Process for recycling waste toothpaste aluminum-plastic composite packaging material

A technology of aluminum-plastic composite and packaging materials, applied in the direction of solid waste removal, etc., can solve the problems of wasting social resources, environmental pollution, etc., and achieve the effects of reducing pollution, being environmentally friendly, and requiring low technological conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

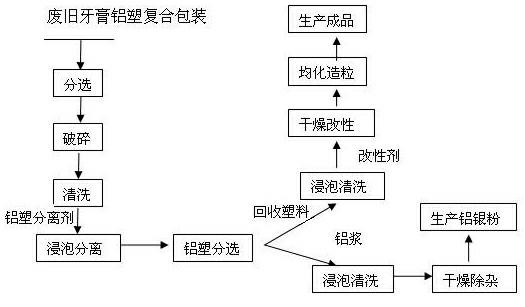

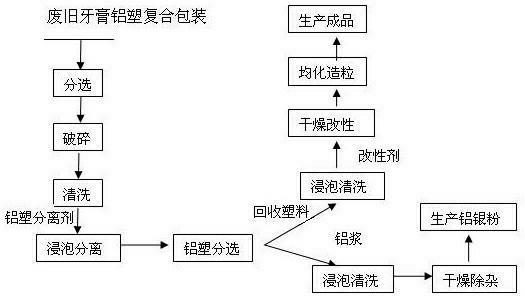

[0017] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0018] from figure 1 As can be seen, the process of the present invention comprises the following steps:

[0019] 1. Broken material treatment

[0020] Sorting: Separating toothpaste aluminum-plastic packaging from waste products to remove impurities;

[0021] Crushing: Put the selected toothpaste into the aluminum-plastic package and put it into the hammer crusher with water to break it into pieces with a diameter of 2-3 cm;

[0022] Cleaning: Use cleaning equipment to clean the toothpaste on the toothpaste aluminum-plastic packaging.

[0023] 2. Aluminum-plastic separation

[0024] Soaking and separation: Add the cleaned toothpaste aluminum-plastic packaging crushed material to the aluminum-plastic separation equipment, then add the aluminum-plastic separation soaking penetrating agent, soak for 1 to 4 hours at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com