High-temperature-resistant pressure-sensitive adhesive-film for COF and preparation method thereof

A pressure-sensitive adhesive film, high temperature resistant technology, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc. problems, to achieve the effect of small cost and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

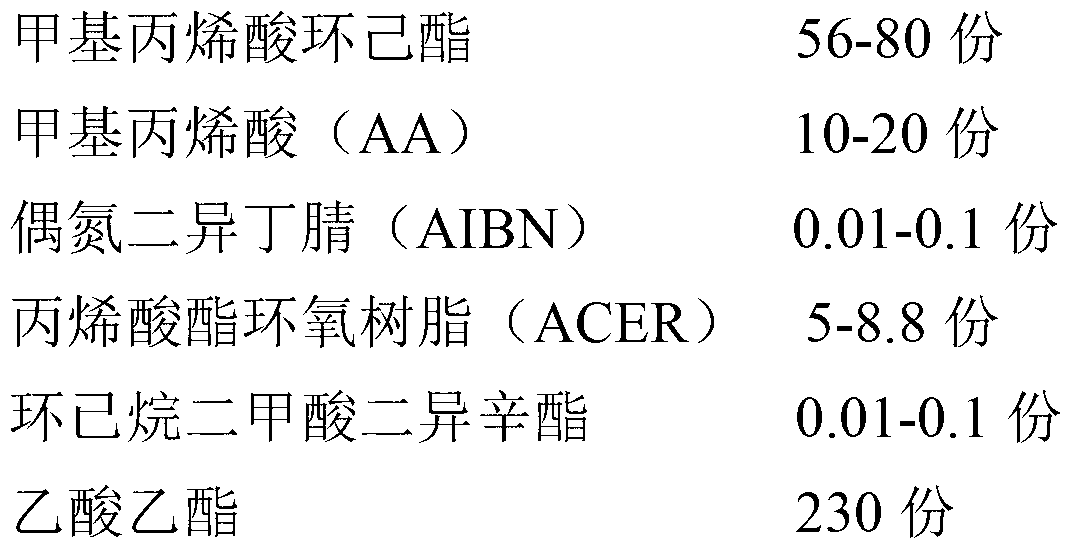

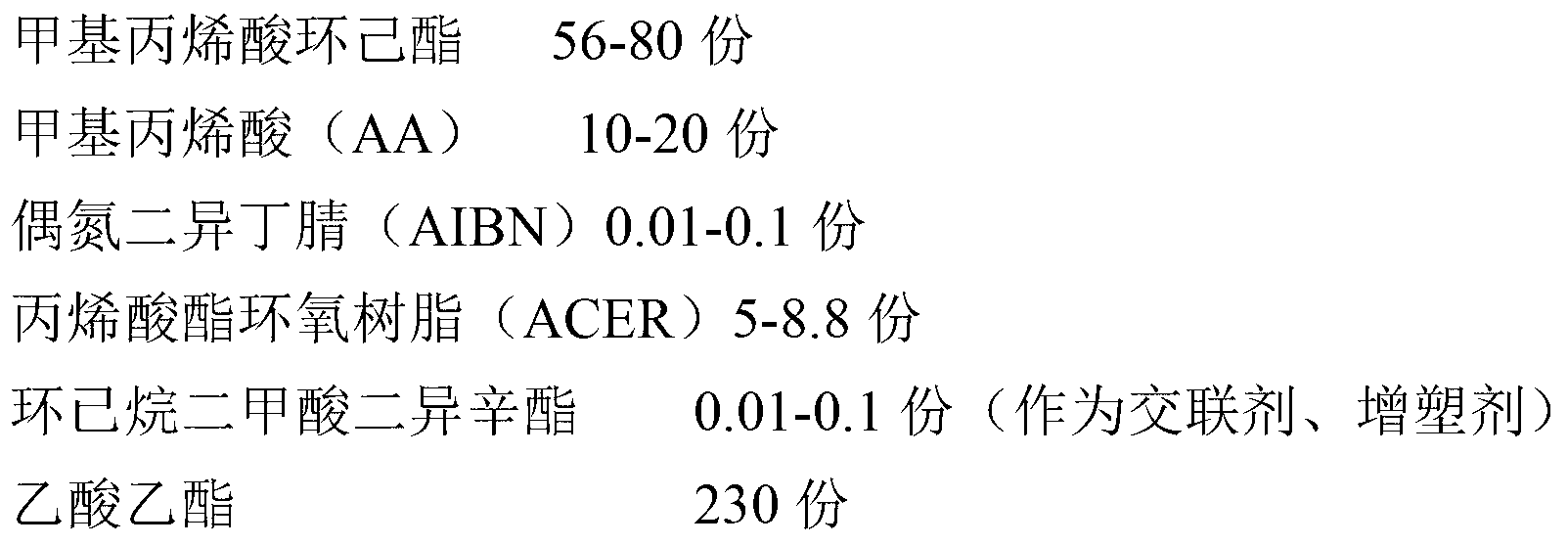

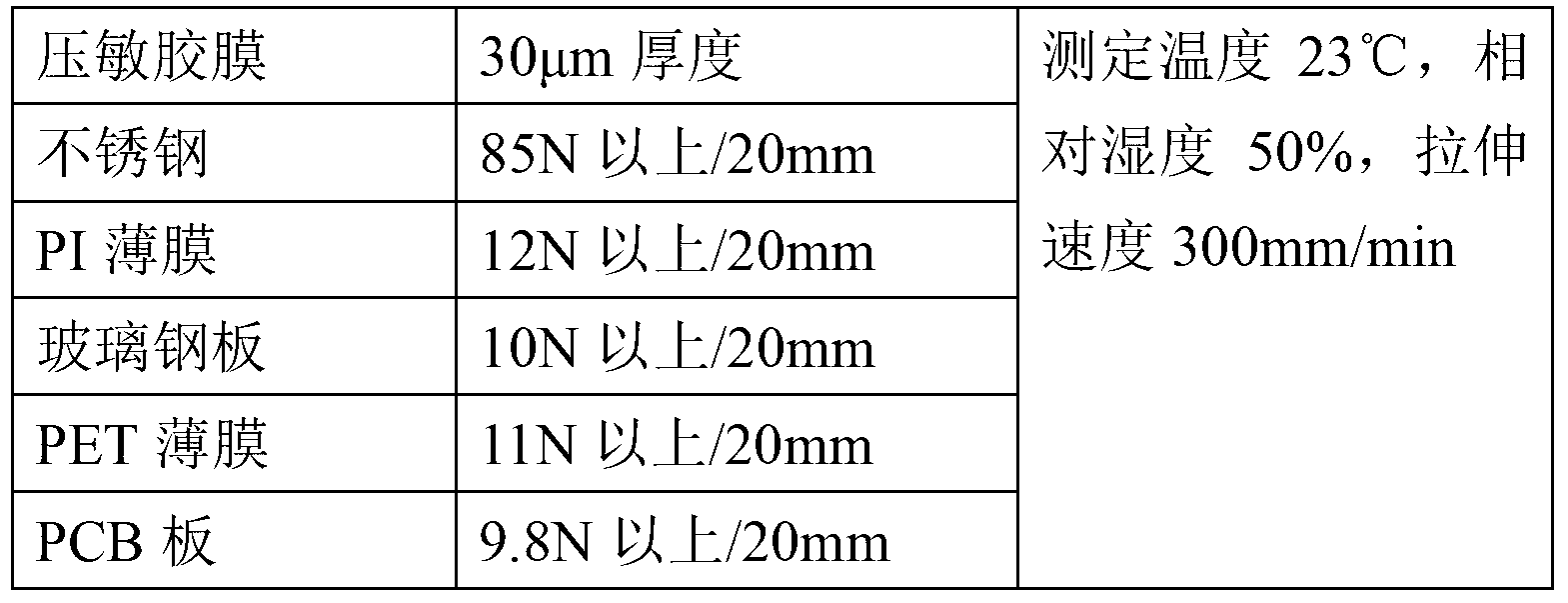

example 1

[0054] In a 1000 ml three-neck flask equipped with a thermometer reflux condenser and a stirrer, the monomers of 80 parts by weight of cyclohexyl methacrylate and 20 parts by weight of methacrylic acid are charged, and then 0.1 parts by weight of azo Diisobutyronitrile, dissolved in 150 parts of solvent ethyl acetate and stirred to dissolve, heated to reflux of ethyl acetate, reacted at reflux temperature for 6-8 hours, cooled to room temperature, added 8.8 parts of acrylate epoxy resin and 0.1 Parts by weight of diisooctyl cyclohexanedicarboxylate and the remaining 80 parts of ethyl acetate solution are mixed and copolymerized with 20 parts by weight of thermoplastic polyimide resin to obtain thermoplastic polyimide, acrylic Composition of copolymers of polymers. Apply it to a yellow silicone-treated release liner. After drying, the thickness of the adhesive film is 30 μm, and the heat-resistant pressure-sensitive adhesive film is obtained by pressing on the anti-adhesive re...

example 2

[0066] In 1000 milliliters of there-necked flasks equipped with a thermometer reflux condenser and agitator, the monomers of 80 parts by weight of cyclohexyl methacrylate and 18 parts by weight of methacrylic acid are charged, and then 0.1 parts by weight of azobisisobutyronitrile, Dissolve in 150 parts of solvent ethyl acetate and stir to dissolve, heat up to reflux of ethyl acetate, react at reflux temperature for 7-8 hours, cool to room temperature, add 8.3 parts of acrylate epoxy resin and 0.1 parts by weight of cyclohexane Diisooctyl diformate and the remaining 80 parts of ethyl acetate solution are formulated into glue, and mixed with 10 parts by weight of thermoplastic polyimide resin to obtain a copolymer containing thermoplastic polyimide and acrylic polymer. Composition. Coated on yellow silicone-treated release paper, dried to obtain a film thickness of 30 μm, and pressed on release paper coated with silicone on both sides to obtain a heat-resistant pressure-sensiti...

example 3

[0078] In 1000 milliliters of there-necked flasks equipped with a thermometer reflux condenser and agitator, the monomers of 80 parts by weight of cyclohexyl methacrylate and 15 parts by weight of methacrylic acid are charged, then 0.1 part by weight of azobisisobutyronitrile is added, Dissolve in 150 parts of solvent ethyl acetate and stir to dissolve, heat up to ethyl acetate reflux, react at reflux temperature for 7.5 hours, cool to room temperature, add 8.5 parts of acrylate epoxy resin and 0.1 parts by weight of cyclohexane dicarboxylic acid Diisooctyl ester and the remaining 80 parts of ethyl acetate solution are prepared into a glue solution, mixed and copolymerized with thermoplastic polyimide resin in a weight ratio of 15 parts, to obtain a composition containing a copolymer of thermoplastic polyimide and acrylic polymer . Coat it on a yellow silicone-treated release paper, dry it to obtain an adhesive film with a thickness of 30 μm, and press it on a release paper co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com