Method for preparing nanoscale sheet cerium oxide by hydrothermal method

A nano-cerium oxide, hydrothermal method, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of high cost, harsh production conditions, complex production process, etc., and achieve low production cost and process conditions. Mild and controllable effect with simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for preparing nano-scale flaky cerium oxide by the hydrothermal method comprises the following steps:

[0033] 1) Prepare 0.01 mol / L Ce(NO 3 ) 3 ·6H 2 O aqueous solution and ammonia aqueous solution with a pH value of 12;

[0034] 2) Put the above 9mL ammonia solution in the reaction kettle at -10℃, take 1ml of Ce 3+ Ionic aqueous solution, slowly added dropwise to the ammonia solution under stirring;

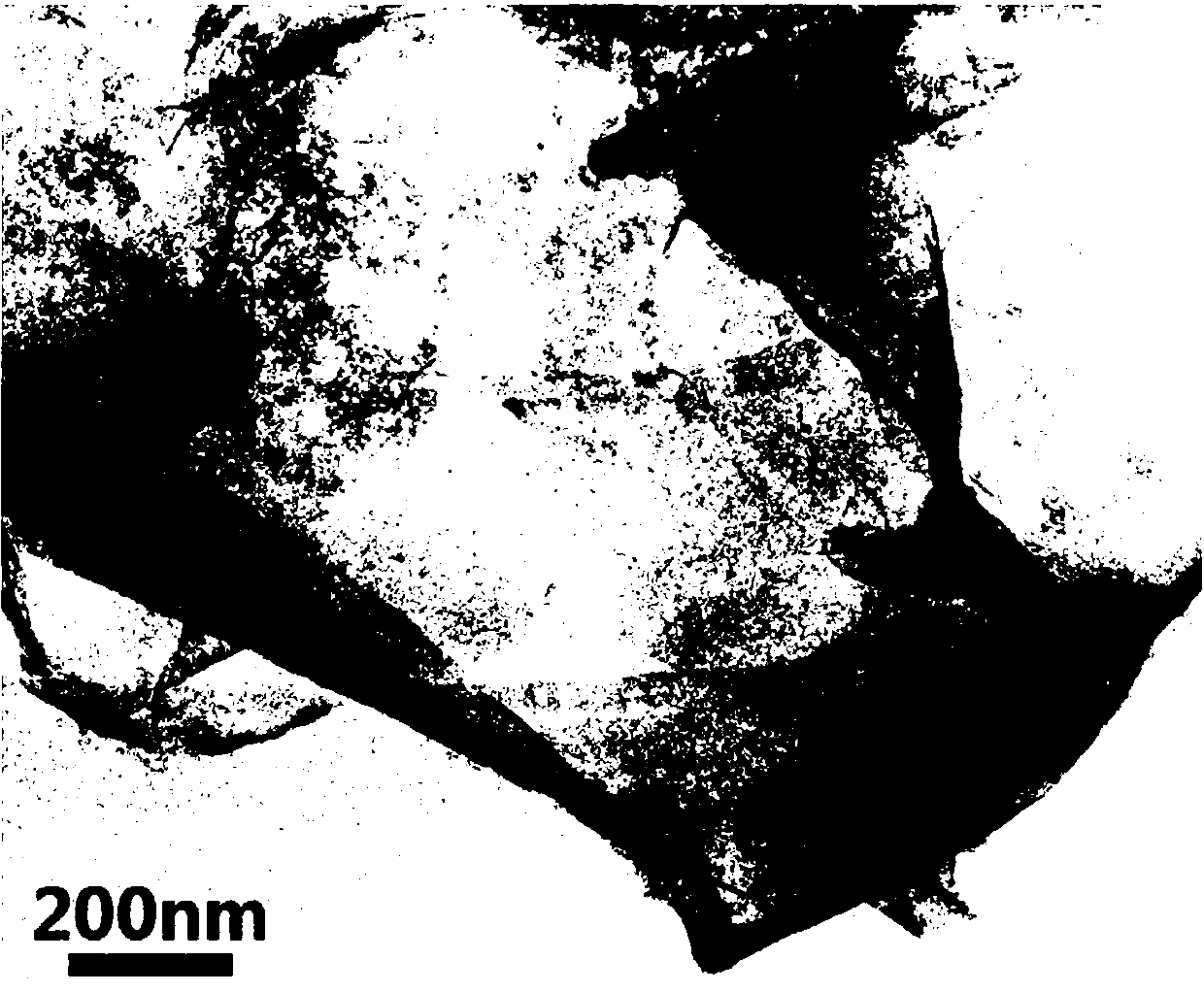

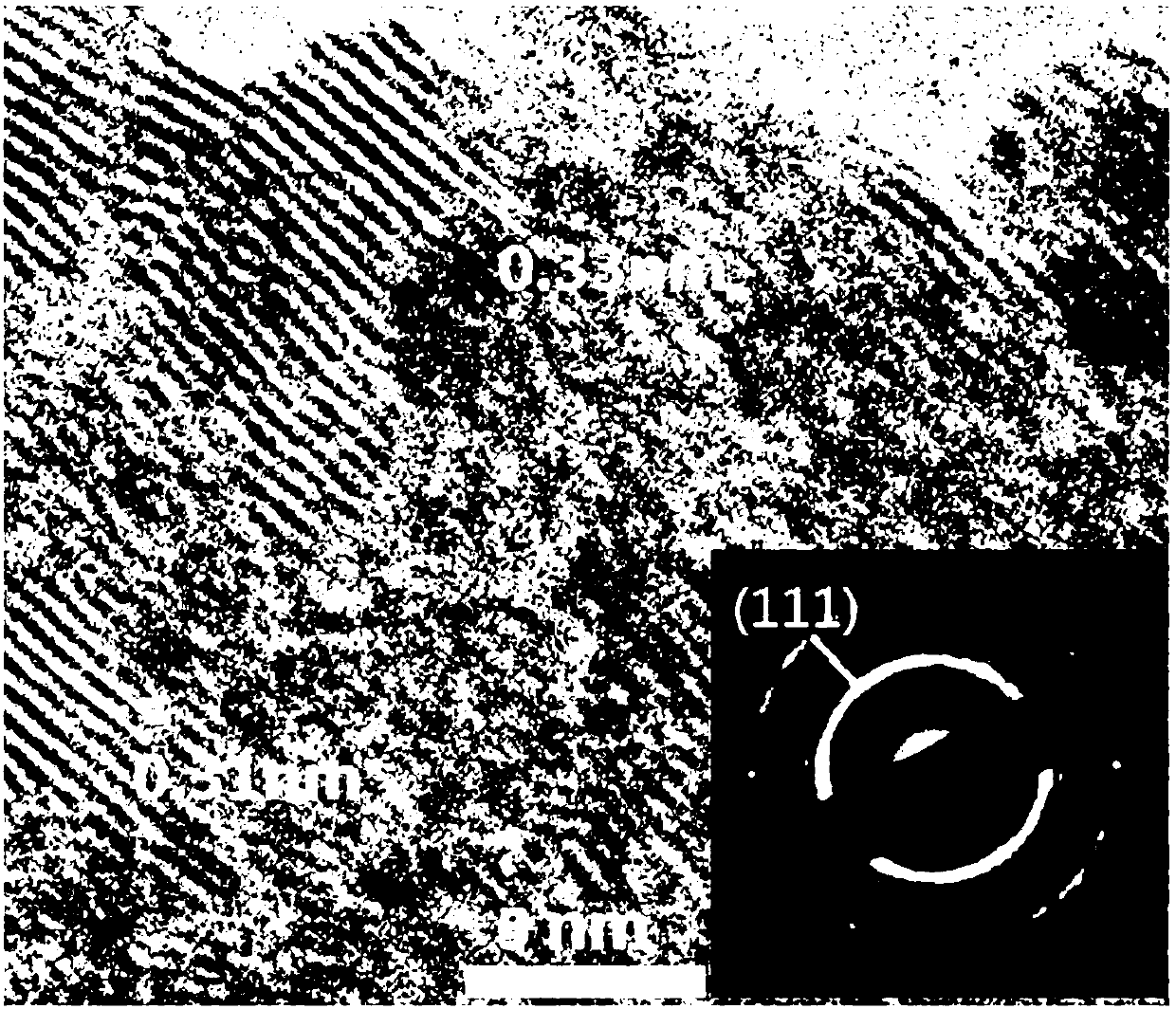

[0035] 3) The above mixed solution was reacted under stirring, and the temperature was kept at -10°C for 2 hours. After the end, the reaction solution was centrifuged to remove the upper liquid. Wash the powder obtained by centrifugation with pure water, then place it in a drying oven and dry it into a solid powder, observe with a transmission electron microscope, and find that the obtained product is a flaky cerium oxide with a thickness of 10-30nm, such as figure 1 shown.

Embodiment 2

[0037] The method for preparing nano-scale flaky cerium oxide by the hydrothermal method comprises the following steps:

[0038] 1) Prepare 0.03 mol / L CeCl at room temperature 3 aqueous solution and ammonia solution at pH 11.5;

[0039] 2) Put the above 15 mL ammonia solution in the reaction kettle at a temperature of 0°C, and take 3 ml of Ce 3+ Ionic aqueous solution, slowly added dropwise to the ammonia solution under stirring;

[0040] 3) The above mixed solution was reacted under stirring, and the temperature was kept at 0°C for 5 hours. After the end, the reaction solution was centrifuged to remove the upper liquid. The powder obtained by centrifugation was washed with pure water, and then placed in a drying oven to dry into a solid powder. Observing with a transmission electron microscope, it was found that the obtained product was flaky cerium oxide with a thickness of 10-30nm.

Embodiment 3

[0042] The method for preparing nano-scale flaky cerium oxide by the hydrothermal method comprises the following steps:

[0043] 1) Prepare 0.05 mol / L Ce(NO 3 ) 3 ·6H 2 O aqueous solution and ammonia aqueous solution with a pH value of 13;

[0044] 2) Put the above 10 mL ammonia solution in the reaction kettle at a temperature of 20 °C, and take 2 ml of Ce 3+ Ionic aqueous solution, slowly added dropwise to the ammonia solution under stirring;

[0045] 3) The above mixed solution was reacted under stirring, and reacted at a constant temperature of 20°C for 8 hours. After the end, the reaction solution was centrifuged to remove the upper liquid. The powder obtained by centrifugation was washed with pure water, and then placed in a drying oven to dry into a solid powder. Observing with a transmission electron microscope, it was found that the obtained product was flaky cerium oxide with a thickness of 10-30nm.

PUM

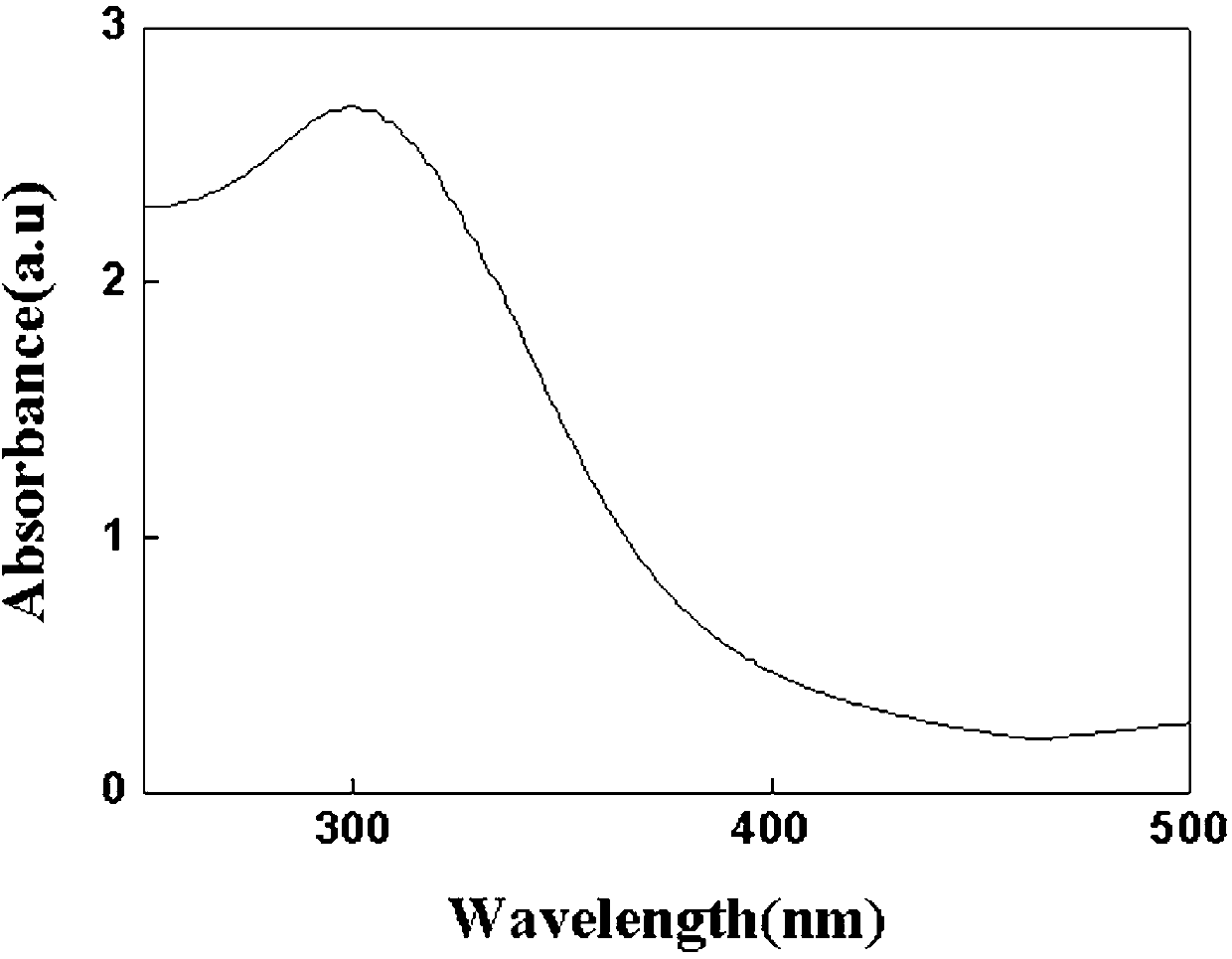

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com