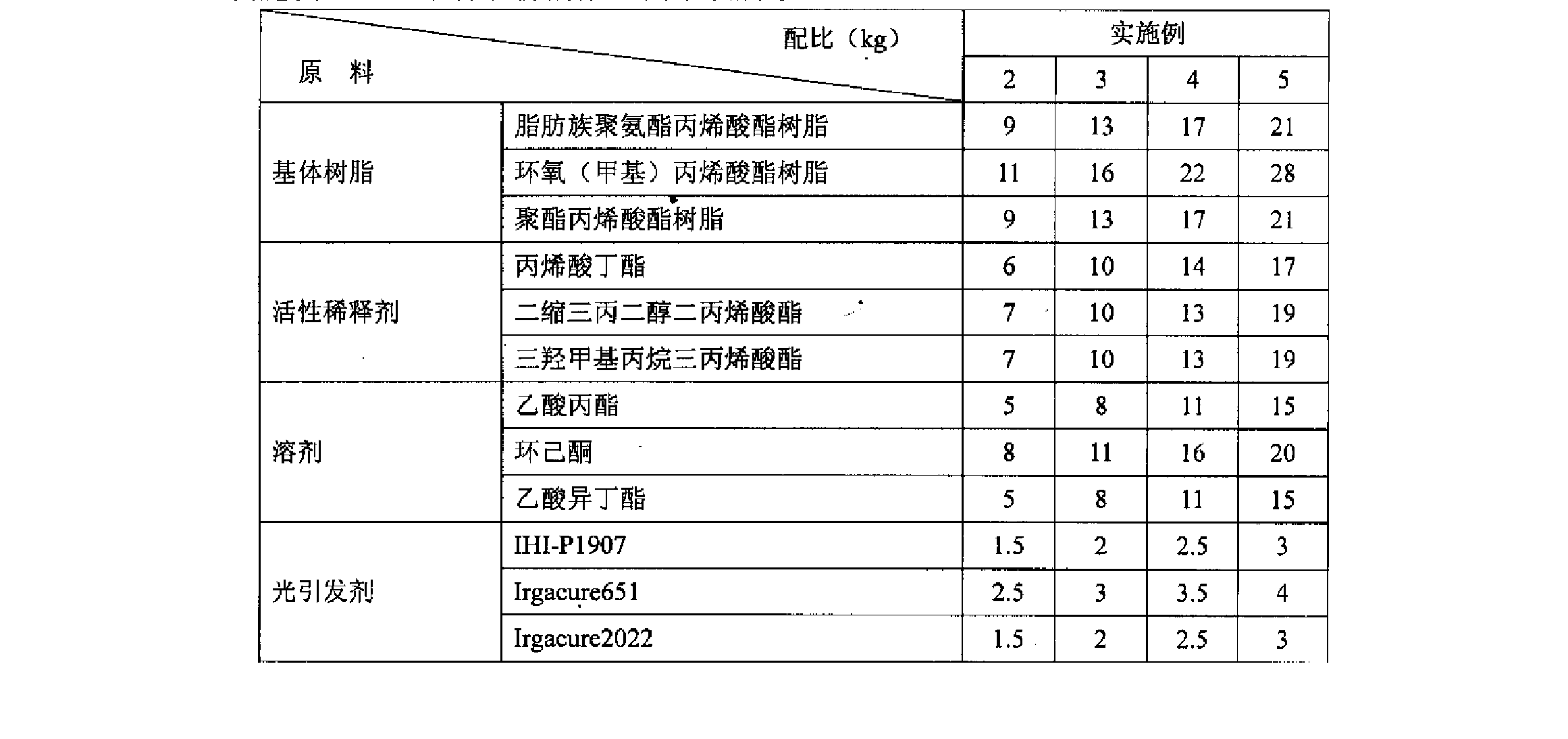

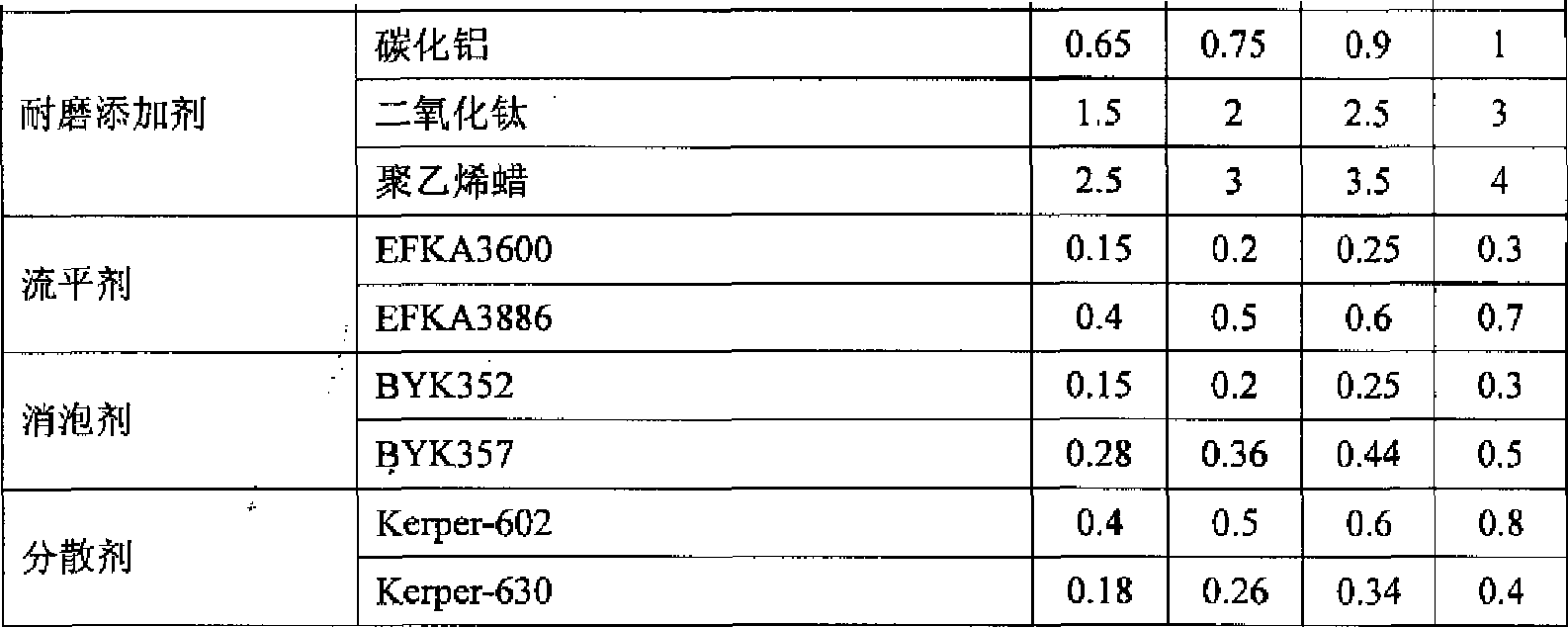

Examples

Embodiment 1

[0028] 1) Preparation of matrix resin: Add 5kg of aliphatic urethane acrylate resin, 6kg of epoxy (meth)acrylate resin, and 5kg of polyester acrylate resin into the synthesis kettle, stir and heat up to 70°C, and keep for 30min;

[0029] 2) Add active diluent: mix 2kg butyl acrylate, 4kg tripropylene glycol diacrylate, and 4kg trimethylolpropane triacrylate evenly, and use it for 1 hour at a temperature of 70°C under constant stirring. Add slowly;

[0030] 3) Add Solji: Mix 2kg propyl acetate, 5kg cyclohexanone, and 2kg isobutyl acetate evenly, then add them into the synthesis kettle three times, raise the reaction temperature to the reflux temperature, and keep it warm for 20 minutes;

[0031] 4) Add photoinitiator: After mixing 1kg IHI-P1907, 2kg Irgacure651, and 1kg Irgacure2022 evenly, slowly add it dropwise within 1 hour under the condition of reflux temperature and constant stirring;

[0032] 5) Add wear-resistant additives: 0.5kg of aluminum carbide, 1kg of titanium di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com