Sealant extruding gun nozzle assembly for automobile painting

A technology of sealant and gun nozzle, which is applied in the direction of spraying device, spraying device, etc., can solve the problems such as difficult operation and sealing, and achieve the effect of convenient operation, convenient extrusion coating and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

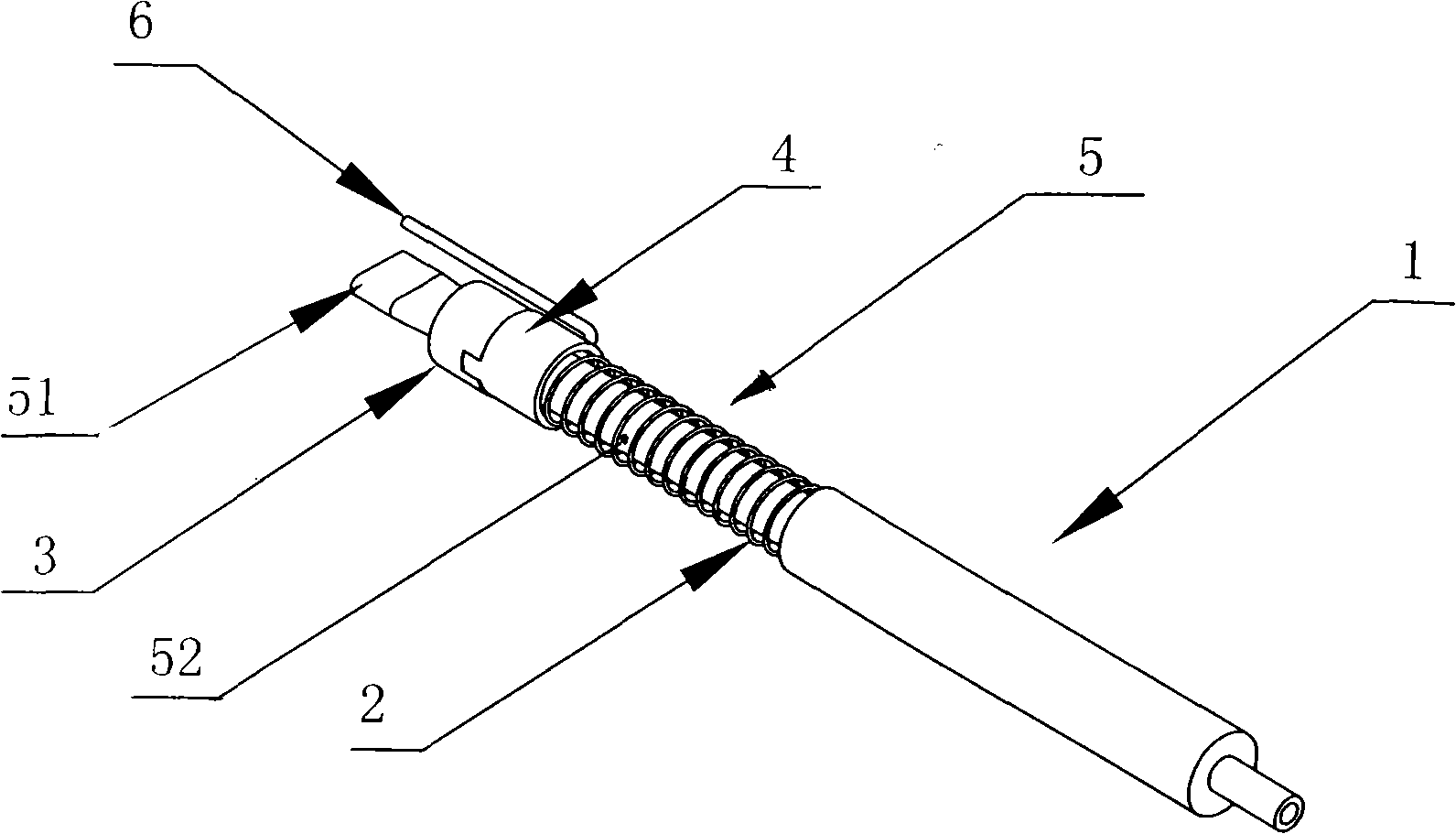

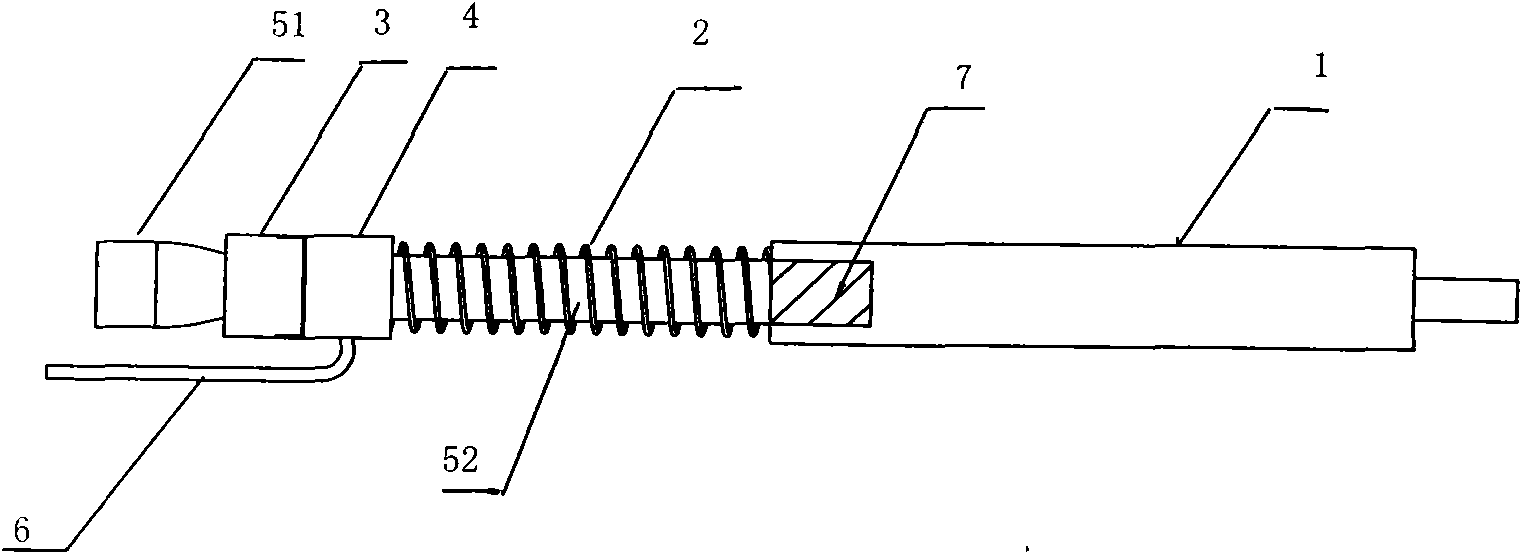

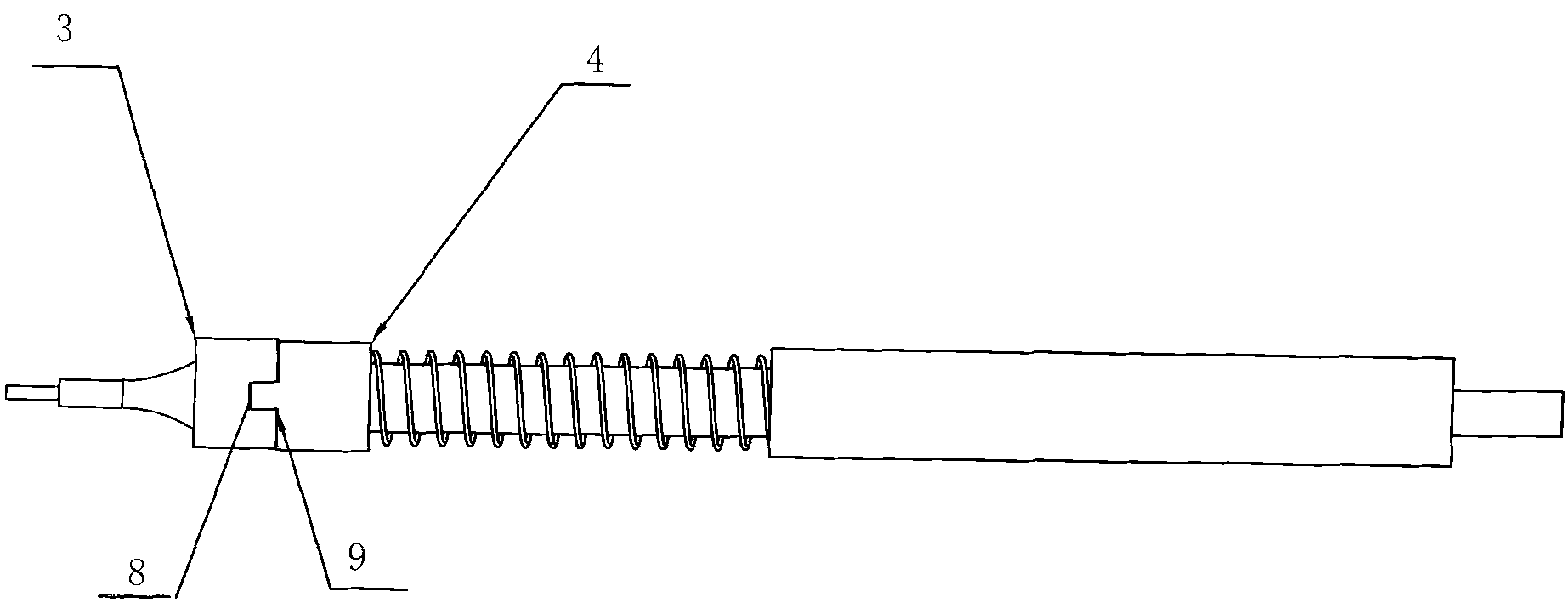

[0018] Such as figure 1 , figure 2 and image 3 As shown, the nozzle assembly of the automobile coating sealant extrusion gun includes two parts, the straight pipe 1 and the nozzle assembly. The gun nozzle assembly includes gun nozzle 5, locking spring 2, front limit block 3, rear limit block 4 and door limit limit rod 6. The front end of the gun nozzle 5 is stamped into a flat shape by a steel pipe to form a flat nozzle head 51, and the rear portion is a nozzle pipe 52, which is connected with the connecting straight pipe 1 by the connecting thread 7. The rear end outside of the flat nozzle 51 is covered with a front limit block 3, and the front limit block 3 is welded and fixed with it. After the front limit block 3, a rear limit block 4 is also covered with a front limit block. The block 3 and the rear limit stopper 4 are limitedly connected through the correspondingly provided limit slots 8 and limit blocks 9 at their adjacent ends. And the limit groove 8 and the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com